Documente Academic

Documente Profesional

Documente Cultură

WPS Smaw1g

Încărcat de

Danem Halas0 evaluări0% au considerat acest document util (0 voturi)

79 vizualizări1 paginăWPS-SMAW1G.docxWPS-SMAW1G.docxWPS-SMAW1G.docx

Titlu original

WPS-SMAW1G

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentWPS-SMAW1G.docxWPS-SMAW1G.docxWPS-SMAW1G.docx

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

79 vizualizări1 paginăWPS Smaw1g

Încărcat de

Danem HalasWPS-SMAW1G.docxWPS-SMAW1G.docxWPS-SMAW1G.docx

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

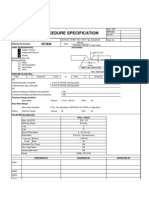

WELDING PROCEDURE SPECIFICATION ( WPS )

Reference code: AWSD14.1

Identification : 54

Company Name : FASSAN CRANE

Revision : 2

Welding Process(es) : SMAW

Date: 30/6/1388

BY : M.ZAREI

Authorized by : S. PIROOZI

Date: 4/7/1388

.

Type : Manual

Semi- Automatic

Machine

Automatic

POSITION

Position of Groove : 1G

Vertical Progression :

Up

Fillet : ----Down

ELECTRICAL CHARACTERISTICS

Supporting PQR No.(s) : 01

JOINT DESIGN USED

Type : Butt

Single

Double Weld

Backing : Yes

No

Backing Material :----------Root Opening: 0-3 mm

Root Face Dimension: 0-3 mm

Groove Angle : 60

Radius ( J-U) : ------Back Gouging : Yes

No

Method : GRINDING

Transfer Mode (GMAW) Short-Circuiting Spray Globular

Current : AC DCEP DCEN

Other : -------Tungsten Electrode ( GTAW )

Size :N/A

Type : N/A

BASE METALS

Pulsed

Material Spec : Din 17100 or EN 10025

Type or Grade : ST 37-2 or S 235JR

Thickness :

Groove: 8 T 30

Fillet : ---Diameter (Pipe) : N/A

FILLER METALS

TECHNIQUE

AWS Specification : A 5.1

AWS Classification : E7018 BRAND : 1230F AMA

Stringer or Weave Bead : Stringer/ Weave

Multi-Pass or Single Pass ( per side ) : Multi-Pass

Number of Electrodes : 1

Electrode Spacing :

SHIELDING

Flux :N/A

Electrode- Flux (Class) : N/A

Flow Rate : N/A

Longitudinal : N/A

Lateral : N/A

Angle : N/A

Gas : N/A

Composition : N/A

Gas Cup Size :N/A

PREHEAT TEMPERATURE

Preheat Temp ; Min : 10 C

Contact Tube to Work Distance : 1/ 4 " - 1"

Peening : N/A

Interpass Cleaning : wire Brush

Interpass Temp ; Min : 20 C Max : 200 C

POSTWELD HEAT TREATMENT

Temp : N / A

Time : N/A

Pass

No

Proces

s

Filler Metals

Class

SMAW

.Diam

mm

Current

Type&

Polarity

Amp

Volts

Travel

Speed

Cm/min

3.2

DCEP

100-140

24-26

10-20

DCEP

140-190

24-26

10-20

E7018

N~ 2

SMAW

F.Q.C.D

Joint Details

S-ar putea să vă placă și

- Flybus Boeing 738 ChecklistDocument8 paginiFlybus Boeing 738 ChecklistThommas HofmannÎncă nu există evaluări

- Sim Check Reviewer (Revision April 2016) 2-1Document720 paginiSim Check Reviewer (Revision April 2016) 2-1Devdatt Sonde100% (5)

- Manual Vibro SanyDocument241 paginiManual Vibro SanyGabby BautistaÎncă nu există evaluări

- CRJ 550-700 Normal ChecklistDocument6 paginiCRJ 550-700 Normal ChecklistDan KösterÎncă nu există evaluări

- CLA-100-data Sheet PDFDocument5 paginiCLA-100-data Sheet PDFmdalt9180Încă nu există evaluări

- Ukv PRD Dash8 q400 Checklist v1Document2 paginiUkv PRD Dash8 q400 Checklist v1REF - Radio Escuta FloripaÎncă nu există evaluări

- Dehaviland Canada Bombardier Q400 Dash 8 Normal ChecklistDocument2 paginiDehaviland Canada Bombardier Q400 Dash 8 Normal ChecklistGourav DasÎncă nu există evaluări

- External Application Form-Course FacilitatorDocument2 paginiExternal Application Form-Course FacilitatorRaymond M KamundimuÎncă nu există evaluări

- A310 ChecklistDocument1 paginăA310 ChecklistThomas Bunt100% (1)

- Mustafa BhaiDocument1 paginăMustafa Bhaiabdul qyyoomÎncă nu există evaluări

- Sany Rough Terrain Crane Src840 Parts BookDocument20 paginiSany Rough Terrain Crane Src840 Parts BookJames100% (46)

- ASY - Installation ManualDocument89 paginiASY - Installation ManualashukbashaÎncă nu există evaluări

- Application For Issue of Ppo For Air Veteran Retired As On or Before 1.1.2006Document1 paginăApplication For Issue of Ppo For Air Veteran Retired As On or Before 1.1.2006EXSELLANCE VENTURESÎncă nu există evaluări

- Diagnostico Del Trabajo de Campo: Espacio/Lugar: FechaDocument1 paginăDiagnostico Del Trabajo de Campo: Espacio/Lugar: FechaKaren ValverdeÎncă nu există evaluări

- NORMAL CHECKLIST FLY BY WIRE A320neoDocument3 paginiNORMAL CHECKLIST FLY BY WIRE A320neoAntoni GarciaÎncă nu există evaluări

- EOM017Document140 paginiEOM017the dovanÎncă nu există evaluări

- Parts Manual - SR250 Rockwell Parts BookDocument267 paginiParts Manual - SR250 Rockwell Parts Bookikhtiyar ali khan ikhtiyar100% (1)

- Aer Lingus320Document2 paginiAer Lingus320jamiegilligan1Încă nu există evaluări

- TOLISS A319 NORMAL PROCEDURES ChecklistDocument4 paginiTOLISS A319 NORMAL PROCEDURES Checklistguilherme_rodrigues_14100% (3)

- 434-590171-0003_Section3a-1Document34 pagini434-590171-0003_Section3a-1winiciusoliperÎncă nu există evaluări

- Checklist A32x FamilyDocument2 paginiChecklist A32x FamilyGuilherme KaiserÎncă nu există evaluări

- Normal Checklist Atr 72 600Document33 paginiNormal Checklist Atr 72 600arciÎncă nu există evaluări

- Sharpe's WT v0.12.7 CJ4 Checklist (06.09.21)Document2 paginiSharpe's WT v0.12.7 CJ4 Checklist (06.09.21)marcusdbptscribdÎncă nu există evaluări

- Boeing 737 Next Generation Checklist: Preflight & Power Up Before Taxi/After StartDocument3 paginiBoeing 737 Next Generation Checklist: Preflight & Power Up Before Taxi/After StartFlightMotor AviationÎncă nu există evaluări

- A300 Checklist PT1Document2 paginiA300 Checklist PT1Sam AlcaláÎncă nu există evaluări

- Intellisys SSR 10-450 (APDD 422C)Document107 paginiIntellisys SSR 10-450 (APDD 422C)Miguel NavarreteÎncă nu există evaluări

- Inibuilds A306 Checklist BritishAvgeek v1Document2 paginiInibuilds A306 Checklist BritishAvgeek v1koepfjulianÎncă nu există evaluări

- Agency Office Allowance FormDocument2 paginiAgency Office Allowance FormMUHAMMAD SAFWAN AHMAD MUSLIMÎncă nu există evaluări

- Installation Start-Up and Operation Manu PDFDocument104 paginiInstallation Start-Up and Operation Manu PDFmd ayazuddinÎncă nu există evaluări

- Bird/Animal Hit Report FormDocument1 paginăBird/Animal Hit Report FormFaisal KhanÎncă nu există evaluări

- Normal Checklist Atr 72 600 PDFDocument33 paginiNormal Checklist Atr 72 600 PDFMarie100% (1)

- Aux. Transformer Test Report For General DataDocument5 paginiAux. Transformer Test Report For General DataAnoop KsÎncă nu există evaluări

- Aer Lingus A330 CHKLSTDocument2 paginiAer Lingus A330 CHKLSTjamiegilligan1Încă nu există evaluări

- Normal Checklist A320Document1 paginăNormal Checklist A320tej swaroopÎncă nu există evaluări

- QRH2 ch88 Appendices-1Document22 paginiQRH2 ch88 Appendices-1nashÎncă nu există evaluări

- Pre-Flight / Before Start Engine Start: Summarised ChecklistDocument2 paginiPre-Flight / Before Start Engine Start: Summarised ChecklistIuriÎncă nu există evaluări

- Machine Data Sheet: Model G0555Xh 14" 1 3/4 HP Extreme Series Resaw BandsawDocument3 paginiMachine Data Sheet: Model G0555Xh 14" 1 3/4 HP Extreme Series Resaw Bandsawcarl12Încă nu există evaluări

- HRDC Grant FormDocument4 paginiHRDC Grant FormZabeel RahimanÎncă nu există evaluări

- CAT Electric Drives Product Catalogue eDocument60 paginiCAT Electric Drives Product Catalogue eAnonymous 8rb48tZS100% (1)

- Pre-Flight: ANNUNCIATORS........................................... TEST FUEL SYSTEM................. FUEL QUANTITY TESTDocument9 paginiPre-Flight: ANNUNCIATORS........................................... TEST FUEL SYSTEM................. FUEL QUANTITY TESTAlejandroÎncă nu există evaluări

- JVV-2000 TachoMGSET A 4.7Document128 paginiJVV-2000 TachoMGSET A 4.7Bennecer HasniÎncă nu există evaluări

- GE E9000 Application-Guide DET-291H PDFDocument204 paginiGE E9000 Application-Guide DET-291H PDFRei ArmellaÎncă nu există evaluări

- CAT Electric Drives Product Catalogue eDocument60 paginiCAT Electric Drives Product Catalogue eSyed Mohammad NaveedÎncă nu există evaluări

- DA42 - Twin Star ChecklistDocument2 paginiDA42 - Twin Star ChecklistNamgay TshewangÎncă nu există evaluări

- Tagging ScafftagDocument1 paginăTagging ScafftagTeguh Tandi KaraengÎncă nu există evaluări

- JCB VIBROMAX VM186 Single Drum Roller Service Repair Manual PDFDocument18 paginiJCB VIBROMAX VM186 Single Drum Roller Service Repair Manual PDFfjjskekdmmekm100% (1)

- Application For Aircraft Maintenance Engineer's LicenceDocument3 paginiApplication For Aircraft Maintenance Engineer's LicenceAbed Almajeed AlowioiÎncă nu există evaluări

- Cockpit Preperation Before Start ChecklistDocument4 paginiCockpit Preperation Before Start ChecklisttoniÎncă nu există evaluări

- Centek CNC Router Operation ManualDocument78 paginiCentek CNC Router Operation ManualNguyen Quyet ThangÎncă nu există evaluări

- Ukv PRD b737 Checklist v2Document2 paginiUkv PRD b737 Checklist v2fabiozimba100% (2)

- Supersigma2 HandleidingDocument44 paginiSupersigma2 HandleidingVladimir KrivenokÎncă nu există evaluări

- Sany Scc500e r1 Crawler Crane Assembly Part BookDocument20 paginiSany Scc500e r1 Crawler Crane Assembly Part Bookdarrell100% (27)

- Flujos Inicial B767 - QRHDocument26 paginiFlujos Inicial B767 - QRHBenjamin Auad RodriguezÎncă nu există evaluări

- RX Engines Manual EngDocument54 paginiRX Engines Manual EngRafi Al BaihaqiÎncă nu există evaluări

- Maintenance Manual: HT Toggle Clamp Injection Molding Machine With Allen Bradley Pro-Set 700 Series Control SystemDocument197 paginiMaintenance Manual: HT Toggle Clamp Injection Molding Machine With Allen Bradley Pro-Set 700 Series Control SystemGil HdzÎncă nu există evaluări

- Risk Management and System SafetyDe la EverandRisk Management and System SafetyEvaluare: 5 din 5 stele5/5 (1)

- Consignation HTDocument6 paginiConsignation HTDanem HalasÎncă nu există evaluări

- TWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDocument26 paginiTWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDanem HalasÎncă nu există evaluări

- Chapter 13 - Designing For Quality: PTTE 434 Jim Wixson - InstructorDocument72 paginiChapter 13 - Designing For Quality: PTTE 434 Jim Wixson - InstructorPrabhat SharmaÎncă nu există evaluări

- Ut Proceduregeneral 141118232235 Conversion Gate02Document24 paginiUt Proceduregeneral 141118232235 Conversion Gate02Danem HalasÎncă nu există evaluări

- Everything You Need to Know About Stainless Steel Welding Procedure SpecificationDocument6 paginiEverything You Need to Know About Stainless Steel Welding Procedure SpecificationDanem HalasÎncă nu există evaluări

- CV Ait KoufiDocument3 paginiCV Ait KoufiDanem HalasÎncă nu există evaluări

- Crane SafetyDocument12 paginiCrane SafetymytheeÎncă nu există evaluări

- Construction IssuesDocument50 paginiConstruction IssuesDanem HalasÎncă nu există evaluări

- A 6 - A 6m - 02 QtytmdiDocument63 paginiA 6 - A 6m - 02 QtytmdiDanem HalasÎncă nu există evaluări

- A 6 - A 6m - 02 QtytmdiDocument63 paginiA 6 - A 6m - 02 QtytmdiDanem HalasÎncă nu există evaluări

- Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocument3 paginiCarbon Steel Girder Rails of Plain, Grooved, and Guard TypesDanem HalasÎncă nu există evaluări

- 13 L1 L2 Reactor DesignDocument48 pagini13 L1 L2 Reactor DesignStan LouisÎncă nu există evaluări

- WPS PQR Checklist 2014Document2 paginiWPS PQR Checklist 2014Sebastian Rajesh100% (1)

- Part2 Notice 1Document21 paginiPart2 Notice 1Danem Halas100% (1)

- Inspection & Test Plans 1 of 50Document49 paginiInspection & Test Plans 1 of 50jok1974Încă nu există evaluări

- Welding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDocument7 paginiWelding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDanem HalasÎncă nu există evaluări

- WPQRDocument27 paginiWPQRJayaram MVÎncă nu există evaluări

- WSS Welding Handbook 2013 Full Lowres PDFDocument552 paginiWSS Welding Handbook 2013 Full Lowres PDFsridharchowdary3490% (1)

- 254-SmoDocument12 pagini254-SmoDanem Halas100% (1)

- En Metalwork Gas Tungsten Arc WeldingDocument48 paginiEn Metalwork Gas Tungsten Arc WeldingadammzjinÎncă nu există evaluări

- MT Training SpecifiqueDocument4 paginiMT Training SpecifiqueDanem HalasÎncă nu există evaluări

- Duplex 2101Document6 paginiDuplex 2101Anonymous AlhzFE9EVNÎncă nu există evaluări

- WPS PQR Checklist 2014Document2 paginiWPS PQR Checklist 2014Sebastian Rajesh100% (1)

- Office: Printout Sample - ASME WPSDocument2 paginiOffice: Printout Sample - ASME WPSDanem HalasÎncă nu există evaluări

- WeldingofStainlesssSteelandotherJoiningMethods 9002Document0 paginiWeldingofStainlesssSteelandotherJoiningMethods 9002jvs11021102Încă nu există evaluări

- WPS GTAW Stainless SteelDocument2 paginiWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WLD 290 Submerged Arc WeldingDocument52 paginiWLD 290 Submerged Arc WeldingDanem HalasÎncă nu există evaluări

- Clad PQRDocument5 paginiClad PQRRinshadÎncă nu există evaluări

- 8a Codes and Q & CDocument35 pagini8a Codes and Q & CDanem HalasÎncă nu există evaluări

- Office: Printout Sample - ASME WPSDocument2 paginiOffice: Printout Sample - ASME WPSDanem HalasÎncă nu există evaluări