Documente Academic

Documente Profesional

Documente Cultură

Cutting Tools

Încărcat de

Naman DaveDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cutting Tools

Încărcat de

Naman DaveDrepturi de autor:

Formate disponibile

PowerPoint to accompany

Technology of Machine Tools

Cutting Tools

Unit 29

29-2

Objectives

Use the nomenclature of a cutting-tool

point

Explain the purpose of each type of rake

and clearance angle

Identify the applications of various types

of cutting-tool materials

Describe the cutting action of different

types of machines

29-3

Cutting Tools

One of most important components in

machining process

Performance will determine efficiency of

operation

Two basic types (excluding abrasives)

Single point and multi point

Must have rake and clearance angles ground

or formed on them

29-4

Cutting-Tool Materials

Lathe toolbits generally made of five

materials

High-speed steel

Cast alloys (such as stellite)

Cemented carbides

Ceramics

Cermets

More exotic finding wide use

Borazon and polycrystalline diamond

29-5

Lathe Toolbit Properties

Hard

Wear-resistant

Capable of maintaining a red hardness

during machining operation

Red hardness: ability of cutting tool to

maintain sharp cutting edge even when turns

red because of high heat during cutting

Able to withstand shock during cutting

Shaped so edge can penetrate work

29-6

High-Speed Steel Toolbits

May contain combinations of tungsten,

chromium, vanadium, molybdenum, cobalt

Can take heavy cuts, withstand shock and

maintain sharp cutting edge under red heat

Generally two types (general purpose)

Molybdenum-base (Group M)

Tungsten-base (Group T)

Cobalt added if more red hardness desired

29-7

Cemented-Carbide Toolbits

Capable of cutting speeds 3 to 4 times highspeed steel toolbits

Low toughness but high hardness and

excellent red-hardness

Consist of tungsten carbide sintered in

cobalt matrix

Straight tungsten used to machine cast iron

and nonferrous materials (crater easily)

Different grades for different work

29-8

Coated Carbide Toolbits

Made by depositing thin layer of wear-resistant

titanium nitride, titanium carbide or aluminum

oxide on cutting edge of tool

Fused layer increases lubricity, improves cutting

edge wear resistance by 200%-500%

Lowers breakage resistance up to 20%

Provides longer life and increased cutting speeds

Titanium-coated offer wear resistance at low

speeds, ceramic coated for higher speeds

29-9

Ceramic Toolbits

Permit higher cutting speeds, increased tool

life and better surface finish than carbide

Weaker than carbide used in shock-free or lowshock situation

Ceramic

Heat-resistant material produced without metallic

bonding agent such as cobalt

Aluminum oxide most popular additive

Titanium oxide or Titanium carbide can be added

29-10

Diamond Toolbits

Used mainly to machine nonferrous metals

and abrasive nonmetallics

Single-crystal natural diamonds

High-wear but low shock-resistant factors

Polycrystalline diamonds

Tiny manufactured diamonds fused together and

bonded to suitable carbide substrate

29-11

Cutting-Tool Nomenclature

Cutting edge: leading edge of that does cutting

Face: surface against which chip bears as it is

separated from work

Nose: Tip of cutting tool formed by junction of

cutting edge and front face

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

29-12

Cutting-Tool Nomenclature

Nose radius: radius to which nose is ground

Size of radius will affect finish

Rough turning: small nose radius (.015in)

Finish cuts: larger radius (.060 to .125 in.)

Point: end of tool that has been ground for cutting

purposes

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

29-13

Cutting-Tool Nomenclature

Base: Bottom surface of tool shank

Flank: surface of tool adjacent to and below cutting

edge

Shank: body of toolbit or part held in toolholder

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

29-14

Lathe Toolbit Angles

and Clearances

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

29-15

Lathe Cutting-tool Angles

Negativerake:

Positive

rake:point

face of

cutting tool contacts

and cutting

metal

edge

contact

first

andmetal

chip moves

first and chip

moves

up

the face

downofthe

theface

toolbit

of

the toolbit

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

29-16

Positive Rake Angle

Considered best for efficient

removal of metal

Creates large shear angle at shear zone

Reduces friction and heat

Allows chip to flow freely along chip-tool

interface

Generally used for continuous cuts on

ductile materials not too hard or abrasive

29-17

Factors When Choosing Type and

Rake Angle for Cutting Tool

Hardness of metal to be cut

Type of cutting operation

Continuous or interrupted

Material and shape of cutting tool

Strength of cutting edge

29-18

Shape of Chip

Altered in number of ways to improve

cutting action and reduce amount of power

required

Continuous straight ribbon chip can be

changed to continuous curled ribbon

Changing angle of the keeness

Included angle produced by grinding side rake

Grinding chip breaker behind cutting edge of

toolbit

29-19

Tool Life

Crater wear occurs as result

of chips sliding along

chip-tool interface,

result of built-up

edge on cutting

tool

Nose wear occurs

as result of friction between

nose and metal being machined

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

When flank wear

is .015 to .030 in.

need to be reground

Occurs on side of cutting

edge as result of friction

between side of cutting-tool

edge and metal being

machined

29-20

Factors Affecting the Life of a

Cutting Tool

Type of material being cut

Microstructure of material

Hardness of material

Type of surface on metal (smooth or scaly)

Material of cutting tool

Profile of cutting tool

Type of machining operation being performed

Speed, feed, and depth of cut

29-21

Turning

Assume cutting machine steel: If rake and relief clearance

angles correct and proper speed and feed used, a continuous

chip should be formed.

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

29-22

Nomenclature of a Plain Milling Cutter

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

29-23

Nomenclature of an

End Mill

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

29-24

Nomenclature of an

End Mill

Copyright The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

29-25

Characteristics of a

Drill Point

Cutting-point angles for

standard drill

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

Chip formation

of a drill

PowerPoint to accompany

Technology of Machine Tools

6th Edition

Krar Gill Smid

Operating Conditions

and Tool Life

Unit 30

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

30-27

Objectives

Describe the effect of cutting conditions

on cutting-tool life

Explain the effect of cutting conditions

on metal-removal rates

State the advantages of new cutting-tool

materials

Calculate the economic performance

and cost analysis for a machining

operation

30-28

Operating Conditions

Three operating variables influence metalremoval rate and tool life

Cutting speed

Feed rate

Depth of cut

30-29

Reduction in Tool Life

Operating Conditions

CUTTING

SPEED + 50%

90%

FEED

RATE + 50%

60%

DEPTH OF

CUT + 50%

15%

30-30

General Operating Condition

Rules

Proper cutting speed most critical factor to

consider establishing optimum conditions

Too slow: Fewer parts produced, built-up edge

Too fast: Tool breaks down quickly

Optimum cutting speed should balance

metal-removal rate and cutting-tool life

Choose heaviest depth of cut and feed rate

possible

PowerPoint to accompany

Technology of Machine Tools

6th Edition

Krar Gill Smid

Carbide Cutting

Tools

Unit 31

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

31-32

Objectives

Identify and state the purpose of the

two main types of carbide grades

Select the proper grade of carbide for

various workpiece materials

Select the proper speeds and feeds for

carbide tools

31-33

Carbide Cutting Tools

First used in Germany during WW II as

substitute for diamonds

Various types of cemented (sintered)

carbides developed to suit different

materials and machining operations

Good wear resistance

Operate at speeds ranging 150 to 1200 sf/min

Can machine metals at speeds that cause

cutting edge to become red hot without

loosing harness

31-34

Blending

Five types of powders

Tungsten carbide, titanium carbide, cobalt,

tantalum carbide, niobium carbide

One or combination blended in different

proportions depending on grade desired

Powder mixed in alcohol (24 to 190 h)

Alcohol drained off

Paraffin added to simplify pressing

operation

31-35

Compaction

Must be molded to shape and size

Five different methods to

compact powder

Extrusion process

Hot press

Isostatic press

Ingot press

Pill press

Green (pressed) compacts soft, must be

presintered to dissolve paraffin

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

31-36

Presintering

Green compacts heated to about 1500 F in

furnace under protective atmosphere of

hydrogen

Carbide blanks have consistency of chalk

May be machined to required shape

40% oversize to allow for shrinkage that occurs

during final sintering

31-37

Sintering

Last step in process

Converts presintered machine blanks into

cemented carbide

Carried out in either hydrogen atmosphere

or vacuum

Temperatures between 2550 and 2730 F

Binder (cobalt) unites and cements carbide

powders into dense structure of extremely

hard carbide crystals

31-38

Cemented-Carbide

Applications

Used extensively in manufacture of metalcutting tools

Extreme hardness and good wear-resistance

First used in machining operations as lathe

cutting tools

Majority are single-point cutting tools used

on lathes and milling machines

31-39

Types of Carbide Lathe

Cutting Tools

Brazed-tip type

Cemented-carbide tips brazed to steel shanks

Wide variety of styles and sizes

Indexable insert type

Throwaway inserts

Wide variety of shapes: triangular, square,

diamond, and round

Triangular: has three cutting edges

Inserts held mechanically in special holder

31-40

Grades of Cemented Carbides

Two main groups of carbides

Straight tungsten carbide

Contains only tungsten carbide and cobalt

Strongest and most wear-resistant

Used for machining cast iron and nonmetals

Crater-resistant

Contain titanium carbide and tantalum carbide in

addition to tungsten carbide and cobalt

Used for machining most steels

31-41

Tool

Geometry

Terms adopted

by ASME

SIDE RELIEF

SIDE CLEARANCE

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

31-42

Cutting-Tool Terms

Front, End, Relief

(Clearance)

Allows end of cutting tool to

enter work

Side Relief (Side)

Permits side of tool to

advance into work

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

31-43

Cutting Speeds and Feeds

Important factors that influence speeds,

feeds, and depth of cut

Type and hardness of work material

Grade and shape of cutting tool

Rigidity of cutting tool

Rigidity of work and machine

Power rating of machine

PowerPoint to accompany

Technology of Machine Tools

6th Edition

Krar Gill Smid

Cutting Fluids

Types

and Applications

Unit 34

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

34-45

Objectives

State the importance and function of

cutting fluids

Identify three types of cutting fluids and

state the purpose of each

Apply cutting fluids efficiently for a

variety of machining operations

34-46

Cutting Fluids

Essential in metal-cutting operations to

reduce heat and friction

Centuries ago, water used on grindstones

100 years ago, tallow used (did not cool)

Lard oils came later but turned rancid

Early 20th century saw soap added to water

Soluble oils came in 1936

Chemical cutting fluids introduced in 1944

34-47

Economic Advantages to Using

Cutting Fluids

Reduction of tool costs

Reduce tool wear, tools last longer

Increased speed of production

Reduce heat and friction so higher cutting speeds

Reduction of labor costs

Tools last longer and require less regrinding, less

downtime, reducing cost per part

Reduction of power costs

Friction reduced so less power required by

machining

34-48

Heat Generated During

Machining

Heat find its way into one of three places

Workpiece, tool,

Act aschips

disposable

heat sink

Too much, cutting edge

will break down rapidly,

reducing tool life

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

Too much, work

will expand

34-49

Heat Dissipation

Ideally most heat taken off in chips

Indicated by change in chip color as heat

causes chips to oxidize

Cutting fluids assist taking away heat

Can dissipate at least 50% of heat created during

machining

34-50

Characteristics of a Good

Cutting Fluid

1. Good cooling capacity

2. Good lubricating

qualities

3. Resistance to

rancidity

4. Relatively low

viscosity

5. Stability (long life)

6.

7.

8.

9.

Rust resistance

Nontoxic

Transparent

Nonflammable

34-51

Types of Cutting Fluids

Most commonly used cutting fluids

Either aqueous based solutions or cutting oils

Fall into three categories

Cutting oils

Emulsifiable oils

Chemical (synthetic) cutting fluids

34-52

Oil Categories

Sulfurized mineral oils

Contain .5% to .8% sulfur

Light-colored and transparent

Stains copper and alloys

Sulfochlorinated mineral oils

3% sulfur and 1% chlorine

Prevent excessive built-up edges from forming

Sulfochlorinated fatty oil blends

Contain more sulfur than other types

34-53

Inactive Cutting Oils

Oils will not darken copper strip immersed

in them for 3 hours at 212F

Contained sulfur is natural

Termed inactive because sulfur so firmly

attached to oil very little released

Four general categories

Straight mineral oils, fatty oils, fatty and

mineral oil blends, sulfurized fatty-mineral oil

blend

34-54

Emulsifiable (Soluble) Oils

Mineral oils containing soaplike material

that makes them soluble in water and causes

them to adhere to workpiece

Emulsifiers break oil into minute particles

and keep them separated in water

Supplied in concentrated form (1-5 /100 water)

Good cooling and lubricating qualities

Used at high cutting speeds, low cutting

pressures

34-55

Functions of a Cutting Fluid

Prime functions

Provide cooling

Provide lubrication

Other functions

Prolong cutting-tool life

Provide rust control

Resist rancidity

34-56

Functions of a Cutting Fluid:

Cooling

Heat has definite bearing on cutting-tool wear

Small reduction will greatly extend tool life

Two sources of heat during cutting action

Plastic deformation of metal

Occurs immediately ahead of cutting tool

Accounts for 2/3 to 3/4 of heat

Friction from chip sliding along cutting-tool face

Water most effective for reducing heat (rust)

34-57

Functions of a Cutting Fluid:

Lubrication

Reduces friction between chip and tool face

Shear plane becomes shorter

Area where plastic deformation occurs

correspondingly smaller

Extreme-pressure lubricants reduce amount

of heat-producing friction

EP chemicals of synthetic fluids combine

chemically with sheared metal of chip to

form solid compounds (allow chip to slide)

34-58

Cutting-Tool Life

Heat and friction prime causes of cuttingtool breakdown

Reduce temperature by as little as 50F, life

of cutting tool increases fivefold

Built-up edge

Pieces of metal weld themselves to tool face

Becomes large and flat along tool face,

effective rake angle of cutting tool decreased

34-59

Application of Cutting Fluids

Cutting-tool life and machining operations

influenced by way cutting fluid applied

Copious stream under low pressure so work

and tool well covered

Inside diameter of supply nozzle width of

cutting tool

Applied to where chip being formed

34-60

Milling

Face milling

Ring-type distributor recommended to flood

cutter completely

Keeps each tooth of cutter immersed in cutting

fluid at all times

Slab milling

Fluid directing to both

sides of cutter by fan-shaped

nozzles width of cutter

Copyright The McGraw-Hill Companies, Inc.

Permission required for reproduction or display.

S-ar putea să vă placă și

- Mould BaseDocument8 paginiMould BaseMould Base ManufacturerÎncă nu există evaluări

- Injection Moulding ProcessDocument13 paginiInjection Moulding ProcessSACHIN SINGH 36Încă nu există evaluări

- Stanley Hand ToolsDocument53 paginiStanley Hand ToolsAnonymous WaC9PaQmrÎncă nu există evaluări

- Ball Screw DesignDocument2 paginiBall Screw DesignAnonymous CYdagIÎncă nu există evaluări

- Press Working TerminologyDocument16 paginiPress Working TerminologyAadrika UmashankarÎncă nu există evaluări

- Press Tool Components Die MakingDocument29 paginiPress Tool Components Die Makingmayank123100% (1)

- 53 Tool & Die Maker (Dies &mouldsDocument20 pagini53 Tool & Die Maker (Dies &mouldspankajhkmnÎncă nu există evaluări

- Design and Fabrication of Injection Moulding Machine-Mechanical ProjectDocument4 paginiDesign and Fabrication of Injection Moulding Machine-Mechanical ProjectUr FriendÎncă nu există evaluări

- BroachingDocument22 paginiBroachingvijchoudhary16Încă nu există evaluări

- Topics Covered: Processing of PlasticsDocument30 paginiTopics Covered: Processing of PlasticsParthiban DhakshnamurthyÎncă nu există evaluări

- SPI Tooling SpecificationsDocument3 paginiSPI Tooling SpecificationsJanaka MangalaÎncă nu există evaluări

- Eccentric Turning Attachment On Three Jaw LatheDocument50 paginiEccentric Turning Attachment On Three Jaw LatheSushant MahajanÎncă nu există evaluări

- Mechanical Fasteners - Part IIDocument24 paginiMechanical Fasteners - Part IIsaded05Încă nu există evaluări

- Washing Machine: Case Study: Embedded SystemDocument16 paginiWashing Machine: Case Study: Embedded SystemPreetam KarmakarÎncă nu există evaluări

- 2012 The American Mold Builder Magazine - FallDocument40 pagini2012 The American Mold Builder Magazine - FallAMBAÎncă nu există evaluări

- TD Synchrobelt HTD enDocument82 paginiTD Synchrobelt HTD enReparatii CncÎncă nu există evaluări

- Copy Milling MachineDocument77 paginiCopy Milling MachineAkshay Shinde25% (4)

- Sheet Metal BendingDocument30 paginiSheet Metal BendingZen P MonachanÎncă nu există evaluări

- Shaping MachineDocument25 paginiShaping Machinekatakamharish100% (1)

- Press Dies TutorialDocument13 paginiPress Dies TutorialRaj SatoskerÎncă nu există evaluări

- Mechanics of Metal CuttingDocument86 paginiMechanics of Metal CuttingscorpionarnoldÎncă nu există evaluări

- Machine Tools - 2015-16Document310 paginiMachine Tools - 2015-16Akshay Saxena100% (2)

- Deep Hole Drilling Tools: BotekDocument48 paginiDeep Hole Drilling Tools: Botekcarolina lopesÎncă nu există evaluări

- 16 High Speed MachiningDocument17 pagini16 High Speed MachiningSandeep MeenaÎncă nu există evaluări

- c5 Lathe 120203152613 Phpapp02Document30 paginic5 Lathe 120203152613 Phpapp02Preavin Kutty Thamotharan100% (1)

- Proxxon pd400cnc English 2016 PDFDocument2 paginiProxxon pd400cnc English 2016 PDFPhu TRANÎncă nu există evaluări

- End Mill and Cutting Tool Design Criteria and Technical FeaturesDocument4 paginiEnd Mill and Cutting Tool Design Criteria and Technical FeaturesdkkÎncă nu există evaluări

- 86 Mould Base Series 16 & 20 Individual Plate PricesDocument21 pagini86 Mould Base Series 16 & 20 Individual Plate PricesAmitava DattaÎncă nu există evaluări

- Ryobi P271 Owners ManualDocument36 paginiRyobi P271 Owners ManualDavid Gaines100% (1)

- Machine Tools For MachiningDocument56 paginiMachine Tools For MachiningUmberto PriscoÎncă nu există evaluări

- Frame Cad-Self Tapping Screw SpecDocument2 paginiFrame Cad-Self Tapping Screw Specersivaraj100% (1)

- Sheet Metal OperationsDocument3 paginiSheet Metal OperationsDineshÎncă nu există evaluări

- Grinding Lathe ToolsDocument18 paginiGrinding Lathe ToolsAntónio FrançaÎncă nu există evaluări

- Opportunities and Limits of 2k Injection MouldingDocument22 paginiOpportunities and Limits of 2k Injection Mouldingsa_arunkumarÎncă nu există evaluări

- Injection Moulding BasicsDocument27 paginiInjection Moulding Basicsmrriassaty100% (1)

- Shaper Used As Surface GrinderDocument1 paginăShaper Used As Surface Grinderradio-chaserÎncă nu există evaluări

- Fits and TolerancesDocument15 paginiFits and TolerancesJohn Victor KamelÎncă nu există evaluări

- Vermont Turning Insert CatalogDocument84 paginiVermont Turning Insert CatalogMann Sales & MarketingÎncă nu există evaluări

- Knee Type Milling MachinesDocument6 paginiKnee Type Milling MachinesArchit Jhunjhunwala100% (1)

- 6-Cutting-Tool Materials and Cutting FluidsDocument41 pagini6-Cutting-Tool Materials and Cutting Fluidsmuralict2009Încă nu există evaluări

- EJECTIONDocument11 paginiEJECTIONRatnesh Patel100% (1)

- Drilling Speeds and FeedsDocument1 paginăDrilling Speeds and FeedsLe Hoang HiepÎncă nu există evaluări

- Manufacturing Processes Iiprof A B Chattopadhyay Prof A K Chattopadhyay PDFDocument618 paginiManufacturing Processes Iiprof A B Chattopadhyay Prof A K Chattopadhyay PDFp KumarÎncă nu există evaluări

- MachinabilityDocument5 paginiMachinabilityAshwin KumarÎncă nu există evaluări

- Project Final Year On The Injection Plastic ModuleDocument41 paginiProject Final Year On The Injection Plastic ModuleSajid ZeyaÎncă nu există evaluări

- Manufacturing Technology II - Notes PDFDocument17 paginiManufacturing Technology II - Notes PDFSenthil Kumar Subramanian100% (1)

- Ebook Tapping Away Guide To Tapping and Threading Xometry SuppliesDocument19 paginiEbook Tapping Away Guide To Tapping and Threading Xometry SuppliesAli KhubbakhtÎncă nu există evaluări

- Hydraulic Lines and FittingsDocument23 paginiHydraulic Lines and FittingsMohammed Al-OdatÎncă nu există evaluări

- About Injection MoldingDocument13 paginiAbout Injection MoldingGregg3GÎncă nu există evaluări

- Sms Handbook 01 v01Document78 paginiSms Handbook 01 v01yuvatharikÎncă nu există evaluări

- Biax 7EL Assembly - RepairDocument6 paginiBiax 7EL Assembly - RepairKarsten BergÎncă nu există evaluări

- Gears Cutting and GrindingDocument8 paginiGears Cutting and GrindingАлександар ВујаковићÎncă nu există evaluări

- Unit - Iv: Milling MachineDocument74 paginiUnit - Iv: Milling MachineDevarakonda KondayyaÎncă nu există evaluări

- Pneumatic Auto Feed Sheet Cutting MachineDocument5 paginiPneumatic Auto Feed Sheet Cutting MachineVigneshwaran Srinivasan100% (1)

- MillingDocument33 paginiMillingRavichandran G0% (1)

- Design For InjectionDocument38 paginiDesign For Injectionnurwinantoindra100% (1)

- Cutting ToolsDocument60 paginiCutting ToolsKedar Altekar0% (1)

- Technology of Machine ToolsDocument60 paginiTechnology of Machine Toolsaly_wael71Încă nu există evaluări

- New Cutting ToolsDocument102 paginiNew Cutting ToolsUmasankar IyerÎncă nu există evaluări

- Technology of Machine ToolsDocument60 paginiTechnology of Machine ToolsMayank SharmaÎncă nu există evaluări

- Heat Treatment Part 2Document46 paginiHeat Treatment Part 2Naman DaveÎncă nu există evaluări

- ComparatorsDocument42 paginiComparatorsNaman Dave100% (2)

- Heat Treatment Part 1Document32 paginiHeat Treatment Part 1Naman DaveÎncă nu există evaluări

- I C DiagramDocument26 paginiI C DiagramNaman DaveÎncă nu există evaluări

- Solidification of MaterialDocument28 paginiSolidification of MaterialNaman DaveÎncă nu există evaluări

- Phase and Phase EquilibriumDocument53 paginiPhase and Phase EquilibriumNaman DaveÎncă nu există evaluări

- Orthographic ProjectionsDocument37 paginiOrthographic ProjectionsNaman DaveÎncă nu există evaluări

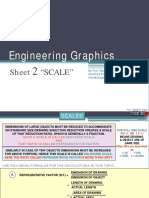

- Scales: Engineering GraphicsDocument12 paginiScales: Engineering GraphicsNaman Dave100% (2)

- Cutting ToolsDocument60 paginiCutting ToolsKedar Altekar0% (1)

- Isometric Projections NMD PDFDocument48 paginiIsometric Projections NMD PDFNaman Dave100% (5)

- Metal Cutting AdditionalDocument122 paginiMetal Cutting AdditionalNaman DaveÎncă nu există evaluări

- Cutting ToolDocument27 paginiCutting Toolvenkateshyadav2116Încă nu există evaluări

- Metal Cutting 2Document39 paginiMetal Cutting 2Naman DaveÎncă nu există evaluări

- Jig and FixtureDocument38 paginiJig and FixtureNaman Dave100% (1)

- Linear MeasurementsDocument54 paginiLinear MeasurementsNaman Dave100% (1)

- Mechanical MeasurementDocument48 paginiMechanical MeasurementNaman Dave100% (2)

- Carbon Steel Bolts and Studs, 60 000 PSI Tensile Strength: Standard Specification ForDocument6 paginiCarbon Steel Bolts and Studs, 60 000 PSI Tensile Strength: Standard Specification Forcarol santosÎncă nu există evaluări

- Eolo Mini 27AE 2Document2 paginiEolo Mini 27AE 2qwe123free1231962Încă nu există evaluări

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument40 paginiDesign and Drawing of RC Structures: Dr. G.S.SureshKanhaiya BhagatÎncă nu există evaluări

- Ultratech Cement: Unit: Birla WhiteDocument24 paginiUltratech Cement: Unit: Birla WhiteAbhishek LambaÎncă nu există evaluări

- Types of Welding ElectrodesDocument34 paginiTypes of Welding ElectrodesAileen May Caminero SumampaoÎncă nu există evaluări

- Phillips Street LightDocument3 paginiPhillips Street LightMarak SaibalÎncă nu există evaluări

- 09b Eurocodes Steel Workshop LANDOLFODocument119 pagini09b Eurocodes Steel Workshop LANDOLFObernaduscaturÎncă nu există evaluări

- Quiz CM 1Document17 paginiQuiz CM 1scrib1 dÎncă nu există evaluări

- 1 CE131P - Introduction To Structural Analysis (Robles) PDFDocument12 pagini1 CE131P - Introduction To Structural Analysis (Robles) PDFCheelsy P. ButronÎncă nu există evaluări

- Injection Moulding: Points CoveredDocument14 paginiInjection Moulding: Points Coveredanilkolekar0% (1)

- DocumentiDocument130 paginiDocumenticnxnrtsÎncă nu există evaluări

- Basic Principles of Eddy Current InspectionDocument16 paginiBasic Principles of Eddy Current InspectionSiphesihle NkosiÎncă nu există evaluări

- A&B Official Pricelist 2019 - Parex - 1550567379Document2 paginiA&B Official Pricelist 2019 - Parex - 1550567379Daren TalanaÎncă nu există evaluări

- Kera Awak Product CatalogueDocument22 paginiKera Awak Product CatalogueAnis TaboubiÎncă nu există evaluări

- Formulas CoolersDocument39 paginiFormulas Coolersbasaca132Încă nu există evaluări

- CBT Mudbug Brochure 3-10-16Document9 paginiCBT Mudbug Brochure 3-10-16mareepierre003Încă nu există evaluări

- BS en 13391 2004Document24 paginiBS en 13391 2004Ronaldo AlmeidaÎncă nu există evaluări

- KA20903 - Lecture 1 Introduction To Mechanics of SolidsDocument6 paginiKA20903 - Lecture 1 Introduction To Mechanics of SolidsKit Meng LimÎncă nu există evaluări

- ASME P NumbersDocument1 paginăASME P NumbersFahri Risfa ZulfiÎncă nu există evaluări

- Grooved Resilient OS&Y Gate Valve (XZ81X), UL/FM Approved Flanged Resilient OS&Y Gate Valve (XZ41X), UL/FM ApprovedDocument1 paginăGrooved Resilient OS&Y Gate Valve (XZ81X), UL/FM Approved Flanged Resilient OS&Y Gate Valve (XZ41X), UL/FM Approvedtaaj77Încă nu există evaluări

- Polyacrylic or Acrylic Resin (Pmma)Document1 paginăPolyacrylic or Acrylic Resin (Pmma)Dl Al-azizÎncă nu există evaluări

- Ale Part 2 Answer KeyDocument27 paginiAle Part 2 Answer KeyTimothy Ryan Wang100% (2)

- Equipment Damage Curves ConductorsDocument5 paginiEquipment Damage Curves ConductorsrobertoseniorÎncă nu există evaluări

- Metal Casting & Welding 15Me35ADocument20 paginiMetal Casting & Welding 15Me35A01061975Încă nu există evaluări

- MaterialsDocument3 paginiMaterialsAnjali DhamayanthiÎncă nu există evaluări

- Highway SpecificationDocument85 paginiHighway SpecificationAkaninyeneÎncă nu există evaluări

- Two-Phase Gas/Liquid Pipe Flow: Ron Darby PHD, Pe Professor Emeritus, Chemical Engineering Texas A&M UniversityDocument61 paginiTwo-Phase Gas/Liquid Pipe Flow: Ron Darby PHD, Pe Professor Emeritus, Chemical Engineering Texas A&M UniversityEjaz Ahmed RanaÎncă nu există evaluări

- Alucobest Aluminum Composite Panel For Sign, Display and Digital PrintingDocument12 paginiAlucobest Aluminum Composite Panel For Sign, Display and Digital PrintingAli ZhangÎncă nu există evaluări

- BJM EC 20 DS 009 A4 Rev - 0 Datasheet Premium Pertamax Tank 5000 KLDocument5 paginiBJM EC 20 DS 009 A4 Rev - 0 Datasheet Premium Pertamax Tank 5000 KLErick SavrinaldoÎncă nu există evaluări