Documente Academic

Documente Profesional

Documente Cultură

Amendment 1 - 2002

Încărcat de

Mamta ShindeTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Amendment 1 - 2002

Încărcat de

Mamta ShindeDrepturi de autor:

Formate disponibile

[Published in Part II, Section 3, Sub-section (i) of the Gazette of India dated 13 th April, 2002]

Government of India

Ministry of Commerce and Industry

Department of Industrial Policy and Promotion

(Central Boilers Board)

New Delhi, the 9th April, 2002.

Notification

G.S.R. .________.- Whereas certain draft regulations further to amend the Indian

Boiler Regulations, 1950 were published, as required by sub-section (1) of section 31 of the

Indian Boilers Act, 1923 (5 of 1923), at pages 2482 to 2490 in Part II, Section 3, Sub-section

(i) of the Gazette of India, dated the 28 th July, 2001, vide notification of the Government of

India in the Ministry of Commerce and Industry (Department of Industrial Policy and

Promotion) (Central Boilers Board) number G.S.R. 393, dated the 17 th July, 2001 for inviting

objections and suggestions from all persons likely to be affected thereby till the expiry of

forty-five days from the date on which copies of the Gazette containing the said notification

were made available to the public;

And whereas the copies of the said Gazette were made available to the public on the

30th July, 2001;

And whereas no objections or suggestions have been received within the specified

period in respect of the amendments contained in this notification;

Now, therefore, in exercise of the powers conferred by section 28 of the Indian

Boilers Act, 1923, the Central Boilers Board hereby makes the following regulations further

to amend the Indian Boiler Regulations, 1950, namely:1. (1) These regulations may be called the Indian Boiler (Amendment) Regulations, 2002.

(2) They shall come into force on the date of their publication in the Official Gazette.

2.

In the Indian Boiler Regulations, 1950 (hereinafter referred to as the principal

regulations),

(a) in regulation 151, after clause (h), the following clause shall be inserted, namely:"(i) All butt welded joints shall be subjected to non-destructive examination by radiographic,

radioscopy or other approved methods such as ultrasonic testing, magnetic particle inspection

or liquid dye penetrant inspection. When radioscopic examination is to be performed in lieu

of radiography on welded components, the following requirements shall be met, namely:(1) A written procedure shall be submitted for approval to the Inspecting Authority which

shall contain the following:

(i)

material and the thickness range;

(ii)

equipment qualifications;

(iii)

test object scan plan;

(iv)

radioscopic parameters;

(v)

image processing parameters;

(vi)

(vii)

(viii)

(ix)

(x)

image display parameters;

image archiving requirements;

accept-reject criteria (Code reference);

performance evaluation;

Operator identification.

(2) The system shall be aided with an image processor to enhance the quality of the

radioscopic images and system performance quality shall exhibit(i)

a thin section contrast sensitivity of 3%;

(ii)

a thick section contrast sensitivity of 2%;

(iii)

a spatial resolution of 3 line pairs per mm;.

(iv)

IQI sensitivity - 2% of the joint thickness when wire IQI's are to be used, the

wire diameter axis shall be oriented along the axis of the least sensitivity of the

system.

(3) Radioscopes are to be properly marked to co-relate with particular part of joint

represented.

(4) The radioscopic examination data shall be recorded and stored on videotape, magnetic

disk or optical disk at the maker's plant for a sufficient period after the date of radioscopic

examination as specified by the Inspecting Authority, efficient radioscopic examination

record recall shall be made available at any time over the record retention period and shall

be traceable to the test objects.

(5) When repair has been performed as a result of radioscopic examination, the repaired areas

shall be re-examined using the same radioscopic technique to evaluate the effectiveness

of the repair.

(6) To aid in proper interpretation of the radioscopic examination data, the details of the

technique used shall accompany the data. As a minimum, the information shall include

the approved procedure requirements and system performance test data.";

(b) For regulation 243 of the principal regulations, the following regulation shall be

substituted, namely:"243. Forging.- The forging shall be made from a solid cast ingot, punched, bored or

trepanned, or alternatively, hollow, cast ingots may be used. The resultant wall in the case of

the solid cast ingot, or the wall of hollow ingot as cast shall be reduced in thickness by at

least one-half in the process of forging.";

(c) Regulation 256 of the principal regulations shall be numbered as clause (a) thereof and

after clause (a) as so numbered, the following clause shall be inserted, namely:"(b) Tolerance (i) The deviation from circularity in any section shall, in the case of

normalised drums, not exceed 2% and in case of stress relieved drum 1%. The deviation

from a straight line shall not exceed 0.3% of the cylindrical length.

(ii) In order to determine the deviation from circularity of the drums the maximum

and minimum internal diameter at one cross section shall be measured. From these measured

values the percentage deviation from circularity shall be calculated according to the following

formula:2(dmax dmin)

C = --------------------- 100

(dmax + dmin)

where, C = percentage deviation from circularity of the drums.

d = internal diameter at one cross section.

In order to determine the deviation from a straight line, a stretched line should be

placed longitudinally against the sides and its largest distance from the shell line concerned

shall be measured. From this distance, and from the cylindrical shell, the deviation from the

straight line shall be calculated.";

(d) In regulation 259 of the principal regulations, (A) in clause (a), (i) for the word and figures "fig. 18", the word, figures and letter "figure 18A" shall be

substituted;

(ii) for the word and figures "figure 18", the word, figures and letter "figure 18B" shall be

substituted;

(B) in Fig. 18A, after the dimension "30mm MAX.", the following shall be inserted, namely:"Thickness of the plate.";

(e) In regulation 265 of the principal regulations, after clause (d), the following clause shall

be inserted, namely:"(e) All butt welded joints shall be subjected to non-destructive examination by radiographic,

radioscopy or other approved methods such as ultrasonic testing, magnetic particle inspection

or liquid dye penetrant inspection. When radioscopic examination is to be performed in lieu

of radiography on welded components, the following requirements shall be met, namely:(1) A written procedure shall be submitted for approval to the Inspecting Authority which

shall contain the following:

(i)

material and the thickness range;

(ii)

equipment qualifications;

(iii)

test object scan plan;

(iv)

radioscopic parameters;

(v)

image processing parameters;

(vi)

image display parameters;

(vii) image archiving requirements;

(viii) accept-reject criteria (Code reference);

(ix)

performance evaluation;

(x)

Operator identification.

(2) The system shall be aided with an image processor to enhance the quality of the

radioscopic images and system performance quality shall exhibit(i)

a thin section contrast sensitivity of 3%;

(ii)

a thick section contrast sensitivity of 2%;

(iii)

a spatial resolution of 3 line pairs per mm;

(iv)

IQI sensitivity - 2% of the joint thickness when wire IQI's are to be used, the

wire diameter axis shall be oriented along the axis of the least sensitivity of the

system.

(3) Radioscopes are to be properly marked to co-relate with particular part of joint

represented.

(4) The radioscopic examination data shall be recorded and stored on videotape, magnetic

disk or optical disk at the maker's plant for a sufficient period after the date of radioscopic

examination as specified by the Inspecting Authority, Efficient radioscopic examination

record recall shall be made available at any time over the record retention period and shall

be traceable to the test objects.

(5) When repair has been performed as a result of radioscopic examination, the repaired areas

shall be re-examined using the same radioscopic technique to evaluate the effectiveness

of the repair.

(6) To aid in proper interpretation of the radioscopic examination data, the details of the

technique used shall accompany the data. As a minimum, the information shall include

the approved procedure requirements and system performance test data.";

(f) In regulation 343 of the principal regulations, for sub-regulation (3), the following subregulation shall be substituted, namely:"(3) Notwithstanding anything contained in Chapter VIII, the hydraulic test for pipes

in maker's premises may be dispensed with by the Inspecting Authority:

Provided that these pipes have been fully tested by approved radiographic or

ultrasonic techniques:

Provided further that in the case of pipes having internal diameter 600mm and more,

the plates used for the manufacture of pipes and the long seam welds of pipes are fully tested

by approved non-destructive test; for example, ultrasonic or radiographic testing and the

soundness of pipes both in the parent material and in the weld is established in the maker's

premises; and the whole component of the pipes, after completion of any further fabrication

and erection at site, are hydraulically tested at a pressure not less than 1.5 times the design

pressure of the piping system:

Provided also that in the event of detection of any defect after conducting hydraulic

test of these pipes at site, it shall be the responsibility of the manufacturer to repair or replace

the defective pipes, as may be deemed necessary by the Inspecting Authority.";

(g) In regulation 350 of the principal regulations,(i) for the portion beginning with "f = Allowable stress determined on the following

basis" and ending with "lowest stress to produce rupture at the temperature", the

following shall be substituted, namely:"f = Allowable stress as provided under regulation 271;

(ii) Table 3 shall be omitted.";

(h) In regulation 360 of the principal regulations, after clause (e), the following clause shall

be inserted, namely:"(f) All butt welded joints shall be subjected to non-destructive examination by radiographic,

radioscopy or other approved methods such as ultrasonic testing, magnetic particle inspection

or liquid dye penetrant inspection. When radioscopic examination is to be performed in lieu

of radiography on welded components, the following requirements shall be met:

(1) A written procedure shall be submitted for approval to the Inspecting Authority which

shall contain the following:(i)

material and the thickness range;

(ii)

equipment qualifications;

(iii) test object scan plan;

(iv)

radioscopic parameters;

(v)

image processing parameters;

(vi)

image display parameters;

(vii) image archiving requirements;

(viii) accept-reject criteria (Code reference);

(ix)

performance evaluation;

(x)

Operator identification.

(2) The system shall be aided with an image processor to enhance the quality of the

radioscopic images and system performance quality shall exhibit(i)

a thin section contrast sensitivity of 3%;

(ii)

a thick section contrast sensitivity of 2%;

(iii)

a spatial resolution of 3 line pairs per mm;.

(iv)

IQI sensitivity - 2% of the joint thickness when wire IQI's are to be used, the

wire diameter axis shall be oriented along the axis of the least sensitivity of the

system.

(3) Radioscopes are to be properly marked to co-relate with particular part of joint

represented.

(4) The radioscopic examination data shall be recorded and stored on videotape, magnetic

disk or optical disk at the maker's plant for a sufficient period after the date of radioscopic

examination as specified by the Inspecting Authority, Efficient radioscopic examination

record recall shall be made available at any time over the record retention period and shall

be traceable to the test objects.

(5) When repair has been performed as a result of radioscopic examination, the repaired areas

shall be re-examined using the same radioscopic technique to evaluate the effectiveness

of the repair.

(6) To aid in proper interpretation of the radioscopic examination data, the details of the

technique used shall accompany the data. As a minimum, the information shall include

the approved procedure requirements and system performance test data.";

(i) In regulation 367 of the principal regulations, after the table, for the portion beginning

with the words "Where tapered threads" and ending with "limits of 31.6 kg/cm 2 (450 lbs./sq.

in)", the following shall be substituted, namely:"Screwed joints are permitted at temperatures exceeding 260oC and size or pressure limits in

excess of those given the table provided that the following conditions are satisfied, namely:(1) All threads are tapered unless pressure tightness depends on a seal weld or a seating

surface other than the threads and experience or test demonstrates the suitability of the

joint.

(2) Pressure or temperature rating in appropriate component standard like BS, ASME, DIN

etc. or as calculated under relevant regulation of these regulations are not exceeded.

(3) Minimum specified tensile strength of screwed pipes is greater than 330 N/mm2.

(4) The minimum thickness of screwed pipes is not to be less than that given in Table No.1.

(5) The design temperature does not exceed 495oC.

(6) The pressure limits given in Table No.2 are not exceeded.

Screwed joints are permitted for temperatures in excess of 495 oC and pressure in excess

of those given in Table No.2 for instrument insertion and tapping and for plug for access

opening for radiographic inspection provided following conditions are satisfied:

(a) They do not exceed 50mm nominal bore size or one quarter of nominal pipe size, which

ever is the smaller.

(b) The minimum thread engagement is not less than

6 for up to and including 20mm nominal bore;

7 for over 20 mm up to and including 40mm nominal bore;

8 for 40 mm up to and including 50mm nominal bore.

(c) The connection is seal welded.

(d) The design of instrument insertion withstands the fluid characteristics, fluid flow and any

vibrations.

Screwed joints are permitted for pressure in excess of those given in Table No.2 up to 345

bar for dead end instrument lines at the outlet end and downstream of shut off valves and

instruments, control apparatus or discharge of a sample cooler provided that the nominal bore

size of the pipe does not exceed 12mm.

Table No.1

MINIMUM THICKNESS OF SCREWED PIPES

Nominal

Pipe sizeMinimum thickness17.5 bar or less for steam

7 bar and less for water

over 105oCOver 17.5 bar for steam

Over 7 bar for water over 105oCmm

8

10

15

20

25

32

40

50

65

80mm

2.24

2.31

2.77

2.87

3.38

3.56

3.68

3.91

5.16

5.49

Mm

3.02

3.20

3.75

3.91

4.55

4.85

5.08

5.54

7.01

7.62

Table No.2

MAXIMUM PRESSURE FOR SCREWED PIPESNominal pipe sizeMaximum

pressuremm

Over 50 up to and including 80

Over 25 up to and including 50

Over 20 up to and including 25

Up to and including 20Bar

27.5

41.5

83

103.5.";

(j) In regulation 374 of the principal regulations, in clause (c), the following shall be

inserted at the end, namely:"Notwithstanding anything contained in this clause, for boiler external piping and

non-boiler external piping which are open to atmosphere such as vent and drain pipes, the

hydraulic test for the portions of such pipes located beyond the last isolation valve may be

dispensed with provided the weld joints in the pipe under reference are tested 100% by

approved non-destructive examination and found satisfactory.";

(k) In regulation 382 of the principal regulations, after "Bihar" and the entry relating there

to, the following shall be inserted, namely:"Chhattisgarh..CG";

(l) In Form III of the principal regulations relating to Constructor's Certificate of

Manufacture and Test, under the heading, "1. Description", the following entry shall be

inserted at the end, namely:"Evaporation capacity .

(for calculation of relieving capacity of safety valves)";

(m) After Form III-E of the principal regulations, the following Form shall be inserted,

namely:"FORM III-F

Certificate of Manufacture and test of castings and forgings

(Regulations 73 to 80 or 81 to 85 as applicable)

Certificate No. ..

Name of part..

Makers name and address.

...

Main dimensions

Drawing Nos. .....

Identification Marks

Chemical composition.

Physical test results.

Tensile strength

Transverse bend test.

Elongation

Certified that the particulars entered herein by us are correct. This satisfies the

requirements of Indian Boiler Regulations, 1950.

Maker's Representative

(Name and signature)

MONOGRAM/

SEAL

MAKERS__________";

(n) In Form XIII of the principal regulations, for the heading "Qualified Boiler Welder's

Certificate issued under Indian Boiler Regulation 1960", the following heading shall be

substituted, namely:"Qualified Boiler Welder's Certificate issued under Indian Boiler Regulation, 1950.".

[File No. 6(3)/2001-Boilers]

(V. K. GOEL)

Secretary, Central Boilers Board

Note:- The principal regulations were published in the Gazette of India vide S.O. 600, dated

the 15th September, 1950 and subsequently amended vide notifications

(i)

G.S.R. 178, dated the 24th March, 1990;

(ii)

G.S.R. 179, dated the 24th March, 1990;

(iii)

G.S.R. 488, dated the 9th October, 1993;

(iv)

G.S.R. 516 dated the 23rd October, 1993;

(v)

G.S.R. 634 dated the 25th December, 1993;

(vi)

G.S.R. 107 dated the 26th February, 1994;

Errata G.S.R. 223 dated the 14th May, 1994;

(vii) G.S.R. 250 dated the 4th June, 1994;

G.S.R. 402 dated the13th August, 1994;

G.S.R. 427 dated the 20th August, 1994;

G.S.R. 562 dated the12th November, 1994;

G.S.R. 607 dated the10th December, 1994;

G.S.R. 83 dated the 25th February, 1995;

G.S.R. 93 dated the 4th March, 1995;

G.S.R. 488 dated the 9th November, 1996;

G.S.R. 582 dated the 28th December, 1996;

G.S.R. 59 dated the 25th January, 1997;

G.S.R. 117 dated the 1st March, 1997;

G.S.R. 172 dated the 29th March, 1997.

G.S.R. 221 dated the 21st November, 1998.

G.S.R. 131 dated 1st May, 1999.

G.S.R. 139 dated 8th May, 1999.

Errata G.S.R. 201 dated 7th April, 2001.

G.S.R. 237 dated 31st July, 1999.

G.S.R. 345 dated 23rd October, 1999.

G.S.R. 397 dated 14th October, 2000

G.S.R. 219 dated 14th April, 2001.

G.S.R. 496 dated 8th September, 2001

G.S.R. 672 dated 15th December, 2001.

To

10

The General Manager,

Govt. of India Press,

Ring Road, Maya Puri,

NEW DELHI-110064.

(i E V{j, M- ** Jhb 3, ={ Jhb (1)

|Exl)

i E

hV B =tM j

+tME xi B vx M

(Exp b)

x< n, nxE 9 +|, 2002

+vSx

.E.x...........i: hV B =tM j

(+tME xi B vx M)

(Exp b) i E, E

nxE 17 V<, 2001 E +vSx

J .E. x 393 E ii <E u |

i x i H

+{k il Z =H +vSx

vi V{j E |i Vxi E

={v Ex E iJ {i nx

E +v {i x iE Mx E B

i +vx, 1923 (1923 E 5) E

v 31 E ={-v (1) V nxE 28

V<, 2001 E i E V{j E M 2,

11

Jhb 3, ={Jhb (1) |` 2482 2490 { ,

u l +{Ii i x

1950 + vx Ex E

Ei{ n x |Ei E M

l;

+ VE =H V{j E |i +

Vxi E 30 V<, 2001 E ={v E

n M< l*

+ VE xn] +v E i <

+vSx xi vx E

E< +{k +l Z |{i

x B

+i: + i +vx 1923

E v 28 |nk H E |M Ei

B Exp b, Bipu

i x, 1950 +

vx Ex i xxJi x

xi : xi:

(1) <x x E i

(vx) x, 2002 E VM*

(2) x E V {j <xE |

Ex E iJ | M*

2.

i x, 1950 (V

<E {Si J x E VM) ,

(E) x 151 , Jhb (V) E n

xxJi Jhb +i:l{i E VM,

+li:(Z) ]] bb Vc E

bOE/bE{ +l +

]xE {Ih Mx]E {]E

xIh +l Cb b< {x]]

xIh V +x +xni v

u +xE VS E VM* V

bb P]E { bO E

n bOE {Ih E Vx

M i xxJi +{I+ E {

Ex M, +li:-

12

xIh |vE E +xnxl BE

Ji |G |ii E VM + =

xxJi E VM :{nl il ]< V

={Eh MiB

{Ih i h Vx

bE{E {]

U |Eh {]

U |nx {]

U |{i +{IiB

Ei-+Ei xnb Eb n

E -x{nx Ex

+{] E {Sx

bE{E U E Mhk gx

i BE <V | E i |

h E lx n VM + |

h E-x{nx Mhk <x

nM :3% E {i Jb nxi

2% E ] Jb nxi

|i B B 3 <x Vc E lxE nx

+< C +< nxi - V i E

+< C +< E |M E VB i Vc

E ]< E 2% i E v |h

E xxi nxi E v E

+ =xJ M *

|ixvi Vc E M E l

-rEh i bE{ E

=Si { Sxi E VM *

xIhE |vE u l

xn] bE{E VS E iJ

E n {{i +v E B

bE{E VS +Ec E

xi E j b]{,

Mx]E bE +l +{]E bE

Eb + bh E VM *

Eb ]x +v E nI

bE{E VS Eb |iix

13

={v E VBM + {Ih

i E B +xJx M *

V bE{E VS E {

i E n Vi i i E

E E Ex Ex E B =

bE{E iExE E |M EE

i E M M E {x: VS E

VM *

bE{ VS v +Ec E

=Si J Ex i {Sx

E B |M M iExE E

+Ec E l nB VM * E

E =H Sx +xni |G

v +{IB + |h x{nx E

{Ih v +Ec i M *

(J) J x , x 243 E B

xxJi x E |il{i E

VBM, xi:243 E] xh- E] xh Upi,

J E M +l Un MB f< E

` vi {b E VM +l E

{ E { , f< E JJ vi {b E |

M E V Ei * f< E `

vi {b E {h n +l

f< E { JJ vi {b E n

E ]<,Mf< E |G E

nx E E +v E n VM *"

(M) J x E x 256 E <xE

Jb (E) E { GEi E VM

+ < |E GEi Jb (E) E n

xxJi Jb E E VM

xi: :(J) xi - (i) E Jb

M< Sx, xGi b E

2% + ixH E M

b E 1% +vE x M *

14

v J S, xE <

E 0.3% +vE x M *

b E M< Sx E xvh

Ex E B E +x|l Jb {

+vEi + xxi +iE {

VM * <x { M x xxJi

j E +x M< |ii Sx

E Mhx E VM :2 (b +vEi - b xxi )

=

--------------------------------- 100

2 (b +vEi - b xxi )

V = b E M< |ii

Sx

b = BE +x|l Jb { +iE

v J Sx E xvi

Ex E B, Ex E l +xnn

BE JS < <x J Vx SB +

vi ES <x <E c

n { VM * < n +

xE ES , v J Sx

E Mhx E VM *"

(P) J x , x 259 , :(E) Jb (E) , :Sj 18 n + +E E Sj 18 E n,

+E + +I |il{i E VM *

Sj 18 n + +E E Sj 18 J n,

+E + +I |il{i E VM *

(J) Sj 18 E { 30 B B +vEi E n

xxJi b VM, +li :{] E ]< *

(b)

J x , x 265

Jb (P) E {Si xxJi Jb b

VM, +li :(b) ]] bb Vc E

bOE/bE{ +l +

]xE {Ih Mx]E {]E

15

xIh +l Cb b< {x]]

xIh V +x +xni v

u +xE VS E VM*V

bb P]E { bO E

n bOE {Ih E Vx

M i xxJi +{I+ E {

Ex M, +li:xIh |vE E +xnxl BE

Ji |G |ii E VM + =

xxJi E VM :{nl il ]< V

={Eh MiB

{Ih i h Vx

bE{E {]

U |Eh {]

U |nx {]

U |{i +{IiB

Ei-+Ei xnb Eb n

E -x{nx Ex

+{] E {Sx

bE{E U E Mhk gx

i BE <V | E i |

h E lx n VM + |

h E-x{nx Mhk <x

nM :3% E {i Jb nxi

2% E ] Jb nxi

|i B B 3 <x Vc E lxE nx

+< C +< nxi - V i E

+< C +< E |M E VB i Vc

E ]< E 2% i E v |h

E xxi nxi E v E

+ =xJ M *

|ixvi Vc E M E l

-rEh i bE{ E

=Si { Sxi E VM *

xIhE |vE u l

xn] bE{E VS E iJ

16

E n {{i +v E B

bE{E VS +Ec E

xi E j b]{,

Mx]E bE +l +{]E bE

Eb + bh E VM *

Eb ]x +v E nI

bE{E VS Eb |iix

={v E VBM + {Ih

i E B +xJx M *

V bE{E VS E {

i E n Vi i i E

E E Ex Ex E B =

bE{E iExE E |M EE

i E M M E {x: VS E

VM *

bE{ VS v +Ec E

=Si J Ex i {Sx

E B |M M iExE E

+Ec E l nB VM * E

E =H Sx +xni |G

v +{IB + |h x{nx E

{Ih v +Ec i M *

(S) J x E x 343 , ={-

x (3) E lx { xxJi ={-

x |il{i E VM, +li :(3) +v-7 E i E i B

, xi E { {<{ E B

<bE {Ih xIh |

vE U] n Ei *

i E <x {<{ E +xni

bOE +l +]xE iExE

{h {Ih E M *

i E 600 B B + Vn +iE

{<{ E {<{ E

xh ={M E M {] {<{

E Vc b E +xni M-

xE {Ih u {h VS E M

, V +]xE +l

17

bOE {Ih + {nl

il b {<{ E =ki xi

E { i{i E VB, + l

{ +M E xh + l{x E

{ Ex E {Si {<{ E {h

P]E E, {<{M ] E bV<x n

E 1.5 Mh { <bE {Ih E

M :

i E l { <x {<{ E

<bE {Ih Ex E {Si

E E E {i Sx E li ,

xi E Vn M E <x

JH {<{ E n n VB +l

=xE i E VB, V xIh |

vE +E Z *

(U) J x E x 350 (i)

B = xxJi +v { xvi

+xY ix + x +

i{x { ]x {n Ex

xxi ix { {i x M

E B xxJi |il{i E VM,

+li :B = x 271 E +iMi l ={vi

+xY ix *

iE 3 E ] n VM ;

(V) =H x , x 360 Jb (b)

E {Si xxJi Jb Vc VBM,

+li:(S) ]] bb Vc E

bOE/bE{ +l +

]xE {Ih Mx]E {]E

xIh +l Cb b< {x]]

xIh V +x +xni v

u +xE VS E VM* V

bb P]E { bO E

n bOE {Ih E Vx

M i xxJi +{I+ E {

Ex M, +li:-

18

xIh |vE E +xnxl BE

Ji |G |ii E VM + =

xxJi E VM :{nl il ]< V

={Eh MiB

{Ih i h Vx

bE{E {]

U |Eh {]

U |nx {]

U |{i +{IiB

Ei-+Ei xnb Eb n

E -x{nx Ex

+{] E {Sx

bE{E U E Mhk gx

i BE <V | E i |

h E lx n VM + |

h E-x{nx Mhk <x

nM :3% E {i Jb nxi

2% E ] Jb nxi

|i B B 3 <x Vc E lxE nx

+< C +< nxi - V i E

+< C +< E |M E VB i Vc

E ]< E 2% i E v |h

E xxi nxi E v E

+ =xJ M *

|ixvi Vc E M E l

-rEh i bE{ E

=Si { Sxi E VM *

xIhE |vE u l

xn] bE{E VS E iJ

E n {{i +v E B

bE{E VS +Ec E

xi E j b]{,

Mx]E bE +l +{]E bE

Eb + bh E VM *

Eb ]x +v E nI

bE{E VS Eb |iix

19

={v E VBM + {Ih

i E B +xJx M *

V bE{E VS E {

i E n Vi i i E

E E Ex Ex E B =

bE{E iExE E |M EE

i E M M E {x: VS E

VM *

bE{ VS v +Ec E

=Si J Ex i {Sx

E B |M M iExE E

+Ec E l nB VM * E

E =H Sx +xni |G

v +{IB + |h x{nx E

{Ih v +Ec i M *

(Z) J x x 367 iE

E n V Mn Sc E l +

x + 31.6 E.O/ .2 (450

{b/M <S) E + E l {i

x M E B xxJi |

il{i E VM, +li :xxJi i E {i x {

{Sn Vc E 2600 +vE i{x

{ + iE n M +E +l

n + +vE +E +l n

+ { +xi n Vi :n E E b +l Sc

+M ]M { x x +

+x +l {Ih Vc E ={Hi

E |nx x iE Sc E M

n E Vi *

B, B B B <, b +< Bx <in V

=Si P]E xE E h +x

+l <x x E Mi x E

+iMi, l {Ei n +l i{x

+vE x *

20

{Sn {<{ E xxi xn] ixIi 330 Bx/B B2 +vE *

{Sn {<{ E xxi ]<

iE J 1 n M< ]< E x

*

+E{ E i{x 4950 . +vE x ,

(6)

n B iE J-2 n M<

n + +vE x *

j |il{x ]{M il bOE

VS i | u {M E B 4950 .

+vE i{x + iE J 2 n

M n +vE n { {Sn

Vc E +xi i E xxJi

i E {i E V :(E) 50 B B x +E +l

x {<{ +E E BE Sl<, <x

V E , +vE x M *

(J) xxi Sc xxJi E x

M :20 B B x iE + i E B

6;

20 B B +vE + 40 B B x

iE + i E B 7;

40 B B 50 B B x iE +

i E B 8 .

(M) Vc bb *

(P) j |il{x E +E{ i

]iB, i | + E |E

E E{x x Ei *

{Sn Vc xM {

BEJ j <x + n Ex

+ ={Eh E xS

xjh ={E +l |in iE j

i iE J 2 n M n

+vE 345 iE E n E B +xi

i E {<{ E x +E

12 B B +vE x *

21

iE J - 1

{Sn {<{ E

xxi ]<

xxi ]<

x {<{ E +E{ E B 17.5

+l < E;

1050 . ={ V E B 7 + <

E{ E B 17.5 +vE

1050 . ={ V E B 7 +vE

B B

B B

B B

8

2.24

3.02

10

2.31

3.20

15

2.77

3.75

20

2.87

3.91

25

3.38

4.55

32

3.56

4.85

40

3.68

5.08

50

3.91

5.54

65

5.16

7.01

80

5.49

7.62

iE - 2

{Sn {<{ E B

+vEi n

x {<{ +E

+vEi n

B B

50

+vE + 80 iE + i

27.5

25 +vE + 50 iE + i

41.5

20 +vE + 25 iE + i

83

20 iE + i

103.5

( )

J x E x 374 , Jb (M) , +J ,

xxJi Vc V, +li :< Jb EU xi x E Vn, E {<{

+ M- {<{ V E E + xE {<{

V ih E B J , E +i |lEEh { li

M E B <bE {Ih E Uc n V i E

nvx {<{ b Vc +xni M-vE VS u

100% {Ii + iVxE { M *

(])

J x E x 382 E n + < r |

] xxJi Vc V, +li

22

UiMg.................................................... V

(`)

J x E xi E xh {Ih |h{j

vi |{ 3 1.h E +iMi +i xxJi |

] Vc V, +li :{Eh Ii.......................................

(I E O Ii E {Ex i)

(b)

J x E |{ III-b E {Si, xxJi |{

E V, +li :|{- III-S

g< Mg< E xh + {Ih v |h{j

(l M x 73 80 +l 81 85)

|h {j J............................................... ...............................................

{V E x..............................................................................................

xi E x {i............................................... ...............................................

.........................................................................................................................................

J {{.............................................................................................. ........................

+Jh J............................................... ............................................... .....................

{Sx Sx............................................... ........................................................................

x P]x......................................................................................................................

iE {Ih {h...........................................................................................................

(i)

ixx Ii....................................................................................................

(ii)

+x|l ZE {Ih....................................................................................

+xnv........................................................................................................

|hi E Vi E < nV h * < i

x, 1950 E +{IB {h Vi *

xi E |ixv

xi.........................

(x iI)

xO/

(g)

J x E, |{ XIII , i x 1960 E

+iMi V E M M b v |h{j,

E E B xxJi E |il{i E VM, +li :i x 1950 E +iMi V E M M

b v |h{j *

(< J 6(3)/2001-)

(.E. M)

S, Exp b

{n ]{{h: J x E B + 600 nxE 15 i 1950 E

ii i E V{j |Ei E M l + ii{Si

xxJi +vSx+ u vx E M :

.E.x. 178 nxE 24, S, 1990

.E.x. 179 nxE 24, S, 1990

.E.x. 488 nxE 9, +C], 1993

.E.x. 516 nxE 23, +C], 1993

.E.x. 634 nxE 25,n, 1993

23

.E.x. 107 nxE 26, 1994 u{j Ex 223 nxE 14, <

1994

.E.x. 250 nxE 4 Vx, 1994

.E.x. 402 nxE 13 +Mi, 1994

.E.x. 427 nxE 20 +Mi, 1994

.E.x. 562 nxE 12 x, 1994

.E.x. 607 nxE 10 n, 1994

.E.x. 83 nxE 25 , 1995;

.E.x. 93 nxE 4 S, 1995;

.E.x. 488 nxE 9 x, 1996;

.E.x. 582 nxE 28 n, 1996;

.E.x. 59 nxE 25 Vx, 1997;

.E.x. 117 nxE 1 S, 1997;

.E.x. 172 nxE 29 S, 1997;

.E.x. 221 nxE 21x, 1998;

.E.x. 131 nxE 1 <, 1999;

.E.x. 139 nxE 8 <, 1999; r{j .E.x. 201 nxE 7 +|, 2001

.E.x. 237 nxE 31 V<, 1999;

.E.x. 345 nxE 23 +C], 1999

.E.x. 397 nxE 14 +C], 2000;

.E.x. 219 nxE 14 +|, 2001;

.E.x. 496 nxE 8 i, 2001;

.E.x. 672 nxE 15 n, 2001

,

|vE

i E ph,

M b, {,

x< n - 110064

S-ar putea să vă placă și

- Industrial Piping and Equipment Estimating ManualDe la EverandIndustrial Piping and Equipment Estimating ManualEvaluare: 5 din 5 stele5/5 (7)

- Qcs 2010 Part 28.02 Irrigation System SpecificationsDocument38 paginiQcs 2010 Part 28.02 Irrigation System SpecificationsRotsapNayrb100% (1)

- Training Guide For X-Ray Service Company PersonnelDocument30 paginiTraining Guide For X-Ray Service Company PersonneljojokawayÎncă nu există evaluări

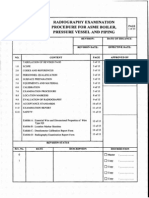

- Radiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingDocument15 paginiRadiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingEko Kurniawan100% (1)

- 7.5.5.2asme Sec Viii Div 2 2017Document3 pagini7.5.5.2asme Sec Viii Div 2 2017James100% (2)

- Acceptance CriteriaDocument11 paginiAcceptance Criteriarajali798890% (10)

- Code Case - 2235-10Document10 paginiCode Case - 2235-10Nilesh Pathare0% (1)

- Qcs 2010 Part 10.02 Telemetry-SCADADocument29 paginiQcs 2010 Part 10.02 Telemetry-SCADARotsapNayrb100% (1)

- Qcs 2010 Section 10 Part 2 Telemetry SCADADocument29 paginiQcs 2010 Section 10 Part 2 Telemetry SCADAbryanpastor106Încă nu există evaluări

- Lloyd S Register Sec V 2017 Edition Key ChangesDocument27 paginiLloyd S Register Sec V 2017 Edition Key ChangesDilip VaradharajanÎncă nu există evaluări

- CFR 2010 Title49 Vol3 Sec195 452 Norma para HCADocument8 paginiCFR 2010 Title49 Vol3 Sec195 452 Norma para HCAafaler01Încă nu există evaluări

- Mandatory Appendix Vi - Asme VDocument3 paginiMandatory Appendix Vi - Asme VAngelTinocoÎncă nu există evaluări

- Specification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Document20 paginiSpecification No. CSC-XX-R-III/DH/UH/P&D/2012-2013mailgunaprithivÎncă nu există evaluări

- Air Conditioning System SpecificationDocument16 paginiAir Conditioning System Specification123agattarÎncă nu există evaluări

- 2.MS For PVDDocument10 pagini2.MS For PVDchandar70Încă nu există evaluări

- Qcs 2010 Part 10 Pipeline Cleaning and Inspection SurveyDocument18 paginiQcs 2010 Part 10 Pipeline Cleaning and Inspection SurveyRotsapNayrbÎncă nu există evaluări

- Specification - Carbon Dioxide Fire Suppression System With Cheetah Xi Control Panel Section 1 - General Conditions I. ScopeDocument11 paginiSpecification - Carbon Dioxide Fire Suppression System With Cheetah Xi Control Panel Section 1 - General Conditions I. ScopeGustavo Márquez TorresÎncă nu există evaluări

- Asme Se 446Document41 paginiAsme Se 446Christian Adiguna PurbaÎncă nu există evaluări

- 04en - Part4 Dynamic Longitudinal Impact Test For Gas ContainersDocument12 pagini04en - Part4 Dynamic Longitudinal Impact Test For Gas ContainersBui Chi TamÎncă nu există evaluări

- 1.MS For Piled Embankment by atDocument9 pagini1.MS For Piled Embankment by atchandar70Încă nu există evaluări

- T4S CGD Consolidated 31.12.2016 FinalDocument65 paginiT4S CGD Consolidated 31.12.2016 FinalcoolmagaÎncă nu există evaluări

- PNGRB T4SDocument56 paginiPNGRB T4SHoney Narang100% (3)

- QCS 2010 Section 28 Part 2Document38 paginiQCS 2010 Section 28 Part 2Saif Abdulla0% (1)

- GSR612 - PNGRB PDFDocument55 paginiGSR612 - PNGRB PDFBenaknaik S GajannavarÎncă nu există evaluări

- FM200 SpecDocument14 paginiFM200 SpecDak Serik100% (1)

- T4S CGD Consolidated 31.12.2016 FinalDocument65 paginiT4S CGD Consolidated 31.12.2016 FinalNikhil SainiÎncă nu există evaluări

- R GSR612 (E) eDocument68 paginiR GSR612 (E) eVamsiKrishnaÎncă nu există evaluări

- Mandatory Appendix Ii - Asme VDocument2 paginiMandatory Appendix Ii - Asme VAngelTinocoÎncă nu există evaluări

- Specification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Document20 paginiSpecification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Pradeep Kumar MaraptlaÎncă nu există evaluări

- 21cfr1040 11Document2 pagini21cfr1040 11associatednewmanÎncă nu există evaluări

- Operating Inertial Profilers and Evaluating Pavement ProfilesDocument19 paginiOperating Inertial Profilers and Evaluating Pavement ProfilesDayner M Sanchez GarciaÎncă nu există evaluări

- Close Tolerance Horizontal Directional Drilling For Gravity MainsDocument8 paginiClose Tolerance Horizontal Directional Drilling For Gravity MainsmobtelecomÎncă nu există evaluări

- Designing of Cranes With StandardsDocument95 paginiDesigning of Cranes With Standardsank_mehraÎncă nu există evaluări

- Procedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDDocument12 paginiProcedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDSushanta NaikÎncă nu există evaluări

- T4S ONGC IndiaDocument66 paginiT4S ONGC IndiaJk KarthikÎncă nu există evaluări

- Design and Construction of Machine Foundations - Code of PracticeDocument12 paginiDesign and Construction of Machine Foundations - Code of PracticeMalar ManoharanÎncă nu există evaluări

- R GSR612 (E) eDocument93 paginiR GSR612 (E) eDevashish SharmaÎncă nu există evaluări

- Is 3177 1977Document66 paginiIs 3177 1977Avijit Dey100% (1)

- 02.34 25635-220-3PS-MHCB-00001 Technical PDFDocument32 pagini02.34 25635-220-3PS-MHCB-00001 Technical PDFEl_memitoÎncă nu există evaluări

- CGD IMS Post Amendment 07.11.2019Document65 paginiCGD IMS Post Amendment 07.11.2019visutsiÎncă nu există evaluări

- Telephone System SpecificationDocument63 paginiTelephone System SpecificationRonaldo RomeroÎncă nu există evaluări

- DSTBDTH PDFDocument6 paginiDSTBDTH PDFwenv_gunturwssÎncă nu există evaluări

- Standard Specification For Survey WorkDocument14 paginiStandard Specification For Survey WorkKS&TAN sdn bhd100% (1)

- EGTYPDocument277 paginiEGTYPThe MatrixÎncă nu există evaluări

- Part CDocument23 paginiPart Ckonainglincho001Încă nu există evaluări

- Other Examination MethodsDocument2 paginiOther Examination Methods새한검사부경출장소Încă nu există evaluări

- HTS Chapter 84Document124 paginiHTS Chapter 84JitendraÎncă nu există evaluări

- ASME Code Case 2600 PDFDocument2 paginiASME Code Case 2600 PDFrotero_pujolÎncă nu există evaluări

- Bs 76712018 Model Forms Minor Electrical Installation Works CertificateDocument4 paginiBs 76712018 Model Forms Minor Electrical Installation Works Certificatehany mohamedÎncă nu există evaluări

- PVD & PHDDocument9 paginiPVD & PHDMahbub AlamÎncă nu există evaluări

- Chapter 84Document126 paginiChapter 84Aashish MuraliÎncă nu există evaluări

- 015 Directional Drilling Rev 1.02Document7 pagini015 Directional Drilling Rev 1.02Mino MinoÎncă nu există evaluări

- Chipless Radio Frequency Identification Reader Signal ProcessingDe la EverandChipless Radio Frequency Identification Reader Signal ProcessingÎncă nu există evaluări

- Opportunistic Spectrum Sharing and White Space Access: The Practical RealityDe la EverandOpportunistic Spectrum Sharing and White Space Access: The Practical RealityÎncă nu există evaluări

- Applied Metrology for Manufacturing EngineeringDe la EverandApplied Metrology for Manufacturing EngineeringEvaluare: 5 din 5 stele5/5 (1)

- OFDM-Based Broadband Wireless Networks: Design and OptimizationDe la EverandOFDM-Based Broadband Wireless Networks: Design and OptimizationÎncă nu există evaluări

- Redemption and The Relief Work RevisedDocument234 paginiRedemption and The Relief Work RevisedYewo Humphrey MhangoÎncă nu există evaluări

- Prejudicial QuestionDocument1 paginăPrejudicial QuestionlmafÎncă nu există evaluări

- Not PrecedentialDocument5 paginiNot PrecedentialScribd Government DocsÎncă nu există evaluări

- LEC 2017 - Post-Test in Organized Crime InvesDocument8 paginiLEC 2017 - Post-Test in Organized Crime InvesBokhary Dimasangkay Manok EliasÎncă nu există evaluări

- Early China 2aDocument4 paginiEarly China 2aapi-205540374Încă nu există evaluări

- Rights As Bribes ResaltadoDocument89 paginiRights As Bribes ResaltadoAndresAmarillaÎncă nu există evaluări

- LM3886Document24 paginiLM3886moacirjmÎncă nu există evaluări

- Docshare - Tips Upstream Advanced c1 Test BookletDocument3 paginiDocshare - Tips Upstream Advanced c1 Test BookletCosmin OaieÎncă nu există evaluări

- Republic Act No. 1125Document8 paginiRepublic Act No. 1125Jazlynn WongÎncă nu există evaluări

- NyirabahireS Chapter5 PDFDocument7 paginiNyirabahireS Chapter5 PDFAndrew AsimÎncă nu există evaluări

- STRUCTURAL CONVERSION Examples PDFDocument5 paginiSTRUCTURAL CONVERSION Examples PDFGerard Salmoral ParramonÎncă nu există evaluări

- Physical Education: Learning Activity SheetDocument13 paginiPhysical Education: Learning Activity SheetRhea Jane B. CatalanÎncă nu există evaluări

- CO - Config Sap Top JobsDocument81 paginiCO - Config Sap Top JobsAditya PakalaÎncă nu există evaluări

- Adh Dialectical JournalDocument4 paginiAdh Dialectical Journalapi-521174998Încă nu există evaluări

- NIA Foundation PLI Proposal Template (Repaired)Document23 paginiNIA Foundation PLI Proposal Template (Repaired)lama dasuÎncă nu există evaluări

- 3 Murex HIV Ag Ab CombinationDocument7 pagini3 Murex HIV Ag Ab CombinationElias Dii Rivas GarvanÎncă nu există evaluări

- Movie Review TemplateDocument9 paginiMovie Review Templatehimanshu shuklaÎncă nu există evaluări

- SATB All Glory Laud and HonorDocument1 paginăSATB All Glory Laud and HonorGeorge Orillo BaclayÎncă nu există evaluări

- Grade 3 MathematicsDocument3 paginiGrade 3 Mathematicsailaine grace alapÎncă nu există evaluări

- Why Do We Hate Hypocrites - Evidence For A Theory of False SignalingDocument13 paginiWhy Do We Hate Hypocrites - Evidence For A Theory of False SignalingMusic For youÎncă nu există evaluări

- Attitudes and Attitude ChangeDocument19 paginiAttitudes and Attitude Changeprajwal-athrey-3069Încă nu există evaluări

- TENSES ExerciseDocument28 paginiTENSES ExerciseKhanh PhamÎncă nu există evaluări

- Hosea - A New Translation With Introduction and Commentary (Anchor Bible 24)Document727 paginiHosea - A New Translation With Introduction and Commentary (Anchor Bible 24)Azoth ImóveisÎncă nu există evaluări

- Culture and Creative Industries in TanzaniaDocument70 paginiCulture and Creative Industries in TanzaniaYana ArsyadiÎncă nu există evaluări

- A0 Unit1 Lesson3A PP GB AmbDocument9 paginiA0 Unit1 Lesson3A PP GB AmbMasterkolo KamisÎncă nu există evaluări

- 3rd Sunday After TrinityDocument11 pagini3rd Sunday After TrinityHmkEnochÎncă nu există evaluări

- Sampling Strategies For Heterogeneous WastesDocument18 paginiSampling Strategies For Heterogeneous Wastesmohammed karasnehÎncă nu există evaluări

- Teacher LOA & TermsDocument3 paginiTeacher LOA & TermsMike SchmoronoffÎncă nu există evaluări

- Ujt and PutDocument35 paginiUjt and Putisraeljumbo100% (1)

- ADDIE - Model - For - E-Learning - Sinteza2017 - Corr-With-Cover-Page-V2 (New)Document6 paginiADDIE - Model - For - E-Learning - Sinteza2017 - Corr-With-Cover-Page-V2 (New)arief m.fÎncă nu există evaluări