Documente Academic

Documente Profesional

Documente Cultură

Method Statement For Formworks, Rebars, Cast-In-Situ Concrete

Încărcat de

Azhar AliTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Method Statement For Formworks, Rebars, Cast-In-Situ Concrete

Încărcat de

Azhar AliDrepturi de autor:

Formate disponibile

Submittal Transmittal

Detailed, Grouped by Each Number

LC3 (R-15-085-BF-0)

Date:

Project # RUH-CP-1502

Tel:

Fax:

3/8/2016

Transmitted To:

Reference Number: 0483

Hadi Omar Harb

SSEM

P.O. Box 6341

Al Rashid Tower, 5th Floor

Al Ma'athar Street

11442 Riyadh

Tel: 4625511

Fax: 4627804

Transmitted By:

Qty

Submittal Package No

Description

0120 - 013300 - D1 - 1

Method Statement for Formworks, Rebars,

Cast-In-Situ Concrete(Pouring, Embedments,

Curing)

Due Date

Transmitted For

Delivered Via

Action

Hand

Items

Qty

Description

001

Method Statement for

Formworks, Rebars,

Cast-In-Situ Concrete(Pouring,

Embedments, Curing)

Cc:

Company Name

Paul Teague

AECOM

P.O. Box 58806

4 Floor, Tower 4, Tatweer Tower

11515 Riyadh

Tel:

Fax:

Reviewed Exceptions Noted

Tracking Number

Notes

Contact Name

Package Action

Item Action

Reviewed - Exceptions

Noted

Copies

Notes

Remarks

Reviewed Exceptions Noted, Resubmission Required.

1. Please see attached.

Best Regards,

Signature

Prolog Converge

Printed on: 3/9/2016

Prolog KKIA

Signed Date

Page 1

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

17.01.16

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

METHOD STATEMENT FOR

FORMWORKS, REBARS,

CAST-INSITU CONCRETE

(POURING,

EMBEDMENTS, CURING)

1.The page header shall also include KKIA logo in the following

sequence from left to right - GACA, KKIA, AECOM & SSEM. SSEM may

opt to place their company logo below the first three mentioned logos.

2.All appendices shall also show the correct (current) logos of GACA,

KKIA and AECOM accordingly.

ProjectQuality Manager: ProjectManager:

ENGR.AmrIbrahimMetwally ENGR.HADIOMARHARB

Page 1 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

A

17.01.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

18.02.16

Table of Contents

1.0

Purpose ..03

2.0

Scope .. 03

3.0

References and Standards 03

4.0

Abbreviations/Definitions .. 04

5.0

Work Program ...04

6.0

Equipment ..04

7.0

PPE Materials 05

8.0

Manpower Schedule 05

9.0

Responsibilities of Key Personnel .. 06

10.0

Concreting Methodology 07

11.0

Quality Requirements . 12

12.0

Health and Safety . 13

Appendices

Appendix 1.0- Job Risk Assessment ..15

Appendix 1.1- Carpentry Works ...15

Appendix 1.2- Formworks 17

Appendix 1.3- Steel Cutting and Bending . 19

Appendix 1.4- Concrete Works .21

Appendix 2.0- Related ITP . 23

Appendix 3.0- Checklist . 25

Appendix 4.0- Proforma Work Permit .27

Page 2 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

1.0

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

PURPOSE

The purpose of this method statement is to provide description of procedure and method for the

execution of for construction of reinforced concrete structure, the LC-3 Building and related

structures. This include the fabrication/installation of formworks and reinforcing bars, the pouring

of cast in situ concrete, and repair of newly casted concrete. As well as the necessary materials to

ensure health and safety of employees with the requirement stipulated in the Contract

Documents, as well as those in Saudi Construction Specifications (ASTM and SASO-ISO)

2.0

SCOPE

This method statement covers the task related to construction of reinforced concrete building.

This include but is not limited to : raft or strip foundations, retaining walls, columns, girders,

suspended and slab on grade, concrete duct banks, manholes, other equipment supports and

foundation.

3.0

REFERENCES AND STANDARDS

Construction of reinforced concrete building will be in accordance with the following standards:

3.1 Saudi Arabia Construction Specification.

3.2 Employers requirements, Materials Specification

3.3 Approved with Comments (AWC) design and construction drawings.

3.4 ACI-117

3.5 ACI-318

3.6 ACI-347R

3.7 ACI-304R

3.8 ACI-305R

3.9 ASTM-C39

3.10 SASO SSA2

3.11 SASO SA 224

Page 3 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

4.0

5.0

First

Rev.

Issue

Date:

17.01.16

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

ABBREVIATION/DEFINITION

PM

Project Manager

PQP

Project Quality Plan

QIP

Quality Inspection Plan

QA&QC

Quality Assurance & Quality control

MS

Method Statement

PPE

Personal Protective Equipment

HSE

Health, Safety & Environment

PPE

Personal Protective Equipment

ECO

Environmental Control Officer

CR

Construction Regulation

EMP

Environmental Management Plan

OHSA

Occupational Health and Safety Act

SO

Safety Officer

EO

Environmental Officer

WORK PROGRAM

Construction of the building comprise of:

5.1 Two level building with floor area approximately 5,500 sq. m.

5.2 Construction of generator room, 1500 sq. m. with individual support for the equipment.

5.3 Control room area with provision for LV and MV- panel controls.

5.4 Construction of duct banks for the associated power, communication, waterlines and

plumbing lines.

6.0

EQUIPMENT

The contractor (SSEM) will provide the following equipment throughout the project, quantities will

be determined by actual site demand. Equipment will be inspected prior to mobilization and shall

hold valid insurance certificates, as well as certified/competent operators.

Page 4 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

17.01.16

18.02.16

Type of Equipment

Concrete Transit mixers

Concrete Pumps

Portable Concrete Vibrator

Boom trucks

Water Truck

Bar Benders

Bar Cutters

Circular Saw (Table Type)

Portable electric grinders

Portable electric jigsaws

Misc. hand tools

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

Units (No.)

Depend on conc. volume

1

2

1

1

2

2

2

4

4

1 lot

Table I. Equipment Intended for Concrete construction works.

7.0

PPE MATERIALS

Personal Protective Equipment (PPE) should be provided in order to perform all works in

accordance with the safety procedures and taking into consideration the importance of proper

preventive measures to ensure safety in the performance of work.

Type of Equipment

Safety Helmet

Safety Boots/Shoes

Safety Glasses

Safety Masks

Coveralls

High Visibility Vests

Hand Gloves

Fall Arrester

Safety Harness

Table II. Personal Protective Equipment Intended for Concrete Construction Works.

8.0

MANPOWER

The workforce including foremen, operators, and technicians shall be well qualified with third party

certificates wherever applicable/relevant.

Subcontractors for different trades shall be deployed depending on demand, to cover up shortfalls

and to cope up with the construction schedule.

Page 5 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

CONTRACTOR

(SSEM)

Construction Manager

Site Engineer

QC- Engineers

Surveyor

Safety Engineers

Civil Foreman

Carpenters

Steel fixers

Mason

Scaffolders

Equipment Operators

Safety officers

Flagmen

First Aider

Laborers

Table III. Manpower for Concrete Construction Works.

9.0

RESPONSIBILITIES OF KEY PERSONNEL

9.1

Construction Manager

The Construction Manager will plan and expedite for the continuous supply of resources to

cope up with the project demand and schedule. The construction manager will keep record

of the progress of work. He will report to the project manager on matters affecting

completion of project. He will give direct orders to the site engineer for the effective

implementation of work program.

9.2

Site Engineer

The Site Engineer will be in charge for the supervision and implementation of all concrete

construction works as required in the specifications and drawing, especially in giving orders

to Site foremen. Site engineer is also in charge for the preparation of daily, weekly and

monthly reports. He will coordinate with the QC-engineer on matters concerning Inspection

request and attend to final inspection together with SSEM QC-engineer and the owners

Engineer.

Page 6 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

9.3

A

17.01.16

B

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

Quality Control Engineer

The QC Engineer will be responsible for compliance of work to the reference contract

drawings, specifications and other QA/QC conditions required by The Engineer. He will

monitor daily activities and notify concerned parties when works deviates from the standard.

He will issue proactive notification when needed to prevent non-compliance works.

9.4 Site Foreman

The Site Foreman will be in charge for the supervision and implementation of various stages

of concrete construction works, as instructed by the Site engineer. He will be responsible for

the execution of works in compliance to approved drawing and contract specifications.

Foreman shall also keep record of all work schedules, work production and daily safety

issues.

9.5

Site Surveyor

The Site Surveyor will be in charge for the setting out for building corners, elevation and

make the vertical/horizontal reference at site. He will stake out for lines and elevations of

underground utilities construction and will prepare reports for excavation and backfilling

works.

10.0 CONCRETING METHODOLOGY

10.1 Sequence of Work

The following are the sequence of work in the construction of Cast-in Situ Concrete:

10.1.1

Fabrication and installation of form works.

10.1.2

Fabrication and installation of steel reinforcements.

10.1.3

Installation of anchor bolts, block-outs and other embedment to concrete when

needed.

10.1.4

Form closure and installation of supports

10.1.5

Pouring of ready mix concrete.

10.1.6

Preparation of concrete sample specimen for testing purposes.

10.1.7

Finishing and curing of concrete.

10.1.8

Stripping of formworks.

10.1.9

Repair of minor concrete imperfection.

Page 7 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

10.2 Formworks

10.2.1

Forms shall be substantial and sufficiently tight to prevent leakage of

mortar from the concrete. Contractor shall use sufficient nailing,

bolting, welding, shoring, whalers, form clamps and forming of

adequate strength to contain the fluid concrete without noticeable

deflection, leaning or bulging

10.2.2

Forms shall be properly braced or tied together to maintain position

and shape. Forms shall be built to resist the pressures to which they

will be subjected and to limit deflections to a practicable minimum

within the specified tolerance.

10.2.3

Formwork shall be anchored to the shores below so that movement of

any part of the formwork system will be prevented during concreting

10.2.4

Block outs, inserts, sleeves, anchors, water stops and other embedded

items shall be properly identified, positioned and secured in the forms

to resist all forces while concrete is being placed and hardens.

10.2.5

Old forms shall be thoroughly cleaned of all dirt, mortar and foreign matter and

coated with a release agent before each use.

10.2.6

A polyethylene sheet shall be placed beneath and around the sides of concrete

that is placed against soil where bitumen or coal tar epoxy cannot be applied.

10.2.7

A polyethylene sheet, minimum 0.15mm thick, shall be placed beneath slabs on

grade and other concrete structure when shown in the drawing.

10.2.8

Water stops shall be provided in joints where watertight construction is required.

Location and type of water stops shall be as shown on construction drawing.

10.2.9

Expansion joint filler strips shall be made from fiber board securely bound together

by a suitable asphaltic binder.

10.2.10 Well trained manpower shall be deployed as the height of formworks increases.

10.2.11 Erecting formwork frames should be erected in a progressive manner to ensure

both the installers safety and the stability of the overall structure.

10.2.12 Braces should be attached to the frames as soon as practical. As erecting the

frames continues, designated access ways should be indicated by using bunting or

by other means.

10.2.13 Provide the side bracing or other edge protection is installed progressively and as

soon as enough material has been raised up.

Page 8 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

10.2.14 Framing is carried out in accordance with on-site design documentation and

manufacturers instructions.

10.3 Steel Reinforcements

10.3.1

Forms shall be inspected and checked before the reinforcing steel is placed to the

dimensions and locations on the structural plans.

10.3.2

The minimum concrete cover shall be measured from the outer most rebar (tie

bar), that shall be provided for reinforcement of cast-in-place concrete structures

as indicated in the drawings.

10.3.3

Reinforcing steel rebar shall be correct in size, quantity, layout, spacing, position

as per the contract drawing

10.3.4

Reinforcing Steel lap splice lengths for each bar size shall be as detailed for each

size as shown on the Contract Drawings.

10.3.5

Welding of reinforcement shall not be allowed unless authorized by The Engineer

or called for specifically on the Contract Drawings.

10.3.6

Provide necessary and safe scaffolding / platform as the height increases for steel

reinforcement installation.

10.3.7

Dowel bars and anchorage shall be as per approved drawing and specifications

and be maintained whenever necessary.

10.3.8

All reinforcement must be cleared to ensure that it is free from oil, dust and

deleterious materials.

10.4 Anchor bolts and Embedded Items

10.4.1

Anchor bolts and embedded items shall be set accurately, using templates.

10.4.2

Anchor bolt projection above the top of concrete is computed as follows:

Single Nuts:

Thickness of grout + thickness of base plate (or height of anchor bolt chair above

the top of grout) + 1.5 x diameter of anchor bolt.

Double Nuts:

Thickness of grout + thickness of base plate (or height of anchor bolt chair above

the top of grout) + 2.5 x diameter of anchor bolt.

Page 9 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

10.5 Form Closure Inspection

10.5.1

Reference markers shall be installed on the formwork shores to detect formwork

movements during concreting

10.5.2

Wedges used for final alignment before concrete placement shall be secured

before placing concrete.

10.5.3

Formwork shall be anchored to shoring to prevent any movement of any part of the

formwork during concreting.

10.5.4

Closure of form joints, settlement of blinding slabs, shrinkage of lumber, elastic

shortening and deflections of form members shall all be countered prior to concrete

placement.

10.6 Concrete Pouring

10.6.1

Concrete pouring shall be done after pre-placement inspection and authorization to

proceed by The Engineer.

10.6.2

Temperature, slump of ready mix concrete shall be checked upon arrival at site.

10.6.3

Experienced form watchers shall be provided during concrete placement to detect

form displacement or the beginning of failure.

10.6.4

Re-tempering of concrete after initial setting is prohibited.

10.6.5

Concrete that has partially hardened or been contaminated by foreign materials

shall not be deposited in the structure.

10.6.6

Concrete shall not be dropped freely where reinforcing will cause segregation nor

where it would fall freely from a height not allowed by the specifications.

10.6.7

Concrete shall be discharged as near as possible to its final position to avoid

segregation due to re-handling or flowing.

10.6.8

Placed concrete shall be consolidated by mechanical vibration equipment

supplemented by hand spading, rodding or tamping.

10.6.9

After completing placing and finishing operations, efforts must continue to protect

concrete from high temperatures, direct sunlight, low humidity, and drying winds.

10.6.10 Concrete paving shall have control joints or construction joints located shown in

the contract drawing.

Page 10 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

10.6.11 Paving or slab construction joints not specified on the Contract Drawings, shall be

located at column centerlines and at intermediate intervals approved by The

Engineer.

10.6.12 Paving or slab construction joints not specified on the drawings, shall meet all

requirements for architectural concrete matching the grade and type of finish

present in the adjacent concrete.

10.6.13 Contraction or isolation joints shall be provided to divide structurally plain concrete

members into flexural discontinuous elements. (ACI 318M, Sec. 2.2.3.1).

10.7 Concrete Finishing and Curing Inspection

10.7.1

Initial floating shall be completed after concrete placement.

10.7.2

The second floating operation shall take place after initial set but before final set

has occurred (usually performed using a power trowel with float shoes or a pan

attached).

10.7.3

The use of any floating or troweling machine that has a water attachment for

wetting the concrete surface during finishing shall be prohibited.

10.7.4

Maximum total dissolved solids in water used for moist curing shall not exceed

1000 parts per million.

10.7.5

Water curing shall be continuous until the compressive strength has reached 70%

of the specified strength, but not less than 7 days after placement.

10.7.6

Continuous water cure can be provided by covering with wet burlap and plastic; the

saturated burlap shall be covered with a polyethylene sheet vapor barrier,

minimum 0.15 mm (150 microns) in thickness.

10.7.7

Where appearance is important, concrete curing by 0.15 mm polyethylene film

shall be avoided; film over damp burlap may be used (ACI 308, Sec. 2.4.2.1)

10.8 Stripping of Formworks

10.8.1

Unless otherwise specified in the project specifications, formwork and shoring shall

be left in place to support the mass of concrete in beams, slabs and in-place

structural members until the specified concrete strength f'c is attained. (ACI 301,

Sec. 2.3.2.5) Note: The preferred method of determining stripping time is by testing

test cylinders that are cured on-site or testing concrete strength in the field.

10.8.2

When finishing is required, remove forms as soon as removal operations will not

damage concrete. (ACI 301, Sec. 2.3.2.1)

Page 11 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

10.8.3

Repairs and treatment on minor concrete damage shall be started immediately.

(ACI 301, Sec. 2.3.2.5).

10.8.4

Forms removal (stripping) shall be based on concrete's achieving minimum

strength requirements as set forth by the design engineer as verified by sample

cylinders compressive strength results.

10.9 Cast-In-Place Concrete Final Acceptance

10.9.1

All concrete surfaces in direct contact with earth shall be coated with two coats of

coal tar or bitumen coating consisting of two coats coal tar epoxy coating system

for Immersion Service or Bituminous Paint for Moderate Temperatures in Buried or

Immersion Service. Overall dry coating thickness shall be from 325m to 605m.

10.9.2

All surface defects such as cracks or honey-combing shall be filled with mortar

consisting of 1 part Portland Cement of the type specified for the job and 2.5 parts

fine sand and ground in smooth with a trowel or carborundum grind stone float.

(ACI 515.1R, Sec. 3.2.1) Note: Proprietary compounds may be used in lieu of

mortar in accordance with the manufacturer's recommendations and with prior

approval of The Engineer.

10.9.3

Finns, protrusions or similar irregularities projecting from the concrete shall be

removed back to the surface by chipping, brush hammering, needle gunning or

wire brushing. (ACI 515.1R, Sec. 3.2.4)

10.9.4

Sharp offsets in the concrete caused by formwork misalignment, shall be

mechanically abraded to provide gradual and smooth transitions between offset

surfaces. (ACI 515.1R, Sec. 3.4.2)

10.9.5

After finishing and curing operations all exposed construction joints, control joints,

expansion-contraction joints or other types shall blend into and match with the

existing adjacent concrete finishes (ACI 301, Sec. 5.3.3)

11.0 QUALITY REQUIREMENTS

To ensure the quality control of reinforced concrete construction works, a third party laboratory

technician will be at site to check the following:

11.1 Temperature of ready mix concrete upon arrival at site.

11.2 Concrete workability by checking concrete slump.

11.3 Preparation and proper curing/preservation of concrete sample specimen.

11.4 Check proper mixing proportion and procedure for application of proprietary compounds

for concrete repairs and surfacing.

Page 12 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

METHOD STATEMENT FOR FORMWORKS, REBARS,

CAST-IN-SITU CONCRETE (POURING, EMBEDMENTS,

CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.16

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

11.5 Check for surface preparation and thickness of coating application.

12.0 HEALTH AND SAFETY

During the progress of works, the necessary welfare facilities shall be provided at the project site.

The workers shall be provided with safe drinking water, toilets, place to eat their food and place to

store their clothes.

Tower lights will be used during night time works and is essential for the safety of workers, the

equipment and the proper execution of work. Barriers around construction area shall be installed.

12.1 ISSUES

12.1.1

The HSE engineer has the responsibility for providing help advice to the

supervisor who is responsible for the work safety.

12.1.2

No one shall be allowed to enter the construction site without wearing the proper

PPEs.

12.1.3

Ensure that there is sufficient scaffolding/platforms and safety harness/fall

protection when working in heights.

12.1.4

Beware of slipping when using ladders in wet conditions.

12.1.5

Provide protective barriers, shield systems complying with applicable standards.

12.2 RESPONSIBILITIES

12.2.1

Safety Engineer

12.2.1.1 Conduct the safety induction course to all personnel involved in the

work.

12.2.1.2 Monitor and supervise the risk assessment.

12.2.1.3 Ensure that necessary Permit to Work is available.

Page 13 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

FORMWORKS, REBARS, CAST-IN-SITU CONCRETE

(POURING, EMBEDMENTS, CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.2016

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

12.2.1.4 Ensure that the projects method statement and risk assessment are

understood, complied and applied in the worksite.

12.2.1.5 Ensure that all workers are provided with sufficient information regarding

workplace hazards and planned control measures.

12.2.1.6 Ensure that necessary equipment (e.g. PPE, tools) is provided prior to start

of works.

12.2.1.7 Ensure that all tools, equipment are certified and serviceable in accordance

with the standard industry practice prior to use.

12.2.1.8 Ensure that adequate level of welfare arrangements are available in the

worksite.

12.2.1.9 Daily inspection of health, safety and environmental compliance is carried

out.

12.2.2 Safety Officer

12.2.2.1 Supervision of equipment handling, transportation and disposal of

construction debris.

12.2.2.2 Ensure that relevant work permit is secured prior to start of work.

12.2.2.3 Ensure that equipment is operational and certified.

12.2.2.4 Ensure that all drivers/operators are qualified to operate the

machines/equipment.

12.2.2.5 Regular inspection and maintenance of the equipment.

12.2.2.6 Perform other duties as instructed by the safety engineer.

Page 14 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

FORMWORKS, REBARS, CAST-IN-SITU CONCRETE

(POURING, EMBEDMENTS, CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.2016

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

APPENDICES

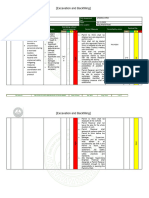

Appendix 1.0 Job Risk Assessment

Appendix 1.1 Carpentry Works

Page 15 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

FORMWORKS, REBARS, CAST-IN-SITU CONCRETE

(POURING, EMBEDMENTS, CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.02.2016

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

Page 16 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

FORMWORKS, REBARS, CAST-IN-SITU CONCRETE

(POURING, EMBEDMENTS, CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.2.2016

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

Appendix 1.2 Formworks

Page 17 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

FORMWORKS, REBARS, CAST-IN-SITU CONCRETE

(POURING, EMBEDMENTS, CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.2.2016

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER: LC3.KKIA-UN-MSM-GEN-CV-0021-B

Page 18 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

FORMWORKS, REBARS, CAST-IN-SITU CONCRETE

(POURING, EMBEDMENTS, CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.2.2016

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

Appendix 1.3- Steel Cutting and Bending

Page 19 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

FORMWORKS, REBARS, CAST-IN-SITU CONCRETE

(POURING, EMBEDMENTS, CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.2.2016

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

Page 20 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

FORMWORKS, REBARS, CAST-IN-SITU CONCRETE

(POURING, EMBEDMENTS, CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.2.2016

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

Appendix 1.4 Concrete Works

Page 21 of 27

KINGDOM OF SAUDI ARABIA

GENERAL AUTHORITY OF CIVIL AVIATION

CONSTRUCTION OF LOAD CENTER -3

FORMWORKS, REBARS, CAST-IN-SITU CONCRETE

(POURING, EMBEDMENTS, CURING)

First

Rev.

Issue

Date:

A

17.01.16

B

18.2.2016

CONTRACT #: R-15-085-BF-0

DOCUMENT NUMBER:LC3.KKIAUNMSMGENCV0021B

Page 22 of 27

Appendix 2.0- Related ITP

CONSTRUCTION OF LOAD CENTER 3 (LC-3) AT KING KHALED INTERNATIONAL AIRPORT (KKIA)

INSPECTION TEST PLAN FOR CIVIL WORKS

CONTRACTOR: SAUDI SERVICES ELECTRO MECHANICAL WORKS. CO. (SSEM) (Close Joint Stock Company)

CONTRACT NO.: R-15-085-BF-0

ITP Ref. No.:

Sec No.:

TITLE: CIVIL WORKS

Sec Title.:

Activity

No.

7

7.1

7.1.1

7.1.2

7.1.3

7.1.4

7.1.5

7.1.6

7.2

Activity Description

Check elevation and level

Check stability of bracing , trying, shoring, false

work and supports

Check of cleanliness, surface smoothness and

form oil coating

Corner chamfering as per drawing requirements

Check stability and position of control joints

Re-bar Quality

7.2.2

Check size and spacing of re-bar and concrete

cover as applicable and also ensure that air

blowing is made to ensure clean surface

7.2.3

Check embedded item for and free from damage

7.3

Check installation of embedded items and proper

support

CONCRETE PLACEMENT

7.3.1

Concrete mix design

7.3.2

Concrete material quality

7.3.3

Check Concrete delivery for correct mix as per

specification

7.3.4

Concrete slump Test

7.3.5

Concrete Yield, Air Content

7.3.6

Concrete making specimen in the field

7.3.7

Check movement and free dropping of concrete

7.3.8

Check for proper vibration while placing concrete

7.3.9

Check Visual/Survey Inspection

Check survey design date

Visual Inspection

Visual Inspection

Visual Inspection

Visual Inspection

Stage / Frequency

After installation of

formworks

After installation of

formworks

After installation of

formworks

After installation of

formworks

After installation of

formworks

After installation of

formworks

Reference Documentation

Test Required

Code/Spec/Etc.

Acceptance Criteria

Technical Specification

Civil Works

Technical Specification

Civil Works

Technical Specification

Civil Works

Technical Specification

Civil Works

Technical Specification

Civil Works

Technical Specification

Civil Works

SSEM CHECK

SSEM CHECK

SSEM CHECK

SSEM CHECK

SSEM CHECK

SSEM CHECK

Approved Construction

Drawings

Approved Construction

Drawings

Method of

Verification

SSEM

AECOM

Demonstrated Evidence

Report/Checklist

RR

Checklist Form IC-C-007

RR

Checklist Form IC-C-007

Project Specification

RR

Checklist Form IC-C-007

Project Specification

Checklist Form IC-C-007

Project Specification

Checklist Form IC-C-007

Approved Construction

Drawings

Checklist Form IC-C-007

LAYING OF REBAR AND EMBEDDED ITEMS

7.2.1

7.2.4

Date: October 2015

Inspection / Test Requirements

Test or Inspection Performed

STRUCTURAL CEMENT CONCRETE

CONSTRUCTION

FORMWORK

Check dimension of formwork for conformity to

the drawings

ISSUANCE: 01

REVISION: 00

Compressive Strength Test

ABBREVIATIONS:

Check Rebar Chemical

Composition, Tensile and

Bending Compliance w/ (ASTM

A 615)

Every 300tons/per size

dia.

Factory

Test/Third Party

Test

Technical Specification

Civil Works

Project

Specification/Approved

Material Submittal

RR

RR

Mill Certificate/Test report

Visual inspection

After assembly of Rebar

SSEM CHECK

Technical Specification

Civil Works

Approved Construction

Drawings/Bar bending

Schedule

Checklist Form IC-C-007

Visual inspection

Visual inspection

Check Approved Concrete Mix

Design

Check Coarse/Fine Aggregate

comply w/ (ASTM C 33)

Check Approved Concrete Mix

Design

Witness checking of Slump

(ASTM C 143)

Witness checking of Yield, Air

Content (ASTM C 138)

Witness checking of sample

cylinder (ASTM C31

Visual Inspection

Visual Inspection

Check result compressive

strength (ASTM C39)

After assembly of Rebar

After assembly of Rebar

SSEM CHECK

Prior to actual

production get started

Third Party Test

daily

Third Party Test

Every Batch Ticket

Third Party Test

Every Truck Mixer

Third Party Test

Control Mix Twice

Weekly

Six test cylinder each

day used for 28 days

test additional test

cylinder may be

prepared for 7 days test

(per 200cu.m.)

During Concrete

Placement

During Concrete

Placement

Six test cylinder each

day used for 28 days

Technical Specification

Civil Works

Technical Specification

Civil Works

SSEM CHECK

Third Party Test

THIRD PARTY

TEST

SSEM CHECK

THIRD PARTY

TEST

N/A NOT

APPLICABLE

Note:

Page 1 of 2

Checklist Form IC-C-007

Checklist Form IC-C-007

Project Specification

RR

RR

Materials Submittal Report

Project Specification

Checklist Form IC-C-007

Technical Specification

Civil Works

Technical Specification

Civil Works

Technical Specification

Civil Works

Technical Specification

Civil Works

Technical Specification

Civil Works

Test Result Compliance w/

Project Specification

Test Result Compliance w/

Project Specification

Technical Specification

Civil Works

Technical Specification

Civil Works

Technical Specification

Civil Works

Technical Specification

Civil Works

SSEM CHECK

Project Specification

Approved Construction

Drawings

Project Specification

Checklist Form IC-C-007

Checklist Form IC-C-007

Checklist Form IC-C-007

Test Result Compliance w/

Project Specification

Checklist Form IC-C-007

Project Specification

Checklist Form IC-C-007

Project Specification

Checklist Form IC-C-007

Test Result of 6 tests

cylinder at 28 days shall be

RR/W

RR

Material Test Report

W-

WITNESS PONT

SURVEILLANCE

HOLD POINT

RR REVIEW OF REPORT

AECOM- Consultant

SSEM-

Contractor

Page

23 of 27

Appendix 2.0- Related ITP

CONSTRUCTION OF LOAD CENTER 3 (LC-3) AT KING KHALED INTERNATIONAL AIRPORT (KKIA)

INSPECTION TEST PLAN FOR CIVIL WORKS

CONTRACTOR: SAUDI SERVICES ELECTRO MECHANICAL WORKS. CO. (SSEM) (Close Joint Stock Company)

CONTRACT NO.: R-15-085-BF-0

ITP Ref. No.:

Sec No.:

TITLE: CIVIL WORKS

Sec Title.:

Activity

No.

Activity Description

ISSUANCE: 01

REVISION: 00

Date: October 2015

Inspection / Test Requirements

Test or Inspection Performed

Stage / Frequency

Reference Documentation

Test Required

Code/Spec/Etc.

Acceptance Criteria

test additional test

cylinder may be

prepared for 7 days test

7.4

Method of

Verification

SSEM

AECOM

Demonstrated Evidence

Report/Checklist

at least 25.0 N/mm2

(Average of 6 Cylinder

FINISHING AND CURING

7.4.1

Check for Curing as per specification

requirements

7.4.2

Check formed surfaces for finish

7.4.3

Repair surface defects as per approved

procedure

7.4.4

Check joints and application of filler and sealant

ABBREVIATIONS:

Check Approved Materials for

curing

After placement of

Concrete

SSEM CHECK

Technical Specification

Civil Works

Visual Inspection

After Dismantling of

Concrete Forms

SSEM CHECK

Technical Specification

Civil Works

As per Approved Material

supplier procedure for Repair

After Dismantling of

Concrete Forms

SSEM CHECK

Technical Specification

Civil Works

Visual Inspection

After Dismantling of

Concrete Forms

SSEM CHECK

Technical Specification

Civil Works

N/A NOT

APPLICABLE

Note:

Page 2 of 2

Approved Materials

compliance w/Project

Specification

Checklist Form IC-C-007

Project Specification

Checklist Form IC-C-007

Approved Materials

compliance Method

Statement /Project

Specification

Checklist Form IC-C-007

Project Specification

Checklist Form IC-C-007

W-

WITNESS PONT

SURVEILLANCE

HOLD POINT

RR REVIEW OF REPORT

AECOM- Consultant

SSEM-

Contractor

Page

24 of 27

Appendix 3.0- Checklist

CONSTRUCTION OF NEW LOAD CENTER-3 AT KING KHALED INTERNATIONAL

AIRPORT

STRUCTURAL CEMENT CONCRETE CONSTRUCTION

IC Checklist No.: 085-IC-C-007

ITP Ref. No.: 085-ITP-C-8.0

Sec:

Area/Location:

Project: Construction of New Load Center-3

Contract No.: R-15-085-BF-O

Facility Name:

Drwg. No. / Line No.:

Work / item for Inspection:

Item

Activity

Formworks dimensions and

elevation conforming to the

drawing

Check stability of bracing ,

trying, shoring, false work and

supports

Check of cleanliness, surface

smoothness and form oil

coating

Corner chamfering as per

drawing requirements

Check Compaction density of

CTB

Check stability and position of

control joints

Check Re-bar Quality

Check size and spacing of rebar and concrete cover as

applicable and also ensure that

air blowing is made to ensure

clean surface

Check quality and installation of

embedded materials

Check Concrete delivery for

correct mix as per specification

Visual inspection of finished

CTB

Concrete slump Test

Concrete making specimen in

the field

Check movement and free

2

3

4

5

6

7

8

9

10

11

12

13

14

SSEM

Engr.

SSEM

QC

GACA/AECOM

Representative

A

R

N/A

Corr.

Sign

Off

Remarks

Page 25 of 27

Appendix 3.0- Checklist

CONSTRUCTION OF NEW LOAD CENTER-3 AT KING KHALED INTERNATIONAL

AIRPORT

dropping of concrete

Check for proper vibration of

concrete

16

Check for compressive strength

of concrete

17

Check for proper curing of

concrete

18

Repair of surface defects as

per approved procedure

19

Check joints and application of

filler and sealant

GACA/AECOM Representative Remarks:

15

Sign:

Name:

Date:

SSEM QC Representative

Legend: A=Acceptable; R=Rejected; N/A=Not

Applicable

GACA / AECOM Representative

Sign:

Name:

Date:

Page 26 of 27

Appendix 4.0- Proforma Work Permit

SSEM-HSE/PERMIT/002/M07-11, Rev0.1, July2011

FORMWORKS, REBARS & CAST-IN-SITU CONCRETE WORK PERMIT

DATE: ______________________PERIOD: __________________TO:__________________PERMIT NO.:_______________

EQUIPMENTS: _______________________________________________________WORK AREA: ______________________

DESCRIPTION OF WORK:_________________________________________________________________________________

NAME OF THE ORIGINATOR:

COMPANY:

DEPARTMENT:

SIGNATURE:

COMPLEMENTARY PERMITS

PERFORMING AUTHORITY

YES

NO

N/A

DRIVING IN UNAUTHORISED AREAS

CLEARANCE FROM YERP AUTHORITY

CLEARANCE FROM ROYAL COMMISSION

CLEARANCE FROM OTHER DEPARTMENTS

NAME:

SIGNATURE & DATE:

CONTACT NO:

RISK ASSESSMENT

SAFETY PRECAUTUONS

YES

NO

YES

N/A

ISOLATION FROM OTHER WORKS

PERSONAL PROTECTIVE EQUIPMENT (P.P.E)

BARRICADES AND WARNING SIGNS

AREA IS SUITABLE FOR CONCRETE REPAIR WORK

ADDITIONAL ILLUMINATION

PROPER ACCESS

ACCESS/EGRESS CLEAR FROM OBSTACLES

FIRE EXTINGUISER / FIRE WATCHMAN

LIFE LINES/ SAFETY HARNESS

BREATHING EQUIPMENT

EMERGENCY RESCUE TEAM AVAILABLE.

SLOPING OR SHIELDLING PROVIDED

AREA CLEAR FROM TOXIC GASES

NO MATERIAL KEPT NEAR THE EXCAVATION

EXISTING TEMPORARY OR

PERMANENT UTILITIES

SUITABLE EQUIPMENT AND TOOLS

AVAILABLE

GAS CYLINDERS KEPT OUT FROM THIS AREA

WORKERS AWARE OF HAZARDS AND PRECAUTUONS

TO BE TAKEN

ELECTRICAL ISOLATION

METHOD STATEMENT / JSA

ENOUGH ACCESS/EGRESS

SUFFICIENT

SCAFFOLDING/PLATFORMS

AREA CLEAR FROM COMBUSTIBLE

SUBSTANCES

ANY OTHER WORKS ADJACENT

NO

N/A

OTHER REQUIREMENTS (IF NECESSARY)

DECLARATION (to be filled by Performing Authority) And Competent Person

I, UNDERSIGNED HAVE CHECKED THE AREA AND COMPLIED TO ALL SAFETY PRECAUTIONS AND RISK ASSESSMENT AND WILL CARRY OUT ACTIVITY WITH

APPROVED METHOD STATEMENT

NAME:

SIGN:

NAME:

SIGN:

PERMIT VALIDITY (to be filled by Site Manager/Engineer)

THE ABOVE WORK HAS BEEN APPROVED AND SHALL BE CARRIED OUT SAFELY. IT HAS TO BE ENSURED THAT THE EMPLOYEE EXECUTING THE JOB HAS A COPY

OF THE PERMIT AT ALL TIMES DURING THE WORK.

NAME:

SIGNATURE:

DATE:

PERMIT CLEARANCE (to be filled by HSE/Safety Representative)

I DECLARE THAT ALL WORK UNDER MY CONTROL HAS NOW BEEN COMPLETED AND THE AREA HAS BEEN CLEARED AND THAT ALL TOOLS AND OTHER

EQUIPMENT HAVE BEEN REMOVED

NAME:

SIGNATURE:

DATE:

PERMIT CLOSED (to be filled by Performing Authority)

THE ABOVE WORK WAS COMPLETED SAFELY AND THE WORK PERMIT SHALL BE CANCELLED

NAME:

SAFETY DEPARTMENT:

NAME:

Yellow- Site

SIGNATURE :

DATE:

SIGNATURE:

DATE:

Blue - HSE office

White - Client Office

Page 27 of 27

S-ar putea să vă placă și

- Method Statement (RC Slab)Document3 paginiMethod Statement (RC Slab)group2sd131486% (7)

- Building Work Method StatementDocument32 paginiBuilding Work Method StatementMuhammad Waqas97% (33)

- BOX CULVERTS-Method StatementDocument2 paginiBOX CULVERTS-Method Statementmemekenya78% (51)

- Excavation Method Statement PDFDocument10 paginiExcavation Method Statement PDFMohammad Bader Al-Dein100% (13)

- Method Statement - Drainage WorksDocument6 paginiMethod Statement - Drainage WorksKhiril Hanaffi67% (3)

- Method Statement For Roadbase ConstructionDocument3 paginiMethod Statement For Roadbase ConstructionNordin Yunus93% (84)

- Method Statement Sheet PilingDocument9 paginiMethod Statement Sheet PilingAMA MUTTAHIZI AHADAN AUHAN100% (1)

- Method Statement For Shoring WorkDocument24 paginiMethod Statement For Shoring WorkAzhar Ali78% (9)

- Block Work-Method StatementDocument7 paginiBlock Work-Method StatementA1994486% (22)

- Method Statement Slab & Beam ConcretingDocument3 paginiMethod Statement Slab & Beam Concretingudithairesha100% (6)

- Construction Method Statement GuideDocument30 paginiConstruction Method Statement GuideEmad Rakat86% (7)

- Method Statement For Structural ErectionDocument15 paginiMethod Statement For Structural Erectionchallam4239100% (11)

- Plastering Works Method StatementDocument7 paginiPlastering Works Method StatementYan Belarmino33% (6)

- Method Statement EarthworkDocument5 paginiMethod Statement EarthworkNurul Abdul Jalil78% (9)

- Method Statement Dewatering (Final) Rev1Document11 paginiMethod Statement Dewatering (Final) Rev1Bala50% (2)

- The Rise Residence & Resort Project Method StatementDocument16 paginiThe Rise Residence & Resort Project Method StatementMin Luo100% (6)

- Method Statement For Columns2Document5 paginiMethod Statement For Columns2Jasmine TsoÎncă nu există evaluări

- Formwork Method StatementDocument3 paginiFormwork Method Statementsarathirv693% (14)

- Method Statement For Civil WorksDocument11 paginiMethod Statement For Civil Workssivanand90% (20)

- Fall Protection Exam - Worksite Safety4Document6 paginiFall Protection Exam - Worksite Safety4Ian Jeff Landingin DumayasÎncă nu există evaluări

- MOS For CMU Block WorkDocument10 paginiMOS For CMU Block WorkAlvene TagocÎncă nu există evaluări

- KPS method statement for concrete worksDocument14 paginiKPS method statement for concrete worksWufei Chang95% (21)

- Method Statement for Parapet ConstructionDocument8 paginiMethod Statement for Parapet Constructionsonusweetyshobha100% (2)

- 3) Method Statement For Formwork Steel & Concrete WorkDocument9 pagini3) Method Statement For Formwork Steel & Concrete WorkMukesh PrajapatÎncă nu există evaluări

- Method Statement For Plastering WorkDocument15 paginiMethod Statement For Plastering Workstrikersam100% (9)

- Method Statement For Excavation and Backfilling WorksDocument2 paginiMethod Statement For Excavation and Backfilling WorksAnonymous wTTx1L86% (22)

- Open Excavation MethodDocument2 paginiOpen Excavation MethodSam Wong86% (7)

- Method Statement of Concreting WorkDocument4 paginiMethod Statement of Concreting WorkChairul Fajri100% (10)

- Method Statement For Construction of Substructure Elements)Document8 paginiMethod Statement For Construction of Substructure Elements)Akash Yadav100% (2)

- Method Statement Samples - Civil WorksDocument64 paginiMethod Statement Samples - Civil WorksShameer Babu Thonnan Thodi94% (31)

- Construction Method StatementDocument7 paginiConstruction Method StatementAddrien Daniel100% (4)

- Method Statement For Finishing Works PDFDocument6 paginiMethod Statement For Finishing Works PDFdndudc92% (12)

- Method Statement For Temporary Construction Facilities (Mos)Document15 paginiMethod Statement For Temporary Construction Facilities (Mos)DSJ100% (1)

- MARJAN INCREMENT PROGRAM Installation of Steel Support and Gratings For TR AreaDocument10 paginiMARJAN INCREMENT PROGRAM Installation of Steel Support and Gratings For TR AreaFaraaz MohammedÎncă nu există evaluări

- SECTION 07720 Roof Accessories Rev 0Document22 paginiSECTION 07720 Roof Accessories Rev 0Azhar AliÎncă nu există evaluări

- OPITO Offshore Oil & Gas Industry Minimum Industry Safety Training Standard 5301Document28 paginiOPITO Offshore Oil & Gas Industry Minimum Industry Safety Training Standard 5301ipin4uÎncă nu există evaluări

- METHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Document7 paginiMETHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Osama MZ100% (1)

- Method Statement Structural Excavation & BackfillingDocument16 paginiMethod Statement Structural Excavation & Backfillingcenkunal83% (12)

- Method Statement For ScaffoldingDocument3 paginiMethod Statement For Scaffoldingamg007100% (5)

- Method Statement Concrete Works PDFDocument18 paginiMethod Statement Concrete Works PDFdndudc95% (22)

- Concrete Works Method StatementDocument41 paginiConcrete Works Method StatementDomie Neil Bucag SalasÎncă nu există evaluări

- General Fill and Compaction-Method Statement (R2)Document4 paginiGeneral Fill and Compaction-Method Statement (R2)A1994494% (18)

- NUTL Building Formwork MethodDocument28 paginiNUTL Building Formwork MethodSimplicio Goncalves100% (1)

- Method Statement For Concrete Works (Rev.01)Document12 paginiMethod Statement For Concrete Works (Rev.01)EmadHassan0% (1)

- CONSTRUCTION DRAINAGE WORKS STATEMENTDocument5 paginiCONSTRUCTION DRAINAGE WORKS STATEMENTYin Mohd100% (4)

- 011-Method Statement For Repair of Concrete Works PDFDocument25 pagini011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- MS Formwork, Reinforcement & Concrete WorksDocument15 paginiMS Formwork, Reinforcement & Concrete Workstomj9104100% (1)

- STRUCTURAL CONCRETE WORK METHODDocument3 paginiSTRUCTURAL CONCRETE WORK METHODRoland Tio67% (3)

- Method Statement For ExcavationDocument7 paginiMethod Statement For Excavationspwong99100% (3)

- Qatar Building Engineering Company Earthwork Inspection PlanDocument4 paginiQatar Building Engineering Company Earthwork Inspection PlanPageduesca RouelÎncă nu există evaluări

- Method Statement - RC Retaining WallDocument9 paginiMethod Statement - RC Retaining WallAnang Sdj100% (1)

- 6.method Statement For Concrete Repairs Rev. 1Document14 pagini6.method Statement For Concrete Repairs Rev. 1mohsin100% (5)

- Method of Statement For Concrete FormworksDocument7 paginiMethod of Statement For Concrete Formworksriel ramos100% (3)

- 01 Method Statement For Pile Cap Foundations (Findal)Document8 pagini01 Method Statement For Pile Cap Foundations (Findal)Joe PS83% (6)

- Method Statements For Reinforcement BarsDocument2 paginiMethod Statements For Reinforcement BarsSupun Sandaruwan0% (1)

- Uganda Entebbe International Airport Upgrading and Expansion Project Steel Work Method StatementDocument14 paginiUganda Entebbe International Airport Upgrading and Expansion Project Steel Work Method StatementAkatwijuka AllanÎncă nu există evaluări

- AGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Document49 paginiAGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Dilshad Ahemad100% (2)

- Mall of Qatar Trolley Corral Installation Method StatementDocument63 paginiMall of Qatar Trolley Corral Installation Method StatementMikku Katta67% (3)

- ELT-07-MT-Q-SERV-0001 - Foundation For Truck Loading RackDocument19 paginiELT-07-MT-Q-SERV-0001 - Foundation For Truck Loading RackEl Charasquiada CharroÎncă nu există evaluări

- Docu Ent Sub Ittal Sheet: Qatar Armed Forces Qatar Emiri Corps of EngineeringDocument20 paginiDocu Ent Sub Ittal Sheet: Qatar Armed Forces Qatar Emiri Corps of EngineeringMohameduwais Badurdeen Haqqiyul QadiriÎncă nu există evaluări

- Vent Nozzle Design CriteriaDocument45 paginiVent Nozzle Design CriteriaChanFK100% (1)

- Civil Module for Thermal Power ProjectsDocument202 paginiCivil Module for Thermal Power ProjectsksshashidharÎncă nu există evaluări

- Client: Consultant: Contractor:: Method Statement For Sub Base and Road Base WorkDocument11 paginiClient: Consultant: Contractor:: Method Statement For Sub Base and Road Base WorkYEHIAÎncă nu există evaluări

- HIC Testing RequirementsDocument2 paginiHIC Testing RequirementsAzhar AliÎncă nu există evaluări

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 paginiInspection & Testing Requirements Scope:: Test and Inspection PerAzhar AliÎncă nu există evaluări

- Saep 135Document8 paginiSaep 135Anonymous 4IpmN7OnÎncă nu există evaluări

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 paginiInspection & Testing Requirements Scope:: Test and Inspection PerAli RazaÎncă nu există evaluări

- Layout Drawings With Highlight (Section Wise)Document1 paginăLayout Drawings With Highlight (Section Wise)Azhar AliÎncă nu există evaluări

- Lightning Protection System Design and Installation SpecificationDocument16 paginiLightning Protection System Design and Installation SpecificationAzhar AliÎncă nu există evaluări

- SECTION 07910 Preformed Joint Seals Rev 0Document16 paginiSECTION 07910 Preformed Joint Seals Rev 0Azhar AliÎncă nu există evaluări

- SECTION 13420 Instruments Rev 0Document43 paginiSECTION 13420 Instruments Rev 0Azhar AliÎncă nu există evaluări

- Saep 32 PDFDocument15 paginiSaep 32 PDFRami ElloumiÎncă nu există evaluări

- SECTION 13112 Sacrificial Anode CP of Submerged and Buried Underground Structures Rev 0 PDFDocument26 paginiSECTION 13112 Sacrificial Anode CP of Submerged and Buried Underground Structures Rev 0 PDFHafed BaccoucheÎncă nu există evaluări

- SECTION 13111 Impressed Current CP of Submerged and Buried Metallic Structures Rev 0Document33 paginiSECTION 13111 Impressed Current CP of Submerged and Buried Metallic Structures Rev 0Azhar Ali100% (1)

- SECTION 13113 Impressed Current CP of Reinforced Concrete Structures Rev 0 PDFDocument46 paginiSECTION 13113 Impressed Current CP of Reinforced Concrete Structures Rev 0 PDFHafed BaccoucheÎncă nu există evaluări

- SECTION 13850 Detection and Alarm Rev 0Document25 paginiSECTION 13850 Detection and Alarm Rev 0Azhar AliÎncă nu există evaluări

- SECTION 13450 Central Control Rev 0Document36 paginiSECTION 13450 Central Control Rev 0Azhar AliÎncă nu există evaluări

- SECTION 13860 Fire Detection and Alarm System Rev 0Document13 paginiSECTION 13860 Fire Detection and Alarm System Rev 0Azhar AliÎncă nu există evaluări

- SECTION 16510 Interior Luminaires Rev 0Document23 paginiSECTION 16510 Interior Luminaires Rev 0Ahmed HashimÎncă nu există evaluări

- Guideline Specification for Indicators, Recorders and ControllersDocument18 paginiGuideline Specification for Indicators, Recorders and ControllersAzhar AliÎncă nu există evaluări

- Power Cable SpecificationsDocument49 paginiPower Cable SpecificationsAhmed HashimÎncă nu există evaluări

- SECTION 16075 Electrical Identification Rev 0Document26 paginiSECTION 16075 Electrical Identification Rev 0Ahmed HashimÎncă nu există evaluări

- SECTION 13430 Boxes, Panels and Control Centers Rev 0Document19 paginiSECTION 13430 Boxes, Panels and Control Centers Rev 0Azhar AliÎncă nu există evaluări

- SECTION 16710 Communication Circuit Rev 0Document32 paginiSECTION 16710 Communication Circuit Rev 0Ahmed HashimÎncă nu există evaluări

- SECTION 16450 Panelboards Rev 0Document14 paginiSECTION 16450 Panelboards Rev 0Ahmed HashimÎncă nu există evaluări

- SECTION 16110 Residential Wiring Connections, Rev 0Document12 paginiSECTION 16110 Residential Wiring Connections, Rev 0Ahmed HashimÎncă nu există evaluări

- SECTION 16130 Raceway and Boxes Rev 0Document19 paginiSECTION 16130 Raceway and Boxes Rev 0Ahmed HashimÎncă nu există evaluări

- SECTION 16440 Switchboards, Panelboards & Control Centers Rev 0Document32 paginiSECTION 16440 Switchboards, Panelboards & Control Centers Rev 0Ahmed HashimÎncă nu există evaluări

- SECTION 16140 Wiring Devices Rev 0Document18 paginiSECTION 16140 Wiring Devices Rev 0Ahmed HashimÎncă nu există evaluări

- SECTION 02840-1 Delineators Rev 0Document14 paginiSECTION 02840-1 Delineators Rev 0Azhar AliÎncă nu există evaluări

- SECTION 02891 Traffic Signs Rev 0Document37 paginiSECTION 02891 Traffic Signs Rev 0Azhar Ali100% (1)

- SECTION 02840-2 Guardrail Rev 0Document11 paginiSECTION 02840-2 Guardrail Rev 0Saldarriaga FranciscoÎncă nu există evaluări

- Handling Chlorine: Safety and Functioning of Chlorination SystemsDocument10 paginiHandling Chlorine: Safety and Functioning of Chlorination SystemsUmairÎncă nu există evaluări

- Th4 Word EnglishDocument81 paginiTh4 Word EnglishLuis CuzcoÎncă nu există evaluări

- SDS for PAC FlocculantDocument4 paginiSDS for PAC FlocculantGerai AchazaÎncă nu există evaluări

- Maintain ToolsDocument26 paginiMaintain ToolsJustine VergaraÎncă nu există evaluări

- Bourdillon Presentation PowerpointDocument41 paginiBourdillon Presentation PowerpointAdedoyin LasisiÎncă nu există evaluări

- Document Code OPERATION PROCEDUREDocument64 paginiDocument Code OPERATION PROCEDUREJonathan Po CaasiÎncă nu există evaluări

- CORDLESS PLUNGE SAW PTS 20-Li A1 PDFDocument68 paginiCORDLESS PLUNGE SAW PTS 20-Li A1 PDFΑλεξης ΝεοφυτουÎncă nu există evaluări

- SBW-RFAMS-008-Submission of Method Statement For Plastering WorkDocument24 paginiSBW-RFAMS-008-Submission of Method Statement For Plastering WorkChamux skalÎncă nu există evaluări

- Chapter 3 Personal Protective Equipment and Self-Contained Breathing ApparatusDocument4 paginiChapter 3 Personal Protective Equipment and Self-Contained Breathing ApparatusMuhammad Alshikh100% (1)

- Balikpapan, April 17, 2007Document5 paginiBalikpapan, April 17, 2007Hasrul Sun100% (1)

- Breaking Containment - Process Cleaning Operations PDFDocument4 paginiBreaking Containment - Process Cleaning Operations PDFAnonymous ocCa18RÎncă nu există evaluări

- UNIMAC - KKR - RA-031 - Excavation and BackfillingDocument17 paginiUNIMAC - KKR - RA-031 - Excavation and Backfillingrustam khanÎncă nu există evaluări

- Reference - Comflor 80 Brochure PDFDocument24 paginiReference - Comflor 80 Brochure PDFgks6043Încă nu există evaluări

- Hargeisa Water Supply Project OHS Management PlanDocument78 paginiHargeisa Water Supply Project OHS Management PlanDejan PetrasÎncă nu există evaluări

- Work PermitDocument3 paginiWork PermitMadhu Babu KancharlaÎncă nu există evaluări

- Tempus RNA Isolation Cms - 042989Document38 paginiTempus RNA Isolation Cms - 042989Alexandru CodreanuÎncă nu există evaluări

- BP500C MSDSDocument3 paginiBP500C MSDSMiguel GonzalezÎncă nu există evaluări

- Tle05 - Module 1Document292 paginiTle05 - Module 1Lifmark Villacorte TalamayanÎncă nu există evaluări

- Workplace Inspection ChecklistDocument5 paginiWorkplace Inspection ChecklistJack Cianfaglione100% (1)

- Maquina w163 PDFDocument20 paginiMaquina w163 PDFantongilÎncă nu există evaluări

- WSH Healthcare GuidelinesDocument75 paginiWSH Healthcare GuidelinesJohn KurongÎncă nu există evaluări

- 23 JSA For Block WorkDocument2 pagini23 JSA For Block WorkWakil AhmadÎncă nu există evaluări

- Work at Height Permit FormDocument3 paginiWork at Height Permit FormEbenezer OpuniÎncă nu există evaluări

- Chemical Safety: Jubail Technical Institute Occupational Health and Safety - Bshs 1502Document19 paginiChemical Safety: Jubail Technical Institute Occupational Health and Safety - Bshs 1502Ibrahim AhmedÎncă nu există evaluări

- Risk Assesment of Brick & Block WorkDocument3 paginiRisk Assesment of Brick & Block WorkGyanendra SrivastavaÎncă nu există evaluări

- Method of Statement For SPI366 Pump Sump Cleaning Without Confined Space EntryDocument5 paginiMethod of Statement For SPI366 Pump Sump Cleaning Without Confined Space EntryKarpana Devi LetchumananÎncă nu există evaluări

- MSDS - Rilsan NylonDocument13 paginiMSDS - Rilsan NylonDv Maria PradhikaÎncă nu există evaluări

- HEF Application Form 2023 New ZealandDocument13 paginiHEF Application Form 2023 New Zealanddelco simao sitoeÎncă nu există evaluări