Documente Academic

Documente Profesional

Documente Cultură

Sub-Modul Advanced Production Technologies and Optimisation (Riegel) 2015 PDF

Încărcat de

Kazi Mehdi0 evaluări0% au considerat acest document util (0 voturi)

34 vizualizări2 paginiAdvanced production techniques and optimization (5 ECTS) module is used in the following degree programms as well. Students are able to face this problems by using experimental, statistical and engineering methods.

Descriere originală:

Titlu original

Sub-Modul Advanced Production Technologies and Optimisation (Riegel)2015.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentAdvanced production techniques and optimization (5 ECTS) module is used in the following degree programms as well. Students are able to face this problems by using experimental, statistical and engineering methods.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

34 vizualizări2 paginiSub-Modul Advanced Production Technologies and Optimisation (Riegel) 2015 PDF

Încărcat de

Kazi MehdiAdvanced production techniques and optimization (5 ECTS) module is used in the following degree programms as well. Students are able to face this problems by using experimental, statistical and engineering methods.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

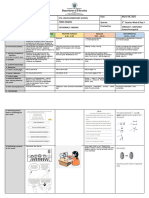

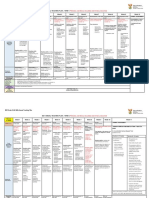

Modul title: Product and process development (10 ECTS)

Submodul title: Advanced production techniques and optimization (5 ECTS)

Modul code

162MI

Student

workload

150 h

Credits

Semester

Frequency

Duration

(according

to ECTS)

3. semester

Winter semester

1 semester

Contact

hours

Independent

study

Class size

4 hours per

week / 60 h

90 h

5

Type of course

Seminaristic lecture: 2 hours per week / 30 h

Practical part: 2 hours per week / 30 h

40

Learning outcomes / competencies

- Students are knowing the relations of production processes with multiple influencing factors and the

problems arising by that

- Students are able to face this problems by using experimental, statistical and engineering methods

- Students are able to work out strategies to control these processes by different means

Contents / subject aims

1

Introduction

Processes with multiple influencing factors

2.1 Bonding Processes (examples profile wrapping, edgebanding and others)

2.2 Sanding Processes

2.3 Moulding Processes

3

Process Models

Experiment Setup

4.1 Measuring techniques

4.2 Determination of characteristic values

4.3 Design of experiments

4.4 Multiple regression

5

Optimization of the process itself

5.1 Statistical optimization strategies

5.2 Robust processes

5.3 Process control strategies

6

Optimization in the surrounding of the process

6.1 Toyota Production System

6.2 Total Productive Manufacturing

Teaching methods

lecture, project work, case studies, group work, discussions, experiments in the laboratory, excursions

Prerequisites for participation

Basic knowledge in statistics, basic knowledge of production processes

(woodworking processes would fit best)

Assessment methods

Oral examination, taking into account the work done and the special knowledge achieved in the

project work

This module is used in the following degree programms as well

???

Responsibility for module

Prof. Dr.-Ing. Adrian Riegel

Other information (literature)

Masing, W.: Handbuch Qualittsmanagement. Mnchen: Hanser, 1999.

VDA (Hrsg): Richtlinien 6.1 ff

Gimpel, B.: Qualittsgerechte Optimierung von Fertigungsprozessen. Dsseldorf: VDI, 1991.

Dietrich, E.; Schulze, A.: Statistische Verfahren zur Maschinen- und Prozequalifikation. Mnchen,

Wien: Hanser, 2005.

Kleppmann, W.: Taschenbuch Versuchsplanung. Mnchen, Wien: Hanser, 2003

Steve Borris: Total Productive Maintenance: Proven Strategies and Techniques to Keep Equipment

Running at Maximum Efficiency. Mcgraw-Hill Professional, 2006.

Taiichi Ohno: Toyota Production System beyond large scale production. New York: Productivity

Press, 1990.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Chapter 1 Quiz and Answer Keys Training and DevelopmentDocument25 paginiChapter 1 Quiz and Answer Keys Training and DevelopmentEwura Esi Eyram Aboagyewaa100% (3)

- Phy202 v1 wk1 Applications of Buoyancy Lab Report ObservationalDocument3 paginiPhy202 v1 wk1 Applications of Buoyancy Lab Report ObservationalSmart Essays100% (1)

- Automotive Software Engineering Master EnglDocument4 paginiAutomotive Software Engineering Master EnglKazi MehdiÎncă nu există evaluări

- Calisthenics For Beginners - 25 - Diane WoodsDocument149 paginiCalisthenics For Beginners - 25 - Diane WoodsKazi MehdiÎncă nu există evaluări

- Ls-Dyna: AboutDocument4 paginiLs-Dyna: AboutKazi MehdiÎncă nu există evaluări

- Space FrameDocument1 paginăSpace FrameKazi MehdiÎncă nu există evaluări

- Federal Motor Vehicle Safety Standards and RegulationsDocument23 paginiFederal Motor Vehicle Safety Standards and RegulationsKazi MehdiÎncă nu există evaluări

- Machine Design 2: View Module Details ForDocument4 paginiMachine Design 2: View Module Details ForKazi MehdiÎncă nu există evaluări

- Machine Design 2: View Module Details ForDocument4 paginiMachine Design 2: View Module Details ForKazi MehdiÎncă nu există evaluări

- PLCs and Pneumatic SystemsDocument5 paginiPLCs and Pneumatic SystemsKazi Mehdi0% (2)

- Machine Design: View Module Details ForDocument4 paginiMachine Design: View Module Details ForKazi MehdiÎncă nu există evaluări

- Lesson Plan On Five SensesDocument8 paginiLesson Plan On Five Sensesneelima goswamiÎncă nu există evaluări

- Education For AdultsDocument315 paginiEducation For Adultschu_chiang_3Încă nu există evaluări

- Embarking On A Journey of Self-AwarenessDocument27 paginiEmbarking On A Journey of Self-AwarenessAlbinMae Caroline Intong-Torres Bracero-CuyosÎncă nu există evaluări

- Comparaison AnglaisDocument4 paginiComparaison AnglaisRanto Andriampenitra RasoamanambolaÎncă nu există evaluări

- My Family and My House: Ingles A1 Unidad 1 - Task 2 - WritingDocument4 paginiMy Family and My House: Ingles A1 Unidad 1 - Task 2 - WritingLeidy JimenezÎncă nu există evaluări

- Lesson Plan 9gDocument2 paginiLesson Plan 9gAdriana Raluca Ayame SalavastruÎncă nu există evaluări

- DLL q3 WK 6 Day 3Document16 paginiDLL q3 WK 6 Day 3CATHERINE FAJARDOÎncă nu există evaluări

- Libre Bulad Action Plan 2019 2020Document5 paginiLibre Bulad Action Plan 2019 2020Jeffreynald Francisco100% (1)

- Lesson 6 DLP Grade 8 Tle-Ict (Interpret Technical Drawing)Document9 paginiLesson 6 DLP Grade 8 Tle-Ict (Interpret Technical Drawing)Ginalyn Melig BandaoÎncă nu există evaluări

- Personal Project Criteria ADocument6 paginiPersonal Project Criteria ASimrita KwatraÎncă nu există evaluări

- lp8 Creative Arts - Shadow and SculptureDocument3 paginilp8 Creative Arts - Shadow and Sculptureapi-465552526Încă nu există evaluări

- Quiz 1 ETHICAL BEHAVIORDocument4 paginiQuiz 1 ETHICAL BEHAVIORAishiar Yvonne ConnerÎncă nu există evaluări

- Edutech The Learning SpecialistsDocument2 paginiEdutech The Learning SpecialistsBi AlÎncă nu există evaluări

- DLL-TLE-TD8-Week 1Document2 paginiDLL-TLE-TD8-Week 1GERRALDINE CAPILLASÎncă nu există evaluări

- M SS 1 10 18 22 PDFDocument2 paginiM SS 1 10 18 22 PDFBernadette DispoÎncă nu există evaluări

- Ministry of Education Manifesto Week May 2020Document115 paginiMinistry of Education Manifesto Week May 2020jadwongscribdÎncă nu există evaluări

- (032121) (041021) Knowledge Management at Unilever IndonesiaDocument17 pagini(032121) (041021) Knowledge Management at Unilever IndonesiaWiasta GuegueÎncă nu există evaluări

- Writing For C1 and C2Document8 paginiWriting For C1 and C245.Võ Phương Vy100% (1)

- Portfolio Met1 - Génesis MolinaDocument14 paginiPortfolio Met1 - Génesis Molinakenia molinaÎncă nu există evaluări

- Semester System Vs Annual System of Examination 388719454Document4 paginiSemester System Vs Annual System of Examination 388719454Muneer50% (4)

- E3sconf Apeem2020 05002Document6 paginiE3sconf Apeem2020 05002Rendy CangakÎncă nu există evaluări

- Project Proposal In-Service TrainingDocument10 paginiProject Proposal In-Service TrainingRosalina Cea100% (2)

- Lesson Plan: Outcomes From Alberta Program of StudiesDocument5 paginiLesson Plan: Outcomes From Alberta Program of Studiesapi-296555605Încă nu există evaluări

- Gr8 Probability HoltDocument4 paginiGr8 Probability Holtshemike_15gurlÎncă nu există evaluări

- Electrostatics PDFDocument53 paginiElectrostatics PDFMahi RamanÎncă nu există evaluări

- Final Las g8q2m4w5 6Document15 paginiFinal Las g8q2m4w5 6Y u c k.Încă nu există evaluări

- 2021 Life Skills ATP Grade 6Document10 pagini2021 Life Skills ATP Grade 6VIRGINIA0% (1)

- Form A (Eligibility Screening) 2021 PDFDocument3 paginiForm A (Eligibility Screening) 2021 PDFallysa almagroÎncă nu există evaluări