Documente Academic

Documente Profesional

Documente Cultură

Analysis and Design of A Continuous R. C. Raker Beam Using Eurocode 2

Încărcat de

Ubani Obinna RanksTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Analysis and Design of A Continuous R. C. Raker Beam Using Eurocode 2

Încărcat de

Ubani Obinna RanksDrepturi de autor:

Formate disponibile

Analysis and Design of Stadium Raker Beam Using EC2

Ubani Obinna U. (2016)

Analysis and Design of a Continuous Reinforced Concrete Raker

Beam for Stadium Using Eurocode 2

Ubani Obinna Uzodimma

Works/Engineering Services Department

Ritman University, PMB 1321, Ikot Ekpene, Akwa Ibom State

rankiesubani@gmail.com

Abstract

A continuous intermediate raker beam in the first tier of a football stadium was analysed using elastic

method and designed using Eurocode 2. The raker beam was analysed for permanent and variable

actions due to crowd load and permanent loads only. Due to its inclination, it was subjected to

significant bending, axial, and shear forces. However, design results show that the effect of axial

force was not very significant in the quantity of shear reinforcement required. Asv/Sv ratio of 1.175

(3Y10mm @ 200 c/c) was found to satisfy shear requirements. The greatest quantity of longitudinal

reinforcement was provided at the intermediate support with a reinforcement ratio of 1.3404%. The

provided reinforcement was found adequate to satisfy ultimate and serviceability requirements.

1.0 Introduction

The most common construction concept of sports stadiums today is a composite type where usually precast

concrete terrace units (seating decks) span between inclined (raker) steel or reinforced concrete beams and rest

on each other, thereby forming a grandstand (Karadelis, 2012). The raker beams are usually formed in-situ with

the columns of the structure, or sometimes may be preferably precast depending on site/construction constraints.

This arrangement usually forms the skeletal frame of a stadium structure.

In this paper, a raker beam isolated from a double tiered reinforced concrete grandstand that wraps around a

football pitch has been presented for the purpose of structural analysis and design. A repetitive pattern has been

adopted in the design which utilizes a construction joint of 25mm gap between different frame units. By

estimate, each frame unit is expected to carry a maximum of 3600 spectators, under full working conditions.

With ten different frames units, the stadium capacity is about 35000 after all other reservations have been taken

into account. Each grandstand frame has precast L-shaped seating terrace units that span in between reinforced

concrete raker beams inclined at angles between 20 - 22 with the horizontal. Crowd load and other loads are

transferred from the seating units to the raker beams, which then transfers them to the columns and then to the

foundations. Load from the service areas and concourse areas are also transferred using the same method.

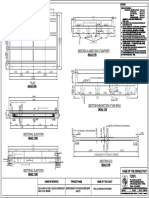

Figure 1.1: 3D skeletal structure of each grandstand frame units (slabs and sitting areas removed)

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 1

Analysis and Design of Stadium Raker Beam Using EC2

Ubani Obinna U. (2016)

The three dimensional view of the skeleton of the grandstand is shown in Figure 1.1, while a section

through the grandstand is shown if Figure 1.2. Section through the L-shaped seating unit is shown in

Figure 1.3.

Figure 1.2: Section through the grandstand

Figure 1.3: Section of the precast seating unit

In simple horizontal beams, vertical forces will produce vertical reactions only. However, once a beam is

statically indeterminate and inclined, vertical forces will produce both vertical and horizontal reactions and as a

result, axial forces which may be compressive or tensile in nature will be induced in the beam. In the design of

horizontal floor beams in normal framed structures, the effect of axial force in the shear force capacity of the

section is usually neglected. This is largely due to the fact that these forces are usually compressive, and in

effect tends to increase the concrete resistance shear stress (Vc) and (VRd,c) of the section in accordance with BS

8110-1:1997 and EC2 respectively. It is a well known phenomenon that compressive axial force increases the

concrete resistance shear stress of a section, while tensile axial force will reduce the concrete resistance shear

stress. So this neglect can be justified in terms of it being a conservative design which can only err in economy.

However for inclined beams members in a frame (as in the case of a grandstand), axial force behaviour can vary

greatly especially when the load is applied in the global direction (which is the prevalent scenario). In other

words, based on the structural configuration of the structure and the loading, it is even common to see the

nature of axial forces moving from positive (tensile) to negative (compressive) in the same span of an

inclined member. If the load is however resolved and applied in the local direction of the inclined member, the

axial forces will be absent. A good design will therefore require the use of less shear reinforcement in the axial

compression zone, and more shear reinforcement in the axial tension zone. While the effect of axial forces may

be neglected in horizontal floor beams under axial compression, it may be unsafe to neglect it in inclined beams

because more often than not, some sections are usually under axial tension.

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 2

Analysis and Design of Stadium Raker Beam Using EC2

Ubani Obinna U. (2016)

1.2 Materials, Model, and Loading

Structural design of stadiums is critical and this becomes more obvious when EN 1990 (Eurocode Basis for

Structural Design) classified it under Consequence Class 3 which by description means high consequence for

loss in terms of human life, economy, environmental considerations, and otherwise if failure should occur.

Several codes of practice across different countries and bodies have provisions made in them for the design of

structures subjected to crowd loading (for example stadiums), but the level of expertise often associated with the

processes in terms of analysis, design and construction is often perceived to be something left to a limited few.

The application of static crowd imposed loads according to both BS 6399-1:1997(Loading on buildings - Code

of practice for dead and imposed loads) and EN 1991-1: (Action on structures: General actions - Densities,

self-weight, imposed loads for buildings) are given in Table 1 below:

Table 1.1: Values of variable actions on grandstands from BS 6399 and EN 1991

CODE

BS 6399-1:1996

EN 1991-1-1

CATEGORY(DESCRIPTION)

C5 (Areas susceptible to

overcrowding e.g. grandstands)

C5( Areas susceptible to large

crowds, e.g

sports halls including stands)

IMPOSED

LOAD/VARIABLE

ACTION (KN/m2)

5

CONCENTRATED

LOAD (KN)

5.0 7.5 *

3.5 4.5*

3.6

*Exact range of value to be set by various national annex

Raker beams in stadiums usually support precast seating terrace units which may be L-shaped, or extended into

a more complex shape (see Figure 1.5). These seating terrace units are designed as simply supported elements

spanning between the raker beams (Karadelis, 2012, Salyards et al 2005). The crowd loading is supported

directly by these terrace units, which then transfer the load to the raker beams through the bearings. This

construction concept has been adopted in the design of Cape Town Stadium (South Africa) for the 2010 FIFA

world Cup (Plate 1.5). The picture in (Figure 1.4) below shows the formwork and construction of in-situ raker

beams at San Diego State University Student Activity Center (Steele and Larson 1996).

Figure 1.4: Typical formwork and

reinforcement for in-situ raker beam (Steele

Plate 1.5: Precast seating units being installed

on raker beams at Cape Town Stadium (2010)

and Larson 1996).

In this design, each L-shaped seating unit is 7m long, which means that the raker beams are spaced at 7m centre

to centre. The crowd loading is supported by the terrace seating units, which is then transferred to the raker

ibeams through the end shears. The raker beams can be analysed as sub-frames or as full 3D structures in order

to get the most realistic behaviour of the structure.

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 3

Analysis and Design of Stadium Raker Beam Using EC2

Ubani Obinna U. (2016)

1.2.1 Partial Factor for load

The partial factor for all permanent actions (dead load) Gk is 1.35 while the partial factor for all variable actions

(imposed load) Qk is 1.5. No reduction factor was applied in the analysis, and the effect of wind was neglected.

1.2.2 Material Properties for the design

Design compressive of concrete fck = 35 N/mm2

Yield strength of steel fyk = 460 N/mm2

Table 1.2: Values used in the computation of loading

Load

Density of concrete

Imposed load/variable action

Weight of finishes, rails, seats, stair units

Value

25 KN/m3

5 KN/m2

2 KN/m2

1.2.3 Concrete cover

Exposure class = XC1

A concrete cover of 40mm is adopted for the section

1.2.4 Design equations according EC2

From EC2 singly reinforced concrete stress block;

MRd = FCz ------------ (1)

FC =

0.85

1.5

0.8 ; z = d 0.4x -------------- (2)

Clause 5.6.3 of EC2 limits the depth of the neutral axis to 0.45d for concrete class less than or equal to C50/60.

Therefore for an under reinforced section (ductile);

x = 0.45d ----------------- (3)

Combining equation (1), (2) and (3), we obtain the ultimate moment of resistance (MRd)

MRd = 0.167 2 ---------------------- (4)

Also from the reinforced concrete stress block;

MEd = FSz ------------------ (5)

FS =

1.15

1 ------------------ (6)

Substituting equ (6) into (5) and making 1 the subject of the formular;

1 =

0.87

-------------------- (7)

The lever arm z in EC2 is given ;

z = d[0.5 + (0.25 0.882) ] ---------------------- (8)

where K =

---------------- (9)

1.2.4.1 For doubly reinforced sections;

Area of compression reinforcement AS2 =

Area of tension reinforcement 1 =

0.87 ( 2 )

0.87

----------------------- (10)

+ AS2 -------------------- (11)

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 4

Ubani Obinna U. (2016)

Analysis and Design of Stadium Raker Beam Using EC2

Where z = d[0.5 + (0.25 0.882 ) ] where K = 0.167

1.2.4.2 Check for deflection (Clause 7.4.2)

The limiting basic span/ effective depth ratio is given by;

L/d = K [11 + 1.5

L/d = K [11 + 1.5

+ 3.2 (

1)

( 0 )

12

1

2

3

2

] if 0 --------------------------- (12)

] if > 0 ---------------------- (13)

Where;

L/d is the limiting span/depth ratio

K = Factor to take into account different structural systems

0 = reference reinforcement ratio = 103

= Tension reinforcement ratio to resist moment due to design load

= Compression reinforcement ratio

1.2.4.3 Shear design

In EC2, the concrete resistance shear stress without shear reinforcement is given by;

1

VRd,c = [CRd,c.k. (1001 )3 + k1. ]bw.d (Vmin + k1. ) ----------------------- (14)

CRd,c = 0.18/ ; k = 1+

200

< 0.02 (d in mm); 1 =

< 0.02 (In which 1 is the area of tensile reinforcement

3

which extends ( + ) beyond the section considered; Vmin = 0.035 2 2

K1 = 0.15; = NEd/Ac < 0.2fcd (Where NEd is the axial force at the section, Ac = cross sectional area of the

concrete), fcd = design compressive strength of the concrete.

1.2.5 Load Analysis

1.2.5.1 Loading on precast seating unit

Permanent Actions

Self weight of the 7m precast seating deck (see Figure 1.4)

(GK1) = (25 0.25 0.15 7) + (25 0.95 0.15 7) = 31.5 KN

Weight of finishes, rails, seats (GK2) = (2 0.95 7) = 13.3 KN

Variable Actions

Imposed load for structural class C5 (QK) = (5 0.95 7) = 33.25 KN

Total action on L-shaped seating terrace unit at ultimate limit state by Eurocode 2

(FE) = 1.35(GKi) + 1.5QK = 1.35(44.8) + 1.5(33.25) = 110.355 KN

1.2.5.2 Loading on the raker beams

Height of beam = 1200mm

Width of beam = 400mm

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 5

Analysis and Design of Stadium Raker Beam Using EC2

Ubani Obinna U. (2016)

Self weight of raker beam

Concrete own weight (waist area) = 1.2m 0.4m 25 KN/m3 = 12.00 KN/m (normal to the inclination i.e. in

the local direction)

Height of riser in the raker beam = 0.4m; Width of tread in the raker beam = 0.8m; Angle of inclination () =

20.556

Stepped area (risers) = 12 0.4 25 = 5 KN/m (in the global direction)

For purely vertical load in the global y-direction, we convert the load from the waist of the beam by;

UDL from waist of the beam = (12.00 cos 20.556) = 11.236 KN/m

Total self weight (Gk) = 11.236 + 5 = 16.235 KN/m

Self weight of raker beam at ultimate limit state;

n = 1.35(GKi) = 1.35 16.235 = 21.917 KN/m

Load from precast seating units

End shear from precast seating unit = FE/2 = 110.355 = 55.1775 KN

Total number of the precast seating units on the beam = 24/0.8 = 30 units

For an intermediate beam supporting seating units on both sides;

Total number of precast seating units = 2 30 = 60 units

Therefore, total shear force transferred from the seating units to the raker beam = 55.1775 60 = 3310.65 KN

3310.65

Equivalent uniformly distributed load in the global direction at ultimate limit state =

= 137.94 KN/m

24

Total load on intermediate raker beams at ultimate limit state in the global direction = 137.94 + 21.917 =

159.857 KN/m

1.3 Structural Analysis

A full 3D elastic analysis of the whole stadium was performed using Staad Pro with all elements

loaded at ultimate limit state. Also, the raker beam is isolated as a subframe and also analysed. The

results from the two models are very comparable.

Figure 1.6: 3D Modelling of the grandstand on Staad Pro

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 6

Analysis and Design of Stadium Raker Beam Using EC2

Ubani Obinna U. (2016)

The internal stresses on the intermediate raker beams from the analysis of the frame at ultimate limit

state are shown in Figures 1.7 to 1.9.

Figure 1.7: Bending Moment Diagram

Figure 1.8: Shear Force Diagram

Figure 1.9: Axial Force Diagram

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 7

Analysis and Design of Stadium Raker Beam Using EC2

Ubani Obinna U. (2016)

1.3.1 Summary of Analysis Results

The summary of the analysis result of the raker beams is shown in Table 1.3.

Table 1.3: Analysis Results of the Raker Beam

Section

Moment

(KN.m)

1967.54

948.078

2283.18

1249.787

1565.63

MA

MABspan

MB

MBCspan

MC

Section

QAB

QBA

QBC

QCB

Shear Force

(KN)

934.62

983.88

999.52

918.98

Section

NAB

NBA

NBC

NCB

Axial Force

(KN)

380.061(C)

339.376(T)

510.767(C)

208.670(T)

1.4 Structural Design

The structural design of the of the raker beam using EN 1992-1-1has been carried out and all the

parameters used in the, and steps followed are shown below in the subsequent sections.

Design compressive of concrete fck = 35 N/mm2

Yield strength of steel fyk = 460 N/mm2

bw = 400mm; h = 1200mm; Cc = 40mm

1.4.1 Flexural Design of span AB (MABspan)

MABspan = 948.078 KNm

d = h Cc /2 link

d = 1200 40 16 10 = 1134mm

k=

948.078 106

= 35 400 11342 = 0.0527

2

Since k < 0.167 No compression reinforcement required

z = d[0.5 + (0.25 0.882) ] = z = d[0.5 + (0.25 0.882(0.0527) ] = 0.95d

1 =

0.87

948.078 106

= 0.87 460 0.95 1134 = 2199 mm2

Provide 5Y25mm BOT (ASprov = 2450 mm2)

To calculate the minimum area of steel required; (TABLE 3.1 EC2)

fctm = 0.3

ASmin = 0.26

2

3

fctm

Fyk

= 0.3 35

2

3

= 3.2099 N/mm2

bw d = 0.26

3.2099

460

400 1134 = 822.962 mm2

Check if ASmin < 0.0013 bw d (589.68 mm2)

Therefore, ASmin = 822.962 mm2

Check for deflection;

K = 1.5 for beam fixed at both ends

L/d = K [11 + 1.5

+ 3.2 (

1)

3

2

] if 0

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 8

Analysis and Design of Stadium Raker Beam Using EC2

L/d = K [11 + 1.5

=

2450

400 1134

500

310

278.241

( )

12

1

2

0.0059

0.0054

Modification factor =

=

] if > 0

= 0.00540 < 103 35

L/d = 1.5 [11 + 1.535

310

Ubani Obinna U. (2016)

+ 3.235 (

0.0059

0.0054

1)

3

2

] = 1.5(20.695 + 0.5333) = 31.842

310

310 500 2199

500 2450

= 278.241 N/mm2

=1.11

Since the span is greater than 7m, allowable span/depth ratio = 31.842

7000

12816

7000

= 1.11 31.842

= 19.374

Actual deflection L/d =

12816

1134

= 11.301

Since 11.301 < 19.374, deflection is ok.

1.4.2 Flexural Design of support A (MA);

MA = 1967.54 KNm

k = 0.1093; la = 0.8919; AS1 = 4861 mm2; ASmin = 822.9785 mm2

Provide 4Y32mm + 4Y25mm TOP (ASprov = 5180 mm2)

1.4.3 Flexural Design of support B (MB);

MA = 2283.18KNm

k = 0.1268; la = 0.8717; AS1 = 5772 mm2; ASmin = 822.9785 mm2

Provide 6Y32mm + 4Y20mm TOP (ASprov = 6080 mm2)

1.4.3 Flexural Design of span BC (MBCspan)

MBCSpan = 1249.787 kNm

k = 0.0694; la = 0.9345; AS1 = 2947mm2; ASmin = 822.9785 mm2

Provide 5Y25mm + 2Y20mm BOT (ASprov = 3083 mm2)

Check for deflection

=

3083

400 1134

= 0.00679 > 103 35

L/d = K [11 + 1.5

L/d = 1.5 [11 + 1.535

500

( )

12

0.0059

0.00679 0

Modification factor =

310

1

2

] if > 0

+ 0] = 28.066

310

310 500 2974

500 3083

= 299.039 N/mm2

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 9

Analysis and Design of Stadium Raker Beam Using EC2

=

310

299.039

Ubani Obinna U. (2016)

= 1.0366

Since the span is greater than 7m, allowable span/depth ratio = 28.066

7000

12816

28.066

7000

= 1.0366

= 15.89

Actual deflection L/d =

12816

1134

= 11.301

Since 11.301 < 15.89, deflection is ok.

1.4.4 Flexural Design of support C (MC);

MC = 1565.63 KNm

k = 0.0870; la = 0.9163; AS1 = 3765 mm2; ASmin = 822.9785 mm2

Provide 5Y32mm TOP (ASprov = 4020 mm2)

Provide Y16 @ 200mm c/c on both faces as longitudinal side bars

1.4.5 Shear Design

1.4.5.1 Support A

VEd = 934.62 KN; N = 380.061 KN (Compression)

Taking shear at the centreline of support; VEd = 934.62 KN

1

VRd,c = [CRd,c.k. (1001 )3 + k1. ]bw.d (Vmin + k1. ) bw.d

CRd,c = 0.18/ = 0.18/1.5 = 0.12

k = 1+

200

= 1+

200

1134

3

2

= 1.4199 < 2.0

1

2

Vmin = 0.035 = Vmin = 0.035 (1.4199)2 (35)2 = 0.3504 N/mm2

1 =

5180

400 1134

= 0.011419 < 0.02; K1 = 0.15

= NEd/Ac < 0.2fcd (Where NEd is the axial force at the section, Ac = cross sectional area of the concrete),

fcd = design compressive strength of the concrete.)

=

380.061 103

400 1200

= 0.7917 N/mm2

1

VRd,c = [0.12 1.4199 (100 0.011419 35 )3 + 0.15 0.7917 ]400 1134 = 318111.948 N = 318.11 KN

Since VRd,c < VEd, shear reinforcement is required.

Assume strut angle = 21.8

Let us now investigate the compression capacity of the strut;

v1 = 0.6(1

fcd =

VRd,max =

250

) = 0.6(1

35

250

) = 0.516

Taking = 0.85; fcd =

0.85 35

1.5

= 19.833 N/mm2; z = 0.9d

1

400 0.9 1134 0.516 19.833

= [

] 103 = 1440.64 KN > VEd

(cot 21.8 + tan 21.8)

( + tan )

Since VEd < VRd,max

VEd,s =

cot = 934620 N

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 10

Analysis and Design of Stadium Raker Beam Using EC2

934620

(0.9 1134 0.87 460 cot 21.8)

Ubani Obinna U. (2016)

= 0.9153

Trying 3Y10mm @ 200mm c/c (235/200 = 1.175)

1.175 > 0.9153 Hence shear reinforcement is ok.

Following the steps described above;

1.4.5.2 Support B; Shear at VBA

VEd = 983.88 KN; N = KN 339.376 (Tension)

Note that due to the tensile axial force in the section, the second term of VRd equation assumes a negative value.

1 = 0.0134; = 0.7070 N/mm2; vmin = 0.3504 N/mm2; VRd = 230.6532 KN

Since VRd,c < VEd, shear reinforcement is required

Assuming that the strut angle = 21.8

v1 = 0.5160; fcd = 19.8450 N/mm2; z = 0.9d = 1020.6 mm; VRDmax =1440.64 KN

Since VRDmax > VEd

= 0.9635

Trying 3Y10mm @ 200mm c/c (235/200 = 1.175)

1.175 > 0.9153 Hence shear reinforcement is ok.

1.4.5.3 Support B; Shear at VBC

VEd = 999.52 KN; N = KN 510.767 (Compression)

Note that due to the tensile axial force in the section, the second term of V Rd equation assumes a negative value.

1 = 0.0134; = 1.0641 N/mm2; vmin = 0.3504 N/mm2; VRd = 351.161 KN

Since VRd,c < VEd, shear reinforcement is required

Assuming that the strut angle = 21.8

v1 = 0.5160; fcd = 19.8450 N/mm2; z = 0.9d = 1020.6 mm; VRDmax =1440.64 KN

Since VRDmax > VEd

= 0.9789

Trying 3Y10mm @ 200mm c/c (235/200 = 1.175)

1.175 > 0.9153 Hence shear reinforcement is ok.

1.4.5.4 Support C; Shear at VCB

VEd = 918.98 KN; N = KN 208.670 (Tension)

Note that due to the tensile axial force in the section, the second term of VRd equation assumes a negative value.

1 = 0.0089; = 0.4347 N/mm2; vmin = 0.3504 N/mm2; VRd = 213.2707 KN

Since VRd,c < VEd, shear reinforcement is required

Assuming that the strut angle = 21.8

v1 = 0.5160; fcd = 19.8450 N/mm2; z = 0.9d = 1020.6 mm; VRDmax =1440.64 KN

Since VRDmax > VEd

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 11

Analysis and Design of Stadium Raker Beam Using EC2

Ubani Obinna U. (2016)

= 0.9000

Trying 3Y10mm @ 200mm c/c (235/200 = 1.175)

1.175 > 0.9153 Hence shear reinforcement is ok.

1.5 Discussion and Conclusion

It is very easy to see that the influence of axial force was not very pronounced in the results produced. It would

have been very significant using BS 8110. The maximum reinforcement was seen at support B due the high

magnitude of moment at that section. This phenomenon is consistent with horizontal continuous beams. See

detailing sketches in Figure 2.0.

Figure 2.0: Reinforcement detailing sketches (not to scale)

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 12

Analysis and Design of Stadium Raker Beam Using EC2

Ubani Obinna U. (2016)

References

[1] BS 6399 part 1: 1996: Loading for Building code of practice for dead and imposed loads.

British Standards Institution.

[2] BS 8110 1:1997: Structural use of concrete Part1: Code of practice for design and

construction. British Standard Institutions.

[3] EN 1991-1-1 (2002): General Actions- Densities, self weight, imposed loads for buildings

[4] EN 1992-1-1 (2004): Design of concrete structures: General Rules and rules for building

[5] Jeff Steele, Mark Larsen (1996): Raker-Beam Construction Requires Rugged Steel Forms.

Publication #C960738 The Aberdeen Group

[6] Karadelis J (2009): Concrete Grandstands. Part 1: Experimental investigations. Proceedings

to the Institution of Civil Engineers Engineering and Computational mechanics. Volume

162,Issue 1 ISSN 1755-0777

[7] Salyards K.A., Honagan L.M (2005): Evaluation of a finite element model for dynamic

characteristic prediction of stadium facility.

Downloaded from www.structville.blogspot.com

Ranks Michael Enterprises (2016) Page 13

S-ar putea să vă placă și

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDe la EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionÎncă nu există evaluări

- Bridge Design - Precast Concrete Bridge Beam Design To BS 5400Document16 paginiBridge Design - Precast Concrete Bridge Beam Design To BS 5400Lavanyan Satchithananthan100% (2)

- Basement Wall DesignDocument2 paginiBasement Wall DesignArindam RoyÎncă nu există evaluări

- Beams With Variable DepthDocument22 paginiBeams With Variable DepthNima Soufiani100% (1)

- Combined Footing Design PDFDocument2 paginiCombined Footing Design PDFRenee100% (1)

- Design of Cable Stayed Truss Chonju WC Stadium JongDocument22 paginiDesign of Cable Stayed Truss Chonju WC Stadium Jongnarens_skÎncă nu există evaluări

- Paper On Floating ColumnDocument8 paginiPaper On Floating Columnমোঃ হাসান ইমামÎncă nu există evaluări

- Waffle SlabDocument2 paginiWaffle SlabKasun Geenath Vithanage100% (1)

- Class A Loads Govt. of West Pakistan - Code of Practice Highway BridgesDocument1 paginăClass A Loads Govt. of West Pakistan - Code of Practice Highway BridgesBunkun150% (1)

- Construction Stage Analysis Reflecting Long-Term DeformationDocument18 paginiConstruction Stage Analysis Reflecting Long-Term DeformationAshish LoyaÎncă nu există evaluări

- Analytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Document15 paginiAnalytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Phan Đào Hoàng Hiệp100% (1)

- Master Series Design NotesDocument11 paginiMaster Series Design NotesGE MutaiÎncă nu există evaluări

- Sway Frame Steel Column DesignDocument1 paginăSway Frame Steel Column DesignChirianu MarianÎncă nu există evaluări

- 1 Lecture 17 - Steel-Concrete Composite Construction - 2sppDocument17 pagini1 Lecture 17 - Steel-Concrete Composite Construction - 2sppCezar Pantelemon100% (3)

- Analysis and Design of Post Tension Slab Using ETABS SoftwareDocument5 paginiAnalysis and Design of Post Tension Slab Using ETABS SoftwareInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- 3) T-BeamsDocument4 pagini3) T-BeamsVanessa Rosal PalerÎncă nu există evaluări

- Learn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareDocument108 paginiLearn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareRahul Kumar100% (2)

- Chapter 9 Pump SelectionDocument40 paginiChapter 9 Pump SelectionDuke ThibbotuwawaÎncă nu există evaluări

- Slab Designer As Per IS 456-2000Document7 paginiSlab Designer As Per IS 456-2000mofizahmed64% (11)

- 3 Lateral Load Resisting System FDocument33 pagini3 Lateral Load Resisting System FReffisa Jiru100% (2)

- Cantilever SlabDocument16 paginiCantilever SlabMukhlish AkhatarÎncă nu există evaluări

- ETABS Building Structure Analysis and Design ReportDocument42 paginiETABS Building Structure Analysis and Design ReportRoshan89% (9)

- Ware House DesignDocument8 paginiWare House DesignJay-Jay JapsÎncă nu există evaluări

- RCC Question BankDocument2 paginiRCC Question Banknambiyanna1100% (1)

- Design of Steel StructureDocument16 paginiDesign of Steel Structuresuraj kumarÎncă nu există evaluări

- Unit 5 DESIGN OF FLANGED BEAM T BEAMDocument41 paginiUnit 5 DESIGN OF FLANGED BEAM T BEAMIan JamillaÎncă nu există evaluări

- Wind Load Calculation As Per IS 875 Part 3-2015 ProblemDocument9 paginiWind Load Calculation As Per IS 875 Part 3-2015 ProblemMahamadali DesaiÎncă nu există evaluări

- Chapter 2 Beams Curved in Plan FinalDocument12 paginiChapter 2 Beams Curved in Plan Finalyosef gemessa100% (1)

- VI Semester Design of Steel and Timber StructureDocument5 paginiVI Semester Design of Steel and Timber Structuredinesh100% (1)

- RC-I Chapter 2 PDFDocument36 paginiRC-I Chapter 2 PDFWendimu TolessaÎncă nu există evaluări

- Column Design Design of Short Braced ColumnsDocument17 paginiColumn Design Design of Short Braced ColumnsPimpa MwiingaÎncă nu există evaluări

- Ultimate Limit State Design of Spread Foundations in The Case of UpliftDocument7 paginiUltimate Limit State Design of Spread Foundations in The Case of UpliftAndoÎncă nu există evaluări

- Vertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisDocument10 paginiVertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisNeven Ahmed HassanÎncă nu există evaluări

- Structure Engineer CertificateDocument1 paginăStructure Engineer CertificateSantosh100% (2)

- Analysis and Design of Shear WallsDocument24 paginiAnalysis and Design of Shear WallsRkkodi100% (3)

- Learn Flat Slab-Flat Slab Analysis Design and Drawing SoftwareDocument137 paginiLearn Flat Slab-Flat Slab Analysis Design and Drawing SoftwareWanda BeasleyÎncă nu există evaluări

- RCD Course Work PDFDocument60 paginiRCD Course Work PDFSaciid LaafaÎncă nu există evaluări

- Design Drawing of Reinforced Concrete StructuresDocument6 paginiDesign Drawing of Reinforced Concrete StructuresRahul RamchandaniÎncă nu există evaluări

- Technical Report - STEEL - FRAMED BUILDING - Seismic - AnalysisDocument6 paginiTechnical Report - STEEL - FRAMED BUILDING - Seismic - AnalysisAdnan NajemÎncă nu există evaluări

- Fence Type-3: Design Calculation Sheet HYD-121 FenceDocument18 paginiFence Type-3: Design Calculation Sheet HYD-121 FenceAbhilash KowndinyaÎncă nu există evaluări

- All Plug-Ins of Arc BdsDocument48 paginiAll Plug-Ins of Arc BdsAshish LoyaÎncă nu există evaluări

- BD3701 - Part1Document10 paginiBD3701 - Part1Fadhli ATZÎncă nu există evaluări

- Crack Width ConcreteDocument1 paginăCrack Width ConcreteRuemu Godwin InikoriÎncă nu există evaluări

- Design of Isolated MatDocument5 paginiDesign of Isolated MatYAROFEÎncă nu există evaluări

- Two Pile GroupDocument12 paginiTwo Pile GroupJammy KingÎncă nu există evaluări

- Strengthening Design of Concrete Beams by Adition of Steel PlatesDocument10 paginiStrengthening Design of Concrete Beams by Adition of Steel PlatesgparratÎncă nu există evaluări

- (LECT-21,22) Prestressed Concrete SlabsDocument22 pagini(LECT-21,22) Prestressed Concrete SlabsSushil MundelÎncă nu există evaluări

- Analysis of Ribbed SlabDocument12 paginiAnalysis of Ribbed Slabmickymat100% (1)

- IAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanDocument29 paginiIAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanSrikanth ReddyÎncă nu există evaluări

- Column Design - As Per BS CodeDocument16 paginiColumn Design - As Per BS CodeYam BalaoingÎncă nu există evaluări

- Verification Manual British CodesDocument32 paginiVerification Manual British CodeshutuguoÎncă nu există evaluări

- Standard Lighting Column FoundationsDocument2 paginiStandard Lighting Column FoundationsEm MarÎncă nu există evaluări

- Chapter-1 Lateral Loads On The StructureDocument67 paginiChapter-1 Lateral Loads On The Structurebereket100% (1)

- Analysis and Design of A Continuous R C Raker Beam Using Eurocode 2Document13 paginiAnalysis and Design of A Continuous R C Raker Beam Using Eurocode 2Eva MarquezÎncă nu există evaluări

- Analysis and Design of A Continuous Reinforced Concrete Raker Beam For Stad PDFDocument13 paginiAnalysis and Design of A Continuous Reinforced Concrete Raker Beam For Stad PDFBogdan Constantin-BabiiÎncă nu există evaluări

- Analysis and Design of A Continuous Reinforced Concrete Raker Beam For StadDocument13 paginiAnalysis and Design of A Continuous Reinforced Concrete Raker Beam For StadHusam MorshedÎncă nu există evaluări

- Analysis and Design of A Continuous R C Raker Beam Using Eurocode 2 PDFDocument13 paginiAnalysis and Design of A Continuous R C Raker Beam Using Eurocode 2 PDFMukhtaar CaseÎncă nu există evaluări

- Chapter 1 and Chapter 2Document12 paginiChapter 1 and Chapter 2Tan Mei QianÎncă nu există evaluări

- Https WWW - Sefindia.org Q System Files Confinement+Reinforcement+for+Columns-ICJ Aug+11Document9 paginiHttps WWW - Sefindia.org Q System Files Confinement+Reinforcement+for+Columns-ICJ Aug+11Igor GjorgjievÎncă nu există evaluări

- Spiral StaircaseDocument48 paginiSpiral StaircaseUbani Obinna RanksÎncă nu există evaluări

- Example On The Analysis of Internal Stresses in Frames Due To Temperature Difference Using Force MethodDocument5 paginiExample On The Analysis of Internal Stresses in Frames Due To Temperature Difference Using Force MethodUbani Obinna Ranks100% (1)

- Model Development and Loads Analysis of An Offshore Wind Turbine On A Tension Leg Platform, With A Comparison To Other Floating Turbine ConceptsDocument129 paginiModel Development and Loads Analysis of An Offshore Wind Turbine On A Tension Leg Platform, With A Comparison To Other Floating Turbine ConceptsUbani Obinna RanksÎncă nu există evaluări

- Design of Continuous Beam and Slab Footing Using BS 8110-1:1997Document8 paginiDesign of Continuous Beam and Slab Footing Using BS 8110-1:1997Ubani Obinna Ranks80% (5)

- 20.0 M Span & 12.00 M Clear Carriageway High Level Bridge Shruti-Layout2Document1 pagină20.0 M Span & 12.00 M Clear Carriageway High Level Bridge Shruti-Layout2samir bendreÎncă nu există evaluări

- Design and Construction of Skyscraper: Fig 1. Burj KhalifaDocument19 paginiDesign and Construction of Skyscraper: Fig 1. Burj Khalifaವಿನಯ್ ಎಮ್. ಆರ್100% (1)

- Concrete Footing Schedule: Isolated Footing Detail Cantilever Footing Detail Wall Footing DetailDocument1 paginăConcrete Footing Schedule: Isolated Footing Detail Cantilever Footing Detail Wall Footing DetailJehrome CruzÎncă nu există evaluări

- ICSMSB-Modelling and Analysis of A Post-Tensioned Straddle Bent Integral With A Multi-Span Light Rail Bridge SuperstructureDocument10 paginiICSMSB-Modelling and Analysis of A Post-Tensioned Straddle Bent Integral With A Multi-Span Light Rail Bridge SuperstructureAshton MartynÎncă nu există evaluări

- Building Construction Part-3Document106 paginiBuilding Construction Part-3toma cristian100% (3)

- Method Statement: Loading / Offloading Stations and Metering Skids Installation at Tank Battery / Guebiba Base & TrapsaDocument13 paginiMethod Statement: Loading / Offloading Stations and Metering Skids Installation at Tank Battery / Guebiba Base & TrapsaAkram FerchichiÎncă nu există evaluări

- LB F Corrosion Design For DurabilityDocument75 paginiLB F Corrosion Design For DurabilityDerogene LaforceÎncă nu există evaluări

- Bca Fsor (2017Q2)Document34 paginiBca Fsor (2017Q2)KaWei100% (1)

- Wind 4 PDF Free PDFDocument139 paginiWind 4 PDF Free PDFCalvin TehÎncă nu există evaluări

- Punching Shear Design BS8110Document10 paginiPunching Shear Design BS811098675Încă nu există evaluări

- Unit 6 (Design & Detailing of Beams)Document32 paginiUnit 6 (Design & Detailing of Beams)prabhu81100% (1)

- Problem 001-Ms - Method of Sections - Engineering Mechanics ReviewDocument5 paginiProblem 001-Ms - Method of Sections - Engineering Mechanics ReviewELMERÎncă nu există evaluări

- Introduction To Structural TheoryDocument13 paginiIntroduction To Structural TheoryChezter ClaveroÎncă nu există evaluări

- Mando 00Document59 paginiMando 00Zelalem TeshomeÎncă nu există evaluări

- Stairs Supported at The Ends of Landings: Detail 'X'Document1 paginăStairs Supported at The Ends of Landings: Detail 'X'Anuja JadhavÎncă nu există evaluări

- Poles+ (Steel) +specification+ +NNSWDocument33 paginiPoles+ (Steel) +specification+ +NNSWcabelmarÎncă nu există evaluări

- Enclosure Mansonry Wall Systems WorldwideDocument229 paginiEnclosure Mansonry Wall Systems Worldwidexxxxx8086Încă nu există evaluări

- 02 Lifting Sockets LRDocument21 pagini02 Lifting Sockets LRHanuman Builders100% (1)

- D2 1 CLASS WP2 SOTA Permeable Pavement Systems and MaterialsDocument96 paginiD2 1 CLASS WP2 SOTA Permeable Pavement Systems and MaterialsAnirudh AgarwallaÎncă nu există evaluări

- Revise Estimate of Subhash UdyanDocument44 paginiRevise Estimate of Subhash UdyanMukesh JangidÎncă nu există evaluări

- Design Base Plate For I Beam - Bottom BracketDocument1 paginăDesign Base Plate For I Beam - Bottom BracketCon CanÎncă nu există evaluări

- Deformations of Reinforced Concrete Members at Yielding and UltimateDocument84 paginiDeformations of Reinforced Concrete Members at Yielding and Ultimateazita1380Încă nu există evaluări

- CulvertsDocument18 paginiCulvertsAmmar A. Ali100% (1)

- Segmenal BridgesDocument5 paginiSegmenal BridgesManikanta SharmaÎncă nu există evaluări

- Bubble Deck Concrete SlabDocument14 paginiBubble Deck Concrete SlabSumit Omar100% (2)

- Orion Flat Slab Design TrainingDocument134 paginiOrion Flat Slab Design TrainingAdigwe George Chima100% (4)

- Membrane Structure and Cable Structures: Subject: Advanced Construction and MaterialsDocument43 paginiMembrane Structure and Cable Structures: Subject: Advanced Construction and MaterialsMohhamad YasinÎncă nu există evaluări

- Arc 313 Notes 1Document21 paginiArc 313 Notes 1ANSLEM ALBERTÎncă nu există evaluări

- Estimated Cost of Different Types of Bridge Structure Per Linear MeterDocument6 paginiEstimated Cost of Different Types of Bridge Structure Per Linear MeterKm TrinidadÎncă nu există evaluări

- HARDY FRAME Retrofit - GuideDocument12 paginiHARDY FRAME Retrofit - GuideThiri AungÎncă nu există evaluări

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDe la EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresEvaluare: 1 din 5 stele1/5 (2)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDe la EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsEvaluare: 4 din 5 stele4/5 (16)

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (138)

- Structural Cross Sections: Analysis and DesignDe la EverandStructural Cross Sections: Analysis and DesignEvaluare: 4.5 din 5 stele4.5/5 (19)

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsDe la EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsEvaluare: 5 din 5 stele5/5 (3)

- Piping Engineering Leadership for Process Plant ProjectsDe la EverandPiping Engineering Leadership for Process Plant ProjectsEvaluare: 5 din 5 stele5/5 (1)

- Net Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and ImplementationDe la EverandNet Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and ImplementationEvaluare: 5 din 5 stele5/5 (1)

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesDe la EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesEvaluare: 4.5 din 5 stele4.5/5 (13)

- Advanced Modelling Techniques in Structural DesignDe la EverandAdvanced Modelling Techniques in Structural DesignEvaluare: 5 din 5 stele5/5 (3)

- Wind Effects on Structures: Modern Structural Design for WindDe la EverandWind Effects on Structures: Modern Structural Design for WindÎncă nu există evaluări

- Marine Structural Design CalculationsDe la EverandMarine Structural Design CalculationsEvaluare: 4.5 din 5 stele4.5/5 (13)

- Non-destructive Testing and Evaluation of Civil Engineering StructuresDe la EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÎncă nu există evaluări

- Mechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsDe la EverandMechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsÎncă nu există evaluări

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDe la EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Earthquake-Resistant Structures: Design, Build, and RetrofitDe la EverandEarthquake-Resistant Structures: Design, Build, and RetrofitEvaluare: 4.5 din 5 stele4.5/5 (8)

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDe la EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsÎncă nu există evaluări

- Predicting Lifetime for Concrete StructureDe la EverandPredicting Lifetime for Concrete StructureÎncă nu există evaluări

- Super Structures: The Science of Bridges, Buildings, Dams, and Other Feats of EngineeringDe la EverandSuper Structures: The Science of Bridges, Buildings, Dams, and Other Feats of EngineeringEvaluare: 4 din 5 stele4/5 (1)