Documente Academic

Documente Profesional

Documente Cultură

Data Sheet

Încărcat de

mkfe2005Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Data Sheet

Încărcat de

mkfe2005Drepturi de autor:

Formate disponibile

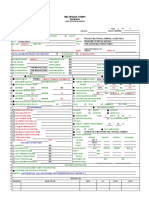

JOB NO.

ITEM NO.

PURCHASE ORDER NO.

SPECIFICATION NO.

CENTRIFUGAL COMPRESSOR

DATA SHEET (API 617-6TH)

SI UNITS

1 APPLICABLE TO:

PROPOSAL

REVISION NO.

PAGE

PURCHASE

00

1

Gazpromneft

UNIT

3 SITE

OMSK

SERIAL NO.

4 SERVICE

Nitrogen

CONTINUOUS

INTERMITTENT

KSTC

MODEL

6 MANUFACTURER

7 NOTE:

NO. REQUIRED

INFORMATION TO BE COMPLETED:

BY

MB

AS BUILT

2 FOR

5/1/2016

DATE

OF

STAND BY

DRIVER TYPE (3.1.1) ELECTRICAL MOTOR

KSTC-140

DRIVER ITEM NO.

BY PURCHASER

BY MANUFACTURER

OPERATING CONDITIONS

OTHER CONDITIONS (3.1.2)

9

(ALL DATA ON PER UNIT BASIS)

10

11

NORMAL

12

3 )

13

GAS HANDLED (ALSO SEE PAGE

14

m/h (1.013 BAR & 0 C DRY)

15

WEIGHT FLOW, kg/h (DRY)

16

INLET CONDITIONS

17

PRESSURE (BAR) (kPa abs)

7.9

18

TEMPERATURE (C)

46

19

RELATIVE HUMIDITY %

20

MOLECULAR WEIGHT (%)

28.02

21

Cp/Cv ( K1) OR (KAVG)

1.398

22

COMPRESSIBILITY (Z1) OR (ZAVG)

0.996

23

INLET VOLUME, (m/h) (WET / DRY)

775

24

DISCHARGE CONDITIONS

25

PRESSURE (BAR) (kPa abs)

26

TEMPERATURE (C)

27

Cp/Cv (K2) OR (KAVG) NOTE 1

1.398

28

COMPRESSIBILITY (Z1) OR (ZAVG) NOTE 1

0.995

6526

9.237

70

29

30

kW REQUIRED (ALL LOSSES INCLUDED)

31

SPEED (RPM)

32

ESTIMATED SURGE, m/h (AT SPEED ABOVE)

33

POLYTROPIC HEAD (N-m/kg)

34

POLYTROPIC EFFICIENCY (%)

35

CERTIFIED POINT

36

PERFORMANCE CURVE NUMBER

37

PROCESS CONTROL

38

METHOD

70

28250

320

16200

53

*

VARIABLE INLET

SPEED VARIATION

DISCHARGE

COOLED BYPASS

39

FROM

SUCTION THROTTLING

(BAR)(kPa abs)

GUIDE VANES

FROM

BLOWOFF

FROM

40

TO

(BAR)(kPa abs)

(3.4.2.4)

TO

TO

TO

41

42

SIGNAL

SOURCE ( 3.4.2.1)

43

TYPE

44

RANGE

ELECTRONIC

MA

PNEUMATIC

OTHER

(BAR)(kPa abs)

45

46

ANTI-SURGE BYPASS

MANUAL

AUTOMATIC

NONE

47

48 REMARKS:

49

50 NOTE 1: IF GAS ANALYSIS IS GIVEN, MANUFACTURER SHALL SUPPLY DATA, OTHERWISE DATA SHALL BE SUPPLIED BY USER.

JOB NO.

CENTRIFUGAL COMPRESSOR

DATA SHEET (API 617-6TH)

SI UNITS

PAGE

00

2

OF

BY

0

5/1/2016

DATE

MB

OPERATING CONDITIONS (Continued) (3.1.2) (3.1.3)

OTHER CONDITIONS

2 GAS ANALYSIS:

3

ITEM NO.

REVISION NO.

(2.11.1.3)

Normal

MOL %

REMARKS:

(2.11.1.8)

MW

5 AIR

28.966

6 OXYGEN

32.000

7 NITROGEN

28.016

8 WATER VAPOR

18.016

9 CARBON MONOXIDE

100

28.010

10 CARBON DIOXIDE

44.010

11 HYDROGEN SULFIDE

34.076

12 HYDROGEN

2.016

13 METHANE

16.042

14 ETHYLENE

28.052

15 ETHANE

30.068

16 PROPYLENE

42.078

17 PROPANE

44.094

18 I-BUTANE

58.120

19 n-BUTANE

58.120

20 I-PENTANE

72.146

21 n-PENTANE

72.146

22 HEXANE PLUS

23 1-BUTENE

24

25 TOTAL

100

26 AVG. MOL. WT.

27 LOCATION:

28

28.02

(2.1.9)

INDOOR

NOISE SPECIFICATIONS: (2.1.10)

OUTDOOR

GRADE

29

HEATED

UNDER ROOF

30

UNHEATED

PARTIAL SIDES

31

ELEC. AREA CLASSIFICATION (2.1.15)

32

WINTERIZATION REQ'D. (2.1.9)

ELEVATION

35

RANGE OF AMBIENT TEMPS:

36

CL 2

BAROMETER

NORMAL

38

MAXIMUM

<=85 dBA @ 1.0 m

GR IIB DIV T3

BAR

SEE SPECIFICATION

ACOUSTIC HOUSING:

YES

NO

APPLICABLE SPECIFICATIONS:

API 617, CENTRIFUGAL COMPR. FOR GEN. REFINERY SERV.

VENDOR HAVING UNIT RESPONSIBILITY (2.9.1.7)

DRY BULB

37

SEE SPECIFICATION

APPLICABLE TO NEIGHBORHOOD:

TROPICALIZATION REQ'D.

(3.4.6.6)

33 SITE DATA:

34

APPLICABLE TO MACHINE:

MEZZANINE

WET BULB

40

compressor vendor

GOVERING SPECIFICATION (IF DIFFERENT)

39

40

MINIMUM

-37

41

Design

46

42 UNUSUAL CONDITIONS:

43

PAINTING:

MANUFACTURER'S STD.

DUST

FUMES

OTHER

OTHER (2.1.9)

44

45

SHIPMENT:

(4.4.1)

DOMESTIC

EXPORT

EXPORT BOXING REQ'D.

46

47 REMARKS:

OUTDOOR STORAGE MORE THAN 6 MONTHS (4.4.1)

48

SPARE ROTOR ASSEMBLY PACKAGED FOR (4.4.3.10)

49

50

HORIZONTAL STORAGE

VERTICAL STORAGE

JOB NO.

CENTRIFUGAL COMPRESSOR

DATA SHEET (API 617-6TH)

SI UNITS

ITEM NO.

REVISION NO.

PAGE

00

OF

BY

0

5/1/2016

DATE

MB

CONSTRUCTION FEATURES

1

2

SPEEDS:

MAX. CONT.

TYPE (OPEN, ENCLOSED, ETC.)

MAX. TIP SPEEDS:

28250

RPM

200

TRIP

RPM

OPEN

TYPE FABRICATION

MACHINED

m/s @ 100% SPEED

MATERIAL

STAINLESS STEEL 17-4PH

m/s @ MAX. CONT. SPEED

MIN. YIELD STRENGTH (N)

LATERAL CRITICAL SPEEDS (DAMPED)

FIRST CRITICAL

10700

RPM

MODE

SMALLEST TIP INTERNAL WIDTH (mm)

SECOND CRITICAL

22320

RPM

MODE

MAX. MACH. NO. @ IMPELLER EYE

THIRD CRITICAL

RPM

MODE

MAX. IMPELLER HEAD @ 100% SPD (N-m/kg)

10

FOURTH CRITICAL

RPM

MODE

SHAFT:

11

TRAIN LATERAL ANALYSIS REQUIRED (2.9.2.3)

MATERIAL

12

TRAIN TORSIONAL ANALYSIS REQUIRED

DIA @ IMPELLERS (mm)

13

BRINNEL HARDNESS:

850 Mpa

(TURBINE DRIVEN TRAIN) (2.9.4.5)

MAX

28-37 HCR

STEEL AISI 4140

SHAFT END:

25.4

DIA @ COUPLING (mm)

TAPERED

TORSIONAL CRITICAL SPEEDS:

MIN. YIELD STRENGTH (N)

1030 Mpa

15

FIRST CRITICAL

3570

RPM

SHAFT HARDNESS (BNH)(Rc)

32 HRC

16

SECOND CRITICAL

17687

RPM

MAX TORQUE CAPABILITY (N-m)

17

THIRD CRITICAL

21530

RPM

BALANCE PISTON:

18

FOURTH CRITICAL

RPM

MATERIAL

19

VIBRATION:

20

ALLOWABLE TEST LEVEL

21

(PEAK TO PEAK)

22

ROTATION, VIEWED FROM DISCH. END

23

MATERIALS INSPECTION REQUIREMENTS (4.2.2)

35

CW

CCW

MATL

Not Applicable

AT SHAFT SEALS

MATL

SS 316

ACCESSILBLE (2.8.2)

RADIOGRAPHY REQUIRED FOR

LABYRINTHS:

ULTRASONIC REQUIRED FOR

INTERSTAGE

27

MAGNETIC PARTICLE REQUIRED FOR

28

LIQUID PENETRANT REQUIRED FOR

NOT APPLICABLE

TYPE

MATERIAL

BALANCE PISTON

IMPELLER

29

CASING:

30

MODEL

31

CASING SPLIT

32

MATERIAL

33

THICKNESS (mm)

34

MAX. WORKING PRESS

10

(BARG)(kPaG)

35

MAX DESIGN PRESS

40

(BARG)(kPaG)

36

TEST PRESS (BARG)(kPaG):

37

MAX OPER. TEMP.

38

MAX NO. OF IMPELLERS FOR CASING

39

MAX CASING CAPACITY (m/h)

40

CASING SPLIT SEALING (2.2.10)

41

SYSTEM RELIEF VALVE SET PT. (2.2.4)

42

DIAPHRAGMS:

TYPE

MATERIAL

SHAFT SEALS:

RADIAL

SEAL TYPE (2.8.3)

CARBON STEEL A216 WCB

MATERIAL

130

HELIUM

C

DRY GAS SEAL

SETTLING OUT PRESSURE (BARG)(kPaG)

19.05min CORR. ALLOW. (mm)

3.2

HYDRO

MIN. OPER. TEMP.

-5

SPECIAL OPERATION (2.8.1)

SUPPLEMENTAL DEVICE REQUIRED FOR CONTACT

SEALS (2.8.3.2)

TYPE

60

BUFFER GAS SYSTEM REQUIRED (2.8.7)

TYPE BUFFER GAS

MANIFOLD (3.5.1.6)

Nitrogen

BUFFER GAS CONTROL SYSTEM SCHEMATIC BY VENDOR

1500

PRESSURIZING GAS FOR SUBATMOSPHERIC SEALS (2.8.8)

radial "O" RING

TYPE SEAL

(BARG)(kPaG)

TANDEM GAS " LP"

INNER OIL LEAKAGE GUAR.

/DAY/SEAL)

BUFFER GAS REQUIRED FOR:

NOT APPLICABLE

AIR RUN-IN

IMPELLERS:

OTHER

BUFFER GAS FLOW (PER SEAL):

45

NO.

46

NO. VANES EA. IMPELLER

DIAMETERS

145

NORM:

kg/MIN @

(BAR)(kPa)

18

MAX.

kg/MIN @

(BAR)(kPa)

BEARING HOUSING CONSTRUCTION:

48 NOTE 1:

TYPE (SEPARATE, INTEGRAL)

49

MATERIAL

50

REFER ON GEARBOX CONSTRUCTION

51

(mm)

AT INTERSTG. CLOSE

CLEARENCE POINTS

25

47

AREA

SHAFT SLEEVES :

SPECIAL CHARPY TESTING (2.11.3)

43

NOT APPLICABLE

FIXATION METHOD

26

44

31.8

CYLINDRICAL

14

24

MIN

SPLIT

JOB NO.

CENTRIFUGAL COMPRESSOR

DATA SHEET (API 617-6TH)

SI UNITS

ITEM NO.

REVISION NO.

PAGE

00

0

5/1/2016

DATE

OF

BY

MB

CONSTRUCTION FEATURES (CONTINUED)

1

2 BEARINGS AND BEARING HOUSINGS

3 RADIAL

ON HIGH SPEED SHAFT

UPPER

LOWER

THRUST

ON HIGH SPEED SHAFT

ACTIVE

INACTIVE

TYPE

PLAIN

PLAIN

TYPE

PLAIN

PLAIN

MANUFACTURER

KSTC

KSTC

MANUFACTURER

KSTC

KSTC

LENGTH (mm)

SHAFT DIA. (mm)

UNIT LOAD (ACT/ALLOW)

N.A.

N.A.

UNIT LOADING (MAX BAR)

38.1

38.1

UNIT LOAD (ULT.) (BAR)

AREA (mm)

BASE MATERIAL

BRONZE

BRONZE

NO. PADS

10

BABBIT THICKNESS (mm)

PIVOT: CENTER / OFFSET, %

11

NO. PADS

12

LOAD: B'TWN/ON PAD

LUBRICATION:

FLOODED

DIRECTED

13

PIVOT: CTR/OFFSET, %

THRUST COLLAR:

INTEGRAL

REPLACEABLE

N.A.

N.A.

PAD BASE MATL

14

15

MATERIAL

BEARING SPAN

mm

16 BEARING TEMPERATURE DEVICES

17

THERMISTORS

18

TYPE

19

20

POS TEMP COEFF

NEG TEMP COEFF

TEMP SWITCH & INDICATOR BY:

PURCH

MFR

SELECTOR SWITCH & INDIC. BY:

PURCH

RESISTANCE MAT'L

24

SELECTOR SWITCH & INDICATOR BY:

MFR

MFR

26

LOCATION-JOURNAL BRG

27

NO.

EA PAD

28

OTHER

29

LOCATION-THRUST BRG

MFR

30

NO.

31

OTHER

32

NO. (INACT)

33

OTHER

34

MONITOR SUPPLIED BY (3.4.7.4)

SCALE RGE

38

SHTDWN

3300

X-Y

TOTAL NO.

3300

KSTC

ENCLOSURE

MODEL

ALARM

SET @

KSTC

3300

SET @

63.5

48.3

TIME DELAY

SEC

PER BRG

AXIAL POSITION DETECTOR:

EVERY OTH PAD

PER BRG

ONE DUAL ON UPPER THRUST

EA PAD

Tech Room

SCALE RGE 0-100

ONE DUAL ON LOWER RADIAL

37

MODEL

MODEL

BENTLY NEVADA

SHTDWN:

EVERY OTH PAD

EA PAD

BENTLY NEVADA

LOCATION

MFR.

PURCH

MFR.

Bently Neveda

OHMS

25

LOCATION

Proximity

MFR

MONITOR SUPPLIED BY (3.4.7.2)

23

36

TYPE

OSCILLATOR-DETECTORS SUPPLIED BY

RESISTANCE TEMP DETECTORS

35

SEE ATTACHED API-670

DATA SHEET

VIBRATION DETECTORS:

NO. AT EA SHAFT BEARING

THERMOCOUPLES

21

22

SEE ATTACHED

API-670 DATA SHT

EVERY OTH PAD

PER BRG

SEE ATTACH. API-670

DATA SHEET

TYPE

MODEL

MFR

NO. REQUIRED

OSCILLATOR-DEMODULATOR SUPPLIED BY

MFR

MODEL

MONITOR SUPPLIED BY (3.4.7.2)

ENCLOSURE

LOCATION

MODEL

ALARM

SET @

SET @

ENCLOSURE

MFR.

TIME DELAY

MODEL

SCALE RGE

SEC

SHTDWN:

ALARM

SET @

SET @

TIME DELAY

SEC

39 CASING CONNECTIONS

40

DESIGN

41

APPROVAL

API605

REQ'D

OTHERS

42

CONNECTION

43

(2.11.2.10)

ASME

FACING

SIZE

FLANGED

MATING FLG

GAS

POSITION

OR

& GASKET

VELOCITY

(2.4.2.1)

STUDDED

BY VENDOR

m/SEC

(2.4.2.1)

(2.4.2.3)

44

45 INLET

3"

RF

SIDE

FLANGED

46 DISCHARGE

2"

RF

SIDE

FLANGED

47

ASME B16.5

48

49 OTHER

50

51

1"

RF

JOB NO.

CENTRIFUGAL COMPRESSOR

DATA SHEET (API 617-6TH)

SI UNITS

1

ITEM NO.

REVISION NO.

PAGE

OTHER CONNECTIONS

00

0

5/1/2016

DATE

OF

BY

MB

ALLOWABLE PIPING FORCES AND MOMENTS:

NO.

2 SERVICE:

SIZE

TYPE

INLET

3 LUBE-OIL INLET

DISCHARGE

FORCE MOMT

N

4 LUBE OIL OUTLET

5 SEAL-OIL INLET

FORCE MOMT

N-m

FORCE

MOMT

N-m

FORCE

MOMT

N-m

N-m

AXIAL

Refer on KSTC

6 SEAL-OIL OUTLET

VERTICAL

7 SEAL GAS INLET

HORIZ. 90

8 SEAL GAS OUTLET

FORCE MOMT

N

9 CASING DRAINS

FORCE MOMT

N-m

N-m

10 STAGE DRAINS

AXIAL

11 VENTS

VERTICAL

12 COOLING WATER

HORIZ. 90

13 PRESSURE

ACCELEROMETER(3.4.7.5)

14 TEMPERATURE

SEE ATTACHED API-670 DATA SHEET

15 SOLVENT INJECTION

TYPE

SEISMIC PROBE

MODEL

330400

16 PURGE FOR:

MFR

BENTLY NEVADA

NO. REQUIRED

17

BRG. HOUSING

LOCATION

OSCILATOR-DEMODULATORS SUPPLIED BY

ON GEAR BOX BEARING PLATE

18

BTWN BRG & SEAL

19

BTWN SEAL & GAS

20

INDIVIDUAL STAGE DRAINS REQUIRED (2.4.3.2)

21

VALVED & BLINDED

LOCATION

22

VALVED & BLINDED & MANIFOLD

MFR

MFR

COMPRESSOR

Tech. Room

DRIVER

ENCLOSURE

BENTLY NEVADA

SCALE RANGE

GEAR

KSTC

3300

MODEL

MONITOR SUPPLIED BY (3.4.7.6)

23 KEY PHASOR REQUIRED

24

BENTLY NEVADA

SHTDWN

0-25

SET @

3300

MODEL

ALARM

SET @

mm/SEC

6.4

mm/SEC

TIME DELAY

SEC

ACCESSORIES

25

26 COUPLING AND GUARDS (3.2)

27 NOTE: SEE ROTATING ELEMENTS - SHAFT ENDS

28

SEE ATTACHED API-671 DATA SHEET

29 COUPLING FURNISHED BY

30 MANUFACTURER

KEYLESS HYDRAULIC

METASTREAM

TYPE

31 COUPLING GUARD FURNISHED BY:

32

TYPE:

KEYED

KSTC

FLEXIBLE

MODEL

KSTC

FULLY ENCLOSED

SEMI-OPEN

OTHER

33 COUPLING DETAILS

VENDOR MOUNT HALF COUPLING

34

MAX O.D.

mm

35

HUB WEIGHT

kg

36

SPACER LENGTH

mm

37

SPACER WEIGHT

kg

LUBRICATION REQUIREMENTS:

NON-LUBE

GREASE

CONT. OIL LUBE

QUANTITY PER HUB

OTHER

kgs or L/MIN

38 MOUNTING PLATES

39

BASEPLATES: FURNISHED BY (3.3.1.1)

40

COMPRESSOR ONLY (3.3.2.1)

41

OTHER

42

DRIP TRIM

43

COLUMN MOUNTING (3.3.2.3)

44

SUB-SOLE PLATES REQ'D (3.3.3.2)

45

STAINLESS STEEL SHIM THICKNESS

46

PRIMER FOR EPOXY GROUT REQ'D (3.3.1.2.9)

47

KSTC

DRIVER

SOLEPLATES: FURNISHED BY:

GEAR

SEAL AND LUBE OIL SYSTEM

TYPE

49

BASE PLATE WILL BE ON CONCRETE FOUNDATION (3.3.2.5)

50

MACHINED MOUNTING PADS REQ'D. (3.3.2.6)

51

mm

SUBSOLE PLATES REQ'D (3.3.3.2)

LEVELING PADS (3.3.2.2)

48

KSTC

THICKNESS

STAINLESS STEEL SHIM THICKNESS - mm

DRIVER

GEAR

COMPRESSOR

PRIMER FOR EPOXY GROUT REQ'D (3.3.1.2.9)

mm

TYPE

JOB NO.

CENTRIFUGAL COMPRESSOR

DATA SHEET (API 617-6TH)

SI UNITS

PAGE

0

5/1/2016

DATE

OF

BY

MB

UTILITIES

UTILITY CONDITIONS:

STEAM:

INLET MIN

ITEM NO.

REVISION NO.

TOTAL UTILITY CONSUMPTION:

DRIVERS

HEATING

COOLING WATER

m/h

BARG(kPaG)

BARG(kPaG)

STEAM, NORMAL

kg/h

NORM

BARG(kPaG)

BARG(kPaG)

STEAM, MAX

kg/h

MAX

BARG(kPaG)

BARG(kPaG)

INSTRUMENT AIR

EXHAUST. MIN

BARG(kPaG)

BARG(kPaG)

HP (DRIVER)

150

kW

NORM

BARG(kPaG)

BARG(kPaG)

HP (AUXILIARIES)

kW

MAX

BARG(kPaG)

BARG(kPaG)

HEATERS

KW

PURGE (AIR OR N2)

m/h

10

ELECTRICITY: (3.4.6.1)

DRIVERS

HEATING

12

VOLTAGE

380

400

110

13

HERTZ

50

50

50

BEFORE SUCTION

14

PHASE

NOMOGRAPHS REQUIRED FOR EACH SECTION (5.3.3.1.5)

11

15

COOLING WATER:

16

TEMP. INLET

17

PRESS NORM

18

DESIGN

19

MIN RETURN

WATER SOURCE

22

INSTRUMENT AIR:

23

MAX PRESS

MISCELLANEOUS:

RECOMMENDED STRAIGHT RUN OF PIPE DIAMETERS

MAX RETURN

45

BARG(kPaG )

8

85C

ON AIR (2.1.17)

BARG(kPaG)

1

PROVISION FOR LIQUID INJECTION (2.1.11)

BAR(kPa)

fouling factor: 0.00034 m2C/W

7.5

PIPING & FOUNDATION (3.5.3.2)

COMPRESSOR TO BE SUITABLE FOR FIELD RUN IN

BARG(kPaG)

4

MAX ALLOW P

20

SHUTDOWN

VENDOR'S REVIEW & COMMENTS ON PURCHASER'S

35

21

CONTROL

m/h

VENDOR'S REVIEW & COMMENTS ON PURCHASER'S

CONTROL SYSTEMS (3.4.1.1)

BARG(kPaG) MIN PRESS 6

24 SHOP INSPECTION AND TESTS: (4.1.4)

BARG(kPaG)

REQ'D.

EXTENT OF PROCESS PIPING BY VENDOR (3.5.3.1)

SHOP FITUP OF VENDOR PROCESS PIPING (4.4.3.11)

25 CLEANLINES (4.2.1.5)

WELDING HARDNESS TESTING (4.2.1.6)

26 HYDROSTATIC

VENDOR'S REPRESENTATIVE SHALL (2.1.14)

27 IMPELLER OVERSPEED

28 MECHANICAL RUN

4hrs

29

CONTRACT COUPLING

IDLING ADAPTORS

30

CONTRACT PROBES

SHOP PROBES

OBSERVE FLANGE PARTING

CHECK ALIGNMENT AT TEMPERATURE

BE PRESENT AT INITIAL ALIGNMENT

31 VARY LUBE & SEAL OIL PRESSURES

32 AND TEMPERATURES (4.3.4.2.5)

WEIGHTS (kg):

COMPR.

33 POLAR FORM VIB DATA (4.3.4.3.3)

ROTORS:

GEAR

COMPR.

34 TAPE RECORD VIB DATA (4.3.4.3.6)

COMPRESSOR UPPER CASE

35 TAPE DATA TO PURCHASER (4.3.4.3.7)

SOUR SEAL OIL TRAPS

36 SHAFT END SEAL INSP (4.3.4.4.1)

L.O. CONSOLE

37 GAS LEAK TEST DISCH PRESS (4.3.5.2)

OVERHEAD SEAL OIL TANKS

38

MAX. FOR MAINTENANCE (IDENTIFY)

BEFORE

AFTER POST TEST INSPECTION (4.3.6.8)

39 PERFORMANCE TEST(GAS)(AIR)(4.3.6.1)

DRIVER

BASE

DRIVER

GEAR

S.O. CONSOLE

TOTAL SHIPPING WEIGHT

40 COMPLETE UNIT TEST (4.3.6.2)

41 TORSIONAL VIB MEAS (4.3.6.2)

SPACE REQUIREMENTS (mm):

42 TANDEM TEST (4.3.6.3)

COMPLETE UNIT:

43 GEAR TEST (4.3.6.4)

L.O. CONSOLE:

44 HELIUM LEAK TEST (4.3.6.5)

S.O. CONSOLE:

45 SOUND LEVEL TEST (4.3.6.6)

SOUR SEAL OIL TRAPS

46 FULL LOAD / SPEED / PRESS TEST (4.3.6.9)

OVERHEAD SEAL OIL TANKS

47 HYDRAULIC COUPLING INSP (4.3.6.10)

48

49

50

51

REMARKS:

S-ar putea să vă placă și

- Rotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsDocument9 paginiRotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsghostamirÎncă nu există evaluări

- Api 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetDocument22 paginiApi 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetmaruthigabbitaÎncă nu există evaluări

- Reciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsDocument10 paginiReciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsÆmanuel J Silva100% (1)

- Technical Standard Specification - Mechanical Section 03 - Pumps, Compressors, Blowers, and CuttersDocument51 paginiTechnical Standard Specification - Mechanical Section 03 - Pumps, Compressors, Blowers, and CuttersRenju RadhakrishnapillaiÎncă nu există evaluări

- Technical - Query - JIND - 2april2020 (Ed. LAPI)Document1 paginăTechnical - Query - JIND - 2april2020 (Ed. LAPI)Nyayu SitimayaÎncă nu există evaluări

- Data Sheet Multiphase Pump BornermanDocument5 paginiData Sheet Multiphase Pump BornermanUmar Ijaz KhanÎncă nu există evaluări

- Data Sheet For Flare Package (PK-720)Document3 paginiData Sheet For Flare Package (PK-720)samynatha PrasathÎncă nu există evaluări

- Centrifugal Compressor Specification Sheet: Operating ConditionsDocument6 paginiCentrifugal Compressor Specification Sheet: Operating ConditionsIsmail SayyedÎncă nu există evaluări

- 8474L-000-JSS-1031-001-0 (Specification For Rotary Compressor)Document22 pagini8474L-000-JSS-1031-001-0 (Specification For Rotary Compressor)LongTuanÎncă nu există evaluări

- Data Sheet-Coarse Ash PumpDocument6 paginiData Sheet-Coarse Ash PumpEESL AACÎncă nu există evaluări

- Nioec SP 00 89 (R0) (Ed1)Document8 paginiNioec SP 00 89 (R0) (Ed1)aminÎncă nu există evaluări

- Atex A1-020-03-En PDFDocument8 paginiAtex A1-020-03-En PDFherrerafaridÎncă nu există evaluări

- Project Standards and Specifications Dryers Systems Rev01Document18 paginiProject Standards and Specifications Dryers Systems Rev01Christian CleofasÎncă nu există evaluări

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 paginiOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodÎncă nu există evaluări

- vs1 DatasheetDocument22 paginivs1 DatasheetMojtabaÎncă nu există evaluări

- Air Blower Haya Water VerfDocument9 paginiAir Blower Haya Water Verfgharsallah mounaÎncă nu există evaluări

- Design Data Performance (Dryer) : ClientDocument2 paginiDesign Data Performance (Dryer) : ClientEDUARDOÎncă nu există evaluări

- Brown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsDocument12 paginiBrown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsPebriyantoÎncă nu există evaluări

- Mechanical Data Sheet For Fuel Gas FiltersDocument4 paginiMechanical Data Sheet For Fuel Gas FilterssudjonoÎncă nu există evaluări

- 2009 02 M HD 319 0Document5 pagini2009 02 M HD 319 0ZoebairÎncă nu există evaluări

- Air CompressorDocument51 paginiAir CompressorInaam Ur RehmanÎncă nu există evaluări

- Air CompressorsDocument13 paginiAir CompressorsCalin SeraphimÎncă nu există evaluări

- Centrifugal CompressorDocument5 paginiCentrifugal CompressorDeliaChiaÎncă nu există evaluări

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pagini22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Air ComprDocument118 paginiAir ComprMoaaz KhanÎncă nu există evaluări

- Specification - Api 619 4 Edition - Rotary Type Positive Displacement Compressors For Petroluem, Petrochemical and Antural Gas IndustriesDocument11 paginiSpecification - Api 619 4 Edition - Rotary Type Positive Displacement Compressors For Petroluem, Petrochemical and Antural Gas IndustriesjaseelÎncă nu există evaluări

- PC PumpDocument5 paginiPC Pumpphantanthanh100% (1)

- Centrifugal Pump Data SheetDocument4 paginiCentrifugal Pump Data SheetJohnÎncă nu există evaluări

- Brochure HRFGDocument16 paginiBrochure HRFGjhobanybernalÎncă nu există evaluări

- Unit 8 Reciprocatng Compressors: StructureDocument26 paginiUnit 8 Reciprocatng Compressors: StructureRakeshKrÎncă nu există evaluări

- Air Blowe DatasheetDocument1 paginăAir Blowe DatasheetMoein PÎncă nu există evaluări

- Tech Specs For Nitrogen GeneratorDocument5 paginiTech Specs For Nitrogen Generatordhanu_lagwankarÎncă nu există evaluări

- SA-980-P-11449 - API 685 Submerged Pump PZ - Vert02Document5 paginiSA-980-P-11449 - API 685 Submerged Pump PZ - Vert02altipatlarÎncă nu există evaluări

- BB1 Vs BB2Document1 paginăBB1 Vs BB2bomthanhphuÎncă nu există evaluări

- 3DG-B10-00051 CompressorsDocument37 pagini3DG-B10-00051 CompressorsCarlosÎncă nu există evaluări

- Alinhamento de Máquinas ConvencionalDocument117 paginiAlinhamento de Máquinas ConvencionalKrammer Kodel100% (1)

- 2.11.1 Blowers Data Sheet Including Performance CurveDocument4 pagini2.11.1 Blowers Data Sheet Including Performance Curvemayukhguha1988Încă nu există evaluări

- API 610 Data Sheet 1 PDFDocument6 paginiAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliÎncă nu există evaluări

- AIr Heater CompareDocument15 paginiAIr Heater CompareRamalingam PrabhakaranÎncă nu există evaluări

- PDH Online Course M371Document32 paginiPDH Online Course M371Andres WhiteÎncă nu există evaluări

- Lavalin Bomba SumergibleDocument3 paginiLavalin Bomba SumergibleEyffer Cabrera PalominoÎncă nu există evaluări

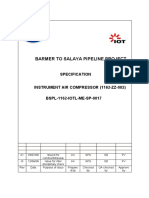

- Mechanical Specification - Instrument Air CompressorDocument7 paginiMechanical Specification - Instrument Air Compressorsajeesh5113699Încă nu există evaluări

- Datasheet For Vent ScrubberDocument5 paginiDatasheet For Vent ScrubbercliffrajjoelÎncă nu există evaluări

- Centrifugal Compressor Power-US Field UnitsDocument4 paginiCentrifugal Compressor Power-US Field UnitssurawutwijarnÎncă nu există evaluări

- Screw CompressorDocument2 paginiScrew CompressorRiti AdhikariÎncă nu există evaluări

- CAGI ElectHB ch8Document112 paginiCAGI ElectHB ch8rcangeliÎncă nu există evaluări

- Equipment Specification Project - RFQ - #: Page 1 of 12Document12 paginiEquipment Specification Project - RFQ - #: Page 1 of 12Calin SeraphimÎncă nu există evaluări

- Petrosadid - Centrifugal (API 617)Document16 paginiPetrosadid - Centrifugal (API 617)lafsifatÎncă nu există evaluări

- Heat of Compression Dryer ArticleDocument5 paginiHeat of Compression Dryer ArticleAshwin ChandaranaÎncă nu există evaluări

- 10P87-D0003-046-R0-WHRU by TEPLDocument23 pagini10P87-D0003-046-R0-WHRU by TEPLjigarÎncă nu există evaluări

- Asme2b sb-234Document10 paginiAsme2b sb-234fdfsdfsdfsdfÎncă nu există evaluări

- TGI Sabana Gas Transport: Operating Conditions Normal D E F A B CDocument3 paginiTGI Sabana Gas Transport: Operating Conditions Normal D E F A B Chernan plazasÎncă nu există evaluări

- Compressed Air System For Chemical and Industrial PlantsDocument23 paginiCompressed Air System For Chemical and Industrial Plantsjkhan_724384Încă nu există evaluări

- API 682 Accumulator Data SheetDocument1 paginăAPI 682 Accumulator Data SheetBhyrappaÎncă nu există evaluări

- BZM Centrifugal CompressorDocument16 paginiBZM Centrifugal CompressorMachineryengÎncă nu există evaluări

- Api 619 SiDocument9 paginiApi 619 SitutuionutÎncă nu există evaluări

- Api 673 SiDocument11 paginiApi 673 Situtuionut100% (1)

- API 674 Pump Data SheetDocument5 paginiAPI 674 Pump Data SheetEason Ng100% (2)

- API STD 676-2009 - Hoja de RequisiciónDocument28 paginiAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroÎncă nu există evaluări

- 610 SIdata SheetsDocument26 pagini610 SIdata Sheetssjois_hsÎncă nu există evaluări

- TC-0150 Material SpecsDocument3 paginiTC-0150 Material Specsmkfe2005Încă nu există evaluări

- Process Critical Compressors by Akamo (1) .DesbloqueadoDocument5 paginiProcess Critical Compressors by Akamo (1) .DesbloqueadoMauricio8510Încă nu există evaluări

- 2019SKFTrainingHandbook 1115Document96 pagini2019SKFTrainingHandbook 1115Williams GarciaÎncă nu există evaluări

- Rod 123Document5 paginiRod 123Ankush SehgalÎncă nu există evaluări

- DS PM0202 en Co 3672Document4 paginiDS PM0202 en Co 3672mkfe2005Încă nu există evaluări

- Process Critical Compressors by Akamo (1) .DesbloqueadoDocument5 paginiProcess Critical Compressors by Akamo (1) .DesbloqueadoMauricio8510Încă nu există evaluări

- Thermal Design Calculation Procedure (Rev 00)Document24 paginiThermal Design Calculation Procedure (Rev 00)mkfe2005Încă nu există evaluări

- T6pg123 132 PDFDocument10 paginiT6pg123 132 PDFmkfe2005Încă nu există evaluări

- Oil Cooler DS FormDocument5 paginiOil Cooler DS Formmkfe2005Încă nu există evaluări

- Diptico Container SpreadersDocument4 paginiDiptico Container Spreadersmkfe2005Încă nu există evaluări

- Terastandard Iso 3874 535Document34 paginiTerastandard Iso 3874 535mkfe2005100% (3)

- Insanity CalendarDocument5 paginiInsanity Calendarmkfe2005Încă nu există evaluări

- Dynamic Simulation of Compressor Control SystemsDocument85 paginiDynamic Simulation of Compressor Control SystemsMauricio Huerta Jara100% (1)

- InstinstDocument16 paginiInstinstmkfe2005Încă nu există evaluări

- Scan GhorbaniDocument3 paginiScan Ghorbanimkfe2005Încă nu există evaluări

- 0.001 Engineering ItemsDocument52 pagini0.001 Engineering Itemsmkfe2005Încă nu există evaluări

- Selection of Material Nace - H2S - Technical Paper PDFDocument21 paginiSelection of Material Nace - H2S - Technical Paper PDFajaysharma_1009Încă nu există evaluări

- Vibration Kit LocationDocument1 paginăVibration Kit Locationmkfe2005Încă nu există evaluări

- PCS HV98Document10 paginiPCS HV98mkfe2005Încă nu există evaluări

- Phoenix Compressor / Gearbox Cross-Sectional ViewDocument1 paginăPhoenix Compressor / Gearbox Cross-Sectional Viewmkfe2005Încă nu există evaluări

- BreatherDocument6 paginiBreathermkfe2005Încă nu există evaluări

- The Thermofluids Design of A 100 KW, Single-Shaft Prototype Microturbine As A New Distributed Generation Method in IranDocument8 paginiThe Thermofluids Design of A 100 KW, Single-Shaft Prototype Microturbine As A New Distributed Generation Method in Iranmkfe2005Încă nu există evaluări

- Data Sheet Tr-26 Iecex GBDocument2 paginiData Sheet Tr-26 Iecex GBmkfe2005Încă nu există evaluări

- BreatherDocument6 paginiBreathermkfe2005Încă nu există evaluări

- Insanity CalendarDocument5 paginiInsanity Calendarmkfe2005Încă nu există evaluări

- In Ve RonmentDocument3 paginiIn Ve Ronmentmkfe2005Încă nu există evaluări

- In Ve RonmentDocument3 paginiIn Ve Ronmentmkfe2005Încă nu există evaluări

- In Ve RonmentDocument3 paginiIn Ve Ronmentmkfe2005Încă nu există evaluări

- In Ve RonmentDocument3 paginiIn Ve Ronmentmkfe2005Încă nu există evaluări

- EDU403 Assignment 1Document6 paginiEDU403 Assignment 1NadiaJawadHussainÎncă nu există evaluări

- Carapace DigitalDocument15 paginiCarapace DigitalVillain ChatÎncă nu există evaluări

- Child DevelopmentDocument12 paginiChild DevelopmentPija Mohamad100% (1)

- B 700 FDocument25 paginiB 700 FMohammed HdyliÎncă nu există evaluări

- Nursing Care Plan For Readiness For Enhanced Sleep NCPDocument4 paginiNursing Care Plan For Readiness For Enhanced Sleep NCPderic100% (2)

- The D - Block ElementsDocument30 paginiThe D - Block ElementsNandya AristaÎncă nu există evaluări

- P3 Chapter 2 End-Of-Chapter (Higher) Mark SchemeDocument3 paginiP3 Chapter 2 End-Of-Chapter (Higher) Mark SchemePaul LloydÎncă nu există evaluări

- Helicobacter Pylori InfectionDocument18 paginiHelicobacter Pylori InfectionPMÎncă nu există evaluări

- Electrical Rooms Fire FightingDocument2 paginiElectrical Rooms Fire Fightingashraf saidÎncă nu există evaluări

- Comprehensive Soup ProjectDocument98 paginiComprehensive Soup ProjectSachin Soni63% (8)

- Activity 2: College of EngineeringDocument3 paginiActivity 2: College of EngineeringMa.Elizabeth HernandezÎncă nu există evaluări

- (VOLKSWAGEN) Manual de Taller Volkswagen Jetta 1999 2006Document4 pagini(VOLKSWAGEN) Manual de Taller Volkswagen Jetta 1999 2006Carlos AntonioÎncă nu există evaluări

- Remote Control RC902V1 ManualDocument3 paginiRemote Control RC902V1 ManualdezdoÎncă nu există evaluări

- Manual L W26Document436 paginiManual L W26Taufan ArifÎncă nu există evaluări

- iGCSE Biology Section 1 Lesson 1Document44 paginiiGCSE Biology Section 1 Lesson 1aastha dograÎncă nu există evaluări

- MS Fresher HR DocumentDocument4 paginiMS Fresher HR DocumentJahanvi KambojÎncă nu există evaluări

- Make Swiss RollDocument16 paginiMake Swiss RollFelicia LiÎncă nu există evaluări

- 06-433rev7 HFC-227ea IVO ManualDocument109 pagini06-433rev7 HFC-227ea IVO ManualFelix MartinezÎncă nu există evaluări

- Park Ch. 1 - A1000 - Spring13Document21 paginiPark Ch. 1 - A1000 - Spring13lingyeeÎncă nu există evaluări

- NG Uk RTR 0220 r15 PDFDocument9 paginiNG Uk RTR 0220 r15 PDFDuong Thai BinhÎncă nu există evaluări

- ComFlor 80 Load Span Tables PDFDocument4 paginiComFlor 80 Load Span Tables PDFAkhil VNÎncă nu există evaluări

- Wetted Wall Gas AbsorptionDocument9 paginiWetted Wall Gas AbsorptionSiraj AL sharifÎncă nu există evaluări

- Unit5 TestDocument3 paginiUnit5 TestAndrea MészárosnéÎncă nu există evaluări

- Magnesium L Threonate For Depression and Anxiety PDFDocument6 paginiMagnesium L Threonate For Depression and Anxiety PDFRocco LamponeÎncă nu există evaluări

- SM Electrical Guidelines: General Notes:: Site HereDocument1 paginăSM Electrical Guidelines: General Notes:: Site HereNathaniel DreuÎncă nu există evaluări

- Music Therapy: Treatment For Grade 11 Stem Students Who Suffer Stress From Basic CalculusDocument12 paginiMusic Therapy: Treatment For Grade 11 Stem Students Who Suffer Stress From Basic CalculusArvinel L. VileganoÎncă nu există evaluări

- Yume Beauty Price ListDocument1 paginăYume Beauty Price ListjessicaelaÎncă nu există evaluări

- Vendor Security ChecklistDocument11 paginiVendor Security ChecklistHarisÎncă nu există evaluări

- Dna Recombinant TechnologyDocument20 paginiDna Recombinant TechnologyJuliet Ileto Villaruel - AlmonacidÎncă nu există evaluări