Documente Academic

Documente Profesional

Documente Cultură

19-20. ABS Check Valves PDF

Încărcat de

Prudencio Almonte III0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări2 paginiTitlu original

19-20. ABS Check Valves.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări2 pagini19-20. ABS Check Valves PDF

Încărcat de

Prudencio Almonte IIIDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 2

ABS pressure piping systems show considerable cost saving compared with

traditional materials, particularly when chemical resistance, external coat.

internal lining, resilience and installation time is taken into accout. The

‘engineer understood that using ABS pipe system was of much benefit to the

cend user. In applying design principles to the specific criteria of thermoplastic

materials, the

wwineer can take advantage of the database of case histories,

‘modem industry standards and use the outstanding properties of ABS

SYSierenNcen mnt ne

‘The below 5 points had to be considered

~ Assumption of system design.

= Composition of piping system.

+ Design to accommodate thermal expansio1

= External conditions,

+ Operating temperature and pressure.

Form the above informations, the following decision shall be made.

ipe material to be used.

Diameter, pressure class and stiffness of pipe to be used.

‘Supporting arrangements for pipes and valves.

Trench design,

Route datails.

in

CTION CRITERIA

The table below will assist the selection of suitable ABS valves.

Size range 20mm.-110mm. | 63 mm, -200 mm,

Clean wid Good Good

Slurry Refer to Invigor Refer to Iavigor

Flow control omf/ On Moderate

Position indieator Yes Yes

‘Vacuum proot Yes Yer

Pressure surge behavior | Good Good

Scaling materials EPDM /OTFE EPDM

ax pressure range @ 20 °C | 10 kg/em? 10 kyon?

Yes Yes

End connection Socket, Thread Watersiye

Jointing system, e.g. cold solvent cement welding. Rubber ring joints. Flanges ect.

@

INVIGOR INCORPORATION LIMITED

‘701/05 Soi Pattanakarn 30, Pattanakarn Rd.,Suangluang, Bangkok 10250, Thailand

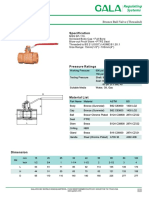

Double union ball check valve

oD, 1D

|

y

La Z

[Standard specification Dimensions of Double union ball check valve. sf

Nominal outside z,

diameter of ty a ‘i a

corresponding pipe

mm, inch,

20 412" 202 349 262 1225

25 3/4" 24.5 55.2 259 122.5

50, Tie 50.4 98.4 347 167.4

63 ze 63.2 119.5 38.0 199.7

75 2a 75.0 119.6 43.7 207.4

Dimensions in milimetres:

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- GALA Valves PDFDocument14 paginiGALA Valves PDFPrudencio Almonte IIIÎncă nu există evaluări

- Installation of Plumbing and HVAC Systems PDFDocument128 paginiInstallation of Plumbing and HVAC Systems PDFPrudencio Almonte IIIÎncă nu există evaluări

- HVAC System Functional Design Description - Commentes - Gusto - 110202 PDFDocument28 paginiHVAC System Functional Design Description - Commentes - Gusto - 110202 PDFPrudencio Almonte III67% (3)

- 3.6 LPG Supply SystemDocument5 pagini3.6 LPG Supply SystemPrudencio Almonte IIIÎncă nu există evaluări

- Mixing StationDocument5 paginiMixing StationPrudencio Almonte IIIÎncă nu există evaluări

- Probe Card Room: Design SpecificationDocument1 paginăProbe Card Room: Design SpecificationPrudencio Almonte IIIÎncă nu există evaluări

- Manual - SMG Battery - UPS PDFDocument15 paginiManual - SMG Battery - UPS PDFPrudencio Almonte III100% (1)

- Fiamm 2 PDFDocument4 paginiFiamm 2 PDFGustavo BessoneÎncă nu există evaluări

- Gen - Battery Description UPS PDFDocument2 paginiGen - Battery Description UPS PDFPrudencio Almonte IIIÎncă nu există evaluări

- Crane Study PDFDocument287 paginiCrane Study PDFPrudencio Almonte IIIÎncă nu există evaluări

- ABS - Pipe Support Spacing PDFDocument1 paginăABS - Pipe Support Spacing PDFPrudencio Almonte IIIÎncă nu există evaluări