Documente Academic

Documente Profesional

Documente Cultură

Design of Two Way Slab (IS 456:2000) (Limit State Method) : 1 Analysis

Încărcat de

Rus TheengTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design of Two Way Slab (IS 456:2000) (Limit State Method) : 1 Analysis

Încărcat de

Rus TheengDrepturi de autor:

Formate disponibile

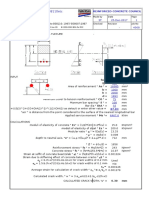

Design of Two way slab (IS 456:2000) (Limit State Method)

Analysis:

Short span

Long Span

B or Lx =

L or Ly =

3.58 m

5.18 m

Input Data:

Size of Slab is =

Slab is contineous over T-Beam

Material use

Concrete

Steel

5.18

3.58 sq. m

M20

Fe500

20 N/mm2

500 N/mm2

xu/d =

Effective Span:

Lx =

Ly =

Ly/Lx=

From preliminary design the overall depth is

3.58 m

5.18 m

1.4 < 2 Two Way Slab

D=

ii

iii

iv

I) Dead Load (DL)

Slab

Thickness

Dead load of Slab = 25 KN/m3 *

0.125m =

Screeding

Thickness

Dead load of Screeding = 20.4 KN/m3

* 0.03m =

19mm thick Marble Flooring

Thickness

Dead load of 19mm thick Marble

Flooring = 27 KN/m3 * 0.019m =

Cement Plaster

Thickness

Dead load of Cement Plaster = 20.4

KN/m3 * 0.0125m =

Total of (I + ii + iii + iv)

I) Live Load (LL)

For Residensial

Total Design Load (DL + LL)

The Factored Load (Wu) = 1.5*Design

Load =

125 mm

25 KN/m3

3.125 KN/m2

30 mm

20.4 KN/m3

0.612 KN/m2

19 mm

27 KN/m3

0.513 KN/m2

12.5 mm

20.4 KN/m3

0.255 KN/m2

4.51 KN/m2

2 KN/m2

6.51 KN/m2

9.765 KN/m2

1.5 Factor

Critical Support Condition:

Two adjacent edge discontinuous

Consider one meter width of slab along short span & along long span.

Calculation of Moments:

Short Span

125 mm

Calculation of Load:

I

0.46

-ve moment at contineous edge (support)

x1

0.07100

Long Span

y1

0.047

+ve moment at mid span

Along Short Span:

-ve moment at contineous edge (support)

-Mx = x1*wu*lx2

-My = y1*wu*lx2

Along Long Span:

+ve moment at mid span

+Mx = x2*wu*lx2

+My = y2*wu*lx2

x2

0.05300

y2

0.35

8.89 KN-m

5.88 KN-m

6.63 KN-m

43.80 KN-m

Depth Calculation:

Minimum depth of slab is calculated considering maximum bending moment.

Here obs maximum bending moment is

Mu=

Depth Required (d) = sqrt(Mu/(0.36*xumax/d*(1-.42*xumax/d)*b*fck))

Overall depth

D=d+/2+clear cover

Hence, for safe design adopt above more depth

D=

Effective Depth (main) dx= D-1/2-clear cover

Effective Depth (secondary) dy= D-clear cover-main steel dia- 2/2

8.89 KN-m

128.03 mm

149.03 mm

125 mm

104 mm

95 mm

Not OK

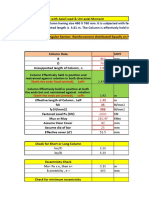

Reinforcement Calculation:

Moment

Support

-ve Mx

Moment (KN-m)

8.89

Solving quadratic equation Mu=0.87fyAstd(1-Astfy/bdfck)

a = 0.87*fy^2/(b*fck)

10.88

b=-0.87fyd

-45240.00

c=Mu

8885802.37

x=(-b+-sqrt(b2-4ac))/2a

x1=(-b+sqrt(b2-4ac))/2a

3953.32

x2=(-b-sqrt(b2-4ac))/2a

206.68

Astx (mm2) =

206.68

Ast req. (mm2)

206.68

Min As(0.12%bD) mm2

150

Ast Actually required as per

minimum reinforcement (mm2)

206.68

Spacing =b*area of one bar/Ast

380.00

Mid Span

-ve My

5.88

+ve Mx

6.63

+ve My

43.80

10.88

-41325.00

5882150.86

10.88

-45240.00

6633063.74

3651.89

148.11

148.11

148.11

150

4007.81

152.19

152.19

152.19

150

150.00

523.60

152.19

330.29

10.88

-41325.00

43803251.10

#NUM!

#NUM!

#NUM!

#NUM!

150

#NUM!

#NUM!

3d

312

312

312

312

300

300

300

300

300

Adopt the spacing (min of above three)

300.00

300.00

300.00

#NUM!

Spacing provided in mm

175

175

175

175

Ast provided (mm2)

448.80

448.80

287.23

287.23

% of Ast (Provided)

0.36

0.36

0.23

0.23

Main Reinforcement

10 @ 175mm c/c 10 @ 175mm c/c 8 @ 175mm c/c 8 @ 175mm c/c

Minimum of 3d or

300

Check:

7.1 Minimum Reinforcement

Min As(0.12%bD) mm2

7.2 Check for Shear

In slab shear is checked along short edge.

Max Shear Force (V) = w*lx/2

v=V/bd

150 mm2

% of steel provided

% of steel=(100*Asty/2)/bd

Shear capacity of section without reinforcement

c from table

100As/bd

0.25

0.5

Shear strength for slab ' = kc

The provided Depth of slab (D) =

D

Since the depth of slab <150mm the value of K=125

' = kc

7.3 Check for Development length

Ld<=1.3M1/V+Lo

a) At short edge

Ld= s*/(4Tbd)

Tbd from IS 456:2000 26.2.1.1 Page 43

M1= 0.87*Asty/2*fy(d-Asty/2*fy/(b*fck))

Lo= 96

<Astx(+ve),Asty(+ve),Astx(-ve),Asty(-ve)

17.47935 KN

0.168 N/mm2

0.36 %

M20

0.36

0.48

0.41 N/mm2

125.00 mm

k

1.3

1.30

0.54 N/mm2 > v

56.64

For deformed bar increase by 60%

9.88

12 or d which ever is greater

Ld<=1.3M1/V+Lo

830.66

56.64=

566.41

Safe in shear

M20

1.2

KN-m

mm

mm

OK in development length

At long edge

Ld= s*/(4Tbd)

M1= 0.87*Asty/2*fy(d'-Asty/2*fy/(b*fck))

Lo= 96

56.64

M20

1.2

8.73 KN-m

12 or d which ever is greater

Ld<=1.3M1/V+Lo

744.96 mm

56.64=

453.13 mm

OK in development length

7.4 Check for deflection

From deflection criteria, we have,

l/d<=

where,

= Basic value of span to effective depth ratios for spans up to spans 10m

=

26 (Since span<10m)

= a factor which accounts for correction in the values of for spans greater than 10m

=

1

= a factor which depends on the stress at service and amount of steel for tension reinforcement

Area of steel of required

#NUM!

mm2

Area of steel of provided

448.80 mm2

% of steel provided

0.36 %

fs=0.58*fy*Ast req./Ast provided

#NUM!

N/mm2

from graph () =

1.98

= a factor which depends on the area of compression reinforcement.

=

1

= a factor for flanged beams which depends on the ratio of web width to the flange width

=

1

lx/d permissible

=

51.48

lx/d provided = 3580/104 =

34.42

Summary:

Overall Depth of slab = 125 mm

Main Bar:

Astx +ve = 8 @ 175mm c/c

Astx -ve = 10 @ 175mm c/c

Asty +ve = 8 @ 175mm c/c

Asty -ve = 10 @ 175mm c/c

Safe in deflection

ate Method)

S-ar putea să vă placă și

- Preliminary Design of RCC Beam ElementDocument3 paginiPreliminary Design of RCC Beam ElementN TÎncă nu există evaluări

- Slab Design Excel FileDocument4 paginiSlab Design Excel FileSuman Resolved NeupaneÎncă nu există evaluări

- Rectangular Combined Footing: Input DataDocument2 paginiRectangular Combined Footing: Input DataAnonymous 5pQf43AJwÎncă nu există evaluări

- Cantilever BeamDocument5 paginiCantilever BeamAnonymous nwByj9LÎncă nu există evaluări

- Beam Design With Deflection CheckDocument4 paginiBeam Design With Deflection Checkdinesh choudharyÎncă nu există evaluări

- Isolated Footing DesignDocument19 paginiIsolated Footing Designmohanty_anantakumar6332Încă nu există evaluări

- RC Beam DesignDocument3 paginiRC Beam DesignBuboy VelasÎncă nu există evaluări

- Sample Calulation BeamDocument9 paginiSample Calulation Beamche azimÎncă nu există evaluări

- Cantilever BeamDocument3 paginiCantilever BeamFeliciano Esteban DominguezÎncă nu există evaluări

- Design of ColumnDocument8 paginiDesign of ColumnAfsar MansuriÎncă nu există evaluări

- Column design details for rectangular columnDocument27 paginiColumn design details for rectangular columnnsureshbabu0% (1)

- Design of Cantilever Slab As Per Is 456 2000Document2 paginiDesign of Cantilever Slab As Per Is 456 2000dhanasekaran33% (3)

- Steeltek ConnectionDocument5 paginiSteeltek ConnectioncadsultanÎncă nu există evaluări

- Beam DesignDocument8 paginiBeam DesignFaraaz FaisalÎncă nu există evaluări

- Unit III Trickling Filter DesignDocument1 paginăUnit III Trickling Filter Designधीरज कुमारÎncă nu există evaluări

- Beam Design Detail Report: Material and Design DataDocument13 paginiBeam Design Detail Report: Material and Design DataazwanÎncă nu există evaluări

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 ST 25-Dec-2017 1 - 4068Document4 paginiSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 ST 25-Dec-2017 1 - 4068vaideehÎncă nu există evaluări

- Machine Foundation Irrigation Pump 1762001 559Document1 paginăMachine Foundation Irrigation Pump 1762001 559Riddhima MukherjeeÎncă nu există evaluări

- Design of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsDocument3 paginiDesign of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsThirdie LerajeÎncă nu există evaluări

- Design of Column For D1 (Column C1) - RDocument9 paginiDesign of Column For D1 (Column C1) - RRajanvmÎncă nu există evaluări

- Design of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)Document3 paginiDesign of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)sivaÎncă nu există evaluări

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument40 paginiDesign and Drawing of RC Structures: Dr. G.S.SureshLeroy TuscanoÎncă nu există evaluări

- Base Plate DesignDocument4 paginiBase Plate DesignPradeep Kumar RajÎncă nu există evaluări

- Slab DesignDocument6 paginiSlab DesignThea DoradoÎncă nu există evaluări

- Check For SBC P/A M /Z M /Z: Provided Area Is OkayDocument2 paginiCheck For SBC P/A M /Z M /Z: Provided Area Is OkayVikunj TilvaÎncă nu există evaluări

- RCC - Design - SLAB DEFLECTIONDocument43 paginiRCC - Design - SLAB DEFLECTIONPratikÎncă nu există evaluări

- Beam Design With RCCDocument24 paginiBeam Design With RCCOsarieme Osakue100% (1)

- Admin - Mission: Design of Footing F4Document6 paginiAdmin - Mission: Design of Footing F4nishusainiÎncă nu există evaluări

- Span/Eff - Depth Ratio Fs Modification Ten. Factor Modification Com. Factor Actual Span/effe - Depth Allowable Span/eff. Depth Long Span FactorDocument1 paginăSpan/Eff - Depth Ratio Fs Modification Ten. Factor Modification Com. Factor Actual Span/effe - Depth Allowable Span/eff. Depth Long Span Factorshamen amarasekaraÎncă nu există evaluări

- Combine Footing FinallDocument227 paginiCombine Footing FinallKhalid BanafaÎncă nu există evaluări

- RCC Retaining WallDocument3 paginiRCC Retaining Wallsuganthi1711Încă nu există evaluări

- IAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanDocument29 paginiIAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanSrikanth ReddyÎncă nu există evaluări

- Design of two-way slab for pump floorDocument3 paginiDesign of two-way slab for pump floorRamakanth PuttyÎncă nu există evaluări

- Box Culvert 2X2Document6 paginiBox Culvert 2X2abhishek singhÎncă nu există evaluări

- Drain SpaceDocument10 paginiDrain Spaceikhsan07Încă nu există evaluări

- Beam Design Calculation and Section SelectionDocument27 paginiBeam Design Calculation and Section SelectionBabu SundararamanÎncă nu există evaluări

- SIDLDocument4 paginiSIDLBathrudeen IshakÎncă nu există evaluări

- International Codes-Is456 - Beam Design in STAAD Pro - V8iDocument5 paginiInternational Codes-Is456 - Beam Design in STAAD Pro - V8iUmesh ChikhlikarÎncă nu există evaluări

- Is 13920 DetailingDocument3 paginiIs 13920 Detailingasingh400Încă nu există evaluări

- Design of inlet chamber reinforcement detailsDocument2 paginiDesign of inlet chamber reinforcement detailsThirumaleshÎncă nu există evaluări

- Summary of IS 3370 Detailing RequirementsDocument2 paginiSummary of IS 3370 Detailing RequirementsKanaiyalal N. ShethÎncă nu există evaluări

- Design Calculations: Clear Water ReservoirDocument2 paginiDesign Calculations: Clear Water ReservoirAnoop KumarÎncă nu există evaluări

- Rigid Pavement Design InputsDocument17 paginiRigid Pavement Design InputsrajÎncă nu există evaluări

- Stair CaseDocument5 paginiStair CaseMahitha ReddyÎncă nu există evaluări

- U G TankDocument5 paginiU G TankVikram GaikwadÎncă nu există evaluări

- Deep Beam TypicalDocument6 paginiDeep Beam TypicalArpit SinghÎncă nu există evaluări

- Design of ColumnDocument54 paginiDesign of ColumnMonika AcharyaÎncă nu există evaluări

- StaadFoundation DesignDocument97 paginiStaadFoundation DesignaquibzafarÎncă nu există evaluări

- Structural Design of Settling Tank and ManholeDocument16 paginiStructural Design of Settling Tank and ManholePAWANÎncă nu există evaluări

- Design of Footing For Corner ColumnDocument4 paginiDesign of Footing For Corner ColumnMegatech Engineering ConsultantsÎncă nu există evaluări

- Footing Design DimensionsDocument3 paginiFooting Design DimensionsMesfinÎncă nu există evaluări

- Column Biaxial ProblemsDocument25 paginiColumn Biaxial ProblemsRajanvmÎncă nu există evaluări

- Design of Slab: Ly/lx 2. So This Is Two Way SlabDocument6 paginiDesign of Slab: Ly/lx 2. So This Is Two Way SlabSudip ShresthaÎncă nu există evaluări

- 2-WAY SLAB OPTIMIZATIONDocument120 pagini2-WAY SLAB OPTIMIZATIONSambhav PoddarÎncă nu există evaluări

- Self Supporting Chimney Problem1Document17 paginiSelf Supporting Chimney Problem1GOVINDARAJU SÎncă nu există evaluări

- Design of Cantilever BeamDocument23 paginiDesign of Cantilever Beamjs kalyana rama83% (12)

- Structural Design ReportDocument99 paginiStructural Design ReportCitizen Kwadwo AnsongÎncă nu există evaluări

- Design SectionDocument19 paginiDesign SectionKrishna KumarÎncă nu există evaluări

- DESIGN OF CANTILEVER BEAM AND LINTEL SUNSHADEDocument31 paginiDESIGN OF CANTILEVER BEAM AND LINTEL SUNSHADENirina ArimananaÎncă nu există evaluări

- FinalDocument42 paginiFinalVishnu Kumar0% (1)

- Joints in Reinforced Concrete Buildings: Building Construction (Assignment - Ii)Document6 paginiJoints in Reinforced Concrete Buildings: Building Construction (Assignment - Ii)JaskiratÎncă nu există evaluări

- EEE Company Profile - NewDocument25 paginiEEE Company Profile - NewAjaya KumarÎncă nu există evaluări

- Grand - Summary: A. Sub-StructureDocument19 paginiGrand - Summary: A. Sub-StructureJoConÎncă nu există evaluări

- Reinforced Concrete One Way Slab DesignDocument4 paginiReinforced Concrete One Way Slab DesignIzzan SabelloÎncă nu există evaluări

- CIV3506 2022 Assign2 Exemplary1Document20 paginiCIV3506 2022 Assign2 Exemplary1Neil WayneÎncă nu există evaluări

- Repairing and Waterproofing Concrete Balcony WalkwaysDocument2 paginiRepairing and Waterproofing Concrete Balcony WalkwayskoliÎncă nu există evaluări

- Concrete Institute of Australia - Recomended Practice - Z15 Cracking in Concrete Slabs On Ground and PavementsDocument70 paginiConcrete Institute of Australia - Recomended Practice - Z15 Cracking in Concrete Slabs On Ground and PavementstimÎncă nu există evaluări

- Comparing RCC and Prestressed Flat Slabs for Cost Savings and PerformanceDocument5 paginiComparing RCC and Prestressed Flat Slabs for Cost Savings and PerformanceaahtagoÎncă nu există evaluări

- Status Rfi Pie Rack & Sleeper.Document20 paginiStatus Rfi Pie Rack & Sleeper.Kurnia AryadiÎncă nu există evaluări

- Sec C - 3 SCH of Rates JKRDocument29 paginiSec C - 3 SCH of Rates JKRAzira Salim100% (1)

- BoQ For Boreholes and Shallow Wells Rehabilitation - GedoDocument13 paginiBoQ For Boreholes and Shallow Wells Rehabilitation - GedoGLORYÎncă nu există evaluări

- RVT350Document26 paginiRVT350kcprazwalÎncă nu există evaluări

- Design of Beam Slide ShareDocument26 paginiDesign of Beam Slide ShareVRKVRK10Încă nu există evaluări

- Rigid Pavement DesignDocument8 paginiRigid Pavement DesignsagarÎncă nu există evaluări

- BOQ-FATORY BD English 04 January 2010Document42 paginiBOQ-FATORY BD English 04 January 2010jimmiilongÎncă nu există evaluări

- TP of RC Design, G7A PDFDocument31 paginiTP of RC Design, G7A PDFJulesÎncă nu există evaluări

- REINFORCEMENT TAKE-OFF SHEETSDocument81 paginiREINFORCEMENT TAKE-OFF SHEETSHailuGelanHubenaÎncă nu există evaluări

- PCCP Method StatementDocument4 paginiPCCP Method StatementWendell ParasÎncă nu există evaluări

- Construct First Floor Columns & Second Floor SlabDocument28 paginiConstruct First Floor Columns & Second Floor Slabecmb73100% (1)

- Bar Bending Schedule of Box CulvertDocument1 paginăBar Bending Schedule of Box CulvertJohannes Gregorii LagueÎncă nu există evaluări

- Chapter 9 - Rigid Pavement - Final VersionDocument19 paginiChapter 9 - Rigid Pavement - Final VersionNabeelSaleemÎncă nu există evaluări

- Construction of 3 - Sets 9M, 1 - Set 12M Flagpole and FaçadeDocument9 paginiConstruction of 3 - Sets 9M, 1 - Set 12M Flagpole and FaçadeAlexander de GuzmanÎncă nu există evaluări

- New Features in PLANBAR 2017-1-01Document68 paginiNew Features in PLANBAR 2017-1-01pablopelaÎncă nu există evaluări

- Blinding Concrete Layer Reinforcement of PDFDocument17 paginiBlinding Concrete Layer Reinforcement of PDFMohamed Amine ZemouriÎncă nu există evaluări

- Planning Analysis and Designing of ShoppDocument63 paginiPlanning Analysis and Designing of Shopppramo_dass100% (1)

- Building Technology Lecture Notes - 2Document4 paginiBuilding Technology Lecture Notes - 2Shemmu100% (1)

- Special Concretes and Concreting Methods PDFDocument26 paginiSpecial Concretes and Concreting Methods PDFSathish Selva100% (1)

- ProjectDocument38 paginiProjectdhanabalÎncă nu există evaluări

- 2c Tender 4 Churches Chitar - DesignDocument16 pagini2c Tender 4 Churches Chitar - DesignJoão LopesÎncă nu există evaluări

- Lift SlabDocument35 paginiLift SlabAnonymous Y9dgyXhA100% (1)