Documente Academic

Documente Profesional

Documente Cultură

Aalco Metals LTD Copper and Copper Alloys CW307G Rod and Bar 118

Încărcat de

Idehen KelvinTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Aalco Metals LTD Copper and Copper Alloys CW307G Rod and Bar 118

Încărcat de

Idehen KelvinDrepturi de autor:

Formate disponibile

Copper and Copper Alloys

CW307G Rod and Bar

SPECIFICATIONS

CHEMICAL COMPOSITION

Commercial

CA104

EN

CW307G

Bronzes are Copper-based alloys with the major

alloying element being Tin. They offer a combination of

properties such as high strength, hardness, corrosion

resistance and wear resistance.

Copper-Aluminium alloys are commonly known as

Aluminium Bronzes. These alloys cover a range of

Copper-based alloys in which the primary alloying

element is up to 14% aluminium. The four major

groups of Aluminium Bronze are:

~ Single phase alloys containing less than 8%

Aluminium.

~ Two-phase (duplex) alloys containing 8 to 11%

Aluminium. These alloys also frequently have additions

of Iron and Nickel to increase strength. This group

contains casting alloys AB1 and AB2, the wrought

alloys CA105, CA104 and Defence Standard (formerly

Naval Engineering Standard NES 747 when cast and

the wrought form NES 833).

~ The low magnetic permeability Aluminium-Silicon

alloys.

~ The Copper-Manganese-Aluminium alloys with good

castability.

Alloy CA104 is an Aluminium Bronze with high

strength. CA104 also has excellent corrosion

resistance, abrasion resistance and ability to withstand

shock loading.

Applications

CW307G/CA104 is typically used in:

~ Valve and pump components

~ Marine equipment

~ Fasteners

~ Engine components

~ High temperature applications

EN 12163:2011

CW307G

Element

% Present

Aluminium (Al)

8.50 - 11.00

Nickel (Ni)

4.00 - 6.00

Iron (Fe)

3.00 - 5.00

Manganese (Mn)

0.0 - 1.00

Zinc (Zn)

0.0 - 0.40

Others (Total)

0.0 - 0.20

Silicon (Si)

0.0 - 0.20

Tin (Sn)

0.0 - 0.10

Lead (Pb)

0.0 - 0.05

Copper (Cu)

Balance

ALLOY DESIGNATIONS

Bronze CW307G corresponds

to

the

following

designations but may not be a direct equivalent:

UNS C63200

CA104

SUPPLIED FORMS

CW307G/CA104 is typically supplied as Round Bar

Bar

GENERIC PHYSICAL PROPERTIES

Property

Value

Density

7.58 g/cm

Melting Point

1035 C

Modulus of Elasticity

115 GPa

Thermal Conductivity

37.7 W/m.K

[1 OF 2] CONTINUED

Aalco is a registered trademark of Aalco Metals Ltd

Copyright: Aalco Metals Ltd, 25 High Street, Cobham, Surrey KT11 3DH

Copper and Copper Alloys

CW307G Rod and Bar

MECHANICAL PROPERTIES

EN 12163:2011

Rod & Bar

10mm to 120mm Dia / AF

Property

Value

Proof Stress

320-400 Min MPa

Tensile Strength

680-740 Min MPa

Hardness Brinell

170 to 210 HB

Elongation A

8-10 Min %

Mechanical properties vary widely according to condition (soft/half

hard/etc)

CORROSION RESISTANCE

Corrosion resistance is considered to be excellent in

most environments.

COLD WORKING

CW307G/CA104 has only a fair rating for cold working.

CONTACT

Address:

HOT WORKING

The hot forgeability rating for CW307G/CA104 is quite

good at 70, compared to Forging Brass which is rated

as 100.

The recommended hot working temperature for this

alloy is between 815 and 900C. The hot working

capabilities of CA104 are considered to be good.

HEAT TREATMENT

Solution treatment or annealing can be done by rapid

cooling after heating to 620-800C.

MACHINABILITY

Bronze alloy CW307G/CA104 has a fairly poor

machinability rating of 30 compared to

Brass

CZ121/CW614N which is rated as 100.

WELDABILITY

Gas shielded arc welding of CW307G/CA104 is rated as

excellent.

Coated metal arc welding, spot welding and butt

welding are rated as good.

Soldering, brazing and seam welding are rated as fair.

Oxyacetylene welding is rated as fair.

Web:

Please make contact directly with your local

service centre, which can be found via the

Locations page of our web site

www.aalco.co.uk

REVISION HISTORY

Datasheet Updated

11 January 2016

DISCLAIMER

This Data is indicative only and as such is not to be relied upon in place of

the full specification. In particular, mechanical property requirements vary

widely with temper, product and product dimensions. All information is

based on our present knowledge and is given in good faith. No liability will

be accepted by the Company in respect of any action taken by any third

party in reliance thereon.

Please note that the 'Datasheet Update' date shown above is no guarantee

of accuracy or whether the datasheet is up to date.

The information provided in this datasheet has been drawn from various

recognised sources, including EN Standards, recognised industry references

(printed & online) and manufacturers data. No guarantee is given that the

information is from the latest issue of those sources or about the accuracy of

those sources.

Material supplied by the Company may vary significantly from this data, but

will conform to all relevant and applicable standards.

As the products detailed may be used for a wide variety of purposes and as

the Company has no control over their use; the Company specifically

excludes all conditions or warranties expressed or implied by statute or

otherwise as to dimensions, properties and/or fitness for any particular

purpose, whether expressed or implied.

Advice given by the Company to any third party is given for that partys

assistance only and without liability on the part of the Company. All

transactions are subject to the Companys current Conditions of Sale. The

extent of the Companys liabilities to any customer is clearly set out in those

Conditions; a copy of which is available on request.

[2 OF 2]

Aalco is a registered trademark of Aalco Metals Ltd

Copyright: Aalco Metals Ltd, 25 High Street, Cobham, Surrey KT11 3DH

S-ar putea să vă placă și

- Aalco Metals LTD Aluminium Alloy 6060 T5 T595 144Document2 paginiAalco Metals LTD Aluminium Alloy 6060 T5 T595 144Gabriel PatileaÎncă nu există evaluări

- Aalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Document2 paginiAalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Hadi UtomoÎncă nu există evaluări

- 90 Tonne Aluminium Collapsible 11-4-15Document2 pagini90 Tonne Aluminium Collapsible 11-4-15ellisforheroesÎncă nu există evaluări

- Aalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Document2 paginiAalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Eric Amoakwa-BoaduÎncă nu există evaluări

- S31803Document2 paginiS31803Elliott RussellÎncă nu există evaluări

- Aalco Metals LTD Aluminium Alloy 6063 T6 Extrusions 158Document3 paginiAalco Metals LTD Aluminium Alloy 6063 T6 Extrusions 158prem nautiyalÎncă nu există evaluări

- Aalco Metals LTD Aluminium Alloy 6063 T6 Extrusions 158Document3 paginiAalco Metals LTD Aluminium Alloy 6063 T6 Extrusions 158rajupetalokeshÎncă nu există evaluări

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 paginiAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102HoangÎncă nu există evaluări

- Aalco Metals LTD Aluminium Alloy 6060 T5 T595 144Document2 paginiAalco Metals LTD Aluminium Alloy 6060 T5 T595 144Bryan PittmanÎncă nu există evaluări

- 1.4462 Duplex PropertiesDocument2 pagini1.4462 Duplex PropertiesEROL30Încă nu există evaluări

- Aalco Metals LTD Aluminium Alloy 6005A T6 Extrusion 157Document3 paginiAalco Metals LTD Aluminium Alloy 6005A T6 Extrusion 157asifÎncă nu există evaluări

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 paginiAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338ganmosesÎncă nu există evaluări

- Aalco Metals LTD - Aluminium Alloy - 5083 0 H111Document2 paginiAalco Metals LTD - Aluminium Alloy - 5083 0 H111rmgsalemÎncă nu există evaluări

- Aalco Datasheet BR Alloy CZ108Document2 paginiAalco Datasheet BR Alloy CZ108Paul RuckÎncă nu există evaluări

- Aalco Metals LTD - Aluminium Alloy - 1050 H14 - 57Document2 paginiAalco Metals LTD - Aluminium Alloy - 1050 H14 - 57lincinkrishnanÎncă nu există evaluări

- Aalco Metals LTD Stainless Steel 201201L202204 97Document3 paginiAalco Metals LTD Stainless Steel 201201L202204 97Nanjappa K NuchumaniandaÎncă nu există evaluări

- 25CR20NIDocument2 pagini25CR20NIShariq KhanÎncă nu există evaluări

- Aalco Metals LTD - Copper and Copper Alloys BSB23 DTD197 - 118Document2 paginiAalco Metals LTD - Copper and Copper Alloys BSB23 DTD197 - 118Alber MoelÎncă nu există evaluări

- Aalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Document4 paginiAalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Sergio CLÎncă nu există evaluări

- Pure Copper:-Copper Alloy C101Document9 paginiPure Copper:-Copper Alloy C101Senthil KumarÎncă nu există evaluări

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Document2 paginiWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200kashyap_structuralÎncă nu există evaluări

- High Temperature Brazing AlloysDocument0 paginiHigh Temperature Brazing AlloysvkmsÎncă nu există evaluări

- Aisi 305Document3 paginiAisi 305Aditya PratapÎncă nu există evaluări

- Aalco Metals LTD Aluminium Alloy 5754 H22 H24 H26 153Document2 paginiAalco Metals LTD Aluminium Alloy 5754 H22 H24 H26 153आनंद चव्हाणÎncă nu există evaluări

- Aalco Metals LTD Aluminium Alloy 6082 T6 T651 148Document2 paginiAalco Metals LTD Aluminium Alloy 6082 T6 T651 148Rohit Raj RanganathanÎncă nu există evaluări

- Overhead SwitchesDocument24 paginiOverhead SwitchesAnthony LagradaÎncă nu există evaluări

- Astm A513 PDFDocument20 paginiAstm A513 PDFpradelles89% (9)

- F568MDocument9 paginiF568Maldert_pathÎncă nu există evaluări

- Aalco Metals LTD Stainless Steel 1.4003 Nirosta 4003 3CR12 96Document2 paginiAalco Metals LTD Stainless Steel 1.4003 Nirosta 4003 3CR12 96Xingfeng HanÎncă nu există evaluări

- Aalco Metals LTD Copper Brass Bronze CW712R Naval Brass CZ112Document2 paginiAalco Metals LTD Copper Brass Bronze CW712R Naval Brass CZ112kriskee13Încă nu există evaluări

- Aalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97Document3 paginiAalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97sgupta_192494Încă nu există evaluări

- Lincolnweld 308/308L: Typical Applications Key FeaturesDocument2 paginiLincolnweld 308/308L: Typical Applications Key Featuresprabu prasadÎncă nu există evaluări

- Aws 5.9Document2 paginiAws 5.9Saravanan KcÎncă nu există evaluări

- Amari Aerospace LTD Aluminium Alloy L168 T6511 Bar 23Document2 paginiAmari Aerospace LTD Aluminium Alloy L168 T6511 Bar 23Vijet BhandiwadÎncă nu există evaluări

- Welding Product Programme: Duplex and Super Duplex Stainless SteelDocument6 paginiWelding Product Programme: Duplex and Super Duplex Stainless SteelFERNANDO MIRANDAÎncă nu există evaluări

- Mechanical Testing: Notched Bar or Impact Testing. Part IIDocument4 paginiMechanical Testing: Notched Bar or Impact Testing. Part IIMehmet Soysal100% (1)

- Carbon Steel: Application Material GroupDocument27 paginiCarbon Steel: Application Material Groupharishkumar.ravichandranÎncă nu există evaluări

- 17.4 PH Material SpecificationDocument2 pagini17.4 PH Material SpecificationDevendra BangarÎncă nu există evaluări

- ASTM A231 - A231M - 10 Standard Specification For Chromium Vanadium Alloy Steel Spring WireDocument2 paginiASTM A231 - A231M - 10 Standard Specification For Chromium Vanadium Alloy Steel Spring WireMahmood Khan0% (1)

- Alluminium SheetsDocument7 paginiAlluminium SheetsVaibhav ShuklaÎncă nu există evaluări

- SAE - AMS 5659mv004Document9 paginiSAE - AMS 5659mv004Nilesh PatilÎncă nu există evaluări

- Dalsteel Metals Pty Limited Aluminium Alloy 6063 T6 158Document2 paginiDalsteel Metals Pty Limited Aluminium Alloy 6063 T6 158arjelalvarez5_705489Încă nu există evaluări

- Technical Brochure - Ferritics - MolyDocument5 paginiTechnical Brochure - Ferritics - MolyJoshua WalkerÎncă nu există evaluări

- Silo - Tips - Nippon Steel Sumitomo Metal Electric Resistance Welded Steel Tubes For Boilers and Heat ExchangersDocument10 paginiSilo - Tips - Nippon Steel Sumitomo Metal Electric Resistance Welded Steel Tubes For Boilers and Heat ExchangersAlonso MaqueraÎncă nu există evaluări

- C 6102Document2 paginiC 6102Mingo EvaÎncă nu există evaluări

- B 211 - 02 - Qjixms0wmgDocument10 paginiB 211 - 02 - Qjixms0wmgmercab15Încă nu există evaluări

- Wilsons LTD Aluminium Alloy L59 H16 or H26 Sheet 3103 174Document2 paginiWilsons LTD Aluminium Alloy L59 H16 or H26 Sheet 3103 174Zoran Stojanovic Zona VarÎncă nu există evaluări

- Duplex Stainless SteelDocument24 paginiDuplex Stainless SteeljeffreymacaseroÎncă nu există evaluări

- Ams 5622 DDocument11 paginiAms 5622 DPma CorpÎncă nu există evaluări

- H010ARDocument22 paginiH010ARMohammed ChaabateÎncă nu există evaluări

- Steel Investment Castings General Requirements, For Pressure-Containing PartsDocument12 paginiSteel Investment Castings General Requirements, For Pressure-Containing PartsManivannanMudhaliarÎncă nu există evaluări

- KOBELCO Welding Handbook 2009Document202 paginiKOBELCO Welding Handbook 2009shamsabbasÎncă nu există evaluări

- Hand Book For Steel Structure Quality Control on SiteDe la EverandHand Book For Steel Structure Quality Control on SiteÎncă nu există evaluări

- Spot Welding Interview Success: An Introduction to Spot WeldingDe la EverandSpot Welding Interview Success: An Introduction to Spot WeldingÎncă nu există evaluări

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesDe la EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesEvaluare: 4.5 din 5 stele4.5/5 (5)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesDe la EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesÎncă nu există evaluări

- Advances in Ceramics for Environmental, Functional, Structural, and Energy ApplicationsDe la EverandAdvances in Ceramics for Environmental, Functional, Structural, and Energy ApplicationsMorsi M. MahmoudÎncă nu există evaluări

- UBA2014 Evaluation Board: Rev. 01 - 14 October 2009 User ManualDocument24 paginiUBA2014 Evaluation Board: Rev. 01 - 14 October 2009 User ManualIdehen KelvinÎncă nu există evaluări

- Me-19F Massuse Relay: FeaturesDocument4 paginiMe-19F Massuse Relay: FeaturesIdehen KelvinÎncă nu există evaluări

- Innovation Funnel TemplateDocument1 paginăInnovation Funnel TemplateIdehen KelvinÎncă nu există evaluări

- OringDocument1 paginăOringIdehen KelvinÎncă nu există evaluări

- Geared DC Instrument Motor 1308 SeriesDocument1 paginăGeared DC Instrument Motor 1308 SeriesIdehen KelvinÎncă nu există evaluări

- Overview of Materials For Polyimide: To View All Available Suppliers For This MaterialDocument3 paginiOverview of Materials For Polyimide: To View All Available Suppliers For This MaterialIdehen KelvinÎncă nu există evaluări

- Friction Forces in O-Ring SealingDocument8 paginiFriction Forces in O-Ring SealingIdehen KelvinÎncă nu există evaluări

- Item # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Document2 paginiItem # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Idehen KelvinÎncă nu există evaluări

- Item # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Document2 paginiItem # Oh, Pneumatic Valve Actuators: Pressures To 150000 Psi (10342 Bar)Idehen KelvinÎncă nu există evaluări

- OringDocument1 paginăOringIdehen KelvinÎncă nu există evaluări

- OH ParkerAutoclaveEngineersFCD 2DSalesDrawing 01 06 2021 PDFDocument1 paginăOH ParkerAutoclaveEngineersFCD 2DSalesDrawing 01 06 2021 PDFIdehen KelvinÎncă nu există evaluări

- LR-360KAS-BROCHURE-LNG Sampling SystemsDocument4 paginiLR-360KAS-BROCHURE-LNG Sampling SystemsIdehen KelvinÎncă nu există evaluări

- BP010 Datasheet For Pressure RegulatorDocument4 paginiBP010 Datasheet For Pressure RegulatorIdehen KelvinÎncă nu există evaluări

- HF300 Datasheet: High-Flow Pressure RegulatorDocument4 paginiHF300 Datasheet: High-Flow Pressure RegulatorIdehen KelvinÎncă nu există evaluări

- In Line High Flow' Insertion Type Regulators For 4" - 8" PipeworkDocument2 paginiIn Line High Flow' Insertion Type Regulators For 4" - 8" PipeworkIdehen KelvinÎncă nu există evaluări

- LF310 Datasheet: Low-Flow Pressure RegulatorDocument4 paginiLF310 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinÎncă nu există evaluări

- LF311 Datasheet: Low-Flow Pressure RegulatorDocument4 paginiLF311 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinÎncă nu există evaluări

- HF250 Datasheet: High-Flow Pressure RegulatorDocument4 paginiHF250 Datasheet: High-Flow Pressure RegulatorIdehen KelvinÎncă nu există evaluări

- HYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionDocument4 paginiHYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionIdehen KelvinÎncă nu există evaluări

- BP-HF301 Datasheet: High-Flow Back Pressure RegulatorDocument4 paginiBP-HF301 Datasheet: High-Flow Back Pressure RegulatorIdehen KelvinÎncă nu există evaluări

- BP301 Datasheet: Back Pressure RegulatorDocument4 paginiBP301 Datasheet: Back Pressure RegulatorIdehen KelvinÎncă nu există evaluări

- BP-HF251 Datasheet: High-Flow Back Pressure RegulatorDocument4 paginiBP-HF251 Datasheet: High-Flow Back Pressure RegulatorIdehen KelvinÎncă nu există evaluări

- Installation and Commisioning of Servo & Propotional Control ValvesDocument3 paginiInstallation and Commisioning of Servo & Propotional Control ValvesIdehen KelvinÎncă nu există evaluări

- Technology Focus: Three Keys To Specifying Long Life Servo ValvesDocument2 paginiTechnology Focus: Three Keys To Specifying Long Life Servo ValvesIdehen KelvinÎncă nu există evaluări

- 2-Stage Servo Valve Nozzle Flapper, Mechanical Feedback Design and OperationDocument3 pagini2-Stage Servo Valve Nozzle Flapper, Mechanical Feedback Design and OperationIdehen KelvinÎncă nu există evaluări

- Metamorphic Rocks PracticalDocument27 paginiMetamorphic Rocks PracticalMr Gk meenaÎncă nu există evaluări

- PC Lexan HP6NR Healthcare - ProspectorDocument5 paginiPC Lexan HP6NR Healthcare - ProspectorcountzeroaslÎncă nu există evaluări

- Nanostructures and NanomaterialsDocument2 paginiNanostructures and NanomaterialsSantosh MysoreÎncă nu există evaluări

- CastMaterials E00510Document6 paginiCastMaterials E00510samir basuniÎncă nu există evaluări

- Checkered PlateDocument1 paginăCheckered PlateMark A FainaÎncă nu există evaluări

- Ejemplo 11.1 - Mott. RDocument10 paginiEjemplo 11.1 - Mott. RDylan Navarro LÎncă nu există evaluări

- Indrakanty Surya ShashankDocument10 paginiIndrakanty Surya ShashankINDRAKANTY SURYA SHASHANKÎncă nu există evaluări

- Bonderite S-FN 213 Acheson: Technical Data SheetDocument2 paginiBonderite S-FN 213 Acheson: Technical Data SheetirisÎncă nu există evaluări

- Joseph Abrusci - Professional Homemade Cherry BombsDocument26 paginiJoseph Abrusci - Professional Homemade Cherry BombsLê Nguyên ĐứcÎncă nu există evaluări

- Value EngineeringDocument20 paginiValue EngineeringSakshi SinghÎncă nu există evaluări

- Assignment Neutralisation ReactionDocument1 paginăAssignment Neutralisation ReactionMaridjan WiwahaÎncă nu există evaluări

- Orsat ApparatusDocument7 paginiOrsat ApparatusTejas Desai100% (1)

- First Manganese (II) Bio-MOF: An Effective Heterogeneous Catalyst For Henry ReactionDocument9 paginiFirst Manganese (II) Bio-MOF: An Effective Heterogeneous Catalyst For Henry ReactionRahul palÎncă nu există evaluări

- 1.1600519 1Document23 pagini1.1600519 1A Mohan BabuÎncă nu există evaluări

- T.Y.Yeh Professor Department of Civil and Environmental EngineeringDocument14 paginiT.Y.Yeh Professor Department of Civil and Environmental EngineeringAlberto Acabal IIÎncă nu există evaluări

- Pneumatic Structures: The Fascination of Pneumatic Structures Begins With The Fascination of The SkyDocument9 paginiPneumatic Structures: The Fascination of Pneumatic Structures Begins With The Fascination of The SkyTangha Muklom KunchaÎncă nu există evaluări

- DVS Technical Codes On Plastics Joining TechnologiesDocument11 paginiDVS Technical Codes On Plastics Joining TechnologiesjavierÎncă nu există evaluări

- 3002001381comprehensive CycleChemistry Guidelines For HRSG AminasDocument50 pagini3002001381comprehensive CycleChemistry Guidelines For HRSG AminasGloria Del Carmen Muñoz RamirezÎncă nu există evaluări

- Drug Product DevelopmentDocument20 paginiDrug Product Developmentducluong28Încă nu există evaluări

- DONE - GoodMechanical Properties of 3D Printed Polymeric Gyroid CONFRONTO Con Altre TPMSDocument9 paginiDONE - GoodMechanical Properties of 3D Printed Polymeric Gyroid CONFRONTO Con Altre TPMSMoad BouzidaÎncă nu există evaluări

- HCLDocument13 paginiHCLHussein AlkafajiÎncă nu există evaluări

- Materials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding FittingsDocument1 paginăMaterials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding Fittingsnaseema1Încă nu există evaluări

- MSDS - GBH7107Document2 paginiMSDS - GBH7107pankaj111Încă nu există evaluări

- Pulpling of Wood EditedDocument6 paginiPulpling of Wood EditedMuhammad Omar Khan GhouriÎncă nu există evaluări

- D 3517 - 19 ResinDocument13 paginiD 3517 - 19 ResinNeeraj kumarÎncă nu există evaluări

- SN 200Document100 paginiSN 200T Mathew Tholoor100% (2)

- Drill CompleteDocument35 paginiDrill Completesiva kumarÎncă nu există evaluări

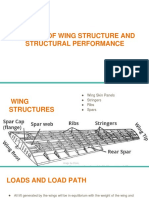

- Bending of Wing Structure and Structural PerformanceDocument21 paginiBending of Wing Structure and Structural Performancemrajadurai700Încă nu există evaluări

- CH 4 PE PipeDocument22 paginiCH 4 PE Pipeanon_104613317Încă nu există evaluări

- Metalworking Woodworking Tool Cut Hand Tool Steel Case Hardened Tang RaspDocument1 paginăMetalworking Woodworking Tool Cut Hand Tool Steel Case Hardened Tang RaspQamar ZamansÎncă nu există evaluări