Documente Academic

Documente Profesional

Documente Cultură

Affect of Water/cement Ratio (W/C Ratio)

Încărcat de

Diego Tafur López0 evaluări0% au considerat acest document util (0 voturi)

433 vizualizări4 paginitraduccion

Titlu original

ATRADUCIR

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documenttraduccion

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

433 vizualizări4 paginiAffect of Water/cement Ratio (W/C Ratio)

Încărcat de

Diego Tafur Lópeztraduccion

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

Affect of Water/cement Ratio (w/c ratio)

Water/cement ratio (w/c ratio) theory states that for

a given combination of materials and as long a

s

workable consistency is obtained, the strength o

f

concrete at a given age depends on the w/c ratio.

In 1918, Duff Abrams established a

water/cement ratio law for the strength of

concrete :

1.5( w / c)

compressive strength at some fixed age, A =

empirical constant (96.5 MPa), B= constant that

depends mostly on the cement properties (about 4) ,

and w/c (water/cement ratio by weight).

c

Advantages of low water/cement ratio:

Increased strength.

Lower permeability.

Increased resistance to weathering.

Better bond between concrete and

reinforcement.

Reduced drying shrinkage and cracking.

Less volume change from wetting and drying.

Methods of Mix Proportioning

Absolute volume method

Most commonly used method (ACI mix dsign)

Other methods

ACI 211.1 Standard practice for selecting Normal,

Heavyweight and Mass Concrete.

ACI 211.2 Standard practice for selecting Structural

lightweight concrete.

ACI 211.3 Standard practice for selecting Proportions

for no-slump concrete.

ACI 211.4R Standard practice for selecting high

strength concrete with Portland cement and fly ash.

Designing Concrete Mixtures

Concrete mixture proportions are usually

expressed on the basis of the mass of ingredient

s

per unit volume.

The unit of volume used is either a cubic yard or

a

cubic meter of concrete.

ACI Mix Design

The most common method used which is

established by ACI Recommended Practice 211.1

Any mix design procedure will provide a first

approximation of the proportions and must be

checked by trial batches.

Local characteristics

considered.

of

materials

should

be

The following sequence of steps should be

followed:

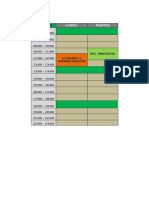

Slump

Type of Construction

(1) determine the following:

(mm)

(inches)

Reinforced foundation

walls and footings

25 - 75

1-3

Plain footings, caissons

and substructure walls

25 - 75

1-3

Beams and reinforced

walls

25 - 100

1-4

Building columns

25 - 100

1-4

the job parameters

aggregate properties

maximum aggregate size

slump

w/c ratio

admixtures,

(2) calculation of batch wei

g

ht, and

(3) adjustments to batch weights based on trial mix.

Pavements and slabs

25 - 75

1-3

the text book rather than the ACI standard).

The aim of the designer should always be to get

concrete mixtures of optimum strength at

minimum cement content and acceptable

workability.

Once the w/c ratio is established and the

workability or consistency needed for the

specific design is chosen, the rest should be

simple manipulation with diagrams and tables

based on large numbers of trial mixes.

ACI METHOD OF PROPORTIONING

CONCRETE MIXES

The ACI Standard 211.1 is a Recommended Practice for

Selecting Proportions for Concrete. The procedure is as

follows:

Step 1. Choice of slump

Step 2. Choice of maximum size of aggregate

Step 3. Estimation of mixing water and air

content

Step 4. Selection of water/cement ratio

Step 5. Calculation of cement content

Step 6. Estimation of coarse aggregate content

Step 7. calculation of Fine Aggregate Content

Step 8. Adjustments for Aggregate Moisture

Step 9. Trial Batch Adjustments

Step 1. Choice of slump

If slump is not specified, a value appropriate for the work can be

selected from the below Table which is reproduced from the

text book below*, (note that the table numbers are given fr

S-ar putea să vă placă și

- Lecture Notes on Reinforced Concrete DesignDe la EverandLecture Notes on Reinforced Concrete DesignÎncă nu există evaluări

- ACI Mix DesignDocument9 paginiACI Mix DesignAbdul Hamid BhattiÎncă nu există evaluări

- Mix DesignDocument10 paginiMix DesignMary Emalaine SerranoÎncă nu există evaluări

- ACI Mix Design PDFDocument9 paginiACI Mix Design PDFHanniel MadramootooÎncă nu există evaluări

- ACI Mix DesignDocument40 paginiACI Mix DesignJannine AvilaÎncă nu există evaluări

- Selection of Concrete CompositionDocument62 paginiSelection of Concrete CompositionMelinda GordonÎncă nu există evaluări

- Module V - 2023Document49 paginiModule V - 2023-黄柏威Încă nu există evaluări

- High Performance ConcreteDocument79 paginiHigh Performance ConcreteShyam Prasad ThiraviamÎncă nu există evaluări

- Selection of Concrete CompositionDocument62 paginiSelection of Concrete CompositionSidharth MahajanÎncă nu există evaluări

- Factors in The Proportioning of Quality Concrete Mixtures: Workability StrengthDocument54 paginiFactors in The Proportioning of Quality Concrete Mixtures: Workability Strengthzzz_monsterÎncă nu există evaluări

- Mix-Design RGPDocument45 paginiMix-Design RGPmehul goyalÎncă nu există evaluări

- Proportioning Concrete MixturesDocument54 paginiProportioning Concrete Mixtureshola_kbÎncă nu există evaluări

- Concrete Mix DesignDocument41 paginiConcrete Mix Designkhalid khanÎncă nu există evaluări

- Week .11 & 12 Mix DesignDocument62 paginiWeek .11 & 12 Mix Designhafsaayaz30Încă nu există evaluări

- Concrete Mix Design Concrete Mix Design: Presentation LayoutDocument28 paginiConcrete Mix Design Concrete Mix Design: Presentation LayoutKris dÎncă nu există evaluări

- l05 092Document7 paginil05 092rammirisÎncă nu există evaluări

- AttachmentDocument23 paginiAttachmentayeshakynaÎncă nu există evaluări

- Lab ReportDocument44 paginiLab ReportNepali Kanchoo100% (1)

- Comparision Code Mix CodesDocument5 paginiComparision Code Mix CodesTabish IzharÎncă nu există evaluări

- Concrete Mixture OptimizationDocument13 paginiConcrete Mixture OptimizationAbdo AtawyÎncă nu există evaluări

- 5 Mix ProportionDocument43 pagini5 Mix ProportionSteven KuaÎncă nu există evaluări

- Job No. 6Document13 paginiJob No. 6chyousufÎncă nu există evaluări

- Aci Method of Mix DesignDocument19 paginiAci Method of Mix DesignJuel Rahaman100% (1)

- Unit IiiDocument9 paginiUnit IiiSri RamÎncă nu există evaluări

- PCCP Design PDFDocument61 paginiPCCP Design PDFKeeperÎncă nu există evaluări

- Mix Design EstimationDocument60 paginiMix Design EstimationKhaled MoslahÎncă nu există evaluări

- Comparison of Fracture Test Standards For A Super Pave Densegraded Hot Mix AsphaltDocument14 paginiComparison of Fracture Test Standards For A Super Pave Densegraded Hot Mix AsphaltharÎncă nu există evaluări

- Proportioning Concrete MixesDocument54 paginiProportioning Concrete Mixesgman444Încă nu există evaluări

- Concrete Slump Test: From Wikipedia, The Free EncyclopediaDocument5 paginiConcrete Slump Test: From Wikipedia, The Free EncyclopediaJenny Ann ValderramaÎncă nu există evaluări

- Koehler Rheology v1Document32 paginiKoehler Rheology v1Narasimham GuggillaÎncă nu există evaluări

- Designing and Proportioning - Normal Concrete MixturesDocument62 paginiDesigning and Proportioning - Normal Concrete MixturesCivilEngClubÎncă nu există evaluări

- CMD (Apparatus, Discussion)Document9 paginiCMD (Apparatus, Discussion)mohdnazminismailÎncă nu există evaluări

- Portland Cement ConcreteDocument47 paginiPortland Cement ConcreteAbbasabbasiÎncă nu există evaluări

- Midterm, Topic 2, ConcreteDocument22 paginiMidterm, Topic 2, ConcreteDhave Airen DomingoÎncă nu există evaluări

- RheologyDocument37 paginiRheologyVassilios Kelessidis0% (1)

- Lect# 4 Self Compacting ConcreteDocument39 paginiLect# 4 Self Compacting ConcreteTaimoor AhmadÎncă nu există evaluări

- Acpa Mix Design PresentationDocument55 paginiAcpa Mix Design PresentationSubodh ChaturvediÎncă nu există evaluări

- Application of Laboratory Asphalt Cracking Tests To Cold in Place Recycled MixturesDocument20 paginiApplication of Laboratory Asphalt Cracking Tests To Cold in Place Recycled MixturesharÎncă nu există evaluări

- Mix DesignDocument29 paginiMix Designshahhassa9Încă nu există evaluări

- Mi Design of ConcreteDocument119 paginiMi Design of ConcreteRufesh YadavÎncă nu există evaluări

- Concrete DesignDocument28 paginiConcrete DesignMichael CanchoÎncă nu există evaluări

- Concrete Mix Design DOE PDFDocument15 paginiConcrete Mix Design DOE PDFkarthiksamp100% (1)

- Chapter 3b-Concrete Mix DesignDocument16 paginiChapter 3b-Concrete Mix DesignPaul SsewankamboÎncă nu există evaluări

- Mix Design For Roller Compacted Concrete RCCDocument3 paginiMix Design For Roller Compacted Concrete RCCpgciprianÎncă nu există evaluări

- Mix DesignDocument37 paginiMix DesignSagarKasarlaÎncă nu există evaluări

- Design of Concrete Mixes .Hw3Document12 paginiDesign of Concrete Mixes .Hw3RawandAlbarodyÎncă nu există evaluări

- Aci Method of Mix DesignDocument15 paginiAci Method of Mix Designvineetkothari1Încă nu există evaluări

- Mix DesignDocument2 paginiMix DesignPrayas SubediÎncă nu există evaluări

- Mix Design MethodDocument8 paginiMix Design MethodWillard ApengÎncă nu există evaluări

- Concrete Slump TestDocument3 paginiConcrete Slump TestShaan LalwaniÎncă nu există evaluări

- Reinforced Concrete Buildings: Behavior and DesignDe la EverandReinforced Concrete Buildings: Behavior and DesignEvaluare: 5 din 5 stele5/5 (1)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeDe la EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeÎncă nu există evaluări

- Seismic Safety Evaluation of Concrete Dams: A Nonlinear Behavioral ApproachDe la EverandSeismic Safety Evaluation of Concrete Dams: A Nonlinear Behavioral ApproachÎncă nu există evaluări

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyDe la EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinÎncă nu există evaluări

- Concrete-Block Manufacture - Processes and MachinesDe la EverandConcrete-Block Manufacture - Processes and MachinesEvaluare: 5 din 5 stele5/5 (1)

- Advances in Ceramic Armor XDe la EverandAdvances in Ceramic Armor XJerry C. LaSalviaÎncă nu există evaluări

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsDe la EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechÎncă nu există evaluări

- 10 1016@j Ijrmms 2020 104273 PDFDocument12 pagini10 1016@j Ijrmms 2020 104273 PDFDiego Tafur LópezÎncă nu există evaluări

- Resumen Locumba 0 2Document6 paginiResumen Locumba 0 2Diego Tafur LópezÎncă nu există evaluări

- Computers and Geotechnics: Shaoqun Dong, Lianbo Zeng, Peter Dowd, Chaoshui Xu, Han CaoDocument12 paginiComputers and Geotechnics: Shaoqun Dong, Lianbo Zeng, Peter Dowd, Chaoshui Xu, Han CaoDiego Tafur LópezÎncă nu există evaluări

- ReadmeDocument1 paginăReadmeDiego Tafur LópezÎncă nu există evaluări

- S1TBX TOPSAR Interferometry With Sentinel-1 TutorialDocument21 paginiS1TBX TOPSAR Interferometry With Sentinel-1 TutorialSantiago El Mago MouradianÎncă nu există evaluări

- IDIOT A Free and Easy-To-use Software Tool For DInDocument8 paginiIDIOT A Free and Easy-To-use Software Tool For DInDiego Tafur LópezÎncă nu există evaluări

- S1TBX Stripmap Interferometry With Sentinel-1 TutorialDocument41 paginiS1TBX Stripmap Interferometry With Sentinel-1 TutorialSantiago El Mago Mouradian100% (1)

- Agenda 33 PDFDocument1 paginăAgenda 33 PDFDiego Tafur LópezÎncă nu există evaluări

- Chris Stevens-Mapping Arctic Bottomfast Sea Ice-SAR InterferometryDocument17 paginiChris Stevens-Mapping Arctic Bottomfast Sea Ice-SAR InterferometryDiego Tafur LópezÎncă nu există evaluări

- Advanced Webinar: Radar Remote Sensing Applications For Land, Water, & Disasters ApplicationsDocument1 paginăAdvanced Webinar: Radar Remote Sensing Applications For Land, Water, & Disasters ApplicationsDiego Tafur LópezÎncă nu există evaluări

- Acknow IntroDocument25 paginiAcknow IntroYaseen MuhammadÎncă nu există evaluări

- Conversion Factors RNDocument1 paginăConversion Factors RNDiego Tafur LópezÎncă nu există evaluări

- International Journal of Applied Earth Observation and GeoinformationDocument9 paginiInternational Journal of Applied Earth Observation and GeoinformationDiego Tafur LópezÎncă nu există evaluări

- Preventive Medicine ReportsDocument5 paginiPreventive Medicine ReportsDiego Tafur LópezÎncă nu există evaluări

- LandsatDocument22 paginiLandsatDiego Tafur LópezÎncă nu există evaluări

- RoutineDocument1 paginăRoutineDiego Tafur LópezÎncă nu există evaluări

- Horario 2016Document3 paginiHorario 2016Diego Tafur LópezÎncă nu există evaluări

- Stationid Locatión Geology Sample - Dat X YDocument4 paginiStationid Locatión Geology Sample - Dat X YDiego Tafur LópezÎncă nu există evaluări

- 2012-10 Doctor ListDocument20 pagini2012-10 Doctor ListDiego Tafur LópezÎncă nu există evaluări

- 2012-10 Doctor ListDocument20 pagini2012-10 Doctor ListDiego Tafur LópezÎncă nu există evaluări

- Truncated CubeDocument1 paginăTruncated CubeDiego Tafur LópezÎncă nu există evaluări

- Crack Meter: Product Brochure InstrumentationDocument2 paginiCrack Meter: Product Brochure InstrumentationDilhara WickramaarachchiÎncă nu există evaluări

- l01 MBLC Darh d05 TRN 024454 Dar ResponseDocument2 paginil01 MBLC Darh d05 TRN 024454 Dar ResponseAsif SafiÎncă nu există evaluări

- Building Contruction Workers Regulation of Employment and Working Conditions Act 1996Document14 paginiBuilding Contruction Workers Regulation of Employment and Working Conditions Act 1996omarmhusainÎncă nu există evaluări

- Grundfos CRDocument48 paginiGrundfos CRharlyganÎncă nu există evaluări

- Client Name: Project Name:: Ezar For Engineering and Technical ServicesDocument1 paginăClient Name: Project Name:: Ezar For Engineering and Technical ServicesdhahiÎncă nu există evaluări

- Installation Instructions ISOnV ENGDocument48 paginiInstallation Instructions ISOnV ENGLuz BarradasÎncă nu există evaluări

- Base Plate & Anchor Bolt Design For Pipe Dia 508 Loading DetailsDocument4 paginiBase Plate & Anchor Bolt Design For Pipe Dia 508 Loading DetailsAsaru DeenÎncă nu există evaluări

- Capitol Steel Corporation-RSB PDFDocument1 paginăCapitol Steel Corporation-RSB PDFeg choloÎncă nu există evaluări

- Development Authority: Bhubaneswar Development Authority RFP Document For EPC contractor-ISBT Baramunda, BhubaneshwarDocument8 paginiDevelopment Authority: Bhubaneswar Development Authority RFP Document For EPC contractor-ISBT Baramunda, BhubaneshwarSARIT SEKHAR MUKHERJEEÎncă nu există evaluări

- This Part Describes Preliminary and Basic Services Which An Architect Will Normally ProvideDocument9 paginiThis Part Describes Preliminary and Basic Services Which An Architect Will Normally ProvidedodsmÎncă nu există evaluări

- Ventilator - S&P - HCTB-HCTT (En)Document9 paginiVentilator - S&P - HCTB-HCTT (En)Muhidin KozicaÎncă nu există evaluări

- Materials For LumbungDocument7 paginiMaterials For LumbungIssnadewi Paramitha WiryaÎncă nu există evaluări

- 0160Document1 pagină0160kevinkaradaÎncă nu există evaluări

- Base Isolation For Multi Storey Buildings PDFDocument311 paginiBase Isolation For Multi Storey Buildings PDFRal GLÎncă nu există evaluări

- Gaurav Dahiphale: Civil EDocument2 paginiGaurav Dahiphale: Civil ESwap DaradeÎncă nu există evaluări

- Thermostatictubular Heaters: Installation and Operating InstructionsDocument4 paginiThermostatictubular Heaters: Installation and Operating InstructionsHpnoteÎncă nu există evaluări

- BS en 14576-2005Document15 paginiBS en 14576-2005bdr85Încă nu există evaluări

- DBB Gate Valve CatalogDocument11 paginiDBB Gate Valve CatalogVipul PanchalÎncă nu există evaluări

- 01-B - Centrifugal PumpsDocument44 pagini01-B - Centrifugal Pumps81q1iyÎncă nu există evaluări

- Wa0040.Document14 paginiWa0040.robert nick eusebio teheranÎncă nu există evaluări

- Streama 2Document3 paginiStreama 2JA MantalÎncă nu există evaluări

- Papercrete4 PDFDocument9 paginiPapercrete4 PDFPrasad TekadeÎncă nu există evaluări

- Jaina Safe Prefab HutDocument26 paginiJaina Safe Prefab Hutamritesh pandeyÎncă nu există evaluări

- Hemp LimeDocument18 paginiHemp LimePranav Chovatiya0% (1)

- Rural Road DesignDocument86 paginiRural Road DesignMilenka Uceda PuiconÎncă nu există evaluări

- Bowles J. E. - FDN - Analysis & DSNDocument2 paginiBowles J. E. - FDN - Analysis & DSNharishÎncă nu există evaluări

- Gabions - Matteres PVC Gabions - Mattress Malaysia, Johor, Batu Pahat Manufacturer, Supplier, Supplies, Supply - CHUN HOE TRADING SDN BHDDocument12 paginiGabions - Matteres PVC Gabions - Mattress Malaysia, Johor, Batu Pahat Manufacturer, Supplier, Supplies, Supply - CHUN HOE TRADING SDN BHDSab RiÎncă nu există evaluări

- Otari D.P.: NAME OF WORK - Proposed ConstructionDocument3 paginiOtari D.P.: NAME OF WORK - Proposed ConstructionDattaraj OtariÎncă nu există evaluări

- Reinhardt 1982Document48 paginiReinhardt 1982Tugce CeranÎncă nu există evaluări

- NON-METALLIC RIGID CONDUIT - Lesson PlanDocument5 paginiNON-METALLIC RIGID CONDUIT - Lesson PlanBriant King Peñas100% (1)