Documente Academic

Documente Profesional

Documente Cultură

A001102 B

Încărcat de

Cherry CardonaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A001102 B

Încărcat de

Cherry CardonaDrepturi de autor:

Formate disponibile

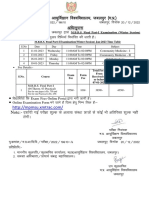

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

Vetco Gray

TREE INSPECTION / MAINTENANCE STAND

FACTORY ACCEPTANCE PROCEDURE

Part No: A190301-105

Prepared by

(Engineering) :

Paul F Milne

Date:

Approved by

(Engineering):

Duncan Mcgavin

Date:

Approved by

(Build Team):

Richard Simpson

Date:

WORKS ORDER No

SERIAL No

PART No

SALES ORDER No

DESCRIPTION

17 Sept 2003

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

REVISION RECORD.

Rev.

Date

Change in Procedure

Para

12/04/02

6.1.1

17/09/03

Added Drawing Number to assembly

procedure.

Removed Watermark

Updated to add latest Quality notes

Page 2 of 11

4.0

Revised

by

MR

Approved

by

MD

PFM

DM

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

TABLE OF CONTENTS.

1.0

SCOPE

2.0

SAFETY

3.0

REFERENCE INFORMATION

3.1

Reference Documents

3.2

Recommended Bolt Torque

3.3

Industry Reference Standards

4.0

QUALITY CONTROL VERIFICATION

5.0

EQUIPMENT LIST

6.0

ASSEMBLY PROCEDURES

6.1

7.0

Specific Assembly Procedures

TEST PROCEDURES

7.1

Pre-Operational Checks.

7.2

Functional Test.

8.0

POST TEST / CHECKOUT PROCEDURES

10

9.0

APPENDICES

11

9.1

Deviation Form

11

9.2

Distribution List

11

Page 3 of 11

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

1.0

SCOPE.

This procedure outlines the recommended acceptance tests to be carried out in

the presence of a customer appointed representative (if required).

1.1

This procedure covers the functional testing of the Xmas Tree Inspection /

Maintenance Stand, any apparent error or deviation should be notified to

engineering for modification of this procedure, if appropriate.

1.2

It should be noted that the order of the test sequence should be as documented

in this procedure. In some instances, the order may be altered subject to prior

approval from Engineering.

1.3

This procedure covers the following Tests:

A. Function Test.

B. Check Out Procedures Prior To Booking to Stock.

1.4

Test medium used within this procedure will be:

Hydrostatic pressure test

N/A.

2.0

SAFETY.

2.1

Every precaution must be taken during testing to ensure the safety of all

personnel in the vicinity of the test area.

2.2

The following component will have been subjected to its respective FAT prior to

commencing this FAT:Production or Injection Xmas Tree

Page 4 of 11

FAT No: A011799

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

3.0

REFERENCE INFORMATION.

3.1

Reference Documents.

The following documents are referenced within this procedure:

(Contact VG documents control for current revisions)

Description

Tree Inspection / Maintenance Stand

Xmas Tree (Production)

Xmas Tree (Injection)

3.2

VG Document

Number

A190301-105

A110575-97A091

A110575-98

Recommended Bolt Torque.

The following table identifies the torque requirements for various bolt sizes based on a

yield strength of 724 N/mm2 (105,000 psi) bolt material.

Values are given for each size assuming the bolt and nut are Zinc Plated.

Using Friction co-efficient = 0.13.

ZINC PLATED NO THREAD COMPOUND

362 N/mm2 (52,500 psi) bolt stress

BOLT SIZE (inches)

TORQUE REQUIRED

Nm

(ft-lbs)

1/2 - 13 UNC

80

59

5/8 - 11 UNC

153

113

3/4 - 10 UNC

266

196

7/8 - 9 UNC

424

313

1 - 8 UN

643

474

1 1/8 - 8 UN

930

686

1 1/4 - 8 UN

1,292

953

1 3/8 - 8 UN

1,737

1,281

1 1/2 - 8 UN

2,272

1,676

1 5/8 - 8 UN

2,910

2,146

1 3/4 - 8 UN

3,654

2,695

1 7/8 - 8 UN

4,516

3,331

2 - 8 UN

5,505

4,060

3.3

Industry Referenced Standards.

API 6A, API 17D, ISO 13628-4.

Page 5 of 11

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

4.0

QUALITY CONTROL VERIFICATION.

4.1 Deviation

Any deviation from the procedure is be recorded on the attached deviation form and signed off

by VG Engineering.

Temporary deviations shall be highlighted as such and are applicable only to the particular unit

under assembly or test.

Deviations to be incorporated as permanent shall be highlighted as such and incorporated into

this document as a revision.

4.2 Non Conforming Components

If the test results for the component under test fail to meet the test procedure requirements, the

test shall be treated as non - conforming and an inspection rejection report (IRR) will be raised

in accordance with Quality System Procedures.

4.3 Hold Periods

Hold periods shall start after pressure and temperature stabilisation has occurred, the

equipment with monitoring device has been isolated from the pressure source, and the exterior

of the component has been thoroughly dried. The time specified for hold periods shall be a

minimum.

Note ; Drying of component or inspection of leaks in components under test is not permitted at

pressures greater than the component working pressure.

4.4 Acceptance Criteria

Acceptance criteria is as per API 6A latest edition - "the equipment shall show no visible

leakage under pressure". This shall be verified by a stable chart or gauge recording, as

applicable.

Note:- Due to practical considerations (e.g. temperature fluctuations etc.) a fluctuation of +/5% shall be deemed acceptable provided that it is assured that any such fluctuation is not due

to leakage.

4.5 PTFE Tape

The use of PTFE tape is not permitted on any component.

Page 6 of 11

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

5.0

EQUIPMENT LIST.

The following specific equipment is required in addition to the assembly

components in order to carry out this procedure :

Item

Qty

1

2

1

1

Description

Part No.

Tree Inspection / Maintenance Stand

Xmas Tree (Production) or

Xmas Tree (Injection)

Tree Lift / Test Cap

A190301-105

A110575-97A091

A110575-98A091

T & A Supply

Page 7 of 11

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

6.0

ASSEMBLY PROCEDURES.

Prior to starting assembly ensure that all equipment listed is available and that the

workplace is clean and free from contamination. Check the components have

sharp edges and burrs removed.

Numbers in ( ) refer to part numbers on the relevant assembly drawing.

6.1

Specific Assembly Procedures.

6.1.1

Assemble per drawing A190301-105, ensuring that all the fasteners are correctly

torqued up as per table 3.2.

Page 8 of 11

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

7.0

TEST PROCEDURES.

The Tree Inspection / Maintenance Stand will be subjected to the following

acceptance tests in the presence of an appointed representative.

7.1

Pre-Operational Checks.

Ensure the Tree Inspection / Maintenance Stand is positioned on a flat level floor

and there is sufficient room to land a Tree along side.

7.2 Functional Test.

7.2.1

Attach the Lift / Test Cap to the Tree Mandrel.

7.2.2

Pick up the Tree and orientate it to the correct position above the Stand. Slowly

lower the Tree until it lands out on the stands four legs on their support shoulders.

7.2.3

Pick up the Tree and rotate through 180 and re-land back down on the stand

again.

7.2.4

Confirm there are no clashes of the Tree with the Stand.

7.2.5

Carefully pick up the Tree off the Stand and set aside.

7.2.6

Remove the in-house Lift / Test Cap from the Tree.

VG

XMAS TREE INTERFACE TEST

SNEPCO / EPC

(Optional)

Page 9 of 11

Date

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

8.0

POST TEST / CHECK OUT PROCEDURES

The following procedures are to be completed after final assembly and testing.

8.1

Touch up any damaged painted areas and lightly grease or spray with rust veto

201 any unprotected or unpainted areas.

8.2

Check that the stamping details are correct.

8.3

Once section 8.0 is complete the Tree Inspection / Maintenance Stand should be

signed off below:-

VG

Post Test / Check Out Procedure

Witnessed By

SNEPCO / EPC

(Optional)

Page 10 of 11

Date

Procedure No: A001102

Revision No:

B

Revision Date: 17/09/03

9.0

APPENDICES

9.1

Deviation Form

Deviations from this procedure to be signed off by Vetco Gray Vetco Gray

Engineering prior to implementation.

Deviation

No.

9.2

Description

Relevant

Para.

Temporary

or

Permanen

t

Approved

by

Date

Distribution List

To ensure latest revision is being used, a copy of this procedure can be obtained from

PIMS.

Page 11 of 11

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- P Hazz Er Enforcer Us A ManualDocument23 paginiP Hazz Er Enforcer Us A ManualArif TjoeripÎncă nu există evaluări

- Evonik-BREAK THRU Brochure Microbials EN Asset 2214205Document5 paginiEvonik-BREAK THRU Brochure Microbials EN Asset 2214205李雷Încă nu există evaluări

- Personal Protective EquipmentDocument45 paginiPersonal Protective EquipmentrizalÎncă nu există evaluări

- Oil & Gas Valves, Flanges, and AccessoriesDocument1 paginăOil & Gas Valves, Flanges, and AccessoriesCherry CardonaÎncă nu există evaluări

- 9 Inch 3M Tree Anti-Extrusion RingsDocument2 pagini9 Inch 3M Tree Anti-Extrusion RingsCherry CardonaÎncă nu există evaluări

- 2S-1008H New Completion Service ReportDocument1 pagină2S-1008H New Completion Service ReportCherry CardonaÎncă nu există evaluări

- 3.12 3M OTIS Tree Cap Test Plug AssyDocument1 pagină3.12 3M OTIS Tree Cap Test Plug AssyCherry CardonaÎncă nu există evaluări

- 3M OTIS Tree Cap Test Plug for 2Document1 pagină3M OTIS Tree Cap Test Plug for 2Cherry CardonaÎncă nu există evaluări

- Oil & Gas Valves, Flanges, and AccessoriesDocument1 paginăOil & Gas Valves, Flanges, and AccessoriesCherry CardonaÎncă nu există evaluări

- Casing Hanger CalculationDocument3 paginiCasing Hanger CalculationCherry Cardona100% (2)

- Casing DesignDocument8 paginiCasing DesignJason Bash100% (1)

- Introduction To Well Integrity - 04 December 2012Document154 paginiIntroduction To Well Integrity - 04 December 2012n73686861Încă nu există evaluări

- Calculation of shell and dish thicknessDocument2 paginiCalculation of shell and dish thicknessThiru AnanthÎncă nu există evaluări

- Amazon To Unionize or NotDocument4 paginiAmazon To Unionize or NotPatrick MutetiÎncă nu există evaluări

- F6003 5W40 Synthetic Oil Technical Data SheetDocument1 paginăF6003 5W40 Synthetic Oil Technical Data SheetValeriy ValkovetsÎncă nu există evaluări

- Nutritional Profile of Ube Yam: High in Fiber, Vitamin C & AnthocyaninsDocument3 paginiNutritional Profile of Ube Yam: High in Fiber, Vitamin C & AnthocyaninsMc SuanÎncă nu există evaluări

- CSHP Template For Small Construction Projects Residential Project/S (2 Storey and Below) or Minor Repair WorksDocument5 paginiCSHP Template For Small Construction Projects Residential Project/S (2 Storey and Below) or Minor Repair WorksZeny BocadÎncă nu există evaluări

- Fabrication and Installation of Vertical Steel Pressure ShaftDocument23 paginiFabrication and Installation of Vertical Steel Pressure ShaftPasan RajasingheÎncă nu există evaluări

- CCE Format For Class 1 To 8Document5 paginiCCE Format For Class 1 To 8Manish KaliaÎncă nu există evaluări

- Step by Step To The Perfect PedicureDocument6 paginiStep by Step To The Perfect PedicurepinkyÎncă nu există evaluări

- A-Plus Beyond Critical Shield & A-Plus Beyond Early Critical ShieldDocument21 paginiA-Plus Beyond Critical Shield & A-Plus Beyond Early Critical ShieldGenevieve KohÎncă nu există evaluări

- Análisis de Estabilidad de TaludesDocument4 paginiAnálisis de Estabilidad de TaludesJosue Acosta EspinozaÎncă nu există evaluări

- Observations of Children's Interactions With Teachers, PeersDocument25 paginiObservations of Children's Interactions With Teachers, PeersMazlinaÎncă nu există evaluări

- MBBS Final Part-I (Winter Session) Time Table (Jan 2023)Document1 paginăMBBS Final Part-I (Winter Session) Time Table (Jan 2023)crystal mindÎncă nu există evaluări

- One Stop English - Cornish Village - Pre-IntermediateDocument5 paginiOne Stop English - Cornish Village - Pre-Intermediatec_a_tabetÎncă nu există evaluări

- Saloni Shah - LLM DissertationDocument156 paginiSaloni Shah - LLM DissertationNilesh BatraÎncă nu există evaluări

- GarrettDocument2 paginiGarrettAndrey MarviantoÎncă nu există evaluări

- Physiology of Women Reproduction SystemDocument52 paginiPhysiology of Women Reproduction Systemram kumarÎncă nu există evaluări

- Grade 8 Science Activity 1 Quarter 4Document8 paginiGrade 8 Science Activity 1 Quarter 4yoshirabul100% (2)

- Anthropometric Measurements Options For Identifying Low Birth Weight Newborns in Kumasi, GhanaDocument9 paginiAnthropometric Measurements Options For Identifying Low Birth Weight Newborns in Kumasi, GhanaDani KusumaÎncă nu există evaluări

- Advantest R3131 Spectrum Analyzer Operator ManualDocument277 paginiAdvantest R3131 Spectrum Analyzer Operator ManualMartin Argay100% (1)

- Financial Plan Checklist: Planning For EmergenciesDocument2 paginiFinancial Plan Checklist: Planning For EmergenciesInsan CornerÎncă nu există evaluări

- Cooking - Sauces and Marinade RecipesDocument96 paginiCooking - Sauces and Marinade Recipesagape_1st7100% (3)

- Study To Assess The Effectiveness of Planned Teaching Programme Regarding Knowledge of Traffic Rules Among Higher Secondary Students 15 18 Years in Selected Schools of DehradunDocument14 paginiStudy To Assess The Effectiveness of Planned Teaching Programme Regarding Knowledge of Traffic Rules Among Higher Secondary Students 15 18 Years in Selected Schools of DehradunEditor IJTSRDÎncă nu există evaluări

- Waste Management: Spoilage of LandscapeDocument7 paginiWaste Management: Spoilage of Landscapeshauryasahu2004Încă nu există evaluări

- Confined Space Planning ChecklistDocument3 paginiConfined Space Planning ChecklistKB100% (1)

- Series NRX With PXR - Type NF Low Voltage Power (Air) Circuit Breaker Instruction ManualDocument70 paginiSeries NRX With PXR - Type NF Low Voltage Power (Air) Circuit Breaker Instruction ManualHamilton GutierrezÎncă nu există evaluări

- Fuel Gas Superheater 195-E-301 A/B: Mechanical - Data SheetDocument3 paginiFuel Gas Superheater 195-E-301 A/B: Mechanical - Data SheetZulfikar N JoelÎncă nu există evaluări

- GSR (ROAD) 2015Document74 paginiGSR (ROAD) 2015Gautam RaiÎncă nu există evaluări

- Multiple Bank Accounts Registration FormDocument2 paginiMultiple Bank Accounts Registration FormAjith JainÎncă nu există evaluări