Documente Academic

Documente Profesional

Documente Cultură

Composite Drive Shaft

Încărcat de

kylegaze100%(1)100% au considerat acest document util (1 vot)

186 vizualizări6 pagini__ Amarillo" Gear Company TABLE I CF - Contact Factory TABLE II DISC Engineering Data (All dimensions shown in inches (mm))

Descriere originală:

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest document__ Amarillo" Gear Company TABLE I CF - Contact Factory TABLE II DISC Engineering Data (All dimensions shown in inches (mm))

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

186 vizualizări6 paginiComposite Drive Shaft

Încărcat de

kylegaze__ Amarillo" Gear Company TABLE I CF - Contact Factory TABLE II DISC Engineering Data (All dimensions shown in inches (mm))

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 6

IAMARIEES)

COMBOSITE

DRIVEISHAETS

FOR COOLING TOWERS

Amarillo®

Gear

"= Company

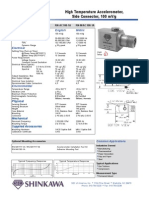

TABLE |

Bi Amari

lo* Gear Company

Dimensional Data (All dimensions shown in inches (mm))

Wedel No

Exchadng Fox Max Bore

M.tcork [a B0ts & ze | Bis | Flex ose | Standard | tax-ore | Minimum

Sita [perFioxdise | Golo |"“oo | “Hob [tame] “Sore” | oma | pms | Dim

Ges2776 [6-Bxs5mm| cee [Eos | oars | 2976 | Besa Go| 2.7siro | B75 M48) | 2.

Geo027s |6- 12x80 mm] green f00(t82}] 2378 | 2975 [osse oa) | a7e(ro) | eas ten) | nae (9)

Gran 475 ase pa) | 425 (roa) | ws 62) | 2. 2]

rer 276 |6-taxcomm| orange] BTSCTH| 3000 | Bare | 4.8640) | 27eco [rise | 275,70

rar 425 56 a0) [-a 25 foay [713 et) [2.7570

FST 00 155140) eotrs2) [713 61) [275 70)

Ge7I425 |B-ExGOmM] Bue | TSO] —Sa7S | See [tar as) | 4.5 (108) | 767 Has) | 2.75 70)

erae00 Teraay [sorts | rer ies) [976 70)

Er300 #51 6) | e.0(@09) [7.67 (195) [275 (70)

ers 950 teas) [aspe) | rer (ies) [2.75 70)

Gra3.425-[8-14x 70mm] yotow | BIB eI] 36S | GF | 2.06 9) [426 H09) | wrse72) [315.09

FBS 600 Zoe(s3) | 601182) | 875222) [3.15 78

Fa 800 Zoe (s3)_[ 6.0 (208) | 8 ro 20) [3.15 (79)

Fa 950 208 (53)| 95 ax) [7S 02) [ 313178)

ra 50 Bossa Las pay Levee) [aa 7a)

3 oe (CF - Contact Factory

[>see rue stent =p

T L

Bp ail

D| q L |

p dy ci

aa)

TABLE Il ont

Engineering Data (All dimensions shown In Inches (mm))

Assembly

wat

weight @ | tiinum

HE Rating [Continous | Peak Minmurn | Bore & Max

#8015 | rio |'@ 1800. | Torq, | Ovetoad | Maxoase | wax Das Boreana | DBSE@

perFiox |eigrent|mmwi20) ZosF | Tomue |'@i7es | @ies | naxoase |Max DBSE| 1725,pm

wodet_| Element |'Caor'| "se | ‘iw | nw) | “tom | “om la tiesipm Ja 1765 | tony

Geszzrau| 6 | red | st] 1790 | 120 [v7 tommy | a ara) | oa neo) | 25 a1

Crs 775 coe) | 20% Ne | (o04 Ny 94 (385) [03 (2020) (2020) [26 33

creo srs] 6 [geo] 90] avs | 2700 | rr(tess) | a4 00) | 99 360) | 31 702

CF6077SL (or en | (989 Ny [1495 Nm [4 (2568) [08 (20) [445 (2020) | — 32 ccs

EBD ZTEX 79626907 [16 2980) [130 (3000]_[ 3 105

EBD APs aero) | Tas (ose0) [es aragy | a 17

FO aP5x 15 (3450) | 149 3790) [467 eze0) [aa 55

Geer zs] 6 [orange | 105 | _a750_| 000 [77 tigs=) [64 130) | 99 (360) | at 475

car aTa tv) | 424 Ney | (1898 Nr SES) [-40S (25207 [5 (2020)—[— er ir

cearzrex| | earge | 150] 5280. ] 21000 [106 2090) 1102960) [120 (9300) | a 178

CEST APs 2k) fies Nin | 2874 N12 (aToo) [3 3580) [res (9780)_[ 5 220

EST 475K 136.50] [49 (9780) [67 4240] [se 28

CET EDO. 151 (940) | te 4190) [195 16700) | 19 35

CEETEDOX 2 at0) [477 14500) [198 6030) | —T1 378

crraazs. | —@ | pue | 205 | read] _srae0 [122 (at00) | 1993380) [149 (9700) 50 288

CET3475% 166) | (685 Ny | 9564 Nm 136 3450) [ a9 3 7eO) | T6rtazeo)_ | 28

CEP EDOL ST (SBA0) [Wes 90) [85 1700) Te ae

CEE EDOX 2 aTt0) [770 [198 (6080) | 72 9

EPS BDOL 5 4220) | ta (4800) [203 5160) [a3 Tr

ETE ADO ee g6y0 | 700 510) [225 57201 [ar 25

et 5 fs0ao} [Fra see0} [Zee e220) | rs —| Te

ceanazsx| a] vetow | 067} ‘as00 | so000 [136 (2450) [149 2790) ver a240)_| 75. 485

FBS oO (268k | 1413 Nm] 680 Nf TS (9840) [15 er99) [85 la700)_ [20 B24

CBS DOL a2 (4110) 177 as00) [98 090) [ 7 337

CERT ADDL 5 4220) | 18 e600) [203 S160) [Tis 375

FET BDO 484 (4670) [201 (110) [225 G720)_[—1e [1025

FEY SSO 200 BOBO) | BTS se6D] [es (6220)_[ 138 —| 550

CEES TSO a (SSBOY | 2A EFEOL [270 (6860) TTP za

‘TABLE Ill - STANDARD KEYWAYS-INCH BORE HUBS.

B§ Amarillo’ Gear Company

TABLE IV - STANDARD KEYWAYS-METRIC BORE HUBS

‘TABLE V - INCH BORE TOLERANCES

Class 2 Clearance Fit per AGMA 9002-A86

‘TABLE VI- METRIC BORE TOLERANCES

FT Clearance Fit per ISO 286-1:1988

Bore Sue | Koyway | BoreSize | Keyway Bore size | Keyway | Boresize | Keyway

< kerma

Bor Cowart rs Sua) Coare F

ier [Yo Bas er a

sm —{ “7000 |[ “0.900 te 0.002 0 ‘Bo 20.028 0.080

'5000—[.00 = =0.008 a0 125 —[-=01635 to 0071,

TABLE Vil

CONSTANTS FOR CALCULATING ACTUAL WEIGHT AND WR?

Tats Fest

igteln digs

soo | ~o.1r6 [2783 1a | 526 [ort | iar]

iso —o288_[aza8

Calculate Actual Drive Shaft Weight

start With» —» —» > ++ +e

minus > —> correction for Bore 1» —» —>» —>

minus —» —» correction for Bore 2—» —» —» —>

minus >» — correction for DBSE —» —» —» —>

equals >» —> + > > + >> eee

Calculate Actual Drive Shaft WR?

Start with» + + > +>eeoes

minus > — correction for Bore 1 —» —» —» —>

minus > —» correction for Bore 2—» —» —» —»

minus > — correction for DBSE —» —>» —> —>

equals >» —» —» >» > + > >>>

tdddd

Weight from Table 2

0.22 x Lx [(bore 1)°- b]

0.22 x Lx [(bore 2)°- b]

ax (DBSE @ 1785 rpm from Table 2 - Actual DBSE)

Actual Weight

WR? from Table 2

dx [(bore 1)*- 6}

Cnue eore

cx (OBSE @ 1785 rpm from Table 2 - Actual DBSE)

S axioore2)- 6)

‘Actual WR?

Limited Warranty

law,

The Amarillo Gear Composite Drive Shaft is guaranteed against defects in workmanship and material for a period of

one year after installation when operated under normal service at rated capacity. Within the above stated period, the

manufacturer will replace the defective parts returned transportation prepaid. The buyer shall not be entitled to

incidental or consequential damages, losses or expenses. The guarantee will not apply to repairs made outside the

factory without the consent of the manufacturer or to drive shafts that have been subject to abuse, accident, neglect or

improper installation. No warranty is made in regard to trade accessories, machinery, or other articles of merchandise

not manufactured by us. This warranty is expressly made in lieu of any warranties otherwise expressed or implied by

oo BA marillo” Gear Company

Amarillo Composite Drive Shafts

Selection Procedures

1. Fax or e-mail a completed Application Data Request Form to Amarillo Gear at F: 806-622-3258, or infowamarilogear.com

Or

2. Use Amarilo Gear Company's automated selection program at www.amarilogear.com. Just enter your application data and let the

program do the rest.

-or-

4, Use the manual selection method as shown below,

Determine the motor torque in in-b using the following equation

Motor torque = Motor HP x 68,000 / Motor RPM.

Select the model that provides equal or more continuous torque rating from the Engineering Data Table Il, Note that the

values in Table Il include a 2.0 service factor. Make sure the motor peak overload torque is less than the allowable

peak avertoad torque shown in the Engineering Data Table I

Select the tube size/type (ast 4 digits of the model number) with a maximum DBSE that meets or exceeds the

application's DBSE at the motor speed,

Example: Motor Torque (1785 rpm, 75 hp motor) = 2647 int

‘pplication OBSE = 120

Setection Model CF80 425L (torque rating = 3175 in-Bb, Max. DBSE at 1785 rpm's 122")

4, Calculate the critical speed (WD, ) of the shaft using the folowing equation:

As7.8 x 10°

Oc= “spBse* “BSE sin inches)

Las aig efMadeiNumter [ave ort[ mrax [ema [ezax [coo ooox [soot [00x [| os0x [ris

ake fr zav7_[ 2967 | ssi | ass | sess | eaat | 7.108 | ast | tose [12778

@. Make sure that the calculated critical speed is at least 15% greater than the intended operating speed, or 2080 for this

example, and that the frst three harmonics of blade pass frequency (fan speed x number of fan blades) are atleast 10%,

115968 36 respectively away rom the cial speed. I ether conan is nat mel choose the next model down Table)

and recalculate the crteal spect

Example: “Tube Size/Type = 425. DBsE = 120"

Fan speed: 120 rpm Number of Blades: 8

Blade pass frequencies: 1x = 960 opm, 2x = 1920 opm, 3x = 2880 cpm

Calculated critical speed = 2102 cpm

“The inital selection is OK.

f. Check both shaft sizes against the maximum hub bore forthe selected model. Specify a “large” hub, or

‘select the next larger model i necessary.

Application Data Request Form

Company Name: Date:

Contact: ‘Tlophone: Fax

Location: Reference:

E-Mail

Distance Between Shaft Ends (DBSE

Number of Drive Shafts Required

Motor Details Gearbox Details

Nameplate Power Rating: Manufacturer:

Full Speed RPM: Mode!

Motor Shaft Diameter: Ratio:

Shatt Keyway Dimensions:

4 Starts per Day:

Input Shaft Dimensions:

‘Shaft Keyway Dimensions:

Fan Details

Fan Manufacturer: —

Model

Single Speed Motor, Yes No

2-Speed Motor Yes. No

VED Motor: Yes No

Speed Range i 2-Speed or VFO:

Reversing! Yes No

Fan Diameter

Fan Speed

# of Fan Blades:

OS

Amarillo Composite Drive Shafts

Amarillo Gear Company, a leader in the design and manufacturing of gear drives for mechanical draft cooling

towers and air cooled condensers, now offers the Amarillo Composite Drive Shaft product line for cooling

tower service. Our many years of experience in cooling tower power transmission systems provided this,

rratural extension into designing and manufacturing composite drive shafts. Each drive shaft connects the

electric motor to the gearbox input shaft, thereby transmitting torque to rotate the cooling tower fan. These

drive shafts will accommodate spans ranging from 2 feet in small HVAC towers, to over 20 feet in large field

erected towers.

Amarillo Gear has always been a leader in new and innovative products for the cooling tower and heat

‘exchanger industries. We listen to what the problems are, and then design our products to provide superior

performance. Based upon customer surveys and input from cooling tower industry professionals, Amarillo

Gear has designed, manufactured and tested its composite drive shafts to incorporate the following features

and benefits:

Comparison with Steel Drive Shafts

Features

High Strength to Weight Ratio

Inherent Corrosion Resistance

Long Spans

Patented Composite Flex Disc

Dimensionally Stable

Vibration & Shock Control

Benefits

Composite center spacer member weight is a mere

fraction of the weight of a steel drive shaft center member.

Composite materials have corrosion resistance

exceeding that of 316 stainless steel

Eliminates requirement for high maintenance and

costly intermediate pillow block bearings.

Low maintenance: no fretting corrosion of steel “shim”

packs, plus much easier installation and maintenance.

Very low Coefficient of Thermal Expansion (CTE).

The natural dampening of composite materials reduces

the transmission of vibration throughout the power train,

resulting in less wear and tear on mechanical equipment.

Comparison with Other Composite Drive Shafts

Features

Greater Misalignment Tolerance

Composite Flex Discs

Registered Bushings & Flanges

High Strength Composite Flange Hubs

316 SS Flange Hubs

Standard 316 SS Hardware

High Service Factor Rating

Durable UV Resistant Coating

Balancing

Process Verification

Easier Installation

Special Shipping Tubes

Benefits

When misalignment occurs due to mechanical equipment

shifting, greater than one degree of angular misalignment

per flex disc allowed.

Color coded by size for easy identification.

Includes integral 316 SS bushings.

Lower stress concentrations and better assurance of

alignment.

Spacer tube flange hubs are strong and corrosion resistant,

while at the same time lightweight, reducing overhung loads.

Corrosion resistance of stainless steel for motor &

gearbox hubs.

. Since precision hardware is not required, fasteners are

easily replaced, and at lower costs. Optional monel

hardware available.

- Capable of withstanding repetitive high start-up torques.

Longer lasting protection from UV degradation

Al drive shafts are dynamically balanced to AGMA

9000-C80, Class 9 specifications.

Each Amarillo composite drive shaft is tested to 4 times,

continuous operating torque prior to shipment.

- Fewer parts required at each flex disc connection.

Designed to give ultimate drive shaft protection for both

international and domestic shipments.

Amarillo Composite Drive Shafts

For Cooling Towers

The composite drive shafts produced by Amarillo Gear Company for cooling towers reflect a long history of

quality workmanship and reliability. Amarillo Gear has been designing and manufacturing power

transmission products since 1934, and the commitment to excellence continues today. Amarillo Gear is,

proud to be a certified ISO 9001:2000 company.

Design features and ratings of the Amarillo Gear Composite Drive Shafts are in accordance with, or exceed,

the minimum requirements of AGMA (American Gear Manufacturers Association) standards.

Catalog DS 3/08

ee cissctio Gear Company

P.O. Box 1789 » Amarillo, Texas 79105 * 2401 Sundown Lane (79118) * 806-622-1273 * Fax 806-622-3258

www.amarillogear.com ‘e-mail: info@amarillogear.com ‘©AG0 2008

S-ar putea să vă placă și

- RN-AC106-3A: Low Frequency Accelerometer, Side Connector, 500 MV/GDocument1 paginăRN-AC106-3A: Low Frequency Accelerometer, Side Connector, 500 MV/GkylegazeÎncă nu există evaluări

- MD 100aDocument2 paginiMD 100akylegazeÎncă nu există evaluări

- RN Ac104 1aDocument1 paginăRN Ac104 1akylegazeÎncă nu există evaluări

- RN Ac102 1aDocument1 paginăRN Ac102 1akylegazeÎncă nu există evaluări

- RN Ac105 3aDocument1 paginăRN Ac105 3akylegazeÎncă nu există evaluări

- Ls CDocument4 paginiLs CkylegazeÎncă nu există evaluări

- LD Stroke Compound-Wound Differential Transformer (LVDT)Document2 paginiLD Stroke Compound-Wound Differential Transformer (LVDT)kylegazeÎncă nu există evaluări

- RN-AC108-1A: High Temperature Accelerometer, Side Connector, 100 MV/GDocument1 paginăRN-AC108-1A: High Temperature Accelerometer, Side Connector, 100 MV/GkylegazeÎncă nu există evaluări

- PM-202A Hand-Held Vibration Meter: Custom ProductsDocument2 paginiPM-202A Hand-Held Vibration Meter: Custom ProductskylegazeÎncă nu există evaluări

- RD Tacho DriverDocument2 paginiRD Tacho DriverkylegazeÎncă nu există evaluări

- SM 50 SM 95 Coaxial Cable TypesDocument3 paginiSM 50 SM 95 Coaxial Cable TypeskylegazeÎncă nu există evaluări

- QJDocument56 paginiQJkylegazeÎncă nu există evaluări

- FK202 SeriesDocument4 paginiFK202 Serieskylegaze100% (1)

- FK452FDocument2 paginiFK452FkylegazeÎncă nu există evaluări

- TPG Inline Centrifugal PumpDocument32 paginiTPG Inline Centrifugal PumpkylegazeÎncă nu există evaluări

- XBCDocument18 paginiXBCkylegaze100% (1)

- EV Capacitance Type Displacement ConverterDocument2 paginiEV Capacitance Type Displacement ConverterkylegazeÎncă nu există evaluări

- Power Aurora User ManualDocument8 paginiPower Aurora User ManualkylegazeÎncă nu există evaluări

- Thermocouples Colour CodesDocument1 paginăThermocouples Colour CodeskylegazeÎncă nu există evaluări

- Habia Cable Twisted WiresDocument8 paginiHabia Cable Twisted WireskylegazeÎncă nu există evaluări

- Standard CoaxDocument25 paginiStandard CoaxkylegazeÎncă nu există evaluări

- Speed FoamDocument6 paginiSpeed FoamkylegazeÎncă nu există evaluări

- Shielded Signal CablesDocument16 paginiShielded Signal CableskylegazeÎncă nu există evaluări

- Speed FlexDocument10 paginiSpeed FlexkylegazeÎncă nu există evaluări

- MB402FJDocument1 paginăMB402FJkylegazeÎncă nu există evaluări

- Signal CablesDocument6 paginiSignal CableskylegazeÎncă nu există evaluări

- Hi FlexDocument1 paginăHi FlexkylegazeÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)