Documente Academic

Documente Profesional

Documente Cultură

Festo Electrical, Pneumatic and Logic Symbols

Încărcat de

Avtomatika Kole NehteninDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Festo Electrical, Pneumatic and Logic Symbols

Încărcat de

Avtomatika Kole NehteninDrepturi de autor:

Formate disponibile

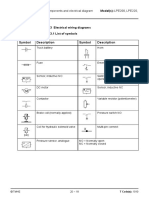

Electrical, pneumatic and logic symbols

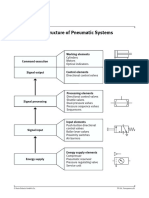

Energy conversion Transfer of ener gy Actuation methods Valves Comparison of logic elements

Manual operation Directional control valves

Line Flexible line Designation Function Equation Symbol to Representation to Representation to

2 (A) 2 (A)

table DIN ISO 1219/1 DIN EN 60617-7

Compressor Constant displacement 40900/12 pneumatic electrical

pump Pressure source Pressure source General Via push Via pull Via Via

– pneumatic – hydraulic 1 (P) 1 (P) Identity E A A=E A

button lever pedal

2/2-way valve, 2/2-way valve, E 1 A E

0 0

normally closed position normally open position 1 1

Mechanical actuation E A

2 (A) 2 (A)

Variable displacement Vacuum pump Line connection Crossing line

pump

1 (P) 3 (R) 1 (P) 3 (R) Negation E A A=E A

E 1 A E

Closed exhaust port Silencer Via stem Via spring Via roller Roller lever in 3/2-way valve, 3/2-way valve, 0 1

one direction normally closed position normally open position 1 0

E A

Pneumatic fixed Pneumatic fixed only under 2 (A) 4 (A) 2 (B)

displacement motor displacement motor with tension

two directions of flow Air outlet without Air outlet with

connection facility connection facility Or E1 E2 A A=E1∨E2 E1 A

1 (P) 3 (R) 1 (P) 3 (R)

E2 ≥1 A

E1 E2

3/3-way valve, 4/2-way valve 0 0 0

mid-position closed 0 1 1

Actuated in initial position 1 0 1 E1 E2

Pressure connection Rotary connection 4 (A) 2 (B) 4 (A) 2 (B) 1 1 1

Hydraulic motor, Hydraulic motor, A

point, closed with one path

adjustable, with one adjustable, with two Pressure actuation

direction of flow directions of flow

1 (P) 3 (R) 1 (P) 3 (R)

4/3-way valve, 4/3-way valve, And E1 E2 A A=E1∧E2 E1 A

Quick coupling, Quick coupling with mid-position closed mid position E2 & A E1

connected mechanically opening Direct via pneu- Via differential Spring centered working lines exhausted 0 0 0

Pneumatic motor with 0 1 0

non-return valves, matic actuation pressure actuation E2

restricted angle of 4 (A) 2 (B) 4 (A) 2 (B) 1 0 0 E1 E2

rotation connected

Electrical actuation 1 1 1

A

5 (R) 3 (S) 5 (R) 3 (S)

1 (P) 1 (P)

Quick coupling, Quick coupling,

Single-acting pneumatic Single-acting pneumatic disconnected, disconnected, 5/2-way valve 5/3-way valve,

Inhibition E1 E2 A A=E1∧E2 E1 A

cylinder, return cylinder, return movement Line open line closed Via solenoid with Via solenoid, e. g. with mid-position closed

E2 & A E1

movement via external via spring one active coil two counteracting 0 0 0

Directional control valve with intermediate 0 1 0

force solenoids E2 E2

switching positions and two end positions 1 0 1 E1

1 1 0

A

Shut-off valve Filter

(simplified representation) Flow control valve

Double-acting Double-acting pneumatic Via electric motor Via electric stepper

pneumtic cylinder cylinder with adjustable with continuous motor E1 E2 A A

Implication A=E1∨E2 E1

cushioning at both ends rotation E2 ≥1 A

E1

0 0 1 E2

Flow control valve with Flow control valve, 0 1 0

Filter with water Filter with water

Combined actuation constant restriction adjustable, any actuation 1 0 1 E1

separator, manually separator, automatic 1 1 1 A

Double-acting pneumatic Telescopic hydraulic E2

operated

cylinder with through cylinder

piston rod Via solenoid Via solenoid or manual

and pilot valve override and pilot valve 2-way flow control valve Flow divider Nor E1 E2 A A=E1∨E2 E1 A

E2 ≥1 A

E1 E2 K1

Flow control valve, adjustable, 0 0 1

mechanical actuation against 0 1 0

Pressure intensifier for Pressure medium Cooler without Cooler with volumetric 1 0 0

volumetric flow lines flow lines to show flow spring

two different media converter Via solenoid General explanatory 1 1 0

to show flow direction direction of coolant or manual operation K A

symbol

of coolant E1 E2

Pressure valve

Mechanical actuating components Nand E1 E2 A A=E1∧E2 E1 A

3 (R) 2 (A) E2 & A E1

Pneumatic linear unit 0 0 1 K1

Dryer Lubricator 0 1 1 E2

1 0 1

Other symbols Detent Over-centre device 1 (P) 1 (P) 1 1 0

K A

Other devices Pressure relief valve,

adjustable

Pressure sequence valve

with exhaust, adjustable E1 E2

Service unit Reservoir 2 (A) 2 (A)

(simplified representation) Memory S R A B R R B AB

S S A S K

Flow meter Flow meter 1 0 1 0

K

(flow) (volume) Special symbols Connection designations 1 (P) 1 (P) 3 (R) 0 0 1 0

0 1 0 1 S R

Pressure regulating Pressure regulating R

0 0 0 1 B A

ISO/ for 2/2- for 4/2- for 5/2- valve, non-relieving, valve, relieving type,

adjustable adjustable K

DIS and and and

11727 3/2-way 4/3-way 5/3-way

Temperature sensor Temperature gauge Reflex sensor Back pressure Nozzle in general,

valves valves valves Non-return valve Timer E t expired A

E

t1

A

A

nozzle sender nozzle – adjustable E

1 P P P 0 0 0

for air barrier – Switch-on 1 0 0 K

2 A B B delayed 1 1 1 E

Pressure gauge Fluid level gauge 3 R R S Non-return valve Non-return valve Dual-pressure A

Receiver nozzle Pneumatic proximity switch, 4 – A A without spring with spring valve

5 – – P R

(with air supply) actuated by permanent R

for air barrier magnet 10* Z – – Timer E t expired A t2 A

Tachometer E A E

Z Y Y – adjustable 0 0 0

12

– Switch-off 1 0 1

14 – Z Z delayed

K

0 1 0 E

Quick exhaust Shuttle valve One-way flow

* Control port, on valves with normally open valve control valve, A

position (NOT function) adjustable

P R

053 614 GB © Festo Didactic GmbH & Co. www.festo.com/didactic

S-ar putea să vă placă și

- Passive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2De la EverandPassive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2Încă nu există evaluări

- ElectroneumaticaDocument144 paginiElectroneumaticaWillyGuerrero100% (2)

- Electropneumatics Basic LevelDocument48 paginiElectropneumatics Basic LevelHamsini712Încă nu există evaluări

- Festo ElectroPneumatics Workbook Advanced Level TP202 44 2005Document44 paginiFesto ElectroPneumatics Workbook Advanced Level TP202 44 2005Avtomatika Kole Nehtenin80% (10)

- Manual MPS-PA Compact Workstation EN PDFDocument72 paginiManual MPS-PA Compact Workstation EN PDFstoka seljacka0% (1)

- Manual MPS-PA Compact Workstation enDocument72 paginiManual MPS-PA Compact Workstation enospidera100% (1)

- Simbologia PDFDocument1 paginăSimbologia PDFMartin Abraham Perez UriasÎncă nu există evaluări

- Hydraulic SymbolsDocument1 paginăHydraulic SymbolsMehmetGörkemDemirÎncă nu există evaluări

- Electro-Hydraulic I/H Converter and WSR Way ValveDocument12 paginiElectro-Hydraulic I/H Converter and WSR Way ValveNAYEEM100% (1)

- OFT2-CAD-Simulationssoftware Für Hydraulik Und Pneumatik OFT2-CAD-Simulationssoftware Für Hydraulik Und PneumatikDocument1 paginăOFT2-CAD-Simulationssoftware Für Hydraulik Und Pneumatik OFT2-CAD-Simulationssoftware Für Hydraulik Und PneumatikGabriel García GutiérrezÎncă nu există evaluări

- Qdoc - Tips - Jis Electrical StandardDocument11 paginiQdoc - Tips - Jis Electrical StandardPrazzt TyoÎncă nu există evaluări

- 005 - Electrical Wiring DiagramsDocument20 pagini005 - Electrical Wiring DiagramsNgo Ngoc TuÎncă nu există evaluări

- 16 Electro Hydraulic Systems1Document9 pagini16 Electro Hydraulic Systems1Filip StojkovskiÎncă nu există evaluări

- Manual TekaDocument7 paginiManual TekaJAVIÎncă nu există evaluări

- Protection DiagramDocument1 paginăProtection DiagramMathias CanalesÎncă nu există evaluări

- Electro-Hydraulic IH ConvertersDocument12 paginiElectro-Hydraulic IH ConverterssendutdutÎncă nu există evaluări

- RANGKAIAN PNEUMATIK - BakDocument1 paginăRANGKAIAN PNEUMATIK - BakDzulatip As ShodikÎncă nu există evaluări

- Figura 9.1Document1 paginăFigura 9.1Walter GuerraÎncă nu există evaluări

- Motor Control Basics PDFDocument7 paginiMotor Control Basics PDFKamal CharbelÎncă nu există evaluări

- Group 9: Group 9 Attachment Flow Control System Attachment Flow Control System (Cluster Type 1)Document1 paginăGroup 9: Group 9 Attachment Flow Control System Attachment Flow Control System (Cluster Type 1)Александр ПанкратовÎncă nu există evaluări

- 6050 FS 3Document1 pagină6050 FS 3medkh0411Încă nu există evaluări

- HYDRAULIC-Workbook VietnamTrainerDocument13 paginiHYDRAULIC-Workbook VietnamTrainerBình LợiÎncă nu există evaluări

- Analog Electronic Drivers E-Ri-Ae: Integral-To-Valve Format, For Proportional Valves Without TransducerDocument3 paginiAnalog Electronic Drivers E-Ri-Ae: Integral-To-Valve Format, For Proportional Valves Without TransducerDanilo DiogoÎncă nu există evaluări

- Q (Jta: AssemblylineDocument10 paginiQ (Jta: AssemblylineAryaman MahajanÎncă nu există evaluări

- Group 9: Group 9 Attachment Flow Control System Attachment Flow Control SystemDocument1 paginăGroup 9: Group 9 Attachment Flow Control System Attachment Flow Control SystemLenomar Bessa de PaulaÎncă nu există evaluări

- Diagram Reference 3Document1 paginăDiagram Reference 3Ihab El SawiÎncă nu există evaluări

- Figura 9.3Document1 paginăFigura 9.3Walter GuerraÎncă nu există evaluări

- Group 9: Group 9 Attachment Flow Control System Attachment Flow Control SystemDocument1 paginăGroup 9: Group 9 Attachment Flow Control System Attachment Flow Control SystemDavidÎncă nu există evaluări

- 2xwolqhri Sduw: 3rzhu) Dfwru &ruuhfwlrq LQ 6Lqjoh3Kdvh6Zlwfklqj&RqyhuwhuvDocument41 pagini2xwolqhri Sduw: 3rzhu) Dfwru &ruuhfwlrq LQ 6Lqjoh3Kdvh6Zlwfklqj&RqyhuwhuvwenchienÎncă nu există evaluări

- 1160 Hydraulic Circuit Orientation Linde Advanced - REV02 - 20100709Document41 pagini1160 Hydraulic Circuit Orientation Linde Advanced - REV02 - 20100709Nikolay KuznetsovÎncă nu există evaluări

- Group 8: Group 8 Variable Power Control Variable Power Control System System (Cluster Type 1) (Cluster Type 1)Document1 paginăGroup 8: Group 8 Variable Power Control Variable Power Control System System (Cluster Type 1) (Cluster Type 1)deniden2013Încă nu există evaluări

- The Structure of Pneumatic Systems: Working ElementsDocument52 paginiThe Structure of Pneumatic Systems: Working ElementsSherylÎncă nu există evaluări

- لقطة شاشة 2022-11-17 في 11.27.29 صDocument1 paginăلقطة شاشة 2022-11-17 في 11.27.29 صHur AliÎncă nu există evaluări

- Zero Sequence CT CatalogueDocument14 paginiZero Sequence CT CatalogueRanjitKumarÎncă nu există evaluări

- Group 8: Group 8 Variable Power Control Variable Power Control System SystemDocument1 paginăGroup 8: Group 8 Variable Power Control Variable Power Control System SystemDavidÎncă nu există evaluări

- Group 9: Group 9 Attachment Flow Control System Attachment Flow Control System (Cluster Type 1) (Cluster Type 1)Document1 paginăGroup 9: Group 9 Attachment Flow Control System Attachment Flow Control System (Cluster Type 1) (Cluster Type 1)deniden2013Încă nu există evaluări

- 140H STD Hyd PDFDocument2 pagini140H STD Hyd PDFFrezgi BirhanuÎncă nu există evaluări

- Diagrama Hidraulico 320d FM HarvesterDocument1 paginăDiagrama Hidraulico 320d FM HarvesterMatiasÎncă nu există evaluări

- 9. نظام التحكم في التدفقDocument1 pagină9. نظام التحكم في التدفقالمهندسوليدالطويلÎncă nu există evaluări

- Servo Transmission D10 T SuiteDocument1 paginăServo Transmission D10 T SuiteMed EkahÎncă nu există evaluări

- 330D 336 PDFDocument2 pagini330D 336 PDFRICHARDÎncă nu există evaluări

- Electronic Drivers E-Rp-Ac: Analog, Sealed and Rugged Box, For Proportional Valves Without TransducerDocument4 paginiElectronic Drivers E-Rp-Ac: Analog, Sealed and Rugged Box, For Proportional Valves Without TransducerCommunications ShipyardÎncă nu există evaluări

- Parker Hydraulic Cartridge Systems Selection GuideDocument76 paginiParker Hydraulic Cartridge Systems Selection GuideAnonymous ntE0hG2TPÎncă nu există evaluări

- Pid 3Document2 paginiPid 3engtp.proc.prequalification2022Încă nu există evaluări

- Circuit Construction Kit AC - Virtual Lab 6Document1 paginăCircuit Construction Kit AC - Virtual Lab 6xxgsxcc4vzÎncă nu există evaluări

- Bhatia CPD 20001Document1 paginăBhatia CPD 20001bilalaimsÎncă nu există evaluări

- ITALVALV-Actuators CatalogueDocument31 paginiITALVALV-Actuators CatalogueM MÎncă nu există evaluări

- F Electrical Wiring Diagram (System Circuits) (Cont. Next Page) F Electrical Wiring Diagram (System Circuits) (Cont'd)Document1 paginăF Electrical Wiring Diagram (System Circuits) (Cont. Next Page) F Electrical Wiring Diagram (System Circuits) (Cont'd)Waleed AlshgaaaÎncă nu există evaluări

- Analog Electronic E-BM-AC Drivers: Obsolete Components - Availability On RequestDocument4 paginiAnalog Electronic E-BM-AC Drivers: Obsolete Components - Availability On RequestCommunications ShipyardÎncă nu există evaluări

- Fluid Power Symbols PDFDocument4 paginiFluid Power Symbols PDFHeno ArdianÎncă nu există evaluări

- Fluid Power Symbols PDFDocument4 paginiFluid Power Symbols PDFArdian20Încă nu există evaluări

- Fluid Power Symbols PDFDocument4 paginiFluid Power Symbols PDFPavle KrstevskiÎncă nu există evaluări

- Festo PLC Basic Level TP301-218Document218 paginiFesto PLC Basic Level TP301-218Marcos Aldana Villalda0% (1)

- Festo Hydraulics Workbook Basic Level TP501 204Document204 paginiFesto Hydraulics Workbook Basic Level TP501 204Avtomatika Kole NehteninÎncă nu există evaluări

- Festo-Hydraulics Advanced LevelDocument164 paginiFesto-Hydraulics Advanced Levelarm43994% (16)

- Festo ElectroPneumatics Basic Level TP201 012002 294Document294 paginiFesto ElectroPneumatics Basic Level TP201 012002 294Avtomatika Kole Nehtenin100% (1)

- Jovanovski Goce b3 171-178Document25 paginiJovanovski Goce b3 171-178Avtomatika Kole NehteninÎncă nu există evaluări

- Jordanov Stole b5 211-223Document21 paginiJordanov Stole b5 211-223Avtomatika Kole NehteninÎncă nu există evaluări

- Simultaneous Heat & Mass Transfer Lab: Submitted ToDocument12 paginiSimultaneous Heat & Mass Transfer Lab: Submitted ToSumair Imtiaz SheikhÎncă nu există evaluări

- USSMARTPIPE - SmartPipe KAESERDocument4 paginiUSSMARTPIPE - SmartPipe KAESERseiman23Încă nu există evaluări

- SOP For Operation of Effulent Treatment PlantDocument3 paginiSOP For Operation of Effulent Treatment PlantRakesh RauniyarÎncă nu există evaluări

- Centrifugal PumpsDocument27 paginiCentrifugal PumpsHossam SalahÎncă nu există evaluări

- HKN-EFI-00970 - 00 - Deck Wash System - Piping and Instrumentation Diagram (P&ID) - AXD20Document2 paginiHKN-EFI-00970 - 00 - Deck Wash System - Piping and Instrumentation Diagram (P&ID) - AXD20timualrÎncă nu există evaluări

- Lab Report 4 (Physical Chemistry)Document10 paginiLab Report 4 (Physical Chemistry)Hanif YusofÎncă nu există evaluări

- D350E Series II and Hydraulic Schematic D400E Series II Articulated TrucksDocument2 paginiD350E Series II and Hydraulic Schematic D400E Series II Articulated Trucksمهدي شقرونÎncă nu există evaluări

- Combustion and FlamesDocument4 paginiCombustion and FlamesSURYA PRAKASHÎncă nu există evaluări

- Biannual Maintenance of CFB BoilerDocument3 paginiBiannual Maintenance of CFB BoilerAamirMalikÎncă nu există evaluări

- Thorburn Flex Powergen2012Document4 paginiThorburn Flex Powergen2012Raja Syahmarizal Raja BaharuddinÎncă nu există evaluări

- Design of High-Lift Airfoil For Formula Student Race CarDocument12 paginiDesign of High-Lift Airfoil For Formula Student Race Carsiddharth GautamÎncă nu există evaluări

- Ultrafiltration 30 Years Article PDFDocument5 paginiUltrafiltration 30 Years Article PDFcarlosÎncă nu există evaluări

- DTHC.121413.ISB.00H (Working Conditions)Document4 paginiDTHC.121413.ISB.00H (Working Conditions)tmtt44Încă nu există evaluări

- Proposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)Document2 paginiProposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)John Axl LajomÎncă nu există evaluări

- CoverteredDocument4 paginiCoverteredSuyog GawandeÎncă nu există evaluări

- Chapter 3 ManometryDocument3 paginiChapter 3 ManometryJovilyn SantiagoÎncă nu există evaluări

- Splbe - Master Plumber 2015 15.: Page 1 of 7Document7 paginiSplbe - Master Plumber 2015 15.: Page 1 of 7gregÎncă nu există evaluări

- HAZOP WorksheetDocument5 paginiHAZOP WorksheetchristyleneÎncă nu există evaluări

- Transieant - Semi InfiniteDocument10 paginiTransieant - Semi InfiniteYulfaa BahtiyarÎncă nu există evaluări

- Qatar Liquified Gas Company Limited (II) : QG2, The Designs and Technologies For A 7.8 MTPA TrainDocument16 paginiQatar Liquified Gas Company Limited (II) : QG2, The Designs and Technologies For A 7.8 MTPA TrainweldsvÎncă nu există evaluări

- Presentation: Feasibility Study of Integrated Gasification Combined Cycle (IGCC) in Terms of The Following Parameters: Technology, Reliability and Economy For High High-Ash Content Indian Coal.Document14 paginiPresentation: Feasibility Study of Integrated Gasification Combined Cycle (IGCC) in Terms of The Following Parameters: Technology, Reliability and Economy For High High-Ash Content Indian Coal.Prithvi JawaharÎncă nu există evaluări

- Annular Pressure Operated Production VentDocument1 paginăAnnular Pressure Operated Production VentDenier RubianoÎncă nu există evaluări

- Nutts 01 2010 Duisburg PDFDocument153 paginiNutts 01 2010 Duisburg PDFAnaa ChiroşcăÎncă nu există evaluări

- Models - Mfl.controlled Diffusion Micromixer PDFDocument36 paginiModels - Mfl.controlled Diffusion Micromixer PDFvarun singhÎncă nu există evaluări

- SPH SWRO 1,5 M3 Jam BPK Ardi Makasar-DikonversiDocument6 paginiSPH SWRO 1,5 M3 Jam BPK Ardi Makasar-DikonversiRyanWennoÎncă nu există evaluări

- Water Distribution System PDFDocument39 paginiWater Distribution System PDFAlif KarimiÎncă nu există evaluări

- Mechanical OperationDocument14 paginiMechanical OperationThiyaga RajanÎncă nu există evaluări

- Industrial Gases DissertationDocument106 paginiIndustrial Gases DissertationAjay Singh TalyanÎncă nu există evaluări

- RTD in PFRDocument12 paginiRTD in PFRAmoluck BhatiaÎncă nu există evaluări

- Supersonic SeparatorDocument4 paginiSupersonic SeparatormortezasabetiÎncă nu există evaluări