Documente Academic

Documente Profesional

Documente Cultură

Diesel Electric Power Plant

Încărcat de

Shailesh Sankdasariya100%(5)100% au considerat acest document util (5 voturi)

7K vizualizări7 paginiREFERANCE.

CONCLUSION.

STATUS

ADVANTAGES & DISADVANTAGES.

VARIOUS FACTOR

VARIOUS TYPES

WORKING

BLOCK DIAGRAM&IT’S COMPONANTS.

Titlu original

Diesel Electric power plant

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentREFERANCE.

CONCLUSION.

STATUS

ADVANTAGES & DISADVANTAGES.

VARIOUS FACTOR

VARIOUS TYPES

WORKING

BLOCK DIAGRAM&IT’S COMPONANTS.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

100%(5)100% au considerat acest document util (5 voturi)

7K vizualizări7 paginiDiesel Electric Power Plant

Încărcat de

Shailesh SankdasariyaREFERANCE.

CONCLUSION.

STATUS

ADVANTAGES & DISADVANTAGES.

VARIOUS FACTOR

VARIOUS TYPES

WORKING

BLOCK DIAGRAM&IT’S COMPONANTS.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 7

DIESEL POWER PLANT

ENERGY SYSTEMS,

BY SHAILESH B. PATEL -090760111025

DIESEL-ELECTRIC

POWER PLANT

CONTENTS:-

BLOCK DIAGRAM & IT’S COMPONANTS.

WORKING OF DIESEL POWER PLANT.

ADVANTAGES & DISADVANTAGES.

APPLICATION OF DIESEL POWER PLANT.

STATUS OF DIESEL ELECRIC POWER PLANT IN INDIA.

CONCLUSION.

REFERANCE.

ggaagaaa

DIESEL ELECTRIC POWER PLANT

ENERGY SYSTEMS

SANKDASARIYA SHAILESH B.

ENRL NO-090760111025

SSASIT (E.C. DEPARTMENT)

DIESEL POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

DIESEL POWER PLANT

Al

- TO STUDY ABOUT DIESEL POWER PLANT.

"A generating station in which diesel engine is used as the prime mover for the

generation of electrical energy is known as diesel power station.

"In a diesel power station, diesel engine is used as the prime mover. The diesel burns

inside the engine and the products of this combustion act as the working fiuid to

produce mechanical energy. The diesel engine drives alternator the which converts

mechanical energy into electrical energy. As thegerneration cost is considerable due to

high price of diesel, therefore, such power stations are only used to produce small

power.

@ BLOCK DIAGRAM:-

SSASIT| BY SHAILESH B, PATEL(E.C. DEPARTMENT)

DIESEL POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

© DIESEL ENGINE :- This is the main component of the diesel electric power plant which

develops power. They may be 4 strokes or 2 stroke engine. 4 stroke engines has lower

fuel consumption, more flexibility, better scavenging and higher efficiency than 2

stroke. Cylinders are arranged in V shape to make the engine more compact. 6 to 8

cylinders are commonly used. Speed is in the range of 500-1000 rpm. The diesel

engines are compression ignition type. Diesel engines are available in sizes from 75kW

to 3750kW.

AIR INTAKE SYSTEM: This system supplies necessary air to the engine for fuel

combustion. It consists of pipes for the supply of fresh air to the engine manifold.

Filters are provided to remove dust particles from air which may act as abrasive in the

engine cylinder.

© AIR FILTER AND SUPERCHARGER :- The function of air filter is to remove the dust from

the air, which is taken by the engine. The function of supercharger is to increase the

pressure of air supplied to the engine to increase the power of the engine. The

supercharger is driven by the engine.

© EXHAUST SYSTEM: This includes silencer and connecting ducts. silencer is required in

between the engine and the intake system, since the noise may be transmitted back to

outside air via the air intake system. The temperature of exhaust gases are really high

that heat is used for heating the oil or air supplied to the engine.

“FUEL SUPPLY SYSTEM: It consists of storage tank, strainers, fuel transfer pump and all

day fuel tank. The fuel oil is supplied at the plant site by rail or road. The oil is stored in

the storage tank. From the storage tank, oil is pumped to smaller all day tank at daily

or short intervals. From this tank, fuel oil is passed through strainers to remove

suspended impurities. The clean oil is injected into the engine by fuel injection pump.

"COOLING SYSTEM:The heat released by the burning of fuel in the engine cylinder is

partially converted into work. The remainder part of the heat passes through the

cylinder wall, piston, rings etc. and may cause damage to system. In order to keep the

temperature of the engine parts within the safe operating limits, cooling is provided.

The cooling system consists of a water source, pump and cooling towers. The pump.

circulated water through cylinder and head jacket. The water takes away heat form the

engine and itself becomes hot. The hot water is cooled by cooling towers and

recirculated for cooling

"LUBRICATING SYSTEM:The system minimises the wear of rubbing surfaces of the

engine.It comprises of lubricating oil tank,pump,filter and oil cooler.The lubricatiion oil

is drawn from the lubricating oil tank by the pump and is passed through filter to

remove impurities .The clean lubrication oil is delivered to the points which require

lubrication.The oil coolers incorporated in the system keep the temperature of the oil

low.

SSASIT| BY SHAILESH B, PATEL(E.C. DEPARTMENT) [EAI

DIESEL POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

© ENGINE STARTING SYSTEM:This is an arrangement to rotate the engine initially, while

starting, until firing starts and the unit runs with its own power.Small sets are started

manually by handles but for larger units,compressed air is used for starting.In the latter

case,air at high pressure is admitted to a few of the cylinders,making them to act as

reciprocating air motors to turn over the engine shaft.The fuel is admitted to the

remaining cylinders which makes the engine to start under its own power.

©GOVERNING SYSTEM = Their function is to maintain the speed of the engine constant

irrespective of load on the plant. This is done by varying fuel supply to the engine

according to load.

©DIESEL ENGINE GENERATOR :- The generators used in diese! power plants are of rotating

field, salient pole construction, speed ranging from 214 to 1000 rpm and capacities

ranging from 25-5000 kVA at 0.8 power factor lagging. Generators are coupled directly

to diesel engine. They are provided with voltage regulators to allow voltage regulation.

The excitation is usually provided at 115 to 230 V from a DC exciter, usually coupled to

the engine shaft through a belt

@WORKING OF DIESEL ENGINE POWER PLANT :-

The main part is diesel engine in diesel power plant so we here we explained the

workind of 4 stroke diesel engine after performing this four stroke we get the energy

into mechanicle form in rotary motion which is coupled with the turbine directly or to a

generator and through this we get electricity

[fr stack

t\ Fuel Gas

4 _|Desulphurisation

and dnox system

Heat Recovery

‘Steam Generator

Fuel

Diesel

Engine

- or Gas

CO Engine

NL

an ‘Generator

SSASIT| BY SHAILESH B, PATEL(E.C. DEPARTMENT)

DIESEL POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

@HOW IT WORKS:-

There are different types cycles in thermodynamics.Such as Otto cycle,Carnot vapour

cycle, Diesel cycle etc.Out of that cycle diesel engine works on diesel cycle.This cycle is

also known as constant pressure cycle.Diesel engine is mostly employed in Stationary

Power plants,Ships,Heavy Motor Vehicles.

Diesel Engine is mainly worked on below strokes.

fuel injector exhaust valve

Intake compression power

© 2007 Encyclopsedia Britannica, Inc

SUCTION OR INTAKE STROKE:- In this stroke,the piston moves down from the top

dead centre.As a result,inlet valve opens and air is drawn into the cylinder. After

sufficient quantity of air with pressure is drawn,suction valve closes at the end of the

stroke.The exhaust valve remains closed during this stroke.

COMPRESSION STROKE:- In this stroke,piston moves up from the bottom dead

centre.During this stroke both inlet and exhaust valve are closed.The air drawn into the

cylinder during suction stroke,is entrapped inside the cylinder and compressed due to

upward movement of the piston.In diesel engine,the compression ratio used is very

high as a result,the air is finally compressed to a very high pressure up to 40 kilogram

per centimeter square,at this pressure,the temperature of the air is reached to 1000

degree centigrade which is enough to ignite the fuel.

SSASIT| BY SHAILESH B, PATEL(E.C. DEPARTMENT) [EN

DIESEL POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

WORKING OR POWER STROKE:- In this stroke,both inlet and exhaust valve

remain closed.The hot gases (which are produced due to ignition of fuel during

compression stroke) and compressed air,now expand adiabatically, in the cylinder

Pushing the piston down and hence work is done.At the end of stroke,the piston finally

reaches the bottom dead centre.

EXHAUST STROKE:- In this stroke,the piston again moves upward.The exhaust

valve opens,while inlet and fuel valve are closed. greater part of the burnt fuel gases

escape due to their own expansion. The upward movement of the piston pushes the

remaining gases out through the open exhaust valve.Only a small quantity of exhaust

gases stay in the combustion chamber.At the end of exhaust stroke,the exhaust valve

closes and the cycle is thus completed

@ ADVANTAGES & DISADVANTAGES OF DIESEL POWER PLANTS:

SW ADVANTAGES:

+ Very simple design also simple installation

Limited cooling water requirement.

Standby losses are less as compared to other Power plants.

Low fuel cost.

Quickly started and put on load.

Smaller storage is needed for the fuel.

Layout of power plant is quite simple.

There is no problem of ash handling,

Less supervision required.

“* For small capacity diesel power plant is more efficient as compared to steam power

plant.

* They can respond to varying loads without any difficulty.

‘+ They can be easily located at the load centre without causing pollution in the

environment.

* Diesel power plants maintain their high operating efficiency irrespective of load.

“There is less fire hazard.

“ Maintenance charges are less as the auxiliary plant is also small in size.

* Plant is compact and light.

“ Thermal efficiency of a diesel power station is always higher than that of a steam

plant of equivalent size.

‘© DISADVANTAGES:

“© High Maintenance and operating cost.

Fuel cost is more, since in India diesel is costly.

+ The plant cost per kW is comparatively more.

“The life of diesel power plant is small due to high maintenance.

“ Noise is a serious problem in diesel power plant,

“ Diesel power plant cannot be constructed for large scale.

DIESEL POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

APPLICATION OF DIESEL POWER PLANT:

Since there are many disadvantage of diesel power plant, although the plant find wide

application in the following fields.

* They are quite suitable for mobile power generation and are widely used in

transportation systems consisting of railroads, ships, automobiles and aeroplanes.

“They can be used for electrical power generation in capacities from 100 to 5000 H.P.

* They can be used as standby power plants.

“They can be used as peak load plants for some other types of power plants.

“Industrial concerns where power requirement are small say of the order of 500 kW,

diese! power plants become more economical due to their higher overall efficiency.

@STATUS OF DIESEL ELECTRIC POWER PLANT IN INDIA:-

POWER STATION STATE CAPACITY(MW)

| Ambala Diesel Power Station Haryana 392 |

Keylong Diesel Power Station Himachal Pradesh 0.13

| Bemina Diesel Power station Jammu & Kashmir 5 |

Kamah Diesel Power Station Jammu & Kashmir 0.06

| Leh Diesel Power station Jammu & Kashmir 218 |

Upper Sindh Diesel Power Station Jammu & Kashrnir 17

| Yelahanka Diesel Power tation Karnataka 12792 |

Brahmapuram Diesel Power Station Kerala 106.6

| Kozhikode Diesel Power Station Kerala 128 |

Gangtok Diesel Power Station sikkim 4

| Ranipoot Diesel Power Station Sikkim 1 |

Suryachakra Diesel Power Station Andaman & Nicobar 20

#-CONCLUSION:

After studying diesel electrc power plant we can say that this is the most efficient

power plant when the generation of electricity is at rapid speed. This power plant is

setting up nearer to the requirmgnt area so losses is less than other power

plant.Starting and stop operation is very rapid so we can us this power plant in

emergancy services

@REFERANCE :

"WWW. ELECTRICALANDELECTRONICS.ORG

WWW. EN.WIKIPEDIA.ORG

© BOOKS OF POWER PLANT ENGINEERING (NEW_AGE_INTERNATIONAL)

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- PRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpDocument3 paginiPRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpSuman GhoshÎncă nu există evaluări

- Calculating monthly electricity consumptionDocument2 paginiCalculating monthly electricity consumptionStella KazanciÎncă nu există evaluări

- Chetan Bhagat - Three Mistakes of My LifeDocument144 paginiChetan Bhagat - Three Mistakes of My LifeGayathri ParthasarathyÎncă nu există evaluări

- Thermal Power PlantDocument8 paginiThermal Power PlantShailesh Sankdasariya100% (3)

- 7.MMCR JuliDocument5.281 pagini7.MMCR JuliAngga StwnÎncă nu există evaluări

- Combined Cycle Gas Turbine.Document9 paginiCombined Cycle Gas Turbine.Shailesh Sankdasariya100% (6)

- Combined Cycle Gas Turbine.Document9 paginiCombined Cycle Gas Turbine.Shailesh Sankdasariya100% (6)

- Combined Cycle Gas Turbine.Document9 paginiCombined Cycle Gas Turbine.Shailesh Sankdasariya100% (6)

- Wind Turbine Power PlantDocument8 paginiWind Turbine Power PlantShailesh SankdasariyaÎncă nu există evaluări

- Wind Turbine Power PlantDocument8 paginiWind Turbine Power PlantShailesh SankdasariyaÎncă nu există evaluări

- Wind Turbine Power PlantDocument8 paginiWind Turbine Power PlantShailesh SankdasariyaÎncă nu există evaluări

- Matlab Finite Element Modeling For Materials Engineers Using MATLABDocument74 paginiMatlab Finite Element Modeling For Materials Engineers Using MATLABPujara ManishÎncă nu există evaluări

- State of Art Research in AlgaeDocument20 paginiState of Art Research in AlgaeSambhavÎncă nu există evaluări

- Eastern Visayas State University-Ormoc City CampusDocument3 paginiEastern Visayas State University-Ormoc City Campuskhellian villameroÎncă nu există evaluări

- Display Devices and PrintersDocument9 paginiDisplay Devices and PrintersShailesh SankdasariyaÎncă nu există evaluări

- 130901-1 Circuit & Networks Gtu 3rd Sem PaperDocument3 pagini130901-1 Circuit & Networks Gtu 3rd Sem PaperShailesh SankdasariyaÎncă nu există evaluări

- Buck BoostDocument18 paginiBuck BoostYang QianÎncă nu există evaluări

- 8051 Based Digital ClockDocument15 pagini8051 Based Digital ClockShailesh SankdasariyaÎncă nu există evaluări

- Digital Logic Design Exam QuestionsDocument2 paginiDigital Logic Design Exam Questionsjayant_2222143Încă nu există evaluări

- 131101-2 Gtu 3rd Sem PaperDocument4 pagini131101-2 Gtu 3rd Sem PaperShailesh SankdasariyaÎncă nu există evaluări

- 8051 Based Simple Digital ClockDocument7 pagini8051 Based Simple Digital ClockShailesh SankdasariyaÎncă nu există evaluări

- 131101-1 Gtu 3rd Sem PaperDocument2 pagini131101-1 Gtu 3rd Sem PaperShailesh SankdasariyaÎncă nu există evaluări

- 8051 Project LCD InterfacingDocument7 pagini8051 Project LCD InterfacingShailesh Sankdasariya100% (5)

- 130701-1 Digital Logic Design Gtu 3rd Sem PaperDocument1 pagină130701-1 Digital Logic Design Gtu 3rd Sem PaperShailesh SankdasariyaÎncă nu există evaluări

- ATMEL MCS 8051 Instruct SetDocument50 paginiATMEL MCS 8051 Instruct Setand3botÎncă nu există evaluări

- 131701-1 Gtu 3rd Sem PaperDocument1 pagină131701-1 Gtu 3rd Sem PaperShailesh SankdasariyaÎncă nu există evaluări

- 130904-3 Gtu 3rd Sem PaperDocument3 pagini130904-3 Gtu 3rd Sem PaperShailesh SankdasariyaÎncă nu există evaluări

- 130904-2 Gtu 3rd Sem PaperDocument1 pagină130904-2 Gtu 3rd Sem PaperShailesh SankdasariyaÎncă nu există evaluări

- Hydro Magnetic Power PlantDocument7 paginiHydro Magnetic Power PlantShailesh SankdasariyaÎncă nu există evaluări

- 130901-2 Circuit & Networks Gtu 3rd Sem PaperDocument2 pagini130901-2 Circuit & Networks Gtu 3rd Sem PaperShailesh SankdasariyaÎncă nu există evaluări

- Hydro Magnetic Power PlantDocument7 paginiHydro Magnetic Power PlantShailesh SankdasariyaÎncă nu există evaluări

- 130001Document2 pagini130001Ashwin PatelÎncă nu există evaluări

- GTU Mathematics III Exam QuestionsDocument3 paginiGTU Mathematics III Exam QuestionsJainish JariwalaÎncă nu există evaluări

- Solar Power PlantDocument8 paginiSolar Power PlantShailesh Sankdasariya50% (2)

- Power DistributionDocument6 paginiPower DistributionShailesh SankdasariyaÎncă nu există evaluări

- Technical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet JD 30 M JD 30 M JD 30 M JD 30 MDocument6 paginiTechnical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet JD 30 M JD 30 M JD 30 M JD 30 MMhammedSimoÎncă nu există evaluări

- 08 Redox NotesDocument12 pagini08 Redox NotesAwais BodlaÎncă nu există evaluări

- Section 8 - Synchronism-Check Protection (25) : SEL-751A Feeder Protection Relay - APP 751ADocument19 paginiSection 8 - Synchronism-Check Protection (25) : SEL-751A Feeder Protection Relay - APP 751ABouazzaÎncă nu există evaluări

- Costa Hosh - SP Final DraftDocument10 paginiCosta Hosh - SP Final Draftapi-551407564Încă nu există evaluări

- Fire Safety Procedures: Prevention, Equipment & AlarmsDocument11 paginiFire Safety Procedures: Prevention, Equipment & AlarmsCyrus SantosÎncă nu există evaluări

- 7.5 01 02 01Document19 pagini7.5 01 02 01Feri SaputraÎncă nu există evaluări

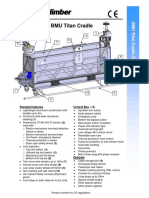

- BMU Titan Cradle: Standard Features Control BoxDocument2 paginiBMU Titan Cradle: Standard Features Control BoxKashyapÎncă nu există evaluări

- 0401544-Hydraulic StructuresDocument38 pagini0401544-Hydraulic StructuresEfremWakjiraHodeÎncă nu există evaluări

- Упражнения на отработку Second ConditionalDocument6 paginiУпражнения на отработку Second ConditionalНаргиля ГаджиеваÎncă nu există evaluări

- Bhagvender Singh XII-A Physics Project PDFDocument15 paginiBhagvender Singh XII-A Physics Project PDFvoid50% (4)

- DC Motors Specifications and ParametersDocument6 paginiDC Motors Specifications and ParametersHà Tiến ĐôngÎncă nu există evaluări

- Monbat 12V200AhDocument1 paginăMonbat 12V200AhMaria MuresanÎncă nu există evaluări

- Electrocardiograf Ym412i Service ManualDocument14 paginiElectrocardiograf Ym412i Service ManualramarservmedÎncă nu există evaluări

- A4 G970 - G990 Product Brochure enDocument17 paginiA4 G970 - G990 Product Brochure endalibor_bogdan100% (3)

- International MaxxForce engine fault code troubleshooting guideDocument14 paginiInternational MaxxForce engine fault code troubleshooting guidePablo CervantesÎncă nu există evaluări

- Aoc 712sa+Service+ManualDocument50 paginiAoc 712sa+Service+ManualGiovanny Gregorio Gonzalez SanchezÎncă nu există evaluări

- Utilization of Lignocellulosic Biomass by Oleaginous Yeast and Bacteria For Production of Biodiesel and Renewable DieselDocument18 paginiUtilization of Lignocellulosic Biomass by Oleaginous Yeast and Bacteria For Production of Biodiesel and Renewable DieselIkrar AdiÎncă nu există evaluări

- Quiet Ducted Exhaust Ventilation Fans for Homes and Commercial SpacesDocument2 paginiQuiet Ducted Exhaust Ventilation Fans for Homes and Commercial SpacesKyaw ZawÎncă nu există evaluări

- IAEA-SM-346/113 Regional Safeguards Arrangements: The Argentina-Brazil ExperienceDocument13 paginiIAEA-SM-346/113 Regional Safeguards Arrangements: The Argentina-Brazil ExperiencePeter AngeloÎncă nu există evaluări

- Liebert EXM 80-200 kVA PDFDocument123 paginiLiebert EXM 80-200 kVA PDFrogeriopaulaÎncă nu există evaluări

- Anomaly Events GuideDocument33 paginiAnomaly Events GuideRichard LittlesÎncă nu există evaluări

- CFBC Boilers & TG Set Auxillaries SpecificationsDocument18 paginiCFBC Boilers & TG Set Auxillaries SpecificationsJAY PARIKHÎncă nu există evaluări

- Clivet Carel PcoDocument80 paginiClivet Carel PcoToni Dlabac100% (2)

- Can Your Roof Handle The Weight of Solar Panels?Document2 paginiCan Your Roof Handle The Weight of Solar Panels?Princess Joan UlitÎncă nu există evaluări

- Lessons Learned-Nuclear Gauge002Document66 paginiLessons Learned-Nuclear Gauge002Michael Murillo BaraquioÎncă nu există evaluări