Documente Academic

Documente Profesional

Documente Cultură

Plano de Processos Com Alternativas para A Fabricação de Um Lote Num FMS

Încărcat de

lauropilattiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Plano de Processos Com Alternativas para A Fabricação de Um Lote Num FMS

Încărcat de

lauropilattiDrepturi de autor:

Formate disponibile

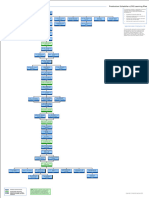

Plano de Processos com Alternativas

para a Fabricação de um Lote num FMS

Part

AND/OR

Graph

Process

Planning

USER Module Process

Plan

AND/OR

or Graph

Planning

Resource

MASTER Module

Linearised Model

PRODUCTION Process

Plan

SCHEDULE AND/OR

NC Program Graph

Generation

Manufatura Via Internet

for each

NC

Resource

Programs

APRESENTAÇÃO IST - SOCIESC João Carlos E. Ferreira (UFSC)

Grafo E/OU para uma Peça

Hole 1 Hole 5

Pocket 1

Hole 2

Hole 4

Hole 3

0

Hole1

1

Hole2

&b 2

Manufatura Via Internet

&e

Hole3

3

Hole4

4 5

Pocket1 Hole5

APRESENTAÇÃO IST - SOCIESC João Carlos E. Ferreira (UFSC)

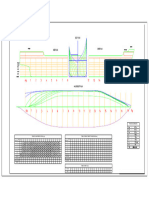

Sistema de Manufatura Considerado

Horiz. Mill

Vert. Mill

Port 5

Port 9

Port 4 Port 6

Port 8 Port 10

ABB #1

Port 11

Robot ABB #2

Horiz. Mill Port 13

Robot

Buffer Vert. Mill Vert. Mill

Port 2 AGV Lathe

Station

Kardex Port 7

AS/RS AGV

PUMA Station

Port 1

Manufatura Via Internet

560 Port 3

Port 12

Robot

APRESENTAÇÃO IST - SOCIESC João Carlos E. Ferreira (UFSC)

Estratégia para a

Geração do Programa NC

G00 X <x> Y <y> H0 M6 T <tool>

H <tool offset> Z <z + 0.10>

Z <z + 0.10>

G01 Z <z - depth> S <rpm> F <feed> M3 M8

G00 Z <z + 0.10>

Z <z + 0.10> M5

Manufatura Via Internet

APRESENTAÇÃO IST - SOCIESC João Carlos E. Ferreira (UFSC)

Peças a Serem Fabricadas

1" diameter hole pocket

0.5" diameter hole

0.5" diameter hole

Manufatura Via Internet

APRESENTAÇÃO IST - SOCIESC João Carlos E. Ferreira (UFSC)

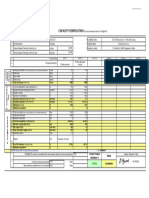

Plano de Processo Gerado

7

boring

6 !e

!b

drilling 8

1 2 reaming

!b !e I

unload load

9

4 5 drilling

!b !e !b

unload load

3 15 16

move boring boring

14

drilling

!b !e II

17

reaming

11 12

boring boring

10

I drilling

!b !e

13 24 25

reaming unload load

22 23

!e !b !e

19 unload load

Manufatura Via Internet

boring 26

18 move

!b !e

drilling 20

II !b reaming !e

21

drilling

Process plan string:

(((1 2 *) 3 !) 4 5 (((( 6 (7 8 !) *) 9 !) 10 ((11 12 *) 13 !) *) (14 ((15 16 *) 17 !) (( 18 (19 20 !) *) 21 !) *) !) 22 23 (( 24 25 *) 26 !) *)

APRESENTAÇÃO IST - SOCIESC João Carlos E. Ferreira (UFSC)

Identificação dos Nós

Node Resource Operation From Port → To Port Node Resource Operation From Port → To Port

ID /Coordinates (x,y) and ID /Coordinates (x,y) and

diameter (∅) diameter (∅)

1 PUMA robot unload 1 → 12 14 Vertical M.C. drilling (1.5, 2.0); 0.4375"

2 PUMA robot load 12 → 2 15 Vertical M.C. boring (1.5, 2.0); 0.48"

3 Human move 1→2 16 Vertical M.C. boring (1.5, 2.0); 0.5"

4 ABB#1 robot unload 2 → 11 17 Vertical M.C. reaming (1.5, 2.0); 0.5"

5 ABB#1 robot load 11 → 6 18 Vertical M.C. drilling (5.0, 3.0); 0.9375"

6 Vertical M.C. drilling (5.0, 3.0); 0.9375" 19 Vertical M.C. boring (5.0, 3.0); 1.0"

7 Vertical M.C. boring (5.0, 3.0); 1.0" 20 Vertical M.C. reaming (5.0, 3.0); 1.0"

8 Vertical M.C. reaming (5.0, 3.0); 1.0" 21 Vertical M.C. drilling (5.0, 3.0); 1.0"

9 Vertical M.C. drilling (5.0, 3.0); 1.0" 22 ABB#1 robot unload 6 → 11

10 Vertical M.C. drilling (1.5, 2.0); 0.4375" 23 ABB#1 robot load 11 → 2

11 Vertical M.C. boring (1.5, 2.0); 0.48" 24 PUMA robot unload 2 → 12

12 Vertical M.C. boring (1.5, 2.0); 0.5" 25 PUMA robot load 12 → 1

13 Vertical M.C. reaming (1.5, 2.0); 0.5" 26 Human move 2→1

Manufatura Via Internet

APRESENTAÇÃO IST - SOCIESC João Carlos E. Ferreira (UFSC)

Programas NC Gerados

Hole ∅ 0.5" Pocket

% %

N001 M64 N001 M64

N002 G80 G40 G17 N002 G80 G40 G17

N003 E2 G90 X0 Y0 N003 E2 G90 X0 Y0

N004 G00 X1.5000 Y2.0000 H0 M6 T1 N004 G00 X1.5000 Y2.0000 H0 M6 T1

N005 H1 Z1.1000 N005 H1 Z2.1000

N006 Z1.1000 N006 Z2.1000

N007 G01 Z0.5000 S829 F9.9531 M3 M8 N007 G01 Z1.5000 S829 F9.9531 M3 M8

N008 G00 Z1.1000 N008 G00 Z2.1000

N009 Z1.1000 M5 N009 Z2.1000 M5

N010 G00 X1.5000 Y2.0000 H0 M6 T2 N010 G00 X1.5000 Y2.0000 H0 M6 T2

N011 H2 Z1.1000 N011 H2 Z2.1000

N012 Z1.1000 N012 Z2.1000

N013 G01 Z0.5000 S458 F6.8755 M3 M8 N013 G01 Z1.5000 S458 F6.8755 M3 M8

N014 G00 Z1.1000 N014 G00 Z2.1000

N015 Z1.1000 M5 N015 Z2.1000 M5

N016 G00 X5.0000 Y3.0000 H0 M6 T3 N016 G00 X4.0000 Y3.1000 H0 M6 T4

N017 H3 Z1.1000 N017 H4 Z2.1000

N018 Z1.1000 N018 Z2.1000

N019 G01 Z0.5000 S363 F7.9832 M3 M8 N019 G01 Z1.7500 S2723 F16.3408 M3 M8

N020 G00 Z1.1000 N020 X5.5000 Y3.7000

N021 Z1.1000 M5 N021 X2.5000 Y3.7000

N022 H0 N022 X2.5000 Y2.5000

N023 G00 X0.0000 N023 X5.5000 Y2.5000

N024 G92 X0 N024 X5.5000 Y3.7000

N025 E0 X0 Y0 N025 G00 X4.0000 Y3.1000 Z1.7500

N026 M65 N026 G01 Z1.5000 S2723 F16.3408 M3 M8

Manufatura Via Internet

N027 M2 N027 X5.5000 Y3.7000

% N028 X2.5000 Y3.7000

N029 X2.5000 Y2.5000

N030 X5.5000 Y2.5000

N031 X5.5000 Y3.7000

N032 G00 X4.0000 Y3.1000 Z1.5000

N033 G00 X4.0000 Y3.1000 Z2.1000 M5

N034 H0

N035 G00 X0.0000

N036 G92 X0

N037 E0 X0 Y0

N038 M65

N039 M2

%

APRESENTAÇÃO IST - SOCIESC João Carlos E. Ferreira (UFSC)

S-ar putea să vă placă și

- Using Aspect-Oriented Programming for Trustworthy Software DevelopmentDe la EverandUsing Aspect-Oriented Programming for Trustworthy Software DevelopmentEvaluare: 3 din 5 stele3/5 (1)

- Kontoloyo ModelDocument1 paginăKontoloyo Modelyogi.aryaÎncă nu există evaluări

- Formal Methods: Industrial Use from Model to the CodeDe la EverandFormal Methods: Industrial Use from Model to the CodeÎncă nu există evaluări

- Rencana Garis - Raihan - A3Document1 paginăRencana Garis - Raihan - A3Raihan AzmiÎncă nu există evaluări

- BIM For PMs 1Document62 paginiBIM For PMs 1manuelramoshÎncă nu există evaluări

- MPEG-4 Facial Animation: The Standard, Implementation and ApplicationsDe la EverandMPEG-4 Facial Animation: The Standard, Implementation and ApplicationsIgor S. PandzicÎncă nu există evaluări

- Parts Production Preparation Plan: Aug-22 Sep-22 Oct-22 Jan-23 Feb-23 May-23 Jun-23 Apr-23Document1 paginăParts Production Preparation Plan: Aug-22 Sep-22 Oct-22 Jan-23 Feb-23 May-23 Jun-23 Apr-23Naswadi NawiÎncă nu există evaluări

- CPE-214 Computer-Aided Engineering Design - Lab - Manual - OBE - 2 PDFDocument64 paginiCPE-214 Computer-Aided Engineering Design - Lab - Manual - OBE - 2 PDFHamza RaufÎncă nu există evaluări

- PFMEA New FormatDocument63 paginiPFMEA New FormatArshad AnsariÎncă nu există evaluări

- Process Analysis - HoutDocument12 paginiProcess Analysis - HoutANN MARY JOSE PGP 2023-25 BatchÎncă nu există evaluări

- 01 Introduction Microprocessor and InterfaceDocument10 pagini01 Introduction Microprocessor and InterfaceFahad MahmoodÎncă nu există evaluări

- 18mee304t - Dfma SyllabusDocument3 pagini18mee304t - Dfma SyllabusSachidhanandam MÎncă nu există evaluări

- 22fa0087 Plans Malinao Municipal-7 - 2Document25 pagini22fa0087 Plans Malinao Municipal-7 - 2KrutteruHeroÎncă nu există evaluări

- Meralco Generation Cost and ChargeDocument1 paginăMeralco Generation Cost and Chargedexterbautistadecember161985Încă nu există evaluări

- 20me702 - Process Planning and Cost Estimation Unit 1 2023-24Document61 pagini20me702 - Process Planning and Cost Estimation Unit 1 2023-24CAD With RaoÎncă nu există evaluări

- OBE Based DSD Lab Manual Updated1 PDFDocument101 paginiOBE Based DSD Lab Manual Updated1 PDFAbdullahÎncă nu există evaluări

- Ie ToolsDocument9 paginiIe ToolsImran sarkerÎncă nu există evaluări

- QAV-2 Step-5 Audit Check Sheet PDFDocument6 paginiQAV-2 Step-5 Audit Check Sheet PDFRajÎncă nu există evaluări

- CIF DebuggingDocument9 paginiCIF Debuggingdanius01Încă nu există evaluări

- DFA Tabel: TotalDocument1 paginăDFA Tabel: Totalapi-329249285Încă nu există evaluări

- Material Requirements Planning (MRP) : Learning ObjectivesDocument20 paginiMaterial Requirements Planning (MRP) : Learning ObjectivesAris SyaifulÎncă nu există evaluări

- Bus Structure NewDocument35 paginiBus Structure NewAnonymous Xr7bf3un0Încă nu există evaluări

- Wim Correction l3 Mc091 - 2016Document1 paginăWim Correction l3 Mc091 - 2016PK KÎncă nu există evaluări

- Nikhil Jaiswal 1804021 Project ProposalDocument3 paginiNikhil Jaiswal 1804021 Project ProposalSHEIKH SOHAIL AMIRÎncă nu există evaluări

- Unified Workflow Review (Gen)Document9 paginiUnified Workflow Review (Gen)Falguni Baijendra GujarathiÎncă nu există evaluări

- Dashboard Project ManagementDocument2 paginiDashboard Project ManagementAdministracion VitriglassÎncă nu există evaluări

- The TOFD ProcedureDocument26 paginiThe TOFD ProceduresrgokuÎncă nu există evaluări

- Run at Rate 200.6.222Document1 paginăRun at Rate 200.6.222Stefan DončevićÎncă nu există evaluări

- Flow Chart Objects:: Session OneDocument2 paginiFlow Chart Objects:: Session Onechetan_winÎncă nu există evaluări

- BIM Document RIBADocument1 paginăBIM Document RIBAGamini Kodikara100% (1)

- PZPSFZ001 00Document1 paginăPZPSFZ001 00anxhelazazaÎncă nu există evaluări

- Troubleshooting & Maintenance With ProfibusDocument25 paginiTroubleshooting & Maintenance With ProfibusZulfiqar ZaidiÎncă nu există evaluări

- QFD Matrix: Design Requirements Product/Service Plan Customer RatingDocument5 paginiQFD Matrix: Design Requirements Product/Service Plan Customer RatingMilton Celis FloresÎncă nu există evaluări

- Project Plan For Abc Project: by Priyanka ChoudharyDocument10 paginiProject Plan For Abc Project: by Priyanka ChoudharyPriyanka ChoudharyÎncă nu există evaluări

- QMB - Session 19 - Worksheet 18 - Winter 2020 PDFDocument4 paginiQMB - Session 19 - Worksheet 18 - Winter 2020 PDFGrace StylesÎncă nu există evaluări

- Programming Steps - Display Array Values Program Flow ChartDocument2 paginiProgramming Steps - Display Array Values Program Flow CharttugasutomoÎncă nu există evaluări

- Relationship Between Planners and Others 2Document1 paginăRelationship Between Planners and Others 2Haytham BarakaÎncă nu există evaluări

- 20me702 - Process Planning and Cost Estimation Unit 4 2023-24Document64 pagini20me702 - Process Planning and Cost Estimation Unit 4 2023-24CAD With RaoÎncă nu există evaluări

- Or 2017 PDFDocument4 paginiOr 2017 PDFVictor HoveÎncă nu există evaluări

- Tool Capacity Planning in Semiconductor Manufacturing: B'ulent C (Atay, S (. Sel (Cuk Ereng'u (C, Asoo J. VakhariaDocument18 paginiTool Capacity Planning in Semiconductor Manufacturing: B'ulent C (Atay, S (. Sel (Cuk Ereng'u (C, Asoo J. VakhariaPranavÎncă nu există evaluări

- 21 Facility Layout 5 - Improvement MULTIPLEDocument24 pagini21 Facility Layout 5 - Improvement MULTIPLEmates4workÎncă nu există evaluări

- Programming For Beginner - SaturngodDocument86 paginiProgramming For Beginner - SaturngodThan Hlaing WonÎncă nu există evaluări

- Pipingengineeringtest 150509193313 Lva1 App6891Document43 paginiPipingengineeringtest 150509193313 Lva1 App6891mengelito almonte100% (1)

- TPD1 EbbDocument7 paginiTPD1 EbbNguyenÎncă nu există evaluări

- Subject: Target:: Reduction of The Open Groupe To 2Document16 paginiSubject: Target:: Reduction of The Open Groupe To 2Amine AmmarÎncă nu există evaluări

- Process Names: Pre Sales Engineering Process: End User Training ManualDocument110 paginiProcess Names: Pre Sales Engineering Process: End User Training ManualmanishÎncă nu există evaluări

- Yangon Thanlyin Bridge 4Document50 paginiYangon Thanlyin Bridge 4ကိုနေဝင်း100% (4)

- Schedule C - Illustrative Concept Plan PDFDocument1 paginăSchedule C - Illustrative Concept Plan PDFReeshi Raj PandeyÎncă nu există evaluări

- Production SchedulerDocument1 paginăProduction SchedulerAdnene ChouchiÎncă nu există evaluări

- Ipcrf Template 2022Document8 paginiIpcrf Template 2022Lauro GacusanaÎncă nu există evaluări

- OpenSAP Abap1 Unit 5 EXTENS PresentationDocument7 paginiOpenSAP Abap1 Unit 5 EXTENS PresentationSergei DelachÎncă nu există evaluări

- Planning (Activity Map PERT & CPM Analysis To Be Included)Document7 paginiPlanning (Activity Map PERT & CPM Analysis To Be Included)Deepak PooranachandranÎncă nu există evaluări

- Manual: Assembly & InstructionDocument52 paginiManual: Assembly & InstructionnxoxeÎncă nu există evaluări

- OSPL 01 Exercise 3 - en - 2023Document8 paginiOSPL 01 Exercise 3 - en - 2023Guowei LanÎncă nu există evaluări

- Panel Inspection Report: T/M Cont Cabel 28391-77P00 Checking Gap and Flush SketchDocument7 paginiPanel Inspection Report: T/M Cont Cabel 28391-77P00 Checking Gap and Flush SketchSanjayÎncă nu există evaluări

- APQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionDocument6 paginiAPQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionParveen KumarÎncă nu există evaluări

- Tablou AutomatizareDocument3 paginiTablou AutomatizareNicu PuscasÎncă nu există evaluări

- Training PlanDocument34 paginiTraining PlanJAYROME OBIDOÎncă nu există evaluări

- Box File Stickers - 1Document10 paginiBox File Stickers - 1malladhinagarjunaÎncă nu există evaluări

- SOAL ASSEMEN PAKET A BAHASA INGGRIS NewDocument3 paginiSOAL ASSEMEN PAKET A BAHASA INGGRIS Newmtsn4 clpÎncă nu există evaluări

- Raro V ECC & GSISDocument52 paginiRaro V ECC & GSISTricia SibalÎncă nu există evaluări

- Pechay Camote Buchi - Aug7Document36 paginiPechay Camote Buchi - Aug7Rockie Alibio JuanicoÎncă nu există evaluări

- Song FlowDocument4 paginiSong FlowEhij ZheyÎncă nu există evaluări

- Paul's Defence of His Apostleship - Gal 1 - 2Document13 paginiPaul's Defence of His Apostleship - Gal 1 - 231songofjoyÎncă nu există evaluări

- James Burt HistoryDocument9 paginiJames Burt HistoryJan GarbettÎncă nu există evaluări

- Online Book Store System: Bachelor of Computer EngineeringDocument31 paginiOnline Book Store System: Bachelor of Computer Engineeringkalpesh mayekarÎncă nu există evaluări

- Manual GPS Trimble Portugues CFX-750 / FM-750Document246 paginiManual GPS Trimble Portugues CFX-750 / FM-750José Luis Mailkut Pires100% (5)

- Abdukes App PaoerDocument49 paginiAbdukes App PaoerAbdulkerim ReferaÎncă nu există evaluări

- Introduction - Types and ApproachesDocument88 paginiIntroduction - Types and ApproachesAritra DeyÎncă nu există evaluări

- Rationale of Labour Welfare To Employers and EmployeesDocument20 paginiRationale of Labour Welfare To Employers and Employeesajit yadav100% (1)

- Case DigestsDocument12 paginiCase DigestsHusni B. SaripÎncă nu există evaluări

- Rapid Prototyping and Rapid Tooling TheDocument24 paginiRapid Prototyping and Rapid Tooling TheGopinath GangadhariÎncă nu există evaluări

- A Study of Consumer Protection Act Related Related To Banking SectorDocument7 paginiA Study of Consumer Protection Act Related Related To Banking SectorParag SaxenaÎncă nu există evaluări

- Business Management Business ManagementDocument31 paginiBusiness Management Business ManagementDoyieÎncă nu există evaluări

- Nonfiction Reading Test The Coliseum: Directions: Read The Following Passage and Answer The Questions That Follow. ReferDocument3 paginiNonfiction Reading Test The Coliseum: Directions: Read The Following Passage and Answer The Questions That Follow. ReferYamile CruzÎncă nu există evaluări

- FABM 1-Answer Sheet-Q1 - Summative TestDocument2 paginiFABM 1-Answer Sheet-Q1 - Summative TestFlorante De Leon100% (2)

- Mouth Tongue and Salivary GlandsDocument52 paginiMouth Tongue and Salivary GlandsIrfan FalahÎncă nu există evaluări

- Ring Spinning Machine LR 6/S Specification and Question AnswerDocument15 paginiRing Spinning Machine LR 6/S Specification and Question AnswerPramod Sonbarse100% (3)

- QinQ Configuration PDFDocument76 paginiQinQ Configuration PDF_kochalo_100% (1)

- Online Gaming and Social BehaviorDocument13 paginiOnline Gaming and Social BehaviorPave Llido100% (1)

- Ventures Onsite Market Awards 22062023 64935868dDocument163 paginiVentures Onsite Market Awards 22062023 64935868dhamzarababa21Încă nu există evaluări

- Maths-Term End Examination-2020-2021 (2020-2021, MATHS)Document6 paginiMaths-Term End Examination-2020-2021 (2020-2021, MATHS)Venkat Balaji0% (1)

- The Liberal Welfare Reforms 1906Document5 paginiThe Liberal Welfare Reforms 1906Skye G-sÎncă nu există evaluări

- Lesson Plan Design: Ccss - Ela-Literacy - Rf.2.3Document6 paginiLesson Plan Design: Ccss - Ela-Literacy - Rf.2.3api-323520361Încă nu există evaluări

- Lecture 1. Introducing Second Language AcquisitionDocument18 paginiLecture 1. Introducing Second Language AcquisitionДиляра КаримоваÎncă nu există evaluări

- Culvert StatementDocument4 paginiCulvert StatementRubul Prasad DasÎncă nu există evaluări

- Allen Science M T Class 10Document14 paginiAllen Science M T Class 10krishnaÎncă nu există evaluări

- City Marketing: Pengelolaan Kota Dan WilayahDocument21 paginiCity Marketing: Pengelolaan Kota Dan WilayahDwi RahmawatiÎncă nu există evaluări

- Machine Tools Design: InstructorsDocument31 paginiMachine Tools Design: InstructorsAladdin AdelÎncă nu există evaluări