Documente Academic

Documente Profesional

Documente Cultură

Are Your Engineers Talking To One Another When They Should

Încărcat de

caradura1593Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Are Your Engineers Talking To One Another When They Should

Încărcat de

caradura1593Drepturi de autor:

Formate disponibile

TOOL KIT

Are Your Engineers Talking to

One Another When They Should?

Cost overruns, schedule slippage, and quality problems often result from a failure to provide

timely information or resources. Here’s a way to help prevent that from happening.

by Manuel E. Sosa, Steven D. Eppinger, and Craig M. Rowles

C

OMPANIES THAT DESIGN COMPLEX, highly engineered prod-

ucts all have their horror stories. Ford and Bridgestone

Firestone lost billions of dollars after their failure to co-

ordinate the vehicle design of the Ford Explorer with the

design of its tires. Similarly, Airbus’s development of the A380

“superjumbo” suffered major delays and cost overruns because

of late emerging incompatibilities in the design of the electri-

cal harnesses of various sections of the plane’s fuselage. These

mistakes probably contributed to the loss of Airbus’s CEO and to

important changes in the management of the A380 program.

What’s striking about these stories and many others like them

Jude Buffum

is that in virtually every case, the people involved all agreed,

in hindsight, that they could have avoided their expensive mis-

takes by making sure that the different teams responsible for

hbr.org | November 2007 | Harvard Business Review 133

1657 Sosa.indd 133 10/5/07 7:30:04 PM

TOOL KIT | Are Your Engineers Talking to One Another When They Should?

developing the products’ components management tool: the design structure gine was divided into eight subsystems,

had communicated more effectively. Of matrix (DSM). Our application helps each of which was further decomposed

course with complex development proj- managers identify where failures in into five to ten components, for a total

ects, you can never be certain that you planned communications could occur of 54 engine components. Typical for

have planned for every contingency. as well as recognize when project teams such projects, the development organi-

However, our experience shows that engage in unplanned technical commu- zation was correspondingly structured

in the design phase of such projects, nications. We also analyze communica- into 54 cross-functional design teams

many companies would benefit from tions between project teams that take responsible for each component, plus

focusing sharply on the critical points place both within and outside the for- six integration teams responsible for

of contact among their various compo- mal project structure. We conclude by managing engine-level requirements

nent development teams to ensure that discussing how managers should han- in areas such as fuel efficiency. These

everyone knows when and with whom dle communications problems that are teams had to interact a lot: There were

they should be sharing information. revealed in the process. While we do not several hundred interfaces among the

This article helps managers mitigate pretend to offer a definitive solution engine components, many of which

this design communication problem. to the design communication problem, would have experienced significant

Drawing on detailed research into how we do believe that managers who use problems without proper communica-

Pratt & Whitney handled the develop- our tools over succeeding generations tion among the relevant design teams.

ment of its highest-thrust commercial of products will improve the quality of To help manage the communications

jet engine – the PW4098, which pow- their development processes. aspect of such projects, we propose the

ers the Boeing 777 – we present a new following approach: (a) identify unat-

application of an established project Catching Missed Interfaces tended interfaces, areas where commu-

Before They Occur nication should be occurring but is not,

Article at a Glance The first thing a project team does when and (b) look for unidentified interfaces,

faced with a complex development areas where communication is occur-

Companies that design complex prod- challenge is break the project down ring but has not been planned. The re-

ucts all have their horror stories. Yet, into manageable pieces that are then sult of implementing this approach is

they can all avoid mistakes by ensuring assigned to dedicated subteams. In the what we call an alignment matrix, which

that the different teams responsible for

context of developing a product like a reveals mismatches between the com-

developing the components of the prod-

jet engine, this results in a large number munications and exchanges that are

ucts communicate more effectively.

of specialized cross-functional teams, supposed to occur and those that actu-

A new application of an established each working on a different component ally do. It also demonstrates, therefore,

project management tool, the design or subsystem of the engine. Of course, how well the project has been planned

structure matrix, can help a company these teams cannot work in isolation; and executed.

identify where failures in planned in addition to designing their assigned To see how the approach works,

communications could occur as well as components, they must also integrate let’s suppose that we plan to develop

recognize when project teams engage their designs with those of the other a product with four components, each

in useful technical communications that

components to ensure that the entire of which requires its own specialized

were not planned.

product or system functions as a whole. design team. (This approach may be

If a company finds that a lot of planned It is critical, therefore, in planning a used when the organizational structure

communication is not taking place, then complex product development process maps directly to the product architec-

it should revisit its product develop- that the project managers specify just ture – that is, component X is designed

ment organization. Even projects that which resources and information differ- by team X – which is the case in most

are completely organized around a ent teams will need from each other at of the complex development projects

product’s architecture are typically vul- particular stages of the project. in the automobile and aerospace firms

nerable to communication breakdowns. In the Pratt & Whitney jet engine we have studied. For cases in which

development project we studied, the en- the organizational and product struc-

A company can ensure that critical com-

munication occurs by tasking special

teams (or the teams involved) with Manuel E. Sosa is an assistant professor of technology and operations management at

making sure that the right people talk to Insead in Fontainebleau, France. Steven D. Eppinger is a professor of management science

each other. It’s also important to ensure and engineering systems and deputy dean at MIT’s Sloan School of Management in Cam-

that the teams are working with the bridge, Massachusetts. Craig M. Rowles was a Module Center manager at Pratt & Whitney,

optimum communication tools. based in East Hartford, Connecticut; he is now CEO of Emegear, a medical device company

in Carpinteria, California.

134 Harvard Business Review | November 2007 | hbr.org

1657 Sosa.indd 134 10/5/07 7:30:13 PM

Assessing the Fit Between Design and Communication

The first step in analyzing the communication problem among In the design interface matrix below, a shaded cell indicates

design engineers is to have the system architects identify the presence of a technical interface between two components.

technical interfaces between components and record their Thus, the first row of the matrix indicates that component A will

responses on a design interface matrix. Next, have component require some input from components B and D but nothing from C.

and subsystem design team members identify the technical The first column shows that A will be expected to provide input to

interactions they have had, are having, or expect to have with (or impose technical constraints on) B and D but not C.

other teams, and present those responses on a team interaction In the team interaction matrix, each row indicates from which

matrix. Then merge the two matrices to generate an alignment other teams a particular team expects to need information and re-

matrix that reveals matches and mismatches between interfaces sources, and each column shows where a team will be expected

and interactions. The matrices below are based on a product with to provide the information and resources. A shaded cell indicates

four components. where the teams expect to interact.

Alignment Matrix Key

Design Interface Matrix

Providing components Matched interface: design

Component A depends interface that is matched by

A B C D

Receiving components

System on component D an actual or expected team

Architects’ A • interaction

Input

B • Unattended interface: design

identify technical Alignment Matrix

C interface identified by system

interfaces between • Providing component teams

architects that lacks corre-

Receiving component teams

components

D • A B C D sponding team interaction

A • Unidentified interface: team

B • interaction that takes place

Team Interaction Matrix or is expected to take place

Providing teams C • without a corresponding design

interface identified by system

Design A B C D D •

architects

Receiving teams

Teams’ A •

Input Lack of interdependence:

determine technical B • components that do not share

interactions teams an interface or involve design

C •

have had, are having, team interactions

or expect to have D •

Team C requests

information from Not applicable

team D •

tures do not map directly, refer to M.E. transfer forces, material, energy, or in- people working on each component

Sosa’s “Aligning Process, Product, and formation to other components to en- design team expect to take place with

Organizational Architectures in Soft- able them to work properly? Answers people from the other teams. Specifi-

ware Development” in the Proceedings to such questions are used to identify cally, we ask members of each team

of the 14th International Conference in the interfaces among all the compo- whether they anticipate the need for

Engineering Design, Paris, August 2007.) nents of the product. technical information or resources

Our analysis involves the following Armed with this data, the project from other teams. In surveying them,

three steps: managers can present the responses we need to make sure they are all fa-

1. Interview the system architects. on a four-by-four design interface ma- miliar with the function and specifica-

We begin by requiring the senior en- trix (a type of DSM used to map the tions of the component or components

gineers responsible for the product’s network of component interfaces), they are developing. (We do not share

overall function and layout – the sys- such as that illustrated in the exhibit with them the matrix produced in the

tem architects in engineering lingo – to “Assessing the Fit Between Design and first step, as this would bias the teams’

identify the technical design interfaces Communication.” responses.) Using these survey data, we

among the four components. Do com- 2. Survey the component design can represent the technical interaction

ponents need to be spatially connected teams. In the second step, we identify patterns of the teams in another four-

with each other? Do some components the technical communications that the by-four matrix (corresponding to the

hbr.org | November 2007 | Harvard Business Review 135

1657 Sosa.indd 135 10/5/07 7:30:18 PM

TOOL KIT | Are Your Engineers Talking to One Another When They Should?

four design teams) that we call a team state where they actually received the (vibration or heat), structural forces, or

interaction matrix, also shown in the ex- information and resources they needed. signals used by the control system of

hibit “Assessing the Fit Between Design Overlaying the new team interaction the engine. The design interface matrix

and Communication.” matrix on the original design inter- drawn from this information is shown

3. Combine the results. In the third face matrix would reveal whether the in the exhibit “Creating an Alignment

and final step, we overlay the two ma- mismatches uncovered at the start of Matrix for Pratt & Whitney.” We then

trices to obtain the alignment matrix the project had persisted and whether asked at least two members of each

(again, see the exhibit “Assessing the other mismatches had appeared. A of the 54 teams involved in the proj-

Fit Between Design and Communica- postmortem of this kind yields valuable ect how often they received technical

tion). This matrix shows the matches insights into future product develop- information from other teams during

and mismatches between the product’s ment projects, especially for companies the detailed design phase of the proj-

ect and how critical they perceived this

information to be. The results of this

survey documented 423 interactions

among component teams, which ap-

pear on the team interaction matrix

shown in the exhibit. We finally com-

puted an alignment matrix by merging

the two first matrices.

Readers armed with a magnifying

glass would count 220 unattended de-

sign interfaces that were not matched

by team interactions and 74 uniden-

tified interfaces in which teams ex-

changed technical information even

though there was no identified design

interface between the components. Al-

though it would be naive to expect a

perfect alignment of design interfaces

and team interactions – and, in this

case, many of the 220 unattended in-

terfaces were unproblematic or not

critical – misalignment on this scale

indicates that Pratt & Whitney was sub-

architecture as conceived by the system that expect to develop similar products ject to considerable risks involving cost

architects and the expectations of the in the future or further generations of overruns or other problems with this

teams involved in the product’s devel- the same product. project.

opment. More important, it highlights We conducted one such analysis of

the mismatches – when design inter- Pratt & Whitney’s development of the Why Mismatches Occur

faces have been identified but team PW4098, the engine that, at the time, Mismatches do not occur randomly

interactions are not taking place (un- set new standards in the aviation indus- in a product or organization. Rather,

attended interfaces) and when team try for development speed and cost. (It they are the result of product design

interactions take place without a corre- was also the first commercial jet engine and organizational factors. Planned

sponding design interface being identi- ever certified for 180-minute extended- key communication points may remain

fied by system architects (unidentified range twin operations from its first day problematic for several reasons, in-

interfaces). As we shall see, sometimes of service.) We began by interviewing cluding the presence of organizational

these unidentified interfaces turn out the engine’s architects, who identified boundaries (cross-boundary interfaces

to be critical. 569 interfaces among the 54 main com- are more likely to be missed than in-

At the end of a project, managers ponents of the engine. Many of these terfaces with a team belonging to the

can update the alignment matrix by interfaces were critical and complex be- same group), the lack of interface criti-

redrawing the team interaction matrix cause they not only involved physically cality (complex and critical interfaces

based on more recent surveys in which adjacent components but also the trans- receive more attention than noncritical

component team members are asked to fer of material (air, fuel, or oil), energy ones), the use of indirect communica-

136 Harvard Business Review | November 2007 | hbr.org

1657 Sosa.indd 136 10/5/07 7:30:25 PM

TOOL KIT | Are Your Engineers Talking to One Another When They Should?

Creating an Alignment Matrix for Pratt & Whitney

This exhibit shows the design interface, team interaction, and project. Note that components (in the design interface matrix)

alignment matrices we developed for Pratt & Whitney after the and teams (in the team interaction matrix) that belong to the

PW4098 project. It is striking how many mismatches (294 in all) same subsystem are clustered together so that we can easily

turned up even in a post hoc analysis. Conducting this exercise distinguish (with the boxes along the diagonal) between inter-

before or during the project would probably have revealed many faces (and interactions) that occur within boundaries versus

additional mismatches that got fixed during the course of the those that fall across boundaries.

Design Interface Matrix

System engineers identified

1 0 0 0 0 0 0 0 0 0 6 3 0 3 0 0 0 0 0 0 0

6 0 0 0 0 0 0 0 0 5 5 6 6 6 3 3 0 0 2 0 0 0

6 0 6 4 4 8 4 4 0 1 0 0 4

6 0 4 4 4 0 0 2 0 0 0 0

4 4 0 0 0 0 0 0 0 0 0 0

2

3

4

8

6

6

4

4

2

1

2

0

0

0

0

4

0

0

4

0

4

4

0

4

0

6

0

4

6

0

0

0

6

6

0

0

4

4

0

0

0

0

0

0

8

8

0

0

6

6

5

5

2

2

5

5

2

2

2

2

0

0

0

0

0

0

569 design interfaces among

engine components

0 6 3 1 6 6 0 0 0 0 0 0 0 0 0 0 0 0 0

2 5 2 0 0 4 4 0 0 6 0 0 0 0 0 0 0 0 0 0 0

4 5 0 0 0 0 0 0 6 0 4 6 0 0 0 0 0 0 0 0

0 0 0 0 0 8 8 0 0 3 0 4 0 0 0 0 0 0 0 0

Alignment Matrix Key

6 0 0 0 6 6 6 0 0 6 4 0 6 6 6 2 2 0 0 8

0 2 0 0 0 2 2 1 6 0 2 5 5 4 8 7

0 0 0 0 0 0 0 0 4 2 0 7 7 0 3 0

0 2 0 0 0 2 2 1 5 5 7 0 8 2 2 0

1 1 1 0 0 2 2 1 2 5 7 8 0 6 2 1

1 1 0 0 0 0 0 2 4 0 2 6 0 0 0

4 8 3 2 2 0 0 8

0 7 0 0 1 0 8 0

0 0 6 4 0 6 0 8 0 0 0

0

0

0

0

6

4

0

4

0

7

5

8

5

0

0

0

5

2

0

0

5

0

0

0

0

0

0

0

4

4

0

0

0

0

0

0

0

4

0

0

4

0

0

0

Matched interface:

0

0

0

0

0

5

0

0

0

2

0

0

4

5

0

2

0

0

0

0

0

4

0

0

0

4

4

7

4

0

4

2

4

4

0

6

7

2

5

0

4

6

6

2

0

0

0

2

0

0

2

0

0

0

0

0

4

0

0

0

0

0

0

0

2

0

0

2

0

0

0

4

0

0

0

(349 instances) design

0 0 0 0 6 0 0 0 0 0 0 0 0

0

0

6

0

7

0

0

0

0

0

0

0

2

0

0

0

6

0

0

0

6

0

1

0

4

4

0

0

0

0

6

0

0

0

0

2

7

0

0

6

0

0

4

0

4

0

7

5

0

8

3

5

4

0

7

3

0

6

0

0

0

0

0 0 0 0 0 4

0 0

0

0

0 0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Alignment Matrix interface that is matched by

0 2 0 0 0 7 0 0 6 3

0

0

6

4

4

0

6

0

0

0

0

3

4

0

0

5

0

0

7

0

4

0

2

7

0

0

3

3

6

0

7 0

4

5

0

0

3

3

0

3

6

3

6

6

0

0

6

2

2

2

4

0

0

2

2

2

2

0

4

0

0

0

3

2

2

0

4

0

0

0

0

0

0

0

1

0

0

0

0

0

1

0

0

1

0

0

0

0

0

1

0

an actual team interaction

0 6 0 3 0 0 0 0 0 0 4 0 0 2 0 2 2 4 0 0 4 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 6 0 0 0 0 2 4 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 2 0 0 6 0 0 0 0 0 2 0 0 0 0 0 0 0 0 0 0 1 1 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 6 0 0 0 0 2 2 0 0 0 0 0 3 2 0 4 0 0 0 0 1 0 1 1 1 1 0

0 6 0 2 0 0 0 0 0 2 2 2 2 2 2 2 0 4 0 2 4 2 0 0 2 0 0 0 0 0 0 0 1 1 1 1 1 0 0

3

0

3

0

3

6

3

3

0 0

0

0

0

0

2

0

0

6

6

4

0

4

0

5

5

0

0

0

0

0

0

0

0

6

0

0

0

7

0

5

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

8

0

5

0

0

0

0

0

6

0

0

0

6

0

0

0

0

0

0

0

6

0

6

0

0

0

0

0

6

0

8

0

8

0

8

5

0

0

0

0

6

0

0

7

5

0

7

0

7

0

7

7

0

0

0

0

0

0

6

0

6

0

4

4

0

6

4

2

0

0

0

0

6

2

0

6

6

0

2

0

6

6

2

6

0

0

6

0

0

6

6

6

0

0

6

4

8

6

6

8

8

6

8

6 0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0 0

0

0

0

0

0

0

1

0

0

1

0

0

0

0

0

0

Unattended interface:

(220 instances) design

0 0 0 4 5 0 0 4 3 0 0 0 0 0 0 0 7 0 0 0 0 0 0 6 0 0 0 0 0 4 5 6 6 0 0 6 4 7 7 0 0 0 0 0 1 1 0 0 1 0 1 1 1 1 0

0 0 0 0 0 0 0 0 0 0 0 0 6 4 0 0 4 0 0 0 0 0 0 3 0 0 0 0 0 0 0 6 0 0 0 6 0 2 6 0 0 0 0 0 0 0 0 0 1 1 0 1 1 0 0 0 0 0 0 0 0 0 0

4 2 0 6 6 0 0 6 2 0 0 0 8 8 0 0 0 0 7 0 7 4 0 7 0 0 0 7 9 4 5 6 6 6 5 0 8 8 8 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 0 1 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 6 0 0 0 2 2 6 0 0 0 0 0 0 0 0 4 0 0 0 0 0 4 0 6 0 0 9 0 4 0 0 0 5 7 7 0 6 4 4 0 6 0 0 6 0 0 0 0 0 0 1 0 0 0 1 0 1 0 1 1 1 0 0 0 0

0 0 0 0 0 0 0 0 0 4 3 0 0 8 6 0 0 0 0 4 0 0 4 0 0 0 0 0 0 0 0 0 6 6 0 0 0 0 8 6 6 6 6 0 0 0 0 4 1 1 0 0 0 0 1 0 0 0 1 0 1 0 1 1 0 0 0 0 0

4 2 0 0 0 0 0 0 0 5 3 0 0 4 0 0 0 0 2 0 0 0 2 0 0 0 0 8 0 8 8 0 3 0 0 0 6 0 8 4 6 6 6 4 6 6 4 0 0 0 0 0 0 0 0 0 0 0 1

2

0

0 0 1

0

0

0

1

0

1

0

0 0 0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

interface identified by system

architects that lacks corre-

0 0 0 0 0 0 0 0 0 1

0 0 0 0 0 0 0 0 0 1 0 1 0 0 0 0 0 0 0 0 0 0 1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

1 1 0 0 0 0 1 1 0 0 0 1 0 1 1 0 1 0 0 0 0 0 0 0

1 0

1

0

0

0

1

0

1 0

0 1 1

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

0

1

0

0

0

0

0

0

0

0 0

0

0

0

0

sponding team interaction

Team Interaction Matrix 0 0 1 0 0

0

0

0

1

0

0

0

0

0

0

0 0

0

0

1

1

0

0 0

0

0

0

0

0

0

0

0 0 0

0

0 1 1

0 0 1 0 0 1

0

0 1 0

0

0

0 1

0

0 1 1 1

0

0

0

1

1

0

0

0

0

0

0

0 0 0

0

0

Unidentified interface:

0 1 1

0

1

0

1

0

0

0

1

0

0

0

1

0

0

0

1

0

0

0

1

1

1

0

1

0

1

0

0

0

0

0

0

0

1

0

0

0

1

0

0

0

1

0

0

0

0

0

0

1

0

0

0

1

1

0

0

0

0

0

0

(74 instances) team interac-

1 1 1 1 1 1 0 1 1 1 0 0 1 0 0 0 0 0 1 1

1

1

1

1

1 1 1 1

0

0

0

0

0

0

0

0

0

0

1

1

0

0

0

0

0

0

0

0

0

0

1 0

0

0

0

0

0

0

0

0

0

1 1

tion that takes place without a

corresponding design interface

0 0 0 0 0 0 0 0 0 0 0 0 0 1

1 1 1 1 1 1 0 0 0 0 0

1 0 0 0 0 0 0 0 3 0 0

1 1 1 1 0 1 0 0 0 0 0 0

1 0 0 0 0

identified by system architects

0

0

Lack of interdependence:

(2,219 instances) components

that do not share an interface or

0

0

Design teams reported the involve design team interactions

occurrence of 423 technical

0

interactions among them

For details, refer to M.E. Sosa, S.D. Eppinger, and C.M. Rowles, “The Misalignment of Product Architecture and Organizational Structure in Complex Product Development,”

Management Science 50, no. 12 (2004): 1674–1689.

tion channels (teams sometimes pass compressor, for example, were virtu- involved teams from different parts

technical information through other ally unchanged from a previous en- of the organization that had fewer

intermediary teams rather than inter- gine generation. As a result, some of opportunities for informal communi-

act directly), the presence of interface the teams responsible for these com- cations, which might have uncovered

carryover (interfaces that have been de- ponents had to pay only marginal at- changes to the previous standards. The

fined in previous projects may not need tention to coordinate their interfaces impact of these unattended interfaces

to be reconfirmed in designing the new among themselves, though they still probably resulted in very small reduc-

project), and the use of interface stan- needed to coordinate with other highly tions in performance or durability of

dardization (interfaces whose specifica- redesigned components. Such inatten- affected components and systems. But

tions have been formally documented tion trickled over into their communi- given the 25- to 30-year life expectancy

are supposed to remain unchanged). cations involving other highly designed of a product like the PW4098, even

In the case of the Pratt &Whitney components. In addition, many struc- small performance deviations could

project, some mismatches occurred be- tural and thermal design interfaces add up and cause significant warranty

cause component designs were carried were left unattended because they or service expense over the life of the

over from previous designs. A number were noncritical or assumed to be stan- product. For example, if a critical com-

of components of the high-pressure dard. In many cases, these interfaces ponent like a turbine airfoil misses its

138 Harvard Business Review | November 2007 | hbr.org

1657 Sosa.indd 138 10/5/07 7:30:31 PM

CORPORATE LEARNING

SOLUTIONS FOCUSED ON

YOUR SUCCESS CORPORATE AND EXECUTIVE EDUCATION life expectancy by only a few percent,

CUSTOM SOLUTIONS integrate industry’s it could mean one or more unplanned

best practices and Drexel University’s engine removals for maintenance over

LeBow College’s innovative development the life of the engine. For such a prod-

programs with your business culture and uct, a single unplanned engine removal

organizational capabilities. could add up to a $150,000 incremen-

LeBow’s Global Knowledge Network, tal cost to the customer.

comprised of leading researchers and Although most unattended inter-

sought-after business consultants, help faces are not critical, some are. Those

you to find contemporary ways to create critical unattended interfaces mostly

long-term sustainable value for your

occur when the teams involved come

company in the global marketplace.

from different parts of the organiza-

Programs are offered online or face-to- tion. The costs can be substantial. In the

face on Drexel’s Philadelphia campus or

on-site at your location. PW4098 project, two unattended inter-

faces turned out to be critical, and their

For more information on custom designing costs varied with the time it took for

a program to complement your organization’s

problems associated with the interfaces

strategic corporate training initiatives, call

215-895-1604, email executive@drexel.edu to be uncovered and resolved. One re-

or visit www.lebow.drexel.edu/execed lated to a change in the structural loads

transferred between rotating hardware

assemblies in the high-pressure core

COLLEGE OF BUSINESS and resulted in excessive loads on cou-

pling hardware during tests of early

LEARN HERE, LEAD ANYWHERE® LeBow development engines. Consequently,

Pratt & Whitney had to disassemble, re-

design, and rebuild the test engines. We

estimate that this one problem added

1% to 2% to the cost of the program and

Harvard Business Review a three- to four-month delay to certain

elements of the program. The other

unattended interface was uncovered

FOR THE BLIND later, after early production assembly

had begun but before any engines were

Subscriptions to Harvard Business Review are available in a special cassette shipped. This one, also related to loads

transferred between engine modules,

format at a new low price of $49 per year for individuals who are print handicapped. reduced the life expectancy of one of

the main engine bearings. The number

For further information on HBR for the Blind and other custom recordings services, of affected parts and engines was sig-

please contact: MAB Recording Studio, 313 Pleasant Street, Watertown, MA, nificantly greater than those associated

with the first problem – and so was the

at 617-972-9117 or e-mail rpierson@mabcommunity.org. impact on the program in terms of cost

and time.

We have found unidentified inter-

faces to be less common than unat-

tended interfaces. However, unlike un-

attended interfaces, their occurrence is

almost always positive for the project

because they reveal potentially critical

but unanticipated interdependencies

among a product’s parts or systems.

Many of the unidentified interfaces we

uncovered at Pratt & Whitney related

to investigations into possible engine-

1657 Sosa.indd 140 9/28/07 7:29:49 PM

A Call to Action

level design problems that could have Potential solutions can be varied, in-

resulted in excessive strain, overheat- cluding redrawing organizational lines,

ing, or insufficient pressure in the test reassigning or creating new interface

engine. Because the teams involved management responsibilities and fa-

talked to each other as they began to see cilitation tools, or even redesigning the

or anticipate the unexpected problems, system architecture (some of these are

they were able to mitigate them before discussed below). To find the solution

the product testing phase of the proj- appropriate for your project, consider

ect, resulting in considerable time and the following three steps:

cost savings potential. When unidenti- 1. Review organizational and system

fied interfaces like these are uncovered, boundaries. For projects in which a sig-

the main question is whether to for- nificant number of unattended inter-

mally incorporate them into a project’s faces span organizational boundaries,

schedule and routines or

leave them be. This deci-

sion depends largely on Most integration teams pay only

“Finally, somebody has written a book about

how critical the commu- marginal attention to the quality of what it really means to be a leader.”

nication is. In the case of Lydia Thomas, President and CEO, Noblis, Inc.

communication between component

the interfaces described

teams. That needs to change.

above, Pratt & Whitney

formalized some of the

relevant team interactions in planning project managers should revisit their or-

the development of its next-generation ganizational structures. Doing so would

engine. probably have helped Airbus avoid the

The conditions that generate un- problems it encountered. The company

identified interfaces are different from based the organizational structure of

those that cause people to overlook in- its programs not only on the architec-

terfaces. Several of Pratt & Whitney’s ture of the plane but also on the share

unidentified interfaces occurred be- of work owned by the various partners

tween teams working on engine-level of EADS (the European consortium to

design scenarios that created adverse which Airbus belongs). The addition of

structural or thermal loads. This, in this extra set of boundaries increased “Great, rich insights into how to improve

turn, generated the need for technical the likelihood of unattended interfaces succession planning.”

Steve McMillan, CEO, Stryker

solutions across distinct components. occurring and reduced the likelihood

In one case, three teams from both of problem-solving unidentified inter-

the high-pressure turbine and the low- faces taking place.

pressure turbine had to interact with To change the organizational struc-

teams working on the combustion ture, though, may necessitate changing

chamber to optimize the thermal en- the system architecture, because that

vironment and resulting durability of is what drives the organizational struc-

their respective components. These ture at most companies. Developing

were deemed critical interfaces that more-modular components that share

had not been identified by the system fewer direct and indirect interfaces

architects. Fortunately, the people on with other components in the product

these teams had worked together in the is especially helpful because technical

same roles in previous projects, making communication in such projects is eas-

it more likely that they would have un- ier to manage than in projects requir-

planned exchanges of information. ing a great deal of component interac- “Tabrizi’s core insights offer important

lessons not only for the business world,

tion. In the Pratt & Whitney project, but also for organizations in general.”

How to Manage Mismatches teams responsible for designing more- Eric Schmidt, Chairman and CEO, Google Inc.

Once the root causes of mismatches modular components missed far fewer

are understood, an organization can critical interfaces with teams from Available wherever books are sold

then decide how to deal with them. other components. There were fewer to

www.HBSPress.org

1657 Sosa.indd 141 9/28/07 7:30:04 PM

TOOL KIT | Are Your Engineers Talking to One Another When They Should?

be missed, and the workload associated properly attended to. In the PW4098 to complete work, the various tools and

with fewer direct and indirect inter- project, the secondary airflow team platforms must be carefully integrated.

faces was more predictable. Too much (one of the six integration teams) was In planning the development of the en-

modularity, though, can lead to myopia, responsible for managing the engine’s gine project that followed the PW4098,

particularly at the subcomponent level. multiple internal thermal and pres- for example, Pratt & Whitney linked full

At Pratt & Whitney we found that the sure management systems to optimize engine aerodynamics and secondary air

design teams of highly modularized engine aerodynamic performance and flow analytical models with component

subsystems were less likely to talk to component durability. It regularly set models to help the design teams man-

teams working on other modularized up meetings and other communica- age their interfaces with the support of

subsystems than were teams working tions between otherwise unconnected the integration teams. Specific people

on more integrated subsystems. In go- teams to address critical interfaces. on each team were then tasked with

ing modular, therefore, product de- Unfortunately, most integration tracking the impact of design changes

signers still need to pay careful atten- teams focus on milestone planning across the component and system mod-

tion to critical interfaces across those and resource allocation, paying only els and communicating those findings

subsystems. marginal attention to the quality of to their counterparts on other teams.

2. Form teams to handle misman- communication between component •••

aged interfaces. Managers also have the teams. That needs to change. Consider Our approach provides a systematic

option to manage critical interfaces – the pain that could have been avoided method for an organization to learn

to ensure that unidentified ones occur in the last phases of the development how and where it is exposed to the risk

or that unattended ones are formal- of the Airbus A380 if one of the integra- of communication failures between

ized – by assigning such work to the tion teams had realized that the elec- design teams working together to de-

teams already tasked with the inter- trical harnesses team in Germany and velop complex products. Moreover, an

action or by making people on the in-

volved teams formally and actively ac-

countable for the interfaces. We would Many design teams miss interfaces because project

recommend this approach for manag- planners haven’t thought through their use of

ing identified interfaces across bound- communication tools and shared platforms.

aries – the interfaces design teams are

most likely to ignore.

Another way to handle missed inter- its counterpart team in France, which organization can use our tools to deter-

faces – one that also avoids the need to were responsible for different sections mine how changes in system architec-

significantly change the organizational of the fuselage, were not properly com- ture, or the emergence and removal of

structure – is to extend the responsibil- municating about their design interface interfaces between system components,

ity of existing integration teams. Most specifications. will affect its ability to avoid communi-

large projects have such teams: At Pratt 3. Select appropriate communica- cation failures in the future. By using

& Whitney there were six teams man- tion support tools. Many design teams DSMs to document the architecture of

aging system issues like air and fuel ef- miss interfaces because project planners the product for every generation of a

ficiency, which affected the design of haven’t thought through their use of product family, managers can identify

practically all engine components. Even communication tools and shared plat- key differences between old and new ar-

though the management of team com- forms. At Airbus, one of the main rea- chitectures. With the alignment matrix,

munications is not usually the primary sons for the communication breakdown managers create a compact and visual

function of integration teams, by the between the A380 teams was the lack representation of interfaces and interac-

nature of their work, these teams com- of compatibility between the computer- tions that allows them to diagnose how

municate with almost all other teams aided design (CAD) tools they used. their organization addresses design in-

in the organization. Accordingly, they Being smarter about using communi- terfaces. Most important, the alignment

are in a position to learn in real time cation tools doesn’t have to involve a lot matrix can help managers properly di-

about the status of critical interfaces of technology: Pratt & Whitney requires rect their efforts to align team interac-

during the design process and to bring teams to regularly complete controlled tions with design interfaces to prevent

unconnected teams together to handle interface documents and component costly problems from occurring later in

critical interfaces that need special at- requirements documents (specifica- the product life cycle.

tention. These integration teams could tions) to ensure that critical interfaces

be made responsible for flagging those are identified and attended to. In cases Reprint R0711J

critical interfaces that are not being where team members use technology To order, see page 155.

142 Harvard Business Review | November 2007 | hbr.org

1657 Sosa.indd 142 10/5/07 7:30:47 PM

S-ar putea să vă placă și

- Mathematical Physics Problems (CSIR NET Physics Guide Book 1) - NodrmDocument219 paginiMathematical Physics Problems (CSIR NET Physics Guide Book 1) - NodrmShubhanshu Karoliya100% (1)

- Inverse kinematics examples of 2R, 3R & 3P manipulatorsDocument10 paginiInverse kinematics examples of 2R, 3R & 3P manipulatorsOssama Ahmed MughalÎncă nu există evaluări

- DevOps Best Practices 2020 Full Guide FinalDocument41 paginiDevOps Best Practices 2020 Full Guide FinalchrisystemsÎncă nu există evaluări

- Power System Analysis SimulationDocument78 paginiPower System Analysis SimulationAkah PreciousÎncă nu există evaluări

- Curved Lines and Surfaces, Vectors, Matrices, Determinants, Dot ProductsDocument49 paginiCurved Lines and Surfaces, Vectors, Matrices, Determinants, Dot ProductsAlex ChalitaÎncă nu există evaluări

- DesignSystem Whitepaper Appway WhitepapersDocument13 paginiDesignSystem Whitepaper Appway WhitepapersArun KumarÎncă nu există evaluări

- SPM IMP Q&A (E-Next - In)Document51 paginiSPM IMP Q&A (E-Next - In)RAQUIB AHMADÎncă nu există evaluări

- The ABC Inventory MatrixDocument9 paginiThe ABC Inventory MatrixOtis MelbournÎncă nu există evaluări

- Concurrent Engineering Seminar on Integrated Product DevelopmentDocument24 paginiConcurrent Engineering Seminar on Integrated Product DevelopmentArjun Prasad100% (1)

- Devops and The Cloud Chef and AwsDocument22 paginiDevops and The Cloud Chef and Awsdiogo alvesÎncă nu există evaluări

- Platforms Def v1.0Document13 paginiPlatforms Def v1.0ADAILTON SANTOSÎncă nu există evaluări

- Uxpin Why Build A Design SystemDocument20 paginiUxpin Why Build A Design SystemReza MuhamadÎncă nu există evaluări

- Architectures, Coordination, and Distance. Conway's Law and BeyondDocument8 paginiArchitectures, Coordination, and Distance. Conway's Law and Beyondyenix64460Încă nu există evaluări

- Auditors and Large Software Projects Part 2 Joa Eng 1015Document3 paginiAuditors and Large Software Projects Part 2 Joa Eng 1015WPJ AlexandroÎncă nu există evaluări

- Silver Bullet Short NotesDocument3 paginiSilver Bullet Short Notesomkar kaleÎncă nu există evaluări

- J2 Aircraft DynamicsDocument12 paginiJ2 Aircraft Dynamicscthembree6Încă nu există evaluări

- A Software Tool For Integrated Electromechanical System DesignDocument8 paginiA Software Tool For Integrated Electromechanical System DesignguramandeepÎncă nu există evaluări

- Semiotic Engineering in PracticeDocument8 paginiSemiotic Engineering in PracticeAsim RazaÎncă nu există evaluări

- 13 Juni 2022 Pre Reading Material UX Designer Vs Developer Engineer Proses Handoff Design Biar Development Product SuksesDocument3 pagini13 Juni 2022 Pre Reading Material UX Designer Vs Developer Engineer Proses Handoff Design Biar Development Product Suksesjjulboy75Încă nu există evaluări

- 10 - Who Needs Release and DevOps Engineers, and Why?Document7 pagini10 - Who Needs Release and DevOps Engineers, and Why?Angel Adrian Camal GarciaÎncă nu există evaluări

- The Usability Engineering Lifecycle: Deborah J. MayhewDocument2 paginiThe Usability Engineering Lifecycle: Deborah J. Mayhewsalsabilaa2455Încă nu există evaluări

- cst438 - Midterm 1Document6 paginicst438 - Midterm 1api-498436043Încă nu există evaluări

- Week 4.06 StoryboardingDocument4 paginiWeek 4.06 StoryboardingNawwar NavaÎncă nu există evaluări

- Agile software development principles and practicesDocument1 paginăAgile software development principles and practicesJames BeruegaÎncă nu există evaluări

- Extreme Programming and Agile Software Development MethodologiesDocument17 paginiExtreme Programming and Agile Software Development MethodologiesMUHAMMAD HASSANÎncă nu există evaluări

- Two-Tiered Architectural Design For Automotive Control Systems: An Experience ReportDocument10 paginiTwo-Tiered Architectural Design For Automotive Control Systems: An Experience ReportRajni MaheshwariÎncă nu există evaluări

- On Language DesignDocument10 paginiOn Language DesignOluwatoyin TinuolaÎncă nu există evaluări

- Doggedness of The Field Issues in A Legacy ApplicationDocument4 paginiDoggedness of The Field Issues in A Legacy ApplicationsimmashÎncă nu există evaluări

- Chapter 24 - Project Management ConceptsDocument32 paginiChapter 24 - Project Management Conceptsmalik assad100% (1)

- Writing A Good ProgramDocument10 paginiWriting A Good Programola pedensÎncă nu există evaluări

- Concurrent Engineering: European Space Agency Concurrent Design FacilityDocument6 paginiConcurrent Engineering: European Space Agency Concurrent Design FacilityTaranjeet SinghÎncă nu există evaluări

- Arid Agriculture University Software Engineering-I CS-452 Assignment - 2 Spring 2021Document5 paginiArid Agriculture University Software Engineering-I CS-452 Assignment - 2 Spring 2021Nisma AslamÎncă nu există evaluări

- MIS-105 AssignmentDocument8 paginiMIS-105 AssignmentNishat Tasnim PunomÎncă nu există evaluări

- The Secret To Accelerated Pipe Design: A Bentley E-BookDocument14 paginiThe Secret To Accelerated Pipe Design: A Bentley E-BookwdyouQÎncă nu există evaluări

- Google Innovation's FactoryDocument4 paginiGoogle Innovation's FactoryRicky WinataÎncă nu există evaluări

- Usabilitv Engineering Life Cycle: UsabilityDocument11 paginiUsabilitv Engineering Life Cycle: Usabilitysalsabilaa2455Încă nu există evaluări

- Design Patterns During Software Reengineering LessDocument8 paginiDesign Patterns During Software Reengineering LessQutab khanÎncă nu există evaluări

- Front End Development Automation Tool: Missing Features?: B. MotivationDocument5 paginiFront End Development Automation Tool: Missing Features?: B. MotivationRAGURAM SHANMUGAMÎncă nu există evaluări

- Distributed Workspace Using Cloud Technology and Version ControllingDocument7 paginiDistributed Workspace Using Cloud Technology and Version ControllingInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- ACHARYA Patashala PolytechnicDocument11 paginiACHARYA Patashala PolytechnicYogeshwara SÎncă nu există evaluări

- Role of IT in Collaborative Product Development ProcessDocument11 paginiRole of IT in Collaborative Product Development ProcessVicky NarayanÎncă nu există evaluări

- How Microsoft Builds SoftwareDocument9 paginiHow Microsoft Builds Softwareapi-3774337100% (1)

- Towards Continuous Deployment of A Multilingual Mobile AppDocument12 paginiTowards Continuous Deployment of A Multilingual Mobile AppWARSE JournalsÎncă nu există evaluări

- Cost EngineeringDocument6 paginiCost EngineeringdnoufalÎncă nu există evaluări

- Angels in The Architecture: Author: Chris Muir Date: 30/JUL/2014Document13 paginiAngels in The Architecture: Author: Chris Muir Date: 30/JUL/2014Gaurav KishanÎncă nu există evaluări

- Achieving Success in Large Complex Software ProjectsDocument5 paginiAchieving Success in Large Complex Software ProjectsRevda Hodžić DžambasÎncă nu există evaluări

- Prduction Assignment-2 MUGUNTHANDocument4 paginiPrduction Assignment-2 MUGUNTHANMugun ThanÎncă nu există evaluări

- Ebk Application Development Without the SprawlDocument10 paginiEbk Application Development Without the SprawlRif ManÎncă nu există evaluări

- Agile Web Engineering (AWE) Process: Multidisciplinary Stakeholders and Team CommunicationDocument4 paginiAgile Web Engineering (AWE) Process: Multidisciplinary Stakeholders and Team Communicationalaa.attiya2854Încă nu există evaluări

- Managing Design ProcessesDocument35 paginiManaging Design ProcessesShabnam SmileÎncă nu există evaluări

- Managing Large, Dispersed, Culturally Diverse Project Teams Complexities Management Approaches AdaptiveDocument7 paginiManaging Large, Dispersed, Culturally Diverse Project Teams Complexities Management Approaches AdaptiveUpasanaKanwalÎncă nu există evaluări

- Chapter 1 To 2Document2 paginiChapter 1 To 2HsjsÎncă nu există evaluări

- A Framework For Integrating Software Design PatterDocument5 paginiA Framework For Integrating Software Design PatterFernanda AlvesÎncă nu există evaluări

- Project Ideas For StudentsDocument12 paginiProject Ideas For StudentsPreeti KherÎncă nu există evaluări

- Class Handout AS322759L Dynamo GitHub DynaHub Adopting A New Innovative Repository For Dynamo Content Andrea TasseraDocument46 paginiClass Handout AS322759L Dynamo GitHub DynaHub Adopting A New Innovative Repository For Dynamo Content Andrea TasseraAlejandra JerezÎncă nu există evaluări

- An Integrated Planning and Programming System For HumanRobotCooperationDocument6 paginiAn Integrated Planning and Programming System For HumanRobotCooperationKarthik SRSÎncă nu există evaluări

- Transitioning to Iterative Software DevelopmentDocument18 paginiTransitioning to Iterative Software Developmentvamsi kiranÎncă nu există evaluări

- Collaborative Design Enables Geographically Distributed TeamsDocument10 paginiCollaborative Design Enables Geographically Distributed TeamsSaras ChandraÎncă nu există evaluări

- Software Framework - Wikipedia, The Free EncyclopediaDocument4 paginiSoftware Framework - Wikipedia, The Free EncyclopediaRabin KoiralaÎncă nu există evaluări

- UC-5 - Design Programing Logic Edit @endasDocument35 paginiUC-5 - Design Programing Logic Edit @endasnigusie debashÎncă nu există evaluări

- Usecases 20181125Document89 paginiUsecases 20181125Micsku TomiÎncă nu există evaluări

- 5 Drawing Management Mistakes and How to Avoid ThemDocument15 pagini5 Drawing Management Mistakes and How to Avoid ThemJavier ContrerasÎncă nu există evaluări

- Unit2 SPMDocument10 paginiUnit2 SPMVaibhav SinglaÎncă nu există evaluări

- Enterprise CAS94Document8 paginiEnterprise CAS94Max TanÎncă nu există evaluări

- Everything About GateDocument44 paginiEverything About GatetigersayoojÎncă nu există evaluări

- CPCS203 07 Ragged ArraysDocument30 paginiCPCS203 07 Ragged ArraysAHMED A FATANIÎncă nu există evaluări

- Scarpelli Simultaneous Equations Final 2Document16 paginiScarpelli Simultaneous Equations Final 2divinemaunze4Încă nu există evaluări

- It Object Exercise 2Document14 paginiIt Object Exercise 2CpE LabÎncă nu există evaluări

- Yearly Lesson Plan Maths F5 2008Document17 paginiYearly Lesson Plan Maths F5 2008trtl_1970Încă nu există evaluări

- J-Electre-v3.0-User GuideDocument39 paginiJ-Electre-v3.0-User GuideÖzgür Hasan AytarÎncă nu există evaluări

- Dynamic Linear Models, Recursive Least Squares and Steepest-Descent LearningDocument11 paginiDynamic Linear Models, Recursive Least Squares and Steepest-Descent Learningstathiss11Încă nu există evaluări

- HMT Lecture 3 - Two-Dimensional Steady State ConductionDocument7 paginiHMT Lecture 3 - Two-Dimensional Steady State ConductiontsegayÎncă nu există evaluări

- 2004 ISR Bouzgarrou Fauroux Gogu Heerah DRAFT Rigidity Analysis of T3R1 Parallel Robot With Uncoupled KinematicsDocument6 pagini2004 ISR Bouzgarrou Fauroux Gogu Heerah DRAFT Rigidity Analysis of T3R1 Parallel Robot With Uncoupled KinematicsDavinci legendsÎncă nu există evaluări

- PROGRAMMING FOR PROBLEM SOLVING (CSE 113) B. Sc. (H), B. Tech.,B. Tech.+M. Tech.,B. Tech.+MBA (SEM. - TERM-01) 2018-19Document2 paginiPROGRAMMING FOR PROBLEM SOLVING (CSE 113) B. Sc. (H), B. Tech.,B. Tech.+M. Tech.,B. Tech.+MBA (SEM. - TERM-01) 2018-19Harshit AroraÎncă nu există evaluări

- fx-CG50 Soft ENDocument623 paginifx-CG50 Soft ENAparna AlagesanÎncă nu există evaluări

- Pre University h2 Further MathematicsDocument22 paginiPre University h2 Further MathematicsLeng RyanÎncă nu există evaluări

- PyquboDocument14 paginiPyquboJose Miguel GimenezÎncă nu există evaluări

- Linear Interpolation Shape Functions: Element Node 1 2 1 2Document17 paginiLinear Interpolation Shape Functions: Element Node 1 2 1 2AnanKayÎncă nu există evaluări

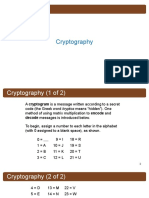

- CryptographyDocument10 paginiCryptographyKarylle AquinoÎncă nu există evaluări

- Linear Algebra Chapter 3Document126 paginiLinear Algebra Chapter 3Cường LêÎncă nu există evaluări

- Transition State Optimization: Z-Matrix Coordinates Generally SuperiorDocument17 paginiTransition State Optimization: Z-Matrix Coordinates Generally SuperiorLorena Monterrosas PérezÎncă nu există evaluări

- VbscriptDocument5 paginiVbscriptSiva PrasadÎncă nu există evaluări

- DSP Lab Manual GEC Dahod 1Document40 paginiDSP Lab Manual GEC Dahod 1Tushar MhuskeyÎncă nu există evaluări

- An Introduction To Multivariate Calibration and Analysis: Kenneth R. Beebe Bruce R. KowalskiDocument9 paginiAn Introduction To Multivariate Calibration and Analysis: Kenneth R. Beebe Bruce R. Kowalskiiabureid7460Încă nu există evaluări

- Proofs That Det (A) Det A.: 1 Proof 1Document2 paginiProofs That Det (A) Det A.: 1 Proof 1Jorge FajardoÎncă nu există evaluări

- Unit-V: Isoparametric FormulationDocument9 paginiUnit-V: Isoparametric FormulationJackson ..Încă nu există evaluări

- Lmdit Pls Manual 4Document426 paginiLmdit Pls Manual 4Juan Manuel Cáceres NevadoÎncă nu există evaluări

- LUMS MATH 120 Linear Algebra and Differential Equations Summer CourseDocument3 paginiLUMS MATH 120 Linear Algebra and Differential Equations Summer CourseAbdullahIsmailÎncă nu există evaluări

- Fitzgibbon AlgorithmDocument5 paginiFitzgibbon AlgorithmoctavinavarroÎncă nu există evaluări