Documente Academic

Documente Profesional

Documente Cultură

VW Digifant Manual

Încărcat de

Chris Rimmer100%(6)100% au considerat acest document util (6 voturi)

9K vizualizări43 paginiTroubleshooting Guidelines engine will not start, hot or cold a. No fuel or excessive fuel - Page 109 Fuel System (Circuit Tests) Page 113 Injector System (circuit tests) Page 107 Air Flow Sensor b. No spark - Page 119 Ignition System Poor idle a. At operating temperature Page 11 5 Throttle Switch Page 121 Idle Stabilizer System b. Engine stalls at highway speeds c. At full throttle - Page

Descriere originală:

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentTroubleshooting Guidelines engine will not start, hot or cold a. No fuel or excessive fuel - Page 109 Fuel System (Circuit Tests) Page 113 Injector System (circuit tests) Page 107 Air Flow Sensor b. No spark - Page 119 Ignition System Poor idle a. At operating temperature Page 11 5 Throttle Switch Page 121 Idle Stabilizer System b. Engine stalls at highway speeds c. At full throttle - Page

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(6)100% au considerat acest document util (6 voturi)

9K vizualizări43 paginiVW Digifant Manual

Încărcat de

Chris RimmerTroubleshooting Guidelines engine will not start, hot or cold a. No fuel or excessive fuel - Page 109 Fuel System (Circuit Tests) Page 113 Injector System (circuit tests) Page 107 Air Flow Sensor b. No spark - Page 119 Ignition System Poor idle a. At operating temperature Page 11 5 Throttle Switch Page 121 Idle Stabilizer System b. Engine stalls at highway speeds c. At full throttle - Page

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 43

eS Sa ee ee

Troubleshooting Guidelines

© Engine will not start, hot or cold

a. No fuel

— Page 109 Fuel System (Circuit Tests)

— Page 113. Injector System (Circuit Tests)

— Page 107 Air Flow Sensor

b. No spark

— Page 119 Ignition System

© Hard starting, hot or cold

a. No fuel or excessive fuel

— Page 108 Coolant Temperature Sensor

— Page 109 Fuel System

— Page 111 Residual Pressure Test

— Page 124 Evaporative Emissions System

b. No spark

— Page 119 Ignition System

© Poor idle

a. At operating temperature

— Page 115 Throttle Switch

— Page 121 Idle Stabilizer System

— Page 124 Evaporative Emissions System

b. Cold engine

— Page 108 Coolant Temperature Sensor

— Page 121 Idle Stabilization System

Engine stalls at highway speeds

a.

— Page 109 Fuel System (Pressure, Volume, Current Draw Tests)

— Page 124 Evaporative Emissions System

— Page 125 Basic AdjustmentsiSpecs

— Page 129 Ground and Terminal Connections

90 Digifant

Troubleshooting Guidelines (Cont’d.)

© Poor performance

a. During warm-up

— Page 108 Coolant Temperature Sensor

— Page 115 Throttle Switch

— Page 121 Idle Stabilizer System

b. At operating temperature

— Page 109 Fuel System (Pressure, Volume, Current Draw Tests)

— Page 115 Throttle Switch

— Page 119 Ignition System

— Page 121 Idle Stabilizer System

c. At full throttle

— Page 109 Fuel System (Pressure, Volume Tests}

— Page 116 Throttle Switch (Full Throttle Enrichment)

— Page 119. Ignition System

© High fuel consumption

a

— Page 109 Fuel System (Pressure, Volume Tests)

— Page 112 Fuel Injector System (Spray Pattern, Leakage Tests)

— Page 116 Throttle Switch (Full Throttle Enrichment)

— Page 124 Evaporative Emissions System (Leakage Test)

System Operation

po Stem Operation —

System Operation

The 2.1 liter Vanagon engine is equipped with improvements in acceleration, deceleration and

Digifant fuel andignition control system. Digifant overall driveability.

is a dovelopment of the DigiJet fuel injection

system combined with the map controlled digital The Digifant system features a larger throttle

ignition system. bore diameter, increased from 45 mm to 50 mm

Through the use of a single control unit, allof the An idle stabilization system has been

functions of the fuel system, ignition system and incorporated to further streamline the system

oxygen sensor system are carefully controlled to and eliminates the need for a digital idle stabilizer

provide optimum mixture and ignition control for and auxiliary air regulator.

Fuel tank

Fuel pump Fuel filte

‘lr temperature

‘sensor and air

P potentiometer

Idle

‘Oxygen {__Istabitization —

sensor control Saar

unit

System Operation

The individual components of the Digifant

system work together to manage all aspects of

engine operation.

Fuel injection control is electronic and is based

on the measurement of air entering the intake

and on engine speed measured by the Hall

sender. The coolant temperature sensor

provides correction during engine starting and

warm up.

The oxygen sensor, intake air temperature

Fuel tank

Fuel pump

ea

Fuel

strainer

Fuel

injectors

Fuel fiter

sensor and throttle switch provide the control

unit with additional information to assure

smooth performance under all driving

conditions. A separate control unitis used forthe

idle stabilization valve,

Ignition timing control is determined by an

engine speed signal from the Hall sender, anda

load signal from the air sensor. A signal from the

coolant temperature sensor provides a

correction factor.

Vacuum hose

Oxygen

comuel Control

unit unit

o2008608028 6 6 6b Ome eee me

®

e

*

e

*

‘

‘

‘

Paar a

Component Description

Sener eee

Electronic Control Unit (E.C.U.)

The Digifant electronic control unit incorporates

all the functions of the fuel system and ignition

system and provides both the actuation signal

for the fuel injectors and optimum ignition timing

point for all engine operating conditions.

Injection duration opening signals are provided

based on the following inputs:

© Engine speed

© Intake air volume

© Coolant temperature

© Oxygen content in the exhaust gas

© Battery voltage

© Throttle position

© Intake air temperature

The injector opening time is taken from a

program in the control unit at 16 points for RPM

and 16 points for load for a total of 256

operational points. injection times can be

determined between these fixed points for a

total of 65,000 theoretical different opening

duration points.

Digifant 97

Component Description

Coolant Temperature Sensor

The coolant temperature sensor is a negative

temperature coefficient resistor (NTC). The

resistance signal it produces is used by the

control unit to determine:

The amount of cold start and warm-up

enrichment

¢ Ignition timing and idle stabilization during

warm-up

@ When the oxygen sensor, idle stabilization, and

full throttle enrichment functions are activated

Fuel Pump

The fuel pumpisa roller cell design. Itis driven by

a permanent magnet electric motor and is

located near the fuel tank.

ee Steel rollers are held in “cut-outs” on the rotor.

cross section of Centrifugal force seals the rollers against the

roller cell walls of the pressure chamber as the rotor spins.

in fuel pump

Fuel that is trapped between the rollers is forced

out the delivery port. The pumpis designed tobe

Ra both cooled and lubricated by the fuel flowing

through it

The pump delivers several times the amount of

fuel needed to operate the engine at any time.

Excess fuel is returned to the fuel tank via the

fuel pressure regulator,

98 Digifant

Component Description

Air Flow Sensor

The air flow sensor measures the amount of air

entering the intake manifold and sends a voltage

signal to the control unit.

Intake air opens the air flow sensor flap which

actuates the potentiometer to determine the

voltage signal. This signal and the engine speed

information supplied by the Hall sender are used

as the principal inputs for the determination of

{uel injector opening duration and ignition timing

points,

Acompensation flap connected to the air sensor

dampens sudden movements of the air sensor

flap due to oscillations of the intake air.

To intake

manifold Compensation flap

Damping chamber

Intake Air Temperature Sensor

‘An intake air temperature sensor is mounted in

the air flow sensor housing. It is a negative

temperature coefficient (NTC) resistor, which

means its resistance value drops as its

temperature increases. The signal it supplies to

the control unit is used to modify fuel injection

rate depending on intake air temperature. The

sensor can be tested by measuring the

resistance value of the sensor and comparing

the reading to a graph.

Component Description

Fuel Pressure Regulator

To intake

‘manifold

The system pressure regulator maintains a

constant fuel pressure to all injectors by

regulating the quantity of fuel returned to the fuel

tank.

The regulator is connected to the intake

manifold. It responds to manifold vacuum

fluctuations, and thereby compensates for

engine-load changes.

When the engines shut off, the regulator closes

and seals to maintain residual fuel pressure in

the injector lines for improved hot-start

capability.

Fuel Injectors

Electro-magnetic

coil

|

Cz : S|}

Needle

valve

100

Digifant fuel injectors are electronically

controlled on/off valves. solenoid actuates 2

needle valve allowing fuel to be forced through

the injector nozzle. Alll four injectors open at the

same time and inject fuel directly into the intake

manifold near the intake valve. Injection quantity

is controlled by the amount of time the injectors

stay open. Injector opening time is regulated by

the E.C.U,, based on inputs from the various

engine sensors.

Note: Digifant injectors (yellow body) are not

interchangeable with A.F.C. injectors

(blue body).

Digifant

Component Description

Throttle Switch

Digifant uses a single throttle switch to signal the Throttle

E.C.U. when the throttle plate is in the fully oe tamn

closed (idle) or fully open (full load) position. The

signal enables the E.C.U. to determine that one eG)

of three auxiliary functions (idle stabilization, |

deceleration fuel shut-off, or full load

enrichment) is required and activate the

appropriate circuit. « c

The throttle switch is an NOC switch, or

normally open unless actuated. The contact ©

arm is actuated by a cam with two eccentrics /—— eee

which attaches to the throttle plate shaft. One 7

eccentric closes the contacts in the fully closed

(idle stabilization or decel fue! shut-off) position, Throttle

and the other in the fully open (full load switch

enrichment) position.

Correct adjustment of the throttle switch is very

important. If switch is misadjusted, engine may

surge at idle or cut out during steady driving or

light acceleration.

Fuel Filters

‘Two types of fuel filters are used on the Digifant

system

One is a square plastic fuel strainer which is

mounted before the fuel pump to protect it from

foreign particles.

The main fuel filter is @ metal cylinder which

mounts behind the fuel pump. It has a finer

filtering mesh to protect the injection

components.

Both are lifetime filters and do not require

replacement under normal circumstances.

S-ar putea să vă placă și

- Electrical SystemDocument315 paginiElectrical SystemMauricio Garcia92% (12)

- Diesel Engine ManagementDocument56 paginiDiesel Engine Managementbravo6dÎncă nu există evaluări

- Jetta SE 2.5 2010Document123 paginiJetta SE 2.5 2010Xexux Salvador Mercado100% (2)

- Jetta & Golf Variant - Maintenance HandbookDocument214 paginiJetta & Golf Variant - Maintenance HandbookHeidy El Awady67% (6)

- Golf MK 3Document79 paginiGolf MK 3banemojsin100% (1)

- Fuel SystemDocument99 paginiFuel SystemPaulus Saing100% (5)

- Bobcat Battery Reference GuideDocument2 paginiBobcat Battery Reference GuideFrancisco Godoy Kutzbach67% (3)

- Mk2 Golf Haynes - 16V Wiring DiagramsDocument20 paginiMk2 Golf Haynes - 16V Wiring DiagramsVikram Sekhar86% (7)

- Hybrid 12Document22 paginiHybrid 12squishbug100% (1)

- Jetta 2005Document315 paginiJetta 2005kopljanik100% (7)

- Volkswagen Golf Mk3 Service Repair ManualDocument1.024 paginiVolkswagen Golf Mk3 Service Repair ManualLeonardo Da Silva Alves91% (11)

- Common Faults VW Golf mk4Document0 paginiCommon Faults VW Golf mk4meinit100% (2)

- Bosch Vp37 PumpsDocument32 paginiBosch Vp37 PumpsLuís Fidalgo92% (13)

- GolfMK1 Low 1-42Document42 paginiGolfMK1 Low 1-42ananthoj100% (1)

- VWvortex Forums - DIY MK 4 Switchblade Keyfob Remote Using Aftermarket AlarmDocument32 paginiVWvortex Forums - DIY MK 4 Switchblade Keyfob Remote Using Aftermarket Alarmapi-37395010% (1)

- Ford Escort Wiring DiagramDocument26 paginiFord Escort Wiring Diagramjaska11178% (9)

- Golf mk3 Wiring DiagramDocument1 paginăGolf mk3 Wiring Diagramspeciall1180% (5)

- mk3 Wiring Diagram Ce2Document9 paginimk3 Wiring Diagram Ce2Rex Autoboutique100% (1)

- Volkswagen Transporters T4 Workshop Manual: Petrol and Diesel Models - 1990 to 1995De la EverandVolkswagen Transporters T4 Workshop Manual: Petrol and Diesel Models - 1990 to 1995Încă nu există evaluări

- Print Version - Volkswagen New Beetle Fuse Box DiagramDocument10 paginiPrint Version - Volkswagen New Beetle Fuse Box DiagramZibran100% (2)

- Webasto Airtop VW T5Document30 paginiWebasto Airtop VW T5pavli999Încă nu există evaluări

- Diys Golf Mkiii: (Info) Fusibles/RelésDocument2 paginiDiys Golf Mkiii: (Info) Fusibles/RelésRichardson Almeida83% (6)

- VW Jetta 2010 Wiring Diagrams EngDocument766 paginiVW Jetta 2010 Wiring Diagrams Engfernando13e100% (3)

- VW Jetta 2011 2013 Suspension Steering EngDocument390 paginiVW Jetta 2011 2013 Suspension Steering Engcloantaf0% (1)

- Toyota Avensis DPFDocument22 paginiToyota Avensis DPFCarl Anthony Chamberlain100% (3)

- DIGIFANT FUEL INJECTIONDocument6 paginiDIGIFANT FUEL INJECTIONembokoÎncă nu există evaluări

- Fusebox Gti mk2 VWDocument56 paginiFusebox Gti mk2 VWJuanAlejandroNuñezVazquez100% (4)

- System Wiring Diagrams 1989 Volkswagen VanagonDocument33 paginiSystem Wiring Diagrams 1989 Volkswagen VanagonAnonymous bp007p8Ws100% (1)

- Digifant Engine Management SystemDocument5 paginiDigifant Engine Management SystemSantz TechÎncă nu există evaluări

- Diagramas Electricos, MK3 1.8 Mono-Motronic, ABS y AMM PDFDocument20 paginiDiagramas Electricos, MK3 1.8 Mono-Motronic, ABS y AMM PDFElio MalvaresÎncă nu există evaluări

- Instrument Cluster VW 90-92Document7 paginiInstrument Cluster VW 90-92pito100% (1)

- Central Elétrica Golf MK3Document10 paginiCentral Elétrica Golf MK3Jhonatan Teodoro100% (1)

- Wiring Diagram VW Golf 1 RabitDocument10 paginiWiring Diagram VW Golf 1 RabitDajanaÎncă nu există evaluări

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)De la EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Evaluare: 1 din 5 stele1/5 (3)

- RelaysDocument3 paginiRelaysSanja Pušara100% (1)

- Wiring Cluster Golf 2-3Document15 paginiWiring Cluster Golf 2-3Nickolas Vladimir100% (1)

- Golf Mk3 ManualDocument156 paginiGolf Mk3 ManualMarin Stojanović100% (3)

- PDF Bosch Motronic Me75 18t Aum Pinout DLDocument14 paginiPDF Bosch Motronic Me75 18t Aum Pinout DLSergio AlvarezÎncă nu există evaluări

- Diagrama Do Golf3 - 94Document43 paginiDiagrama Do Golf3 - 94Marcelo Rovea Serres100% (1)

- 2.0 L-Digifant/110 KW, Engine Codes ABF: Current Flow DiagramDocument5 pagini2.0 L-Digifant/110 KW, Engine Codes ABF: Current Flow DiagramKęstutis Stikliūnas100% (1)

- Evading Thermal Imaging and Radar Detection-1Document8 paginiEvading Thermal Imaging and Radar Detection-1kokiskoÎncă nu există evaluări

- 2,3l Motronic (AGZ) 1Document14 pagini2,3l Motronic (AGZ) 1Bernardo Verber100% (2)

- Golf MK3 Central Electric 2Document18 paginiGolf MK3 Central Electric 2Jesus Barrientos Reali100% (4)

- PIPENET VISION SPRAY MODULE TRAINING MANUALDocument48 paginiPIPENET VISION SPRAY MODULE TRAINING MANUALElton Situmeang50% (2)

- Central Electric VW GOLFDocument16 paginiCentral Electric VW GOLFSantiago Palarik PerezÎncă nu există evaluări

- Boite À Fusible VW Golf 3, Corrado, VentoDocument18 paginiBoite À Fusible VW Golf 3, Corrado, VentoGwermosÎncă nu există evaluări

- Diagramas VW Golf 1.8 DigifantDocument8 paginiDiagramas VW Golf 1.8 DigifantGolo Alcapone100% (1)

- Volkswagen Golf wiring diagramDocument18 paginiVolkswagen Golf wiring diagramArdillon15Încă nu există evaluări

- Volkswagen Cabriolet DIY Guide: Digifant II vs. Digifant IDocument6 paginiVolkswagen Cabriolet DIY Guide: Digifant II vs. Digifant IAbbode Horani100% (2)

- Vanagon Protraining Digifant I 86-91Document51 paginiVanagon Protraining Digifant I 86-91jovicasurÎncă nu există evaluări

- Weber Injection-Ignition SystemDocument27 paginiWeber Injection-Ignition SystemjohnvandurenÎncă nu există evaluări

- Analisis Comparativo Cat® 992G Vs - Cat 993KDocument14 paginiAnalisis Comparativo Cat® 992G Vs - Cat 993KMónica Rada Urbina100% (1)

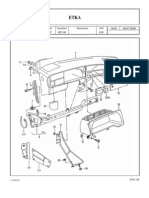

- Dash Panel Insert Mk3Document2 paginiDash Panel Insert Mk3García ZemaCevÎncă nu există evaluări

- Scheme Electrice GOLF 4Document44 paginiScheme Electrice GOLF 4Vlad SinpetruÎncă nu există evaluări

- Interface - Signal Locations: Interface Viewed From BelowDocument2 paginiInterface - Signal Locations: Interface Viewed From Belowmdelvallev100% (3)

- Mirror Power Repair GuideDocument5 paginiMirror Power Repair GuidepitoÎncă nu există evaluări

- Volkswagen Golf 1997 English Wiring DiagramsDocument44 paginiVolkswagen Golf 1997 English Wiring DiagramsJuanca Castillo100% (2)

- 21st Refinery Technology Meet - The CompendiumDocument474 pagini21st Refinery Technology Meet - The CompendiumAnurag Ingle100% (5)

- VW DiagnosticsDocument23 paginiVW DiagnosticsVers Chalvers M100% (1)

- Idle, Slow Running and Progression: 8 Theidle SpeedissetbyanadjusttDocument13 paginiIdle, Slow Running and Progression: 8 Theidle Speedissetbyanadjustt14carlos14100% (1)

- AQA QMS Pvt. LTD.: S No Company Name Membership NoDocument11 paginiAQA QMS Pvt. LTD.: S No Company Name Membership NoDevasyrucÎncă nu există evaluări

- Sistema de Inyeccion Mono-JetronicDocument6 paginiSistema de Inyeccion Mono-JetronicDiego De La FuenteÎncă nu există evaluări

- Tabler A3Document60 paginiTabler A3Angel Einstein100% (1)

- Diagrama de Fusibles JettaDocument2 paginiDiagrama de Fusibles JettaSanti Proudinat100% (2)

- BMW E12 L-Jetronic Fuel Injection GuideDocument38 paginiBMW E12 L-Jetronic Fuel Injection Guidecasecaseinter7Încă nu există evaluări

- Module 3 Automotive ElectronicsDocument38 paginiModule 3 Automotive Electronicsdaalidhananjaya2002Încă nu există evaluări

- Calculate Specific Heat of MetalDocument2 paginiCalculate Specific Heat of MetalIsabelÎncă nu există evaluări

- APOLLO Seacock InstallationDocument2 paginiAPOLLO Seacock Installationelsalou391Încă nu există evaluări

- Craftsman 320.29004Document28 paginiCraftsman 320.29004Pablo DÎncă nu există evaluări

- Mercury 02l STDDocument2 paginiMercury 02l STDNoursine NoursineÎncă nu există evaluări

- Trafo Las, Mesin Las, Kompressor Dan SandblastingDocument10 paginiTrafo Las, Mesin Las, Kompressor Dan SandblastingCv RONATAMA GUSLHANÎncă nu există evaluări

- Fuel ImbalanceDocument7 paginiFuel Imbalancedarryl_baguioÎncă nu există evaluări

- Упражнения на отработку Second ConditionalDocument6 paginiУпражнения на отработку Second ConditionalНаргиля ГаджиеваÎncă nu există evaluări

- Moving Iron InstrumentDocument16 paginiMoving Iron Instrumentmrsirjan802Încă nu există evaluări

- DigitalDocument4 paginiDigitalideal assignment helper 2629Încă nu există evaluări

- Eec203-Week 1Document62 paginiEec203-Week 1NicoÎncă nu există evaluări

- Makalah Tentang AnnouncementDocument10 paginiMakalah Tentang AnnouncementBayu Grafika 2Încă nu există evaluări

- AP TSS General Safety Course For 2019cycleDocument141 paginiAP TSS General Safety Course For 2019cycleFebry Dwi TranspuriÎncă nu există evaluări

- Air Compressor Presentation 1.1Document20 paginiAir Compressor Presentation 1.1ROBERTO FELIX RUEDASÎncă nu există evaluări

- Effinet Service Manual1Document63 paginiEffinet Service Manual1Willian Santiago CardenasÎncă nu există evaluări

- CAT079 SwitchDocument232 paginiCAT079 SwitchDan688100% (1)

- Surge arrestor protectionDocument1 paginăSurge arrestor protectionJae SudÎncă nu există evaluări

- Skyair - LU Series - HeatpumpDocument259 paginiSkyair - LU Series - HeatpumpHai PhanÎncă nu există evaluări

- 11th Five Year Plan 2007-12, India, Agriculture, Rural Development, and IndustryDocument537 pagini11th Five Year Plan 2007-12, India, Agriculture, Rural Development, and IndustryDeepak Pareek100% (6)

- ADIABATIC FLOW IN A DUCT WITH FRICTION (FANNO FLOWDocument30 paginiADIABATIC FLOW IN A DUCT WITH FRICTION (FANNO FLOWHamza AshrafÎncă nu există evaluări

- SYSMEDOCSeries Oxygen Concentrator User ManualDocument24 paginiSYSMEDOCSeries Oxygen Concentrator User ManualHakimÎncă nu există evaluări

- Reference List AW Offshore Installation SYS 2007-08-16Document10 paginiReference List AW Offshore Installation SYS 2007-08-16Sugeng WahyudiÎncă nu există evaluări

- Acids and Bases pH CalculationsDocument35 paginiAcids and Bases pH CalculationsRalph EvidenteÎncă nu există evaluări

- 2013 4N4 Final ExamDocument5 pagini2013 4N4 Final ExamFaishal AushafÎncă nu există evaluări

- Draft MP Net Metering Policy - 4.11Document11 paginiDraft MP Net Metering Policy - 4.11Anand PuntambekarÎncă nu există evaluări