Documente Academic

Documente Profesional

Documente Cultură

Break Pressure Tank Document

Încărcat de

Abdul Rauf Mukaddam0 evaluări0% au considerat acest document util (0 voturi)

1K vizualizări19 paginiDrepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

1K vizualizări19 paginiBreak Pressure Tank Document

Încărcat de

Abdul Rauf MukaddamDrepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 19

(22) INTERNAJIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT)

Tolerational Bureau

143) Tmicrnational Publication Date

21 February 2008 (21.02.2008)

(20) Internationa! Publication Number

WO 2008020367 A2

($1) International Patent Classification: Not classified.

21) International Application Numbe1

PCTHNRDN7A053131

(225 Totermationsl Filing Dies § Anyint 2007 ROR 2007)

(25) Tiling Language: Tinglish

(26) Publication Langage: nalish

(80) Priority Date

OEIC 1Y August 2006 108.2006) ZA

(71 Applicant aud

(72) Anventor: MULLER, Jumes, Douglas (ZAZA: Lave

sng Waters Erm, 127 Munster (24

(7H Agent: ROTTEVERL, Martin: Adams & Adans, PO

Tow 2748, Sue 1,4 The Crescent, Westway OFfies Park,

Bestile, 365 Woscway MMe: Prak (74

(81) Designated States (utloss obhensine infiowied, far every

ind of matinnal praiesion svunlaile: AT, AGAT. AM,

Publish

= withow imesnaiiomal search port and to be republished

AL. AULAZ BARB. BG. BIL, BR, RW. BY, BY,CA.CIL,

CN.CO.CR, CU. CZ, DI DK, DM. 10, D7. PCT. EG.

158. 7, GA, GD. GR, GH. GM, GT. HNLBR, FUL TD. 1.

INAS. JP, KL, BG, KM. LS, KEK, RL LALO, LR

‘LK, LS, LI LU, LY, BA, MB, My MG, MI, MIN, MOM,

MIX, MY. MZ, NANG, NI, NO, NZ ONL PG, PH, PL.

21, RO, RS, RU, Se SD, SK, SC, SK, SI, SM, SV, SY,

TE TM. TS, TR, TT, 17, UA, UG, US, UZ VC, VN.

7M. TW.

(84) Designated States (unless utheonise indicate. for every

‘kindof roglonal predecrion aveuiable|: ARIPO (BW, GH,

GM, KE, LS, MW, MZ, NA, SD, SL, 82, 12, UG, 2M,

AV), Eurasia (AM, AZ, BY, KG, KY, MD, RU, 13. TMi,

>uropean (AT. BE, BG. CL, CY. CA, DE. DK, RE, BS, FL

FR.GB,CR TT, TEAS, TTT TAL TN, MC_MT. NT. PL

‘TRO, 87. ST. SK, TR» GAPY (BT, RI, CEG, CTEM,

GA, GN, GO, GM, ML, MB, NE, SB LD. 1G).

lapom cept of a oops

(84) Tile: A BRIAK PRESSURE TANK

ia

=i

“at

“ls

1 gz

.

i *

F

dR

. .

.

2 fee

<

wo

7

2 is7) atsevt: the ienton sacs each pe sue nl for sein wate soply sey he ea pense ase being

QV Jocated operwively downstwam ol a water supply reservoit between the reservoir and water supply points thet are Jocaved! at an

© Sivnion saosin low tho olesniom ot ha exe, Te ba sce hk ples Mt a pert ea

BB tna conn sco wave nee ins wh th eacepy ef te tex he spy pl ts congo Ya

S ‘conmulling the water supply pressuccs at the supply points, providing for these presmarcs not to excced predetermined levels,

WO 2

10

15

WO 2008020367

2007)053131

ABREAK PRESSURE TANK

THIS INVENTION alates to @ oreak pressure tank.

A broak pressure tank, as herein envisaged, is used in @ downstream location with

respect to 4 water reservoir, particularly for reducing and controlling supply pressures of

‘water suoplied from the reservoir at locations downstream of the break pressure tank, A

break pressure lank is thus operatively located between a waler reservoir and water

supply points to which water is fad fromm the reservoir, particularly where the reservoir is,

Gisposed at an elevation substantially above the supply points, i.e, an elevation that will

induce excessive water pressures at the supply points.

Itis known that existing break pressure tanks, used for the above purpose, for various

reasons do not operate reliably and can in fact cause water supplies from a reservoir to

be interrupted. Also. because these break pressure tanks often are situated in relatively

inaccessible locations, rectifying @ problem often is difficull and time consuming.

Itis thus an object of this invention to provide a break pressure tankin respect of the use

of which the problems associated with known break pressure tanks are al least

ameliorated.

10

15

20

25

30)

WO 20081020367 PCTAD2007¢053131

Although reference is made horain to the location af a break pressure tank between &

water reservoir and water supply points where the reservoir is elevated above the supply

points. it must be understood that in situations where the elevation of a reservoir above

supply points exceeds predetermined levels, two or more break pressure Lanks may be

located al different elevations beiween the reservoir and the supply points.

According to the invention there is provided a break pressure tank which includes

a tank structure;

a pipe arrangement defining a flow line leading through the tank structure from an

inlatend, connectable to a pipoline from a reservoir and entering the tank structure near

the top end thereof, fo an outlet end, connectable to a pipeline leading to water supply

points and leaving the tank structure near the bottom end thereof, the pipe arrangement

including a perforated pipe segment located within the lank structure near the bottom

end thereof and upstream af the oullet end thereof

a control valve, located in line with the flow line defined by the pipe arrangement

within the tank structure between the inlet end of the pipe arrangement and the

perforated pipe segment, for controlling the flow rate of water through the flow line

cluding @ closure member

defined by the pipe arrangement, the control valve

displaceable between a fully epen position, in which free flaw through the flow line is

permitted, and a olosed position, in which the flew line is blocked; and

@ float actueted operating mechanism. located in the tank structure, that is

operatively linked to the closure member of the control valve for displacing it between its

fully open and clsed positions, the float actuated operating mechanism having a float

thatis displaceable, in resoonse to the water level in the tank structure changing during

operation of the break pressure tank, between a first position in the tank structure, when

the tank structure is substantially emply, which coincides with the closure member of the

10

15

20

25

30)

WO 20081020367 PCTAD2007¢053131

control valve being in its fully open position, and a socond position in the tank structure,

when the tank structure is filled to a predetermined level, which coincides with the

closure member of the control valve being in its closed position

The tank siruclure of the break pressure tank of the invention particularly is @

substantially rectengular structure including a base walll having typical dimensions in the

order of 1000mm x 1000mm and having @ height in the order of 1200mm. The tank

strusiure preferably includes 2 lockable lid which contrals access into the interior of the

tank structure, which may be required from time to time for maintenance or other

purposes. The tank structure may be formed of any suitaible material and, particularly, is

formed of a suitable sheet metal material

Further according to the invention, the break pressure tank may inc uGe a Closure valve

located in line with the flow line defined by the pipe arrangement operatively upstream of

the contrel valve, the closure valve being aperable for permilling either Ime flow thraugh

the flow line or for blocking the flow line. The flow line typically is @ lever operated

butterfiy-type valve, As such, the closure valve can serve to open and block the flow line,

particularly to facilitate maintenance to the components and parts of the break pressure

tank. Still further, the break pressure tank may include a strainer arrangement located in

the flow line definec by the pipe arrangement for trapsing debris and like particulate

objects and perticles carried within water fed to the break pressure tank from a reservoir,

the strainer arrangement being located upstream of the closure valve. The strainer

arrangement may include an operating lever that is manually operable for cleaning of the

strainer arrangement, Different configuration strainer arrangements suitable for the

Purpose are already well known.

The closure member of the control valve of the break pressure tank of the invention may

comprise @ plunger-type closure having @ plunger rod extending therefrom, the rod heing

axially displaceable fer displacing the plunger-type closure with respect 10 a seat

formation defined therefor within the body of the conircl valve. The plunger rod of the

10

15

20

25

30)

WO 20081020367 PCTAD2007¢053131

plunger-type closura may be operatively connected lo a diaphragm displaceably located

within 4 chamber defined within the body of the contro! valve, an operating fluid being

displaceable into the chamber for displacing the diaphragm within the chamber end

thereby displacing the plunger-type closure of the contral valve.

For the above configuration control valve, the fost actuated operating mechanism may

include a pistonicylinder arrangement of whieh the cylinder communicates with the

chamber defined by tha body of the control valve for displacing a hydraulic liquid

between the cylinder and the chamber and thereby providing for required displacement

ofthe closure member of the control velve. The piston/eyiinder arrangement may include

a piston rod that extends therefrom and that is mechanically linked with the float of the

float actuated operating meohanism, the displacerient of the piston of the pistorvoylinder

afrangement being controlled by the displacement of the float which, in turn, is controlled

by the level of weter within the tank structure.

The float actuated operating mechanism may incluce a guide structure located in the

tank structure for guiding the displacement of the float along a line paralle! to the line of

displacement of the piston rod of the pistoneylinder arrangement.

The operation of the break pressure tank of the invention as above defined and,

particularly, the operation of the float actuated operating mechanism may be such that

with a water level within the tank structure beneath a predetermined level, the float of the

mechanism will be atts lowest level and the closure member of the control valve will be

in its fully open pasition, with the float cf the mechanism at or above a predetermined

highest level. the closure member of the control valve will be in its closed position, and

with the float of the mechenism located in any intermediate position between the said

levels, the closure member of the control valve will be dispased in an intermediate open

position determined by the specific intermediate position of the float at any particular

time, thereby to control the fow rate of water through the control valve and hence

through a pipeline connected to the outlet of the pipe arrangement, through which water

10

15

20

25

WO 20081020367 PCTAD2007¢053131

can be displaced to water supply points from a reservoir te which the inlot and of the

pipe arrangement is operatively connected,

The operation of the break pressure tank of the invention in the above regard is

explained in more detail hereinafter with reference to an example of a break pressure

tank, which is illustrated in accompanying diagrammatic drawings. In the drawings:

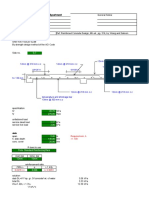

Figura 1 illustrates in perspective view the internal configuration of a break

Pressure tank, in accordance with the invention;

Figure 2 shows the break pressure tank of Figure 1 when viewed in the direction

of arrow A;

Figure 3 shows the break pressure tank of Figure 1 when viewed in the direction

of arrow By

Figure 4 shows the break pressure tank of Figure 1 when viewed in the direction

of arrow C; and

Figure 5 shows the break pressure tank as shown in Figure 2, illustrating

particularly the operation of the control valve thereof.

Referring to the drawings, a break pressure tank, in accordance with the invention, is

designated generally by the reference numeral 10, The break pressure tank 10 includes

a tank structure 12, the tank structure 12 being ¢ rectanguler sheet metal structure

including a base wall 14, four side walls 18 and alid 18, the lid being removable from the

remainder of the tank structure 12 by the operation of a locking mechanism 20. The

dimensions of the base wall 14 typically is in the order of 1000 mm x 1000 mm, whereas

the operative height of the side walls “6 is in the order of 1200 mm, although it must be

10

15

20

25

30)

WO 20081020367 PCTAD2007¢053131

appreciated thal the overall configuration of the tank structure, including its dimensions,

are greatly variable.

The break pressure tank 10 includes further a pipe arrangement 22 that defines a flow

ling through the tank structure 12, the flow line extending from an inlet end 24 inte the

tank, near the operative top end thereof, and from the tank to an outlet end 26, near the

operative bolton end of the tank. The inlet end 24 is connectable to a pipeline leading

from a reservoir, whereas the outlal and is connectable tc a pipaline leading to water

supply points, the break pressure tank, in its operative configuration, being connected

between a reservoir and water supply points at an intermediate level between the

reservoir and the waler supply paints, This is explained in more detail hereafter. The

Pipe arrangement 22 inoiudes a perforated pipe segment 28 located adjacent the base

wall 14 of the tank structure 12, the pipe arrangement further having connected in line

therewith a control valve 30, a closure valve 32 and strainer arrangement 34,

The control valve 30 is operable for controling the flow rate of water through the flaw line

defined by the pice arrangement 22, the control valve tyoically including a closure

member 36 that is displaceable between a closed position, in which flow through the flow

line defined by the pipe arrangement is blocked, and a fully open position, in which free

flow through the flow line is permitted, intermediate positions of the closure member 36

providing for different flow rates through the flow line, as will be explained in more det

hereinafter with reference to Figure 6 of the drawings.

The displacement of the closure member 36 is controlled by the operation of a float

actuated operating mechanism, generally designated by the numeral 38, the mechanism

38 inclu

control valve 30 to provide for the required displacement af the closure member 36, as

explained hereafter. The fioat 40 particularly is connected to a piston rod 42 of a piston

displaceable in the cylinder of a piston/cylincer arrangement 44, the displacement of the

2 float 40 that is operatively linked with the closure member 36 of the

float in the direction of arrows 46 providing for displacement of the piston within the

10

15

20

25

30)

WO 20081020367 PCTAD2007¢053131

cylinder of the pistoweylinder arrangement 44 and, thereby, for tho displacement af @

hydraulic fluid between the cylinder of the piston/cylinder arrangement 44 and a

chamber defined by the body of the control valve 20, within which a diaphragm 48,

effectively forming part of the closure member 36, is displaceable. The diaphragm 48

particularly is connected via a plunger rod to a plunger-type closure 59 of the closure

member 36, the plunger-type closure 50 being configured to seat on a complementary

seal formation defined therefor by the body of the closure valve 30 for blocking the flow

lina defined by the pipe arrsngement and being displaceable from the complementary

seat formation to permit flow through the flow line via the control valve 0. The exact

operation of the control valve 30 in this regard is described in more detail hereafter. Asis

illustrated clearly in the drawings, the displacement of the float 40 is quided by a quide

structure 52 within which the floats trapped and which permits displacomont ofthe float

40 only in the cirection of arrows 46.

The closure valve 32 comprises a lever operated butterfly-type valve that can effectively

black the passage of water through the flow line defined by the pipe arrangement,

particularly to permit maintenance to the break water tank to be attended to whenever

required. The strainer arrangement 34 is configured to trap debris, including solid

particles, carried within walter from a reservoir to the break water tank, the strainer

arrangement also being lever operable to permit the discharge of debris, and other

Particles trapped thereby. from the pipe arrangement 22 into the tank structure 12.

Different strainer arrangements suitable for the purpose are known and the exact mode

of operation of the strainer arrangement 3¢ is thus not described further herein.

As explained above, in the operative configuration of the break water tank 10, it is

connected between a water reservoir at an elevated level and water supply points at @

lower level, water flow from the reservoir to the water supply paints thus being permitted

while the closure member 36 of the control valve 30 is in an open position. The operation

of the break water tank is described hereafter from a starting situation in which the

control valve 30's open to permil “maximum” flow of water to the water supply points, in

10

15

20

25

30)

WO 20081020367 PCTAD2007¢053131

which situation the level of water within the tank structure 12 will be operatively banaath

the perforated pipe section 28 anc the float 40 will be in i

of water through the pipeline is determined by the rate of water use at the water supoly

lowest position. The flow rate

points and with water used being at a maximum demand level, the closure member 36 of

the control valve will be in a position referred to as ils fully open position.

‘When water demand decreases, the control member of the control valve will rernain in

the same position and, as a resull, water will ilinto the tank structure via the perforated

Pipe section 28, the water level within the tank structure thus raising, resulting in

operative upward displacement of the float 40. This displacement of the float will

continue for ag long as water demand decreases and when waler demand stops

completely, the water level within the tank struoture 12 will be al a level that provides for

the float 40 to be in a position which coincides with the closure member being in a fully

closed position. More particularly, as the level of the float rises, hydraulic fluid will be

displaced from the piston/cylinder arangemant 44 to the chamber defined by the body of

the closure valve 30, this hydraulic fluid acting on the diaphragm 48 to thereby provide

for the required displacement of the plunger-tyoe closure 50

When waler use again accurs ai the waler supply points, water from the waler tank 12

will rs-snter the pipe arrangement 22 via the perforated segment 28 and as the resulting

in the tank 19 drops, the downward displacement of the float will resultin

water level wi

the plunger-type closure 50 being forced into an open position, particularly by the

pressure of water acting thereon. Itwill be appreciated that the flow rate of water through

the pipe arrangement to the water sugply paints will be such that the water level within

the tank structure will continue fo drop es weter demand increases and particulerly until

full demand is again reached, in which case the plunger formation 50 will b fully

‘open position and the float will be in its lowest position. It will be appreciated in this

regard that the two positions of the float and, as such, of the plungertype closure 50 of

the closure member 36 of the control valve 30 as described. are limit positions ard for

siluations in which water demand is at intermediate levels, the water level within the tank

10

15

WO 20081020367 PCTAD2007¢053131

structure will ba such thal the fioatis in a position in whieh the plunger-lype closure 50s

maintained in 2 required open position to accommodate water demand, The operation of

the break water tank in this regard is clearly apparent. An overflow 60 is provided to

accommedate overfiling of the tank structure, which may occur if the control valve 30

malfunctions. |t will aso be understood that as tne plungertype closure 50 moves away

from its seat formation, it will act on the diaphragm 48, for displacing hydraulic ‘uid from

the chamber in which itis located to the cylinder of the pisten/cylinder arrangement 44,

Itis submitted that the operation of the oreak water tank of the invention as described

will be extremely r

ible, thus requiring minimum maintenance. Any maintenence that.

may be required can be carried oul by simply removing the lid 18 of the tank structure

12, closing tho closure valve 32 and henve altending to requirements, including cleaning

of the strainer arrangement 3¢. |t is also apparent that any malfunctioning of the break

‘water tank is very unlikely to occur and itis thus submitted that with the use of the break

water lank as described, a reliable waler supply to water supply points from an elevated

reservoir is ensured.

10

15

20

25

30)

WO 20081020367 PCTAD2007¢053131

-10-

CLAIMS,

1.

A break pressure tank which includes

a lank structure;

a pipe arrangement defining a flow line leading through the tank structure from an,

inlet end, connectable to a pipelina from reservoir and entering the tank structure:

near the top end thereof, {o an cullet end, connectable to a pipeline leading to

water supply points and leaving the tank structure near the bottom end thereof, the

pipe arrangement including 2 perforated pipe segment located within the tank

structure near the bottom end thereof and upstream of the outlet end thereof;

a control valve, located in line with the flaw line defined by the pice arrangement

within the tank structure beiween the inlet end of the pipe arrangement and the

perforated pipe segment, for controlling the flow rate of waler through the flow line

defined by the pive arrangement, the control valve including a closure member

displaceable between a fully ogen position, in which free flow through the flow line

is permitted, and a closed position, in which the flow line is blocked; and

a float actuated operating mechanism, located in the tank structure, that is

operatively linked to the closure member of the control valve for displacing it

between its fully open and closed positions. the float actuated operating

mechanism having a float thatis displaceable, in response to the water level in the

tank structure changing during operation of the break pressure tank, between &

first pr ly empty,

which coincides with the closure member of the control valve being in its fully open

position, and 2 second position in the tank structure, when the tank structure is

filled to a predetermined level, which coincides with the closure member of the

nin the tank structure, when the tank siructure is substan

control valve being in its closed pasition.

10

15

20

25

WO 20081020367 PCTAD2007¢053131

ie

‘A break pressure tank as claimed in Claim 1, in which the tank structure is &

substantially rectangular structure including a base wall having dimensions in the

order of 1000mm X 1000mm end having a height in the order of 1200mm.

A break pressure tank as claimed in Claim 1 or Claim 2, in which the tank structure

includes lockable lid which controls access into the interior of the tank structure.

A braak pressura tank as claimed in any one of the preceding claims, in which the

tank structure is formed of a sheet metal material.

A break pressure lank as claimed in any one of the preceding claims, which

includes a closure valve located in line with the flow line defined by the pipe

arrangement operatively upstream of the control valve, the closure valve being

operable for permitting either free flow through the flow line or far blocking the flow

line.

A break pressure tank as claimed in Claim §, in which the closure valve is @ lever

operated butterfly-type valve.

A break pressure tank as claimed in Claim § or Claim 6, which includes a strainer

arrangement located in the flow line defined by the pipe arrangement for trapping

debris and light particulate objacts and particles carriad within water fed to the

break pressure tank from a reservoir, the strainer arrangement being located

upstream of the closure valve.

A break pressure tank as claimed in Claim 7, in which the strainer arrangement

includes an operating lever that is manually operable for cleaning of the strainer

arrangement.

10

15

20

25

30)

WO 20081020367 PCTAD2007¢053131

10.

"

12.

13.

-12-

A break pressure tank as claimed in any one of the preceding claims, in which the

closure member of the control valve comprises @ plunger-type closure having

plunger rod extending therefrom, the rod being axially displaceable for displacing

the plunger-type closure with respect toa seat formation defined thereforwithin the

ody of the control valve.

A break pressure tank as claimed in Claim 9, in which the plunger rod of the

plungar-type closure is operatively connected tc a diaphragm displaceably located

within a chamber defined within the Sody of the control valve, an operating fluid

being displaceable

chamber and thereby displacing the plunger-lype closure of the contral valve.

‘0 the chamber for displacing the diaphragm within the

A break pressure tank as claimed in Claim 10. in which the float actuated operating

mechanism includes a pistoricylinder arrangement of which the cylinder

communicates with the chamber defined by the body of the control valve for

displacing @ hydraulic liquid between the cylinder and the chamber and thereby

providing for required displacement of the closure member of the control valve.

A break pressure tank as Glaimed in Claim 11, in which the piston/cylinder

arrangement includes a piston red that extends therefrom and thats mechanically

linked

the piston of the piston/eylinder arrangement being controlled by the displacement

the float of the float actuated operating mechanism, the displacement of

of the float which, in tum, is controlled by the level of water within the tank

structure.

A break pressure tank as claimed in Claim 11 or Claim 12, in which the float

actuated operating mechanism includes a guide structure located in the tank

structure for guiding the displacement of the float along a line parallel to the line of

displacement of the giston rod of the piston/cylinder amrangement.

10

15

WO 20081020367 PCTAD2007¢053131

14,

16.

-13-

A break pressure tank as claimed in any one of the preceding claims, in which the

operation of the float actuated operating mechanism is such that with 2 water level

within the tank structure beneath a predetermined level, the float of the mechanism

will be atils lowest level and the closure member of the cantrol valve will be in its

fully open position, wilh the float of the mechanism al or above a predetermined

highest level, the closure member of the control valve will be in its closed position,

and with the ficat of the mechanism located in any intermediate position between

the said levels, the closure member of the control valve will be disposad in an

intermediate open position determined by the specific intermediate position of the

float at any particular time. thereby to control the flow rate of weter through the

control valve and hance through a pipeline connected to the cullet of the pipe

arrangement, through which wator oan be displaced to water supply points from a

reservoir fo which the inlet end of the pipe arrangement is operatively connected.

A break pressure tank as claimed in Claim 1, substantially as herein described with

reference to and as illustrated in the accompanying drawings.

15

FIG 1

WO 20081020367 PCTAD2007¢053131

2/5

FIG 2

WO 20081020367 PCTAD2007¢053131

3/5

20

44 ou 24

as 12

lo ‘oT

OF; yy

L

10

38

2 “

16

Bo IN

16

40

WO 20081020367 PCTAD2007¢053131

4/5

FIG 4

WO 2008020367 PCTAB2007/053131

5/5

FIG 5

S-ar putea să vă placă și

- Pipeline Design for Water EngineersDe la EverandPipeline Design for Water EngineersEvaluare: 5 din 5 stele5/5 (1)

- Water Demand CalculationDocument6 paginiWater Demand CalculationValium MorphineÎncă nu există evaluări

- 9-Wastewater Sludge CharacteristicsDocument19 pagini9-Wastewater Sludge CharacteristicsAnonymous Hy5Ir9QXÎncă nu există evaluări

- Sediment Basin Design Example PDFDocument8 paginiSediment Basin Design Example PDFAgus FirdausÎncă nu există evaluări

- Sewage and Drainange System Theories and CalculationDocument19 paginiSewage and Drainange System Theories and CalculationSopi Labu0% (1)

- Stability of PontoonDocument2 paginiStability of Pontoonপ্রিয়দীপ প্রিয়মÎncă nu există evaluări

- Design of One-Way SlabDocument2 paginiDesign of One-Way SlabJm CampitanÎncă nu există evaluări

- Preparation of DPR - Hydrological StudiesDocument30 paginiPreparation of DPR - Hydrological Studiesmathur_nkÎncă nu există evaluări

- Main Water Intake StructuresDocument23 paginiMain Water Intake StructureskkodgeÎncă nu există evaluări

- Design Sump PumpDocument2 paginiDesign Sump PumpAbdullah MofarrahÎncă nu există evaluări

- How To Calculate Septic Tank Size - CivilologyDocument5 paginiHow To Calculate Septic Tank Size - CivilologyHang ChethaÎncă nu există evaluări

- Gravity Sewer SpreadsheetDocument3 paginiGravity Sewer SpreadsheetMazharYasinÎncă nu există evaluări

- Sizing Calculations of Thrust BlocksDocument9 paginiSizing Calculations of Thrust BlocksAbhay ThakurÎncă nu există evaluări

- Kpeve Water Supply Options Oct 2014Document31 paginiKpeve Water Supply Options Oct 2014M.Tugrul Karaduman50% (2)

- Manual On Water Supply and Treatment Cpheeo Government of IndiaDocument3 paginiManual On Water Supply and Treatment Cpheeo Government of IndiaJessicaÎncă nu există evaluări

- Dome FormulasDocument2 paginiDome FormulasKhalaf.geoxÎncă nu există evaluări

- Potable Water Demand Calculation (4G1) PDFDocument1 paginăPotable Water Demand Calculation (4G1) PDFARTURDVARELAÎncă nu există evaluări

- Peak Flow Calculations XYZ Dec 16,2003Document7 paginiPeak Flow Calculations XYZ Dec 16,2003Amit BhamreÎncă nu există evaluări

- Tool For Master Plan Formulation - Water Supply With Surface Water SourceDocument25 paginiTool For Master Plan Formulation - Water Supply With Surface Water SourceaneeshmeloottuÎncă nu există evaluări

- Percolation - Tank DesignDocument25 paginiPercolation - Tank DesignSanthosh Kumar Baswa100% (1)

- Wet Well Pumping Station Design GuideDocument61 paginiWet Well Pumping Station Design Guideawhk2006100% (3)

- Design of Sewage Treatment PlantDocument7 paginiDesign of Sewage Treatment PlantBill Harley VinsmokeÎncă nu există evaluări

- Blue Book Design Spreadsheet V8Document5 paginiBlue Book Design Spreadsheet V8nanesculÎncă nu există evaluări

- Drainage Culverts 07Document17 paginiDrainage Culverts 07Avish GunnuckÎncă nu există evaluări

- Sewerage DesignDocument6 paginiSewerage DesignAsmatSalSabila100% (2)

- Fabric Reinforcement SpecsDocument2 paginiFabric Reinforcement Specsabj7Încă nu există evaluări

- Epa SWMM TutorialDocument16 paginiEpa SWMM TutorialHassan Abib BasalÎncă nu există evaluări

- Time of ConcentrationDocument10 paginiTime of ConcentrationBernard PalmerÎncă nu există evaluări

- 15 Gravity Sewer SpreadsheetDocument3 pagini15 Gravity Sewer SpreadsheetFVTÎncă nu există evaluări

- Estimation of Storm WaterDocument8 paginiEstimation of Storm WaterShanihaKKÎncă nu există evaluări

- Lift Station Calculation - REV2Document13 paginiLift Station Calculation - REV2Rawan Alwan ZarifÎncă nu există evaluări

- Water Hammer in Pumped Sewer MainsDocument45 paginiWater Hammer in Pumped Sewer MainsManikandanÎncă nu există evaluări

- Generator Set RoomsDocument7 paginiGenerator Set RoomsAnonymous TvOpvXÎncă nu există evaluări

- Town Water Supply - Pump, Pumping Main: Delivery PipeDocument2 paginiTown Water Supply - Pump, Pumping Main: Delivery PipeJohn BandaÎncă nu există evaluări

- Moody DiagramDocument18 paginiMoody DiagramAnonymous uL3JlWfh100% (1)

- Abu Dhabi-Sewerage Pipe Theories and CalculationDocument19 paginiAbu Dhabi-Sewerage Pipe Theories and CalculationPatel KalingaÎncă nu există evaluări

- PDF Sea Water IntakeDocument6 paginiPDF Sea Water IntakeMuhammad Aris100% (1)

- SWMM 4 ManualsDocument720 paginiSWMM 4 ManualsFatmah El WardagyÎncă nu există evaluări

- Sutro Weir Design and Flow Calculation - S - Origina - No - ModificarDocument8 paginiSutro Weir Design and Flow Calculation - S - Origina - No - ModificarvalentinaÎncă nu există evaluări

- Sluice Valve ChampersDocument34 paginiSluice Valve ChampersWessam NourÎncă nu există evaluări

- Water DemandDocument9 paginiWater Demandraveena athiÎncă nu există evaluări

- Rising Main Design SheetDocument9 paginiRising Main Design SheetJaspal SinghÎncă nu există evaluări

- 4) Design of Pumping Machinery - Head CalculationsDocument7 pagini4) Design of Pumping Machinery - Head CalculationsNaveen NagisettiÎncă nu există evaluări

- Water Demand Assessment For Urban ProjectsDocument44 paginiWater Demand Assessment For Urban ProjectsShashikant Dattatray ChawatheÎncă nu există evaluări

- Storm Rain CalculationDocument1 paginăStorm Rain CalculationΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥÎncă nu există evaluări

- Lodhama-II Design CivilDocument68 paginiLodhama-II Design Civilnira365Încă nu există evaluări

- 15 Gravity Sewer SpreadsheetDocument3 pagini15 Gravity Sewer SpreadsheetShashank YadavÎncă nu există evaluări

- Sewerage Manual Part-A CPHEEODocument976 paginiSewerage Manual Part-A CPHEEOVanchit Das100% (1)

- Sump DesignDocument4 paginiSump DesignThiru AnanthÎncă nu există evaluări

- Calculating Sump VolumeDocument2 paginiCalculating Sump VolumeSharon LambertÎncă nu există evaluări

- Hydraulic Calculation of Box Culvert: Bekri Primary Canal ##+### BBK1a 3-Barrel BoxDocument1 paginăHydraulic Calculation of Box Culvert: Bekri Primary Canal ##+### BBK1a 3-Barrel BoxelfitaÎncă nu există evaluări

- ENGGBOQEstimation ReportDocument266 paginiENGGBOQEstimation ReportUTTAL RAYÎncă nu există evaluări

- 14Document4 pagini14dpkÎncă nu există evaluări

- Lime-Dosing Wam Inc Brochure 0114 EDIT PDFDocument4 paginiLime-Dosing Wam Inc Brochure 0114 EDIT PDFWidiyanto WidiyantiÎncă nu există evaluări

- A Step by Step Guide To EPANET SimulationsDocument23 paginiA Step by Step Guide To EPANET Simulations17018 Md. Shahariar KabirÎncă nu există evaluări

- Design of Dual Media Filters To Suit Existing Water Treatment Plants in IndiaDocument5 paginiDesign of Dual Media Filters To Suit Existing Water Treatment Plants in IndiareinpolyÎncă nu există evaluări

- Quantity Estimation of SewageDocument8 paginiQuantity Estimation of SewageVijay KumarÎncă nu există evaluări

- Political Parties ManualDocument46 paginiPolitical Parties ManualRaghu Veer YcdÎncă nu există evaluări

- IFF CAGNY 2018 PresentationDocument40 paginiIFF CAGNY 2018 PresentationAla BasterÎncă nu există evaluări

- 1968 Hypogene Texture and Mineral Zoning in A Copper Granodiorite Porphyry Stock NielsenDocument14 pagini1968 Hypogene Texture and Mineral Zoning in A Copper Granodiorite Porphyry Stock NielsenKevin Hiram Torres Montana100% (1)

- BTL VĨ Mô Chuyên SâuDocument3 paginiBTL VĨ Mô Chuyên SâuHuyền LinhÎncă nu există evaluări

- Key Considerations For A Successful Hyperion Planning ImplementationDocument45 paginiKey Considerations For A Successful Hyperion Planning Implementationayansane635Încă nu există evaluări

- Choice of Law RulesDocument23 paginiChoice of Law RulesKranthi Kiran TalluriÎncă nu există evaluări

- Solidcam Glodanje Vjezbe Ivo SladeDocument118 paginiSolidcam Glodanje Vjezbe Ivo SladeGoran BertoÎncă nu există evaluări

- Cloud Controls Matrix v3 0 1Document1.304 paginiCloud Controls Matrix v3 0 1IT SecurityÎncă nu există evaluări

- MABX 2014 Construction Buyers GuideDocument158 paginiMABX 2014 Construction Buyers Guidemabx_PAÎncă nu există evaluări

- ThedinnerpartyDocument2 paginiThedinnerpartyapi-287829605Încă nu există evaluări

- Probationary Contract SampleDocument1 paginăProbationary Contract SampleCharlyn FloresÎncă nu există evaluări

- List of Mumbai SchoolsDocument10 paginiList of Mumbai Schoolsapi-3714390100% (4)

- Development of Science and Technology in The PhilippinesDocument12 paginiDevelopment of Science and Technology in The PhilippinesJyra Shael L. EscanerÎncă nu există evaluări

- Review of The 2010 11 Flood Warnings and Reponse INTERIM REPORTDocument32 paginiReview of The 2010 11 Flood Warnings and Reponse INTERIM REPORTABC VictoriaÎncă nu există evaluări

- YSI Saving 2022Document2 paginiYSI Saving 2022koamanoÎncă nu există evaluări

- Crim SPLDocument202 paginiCrim SPLRoyalhighness18Încă nu există evaluări

- School Teacher Profile DetailsDocument17 paginiSchool Teacher Profile Detailskn.sateeshÎncă nu există evaluări

- Scope PED 97 23 EGDocument54 paginiScope PED 97 23 EGpham hoang quanÎncă nu există evaluări

- K.E.E.I. Notes - Fall 2010Document8 paginiK.E.E.I. Notes - Fall 2010Kijana Educational Empowerment InitiativeÎncă nu există evaluări

- Iso 27001Document84 paginiIso 27001sboukhal100% (2)

- Proposal Argument (FINAL)Document10 paginiProposal Argument (FINAL)NgoziÎncă nu există evaluări

- Reaction Paper of Shawshank Redemption MovieDocument5 paginiReaction Paper of Shawshank Redemption Movieathy3456Încă nu există evaluări

- Natural Law: St. Thomas AquinasDocument50 paginiNatural Law: St. Thomas AquinasGabriel PanganibanÎncă nu există evaluări

- Carnival Internet Package Price Up To 100 Mbps Speed Best Internet Provider 2Document1 paginăCarnival Internet Package Price Up To 100 Mbps Speed Best Internet Provider 2Jahidul Hasan NumanÎncă nu există evaluări

- SEEBURGER WebEDI Wilo ENDocument1 paginăSEEBURGER WebEDI Wilo ENmarketingÎncă nu există evaluări

- NEM326 HW 1 PDFDocument2 paginiNEM326 HW 1 PDFyaprak dönerÎncă nu există evaluări

- College Online Applicant Profile SheetDocument2 paginiCollege Online Applicant Profile SheetRuvie Grace HerbiasÎncă nu există evaluări

- Additional English - 4th Semester FullDocument48 paginiAdditional English - 4th Semester FullanuÎncă nu există evaluări

- Kamran CVDocument1 paginăKamran CVUnibis AccountsÎncă nu există evaluări

- 2019-04-01 BESTPRAC Financial Management of H2020 Projects - Guide To Best Practice PDFDocument87 pagini2019-04-01 BESTPRAC Financial Management of H2020 Projects - Guide To Best Practice PDFDes Des Z MottaÎncă nu există evaluări

- Shorting the Grid: The Hidden Fragility of Our Electric GridDe la EverandShorting the Grid: The Hidden Fragility of Our Electric GridEvaluare: 4.5 din 5 stele4.5/5 (2)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingDe la EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingÎncă nu există evaluări

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- Electric Motor Control: DC, AC, and BLDC MotorsDe la EverandElectric Motor Control: DC, AC, and BLDC MotorsEvaluare: 4.5 din 5 stele4.5/5 (19)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDe la EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentEvaluare: 4.5 din 5 stele4.5/5 (21)

- A Practical Handbook for Drilling Fluids ProcessingDe la EverandA Practical Handbook for Drilling Fluids ProcessingÎncă nu există evaluări

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDe la EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsEvaluare: 4.5 din 5 stele4.5/5 (12)

- Power Electronics Diploma Interview Q&A: Career GuideDe la EverandPower Electronics Diploma Interview Q&A: Career GuideÎncă nu există evaluări

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDe la EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsÎncă nu există evaluări

- Well Integrity for Workovers and RecompletionsDe la EverandWell Integrity for Workovers and RecompletionsEvaluare: 5 din 5 stele5/5 (3)

- Well Control for Completions and InterventionsDe la EverandWell Control for Completions and InterventionsEvaluare: 4 din 5 stele4/5 (10)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe la EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesEvaluare: 4.5 din 5 stele4.5/5 (21)

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- Handbook on Battery Energy Storage SystemDe la EverandHandbook on Battery Energy Storage SystemEvaluare: 4.5 din 5 stele4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDe la EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsEvaluare: 4.5 din 5 stele4.5/5 (2)

- Thermal Power Plant: Design and OperationDe la EverandThermal Power Plant: Design and OperationEvaluare: 4.5 din 5 stele4.5/5 (23)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDe la EverandFlow Analysis for Hydrocarbon Pipeline EngineeringÎncă nu există evaluări

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADe la EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AÎncă nu există evaluări

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsDe la EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsÎncă nu există evaluări

- Pipeline and Energy Plant Piping: Design and TechnologyDe la EverandPipeline and Energy Plant Piping: Design and TechnologyEvaluare: 5 din 5 stele5/5 (2)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDe la EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsÎncă nu există evaluări

- Smart Power Distribution Systems: Control, Communication, and OptimizationDe la EverandSmart Power Distribution Systems: Control, Communication, and OptimizationÎncă nu există evaluări

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977De la EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Încă nu există evaluări

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksDe la EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksÎncă nu există evaluări