Documente Academic

Documente Profesional

Documente Cultură

HSE Awareness Training Materials

Încărcat de

Ashraf S. YoussefTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

HSE Awareness Training Materials

Încărcat de

Ashraf S. YoussefDrepturi de autor:

Formate disponibile

July 11

Awareness of

Health, Safety & Environment

Prepared By: P dB Ashraf S. Youssef, Ph. D. QA & Communications Manager S.M. ASQ, L.A. BSI, M. ELI, M. EMS

July 25, 2011 25,

Training Approach

Focus on Basics Interactive Case Studies Videos Have Fun !

What Do U Think?

HSE are important components of EEICs management system HSE is part of my job I care about HSE HSE will make a difference in EEIC

July 11

EEIC HSE PROGRAM Major Components

HSE Policy g HSE Program Accident/Incident Investigation

HSE Program Implementation Process For achieving goals and continually improving

Plan Implement

Adjust

Measure

Key Definitions (1/2) (1

Loss

Human Injury or illness, production downtime or equipment damage, and/or harm to the environment Undesired events that result in loss An act or condition which is a potential source for accident Hazard Accident Loss

Accident Hazard

July 11

Key Definitions (2/2) (2

Risk Risk Assessment Risk Management

The chance that the loss will be realized Evaluate (qualitative or quantitative) the degree of risk associated with a hazard Management strategies to eliminate or reduce risk

Risk Assessment Example

Assess the Annual Risk of oil leaks given the following last year data: Leak Events 1 2 3 4 5 6 7 8 9 10 Loss (SAR) 5,000 10,000 15,000 10,000 5,000 10,000 5,000 10,000 15,000 10,000

Severity =

5,000 + 10,000 + .. + 10,000

10

= 9,500 SAR/Event

Likelihood = 10 Events/Year Annual Risk = 95,000 SAR/Year

Domino Theory

HAZARDS Social Undesirable Unsafe Acts Environment Traits Or Conditions Accident Loss

July 11

Proactive versus Reactive

Accident Analysis

Hazards

of or Near Misses

Investigation

Preventive Programs

Analysis

Accidents

Preventive

Action

Hazard versus Control

Risk Hazard evaluation

Assessment Severity level X Occurrence

likelihood

Risk

Versus Control (countermeasures) options ( t ) ti

Design to eliminate/ reduce Add safety devices Add warning devices Add administrative measures (procedures, training)

Management

Hazard Evaluation

High

Likelihood

Low

Severity

High

Low

July 11

Hazard Classification

Class A Hazard

A condition or practice likely to cause permanent disability, loss of life or body part and/or extensive loss of structure, equipment or material. E.g. a barrier guard missing from a rotating shaft.

Class B Hazard

A condition or practice likely to cause serious injury or illness illness, resulting in temporary disability or disruptive property damage. E.g. a broken tread near the top of a stairway.

Class C Hazard

A condition or practice likely to cause minor injury or illness, or non-disruptive property damage. E.g. untidy worksite.

How Does Accident Happen?

Hazardous Source

Bad Behavior

Behavior is the most important Element Behaviors are Observable

80-90% accidents caused by behaviors in a labor intensive environment.

Behaviors are Measurable

Performance Mgt: What gets measured gets done

Safety Plan, Policies, Procedures, Programs, Hierarchy of Controls to include Engineering, Enforcement, etc.

Gas_pump.wmv

July 11

Case Studies

VICTIM

July 11

RMU Accident 1AccidentDescription:

OnetechnicianisworkingontheRingmaster.Heisjoiningthecableboxtobusbar box whichisattachedtoRMRunit.Whileheistightentheboltinside,thecablebox;the wrenchslippedandcausetheRMRunittomove.Thetechnicianwasabletogooutthe boxandtrytostoptheunitfromfailingdown.RMRfalldownandcauseadominoes effectontheotherfiveunits.

July 11

Accident Report (Switch Gear) 2Supportedpictures:

EEIC Evacuation Plan

Group Activity

The Group Activity rules Form a group of four members Each group shall assign a leader Each group shall not audit his area

July 11

Group Activity

Assembly Line 1 & 2 No lights in the backside of line 1 Assembly Line 1 & 2 Undetermined Chemical smell smell. Not enough ventilation Not proper use of the extension wires & Hose The Electrical Cables is not cover properly. Not proper place for fabrication. Not proper arrangement for skids

Group Activity

MotorPact Area Fire hose is blocked by material Fire extinguisher is not properly fix. Glass of emergency light is broken. Electrical outlet is closed by material a t g ea Painting Area The temperature is high It is not proper cleaned. Painting cans are open Heavy weights are in high place. Unsafe allocation for LPG gas blower No fire extinguisher inside the painting room There was a problem with exhausting fan. No warning sign on the racks.

Group Activity

Workstations The material put it in the wrong place. The hardware & lugs are mixed. The racks are not arranged properly. No adjustable chairs for Workstations. Difficulty to find the relevant stand for the product. CWB door is not store properly. pp properly. Electrical pipe is not fixed p p y Floor leveling Warehouse Area Chemical and liquid materials are placed beside the panel boards. Chemical 7 Gasoline are kept in the warehouse. Many halls in the walls and the roof. Electrical cables are not covered. No warning sign @ Control panels. The Din rails is stored in a vertical way.

July 11

Group Activity

Shipping Area Leveling of the floor Temperature is high They use the area for welding. They use this area as a store for some materials. The tag area is not fixed properly Fabrication Area The gas cylinder in located in unsafe area The CNC Safety barricade is defeated. Scrap box is over filled Sharp scrap metals on the floor. Missing safety guard for the grinding machine Steel beams is allocated on pass way Vise is fixed on the chair.

10

S-ar putea să vă placă și

- Confined Space Entry Procedure WorksheetDocument5 paginiConfined Space Entry Procedure WorksheetToma AdrianaÎncă nu există evaluări

- Template Contoh HSE PlanDocument31 paginiTemplate Contoh HSE PlanAndi MuliadiÎncă nu există evaluări

- COSHH Assessment RecordDocument4 paginiCOSHH Assessment RecordParashuram PatilÎncă nu există evaluări

- DM-PH&SD-P4-TG01 - (Technical Guidelines For Industrial Compressed Gas Cylinders)Document6 paginiDM-PH&SD-P4-TG01 - (Technical Guidelines For Industrial Compressed Gas Cylinders)kevinÎncă nu există evaluări

- Safe System Of Work A Complete Guide - 2020 EditionDe la EverandSafe System Of Work A Complete Guide - 2020 EditionÎncă nu există evaluări

- Statistical Applications in Laboratories & Uncertainty EstimationDocument48 paginiStatistical Applications in Laboratories & Uncertainty EstimationAshraf S. Youssef100% (1)

- Girl, Interrupted Film Analysis Diana Fox Molloy CollegeDocument5 paginiGirl, Interrupted Film Analysis Diana Fox Molloy CollegeDiana Fox100% (1)

- Postnatal Assessment FormatDocument16 paginiPostnatal Assessment FormatValarmathi92% (13)

- Obstetrics Case Proforma TemplateDocument4 paginiObstetrics Case Proforma TemplateSwapneelShah100% (1)

- LVMH - Code of ConductDocument13 paginiLVMH - Code of ConductElena DianaÎncă nu există evaluări

- Managing Employee Attitudes and Well-BeingDocument2 paginiManaging Employee Attitudes and Well-BeingJayChristian QuimsonÎncă nu există evaluări

- Safety 06.05.2014Document38 paginiSafety 06.05.2014vinay nagvanshiÎncă nu există evaluări

- COSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsDocument2 paginiCOSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsPaulSwinbankÎncă nu există evaluări

- Coporate Hsse Monthly Report Nov.Document3 paginiCoporate Hsse Monthly Report Nov.nzeogwu0% (1)

- PPE TrainingDocument23 paginiPPE TrainingShadeed SalemÎncă nu există evaluări

- Personal Protective Equipment PoliciesDocument6 paginiPersonal Protective Equipment PoliciesSaAhRa100% (1)

- EHS Plan SummaryDocument19 paginiEHS Plan SummaryParshant SainiÎncă nu există evaluări

- Training Procedure for HSE CompetencyDocument11 paginiTraining Procedure for HSE Competencybilo1984100% (1)

- Toolbox Talk - Mounting and Dismounting EquipmentDocument1 paginăToolbox Talk - Mounting and Dismounting Equipmentsl1828Încă nu există evaluări

- Safety Engineer JobDocument3 paginiSafety Engineer Jobخلف الله التوم0% (1)

- HSE Manual 2Document23 paginiHSE Manual 2AhmedA.Hassan100% (1)

- DEE EHU-03!5!1 Health and Safety Committee Meeting MinutesDocument2 paginiDEE EHU-03!5!1 Health and Safety Committee Meeting MinutesFred AlmaÎncă nu există evaluări

- Monthly HSE Report April .2013Document8 paginiMonthly HSE Report April .2013sakthivelÎncă nu există evaluări

- Blinding and De-blinding Safety EssentialsDocument42 paginiBlinding and De-blinding Safety EssentialsMayur NaikÎncă nu există evaluări

- Life Saving Rules Speaker Support Pack Jan 2012Document33 paginiLife Saving Rules Speaker Support Pack Jan 2012Muhammed AliÎncă nu există evaluări

- Chemical Manifest and Hazardous Chemical Substance List KathuDocument13 paginiChemical Manifest and Hazardous Chemical Substance List KathuVictorÎncă nu există evaluări

- ALSA VAPOUR RECOVERY COMPRESSOR MODIFICATION AND PLANT UPGRADESDocument2 paginiALSA VAPOUR RECOVERY COMPRESSOR MODIFICATION AND PLANT UPGRADESsauspy100% (1)

- Unsafe and Unhealthy Acts and ConditionsDocument41 paginiUnsafe and Unhealthy Acts and ConditionsclandestineamorousÎncă nu există evaluări

- Job Hazard and Risk AssessmentDocument5 paginiJob Hazard and Risk Assessmentasponce2003Încă nu există evaluări

- HSE Formats (9508 - Part1)Document50 paginiHSE Formats (9508 - Part1)Paras Jani100% (1)

- Safety ObservationDocument48 paginiSafety Observationpooloo70100% (1)

- Heat Stress ProcedureDocument13 paginiHeat Stress ProcedureKneekEy CastleÎncă nu există evaluări

- Monthly Site Safety Audit ReportDocument3 paginiMonthly Site Safety Audit Reporttajshah283100% (1)

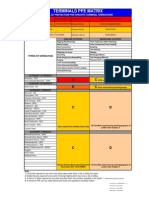

- PPE MatrixDocument1 paginăPPE MatrixcaptainphihungÎncă nu există evaluări

- + Contractor Safety Weekly Statistic Report FormDocument1 pagină+ Contractor Safety Weekly Statistic Report FormNathaniel Kwek100% (2)

- JSA IndexDocument2 paginiJSA IndexDie HArdÎncă nu există evaluări

- Understanding Workplace Accidents & Safety TerminologiesDocument34 paginiUnderstanding Workplace Accidents & Safety Terminologiesadel santosÎncă nu există evaluări

- Planning and Procedures: Pdo Hse Management System Manual (CP-122)Document10 paginiPlanning and Procedures: Pdo Hse Management System Manual (CP-122)AHMEDNABTÎncă nu există evaluări

- HSE Inspection Matrix - c416Document1 paginăHSE Inspection Matrix - c416Venkadesh PeriathambiÎncă nu există evaluări

- Safety AlertsDocument1 paginăSafety AlertsChristine RossÎncă nu există evaluări

- Monthly HSE Performance Report Form DTLP FEB-21Document2 paginiMonthly HSE Performance Report Form DTLP FEB-21Muhammad Khan100% (1)

- BP Safety AlertDocument2 paginiBP Safety AlertRikza AhmadÎncă nu există evaluări

- Gulf Tunneling Company HSEMS Forms ListDocument1 paginăGulf Tunneling Company HSEMS Forms ListEiuol OinraÎncă nu există evaluări

- Njqs Core Audit Module - Rev1.6cDocument14 paginiNjqs Core Audit Module - Rev1.6cNene UmohÎncă nu există evaluări

- Hazard Checklists LinksDocument2 paginiHazard Checklists LinksLuis Enrique100% (1)

- Job Safety Analysis: Calalang Residence J. Fajardo St. Sampaloc ManillaDocument4 paginiJob Safety Analysis: Calalang Residence J. Fajardo St. Sampaloc ManillaJoey Stanley GuzmanÎncă nu există evaluări

- 1 WAH ChecklistDocument2 pagini1 WAH Checklistvirendra kumar singhÎncă nu există evaluări

- Short Service Employees ProcedureDocument7 paginiShort Service Employees ProcedureMuhammad Usman100% (1)

- Appendix 2 Hse Screening QuestionnaireDocument4 paginiAppendix 2 Hse Screening QuestionnaireSuad100% (1)

- Index: Cv. Dira Utama SejahteraDocument12 paginiIndex: Cv. Dira Utama SejahteraFreshop SurabayaÎncă nu există evaluări

- Job Safety Analysis FormDocument2 paginiJob Safety Analysis FormHSE S4Încă nu există evaluări

- HSE Manual Documentation PDFDocument9 paginiHSE Manual Documentation PDFemeka2012Încă nu există evaluări

- Hazard RegisterDocument146 paginiHazard RegisterMirwali Mangal100% (2)

- 01 JSA CLEANING MgO Rev 05 017 BIDocument7 pagini01 JSA CLEANING MgO Rev 05 017 BIMohd KhaidirÎncă nu există evaluări

- Safety equipment checklistDocument36 paginiSafety equipment checklistjiks_i4u100% (2)

- 2) SOP-01 Handling Hazardous ChemicalDocument6 pagini2) SOP-01 Handling Hazardous ChemicalMohd ZaeinÎncă nu există evaluări

- Consequence Management Sytem EsepplDocument1 paginăConsequence Management Sytem Eseppluttam mishra100% (2)

- Health Safety & Environmnetal ChallengesDocument13 paginiHealth Safety & Environmnetal ChallengesSantosh Mhatre88% (8)

- Hse Manual: Document Status PageDocument23 paginiHse Manual: Document Status PagePerwez21Încă nu există evaluări

- Fire Safety ChecklistDocument13 paginiFire Safety ChecklistPampa DasÎncă nu există evaluări

- General Safety Training ProgramDocument72 paginiGeneral Safety Training ProgramSreedhar Patnaik.MÎncă nu există evaluări

- Fire Risk AssessmentDocument13 paginiFire Risk AssessmentAnand ChinnappanÎncă nu există evaluări

- Bab 13 Safety AuditDocument51 paginiBab 13 Safety AuditR Muhammad FathiÎncă nu există evaluări

- Technical Safety EngineeringDocument85 paginiTechnical Safety EngineeringElla Agbettor100% (3)

- 6S - 5S - Evaluation and Implementation Tool - LeanDocument8 pagini6S - 5S - Evaluation and Implementation Tool - LeanShekhar RaviÎncă nu există evaluări

- Expert System For Flexible Manufacturing SystemsDocument10 paginiExpert System For Flexible Manufacturing SystemsAshraf S. YoussefÎncă nu există evaluări

- Blue Ocean Strategy SummaryDocument3 paginiBlue Ocean Strategy SummaryAshraf S. Youssef100% (5)

- ISO 14001 & OHSAS 18001 Awareness Training1Document73 paginiISO 14001 & OHSAS 18001 Awareness Training1Ashraf S. YoussefÎncă nu există evaluări

- IMS Awarness TrainingDocument103 paginiIMS Awarness TrainingAshraf S. YoussefÎncă nu există evaluări

- Leadership Skills: Dr. Ashraf S. YoussefDocument14 paginiLeadership Skills: Dr. Ashraf S. YoussefAshraf S. Youssef100% (1)

- Forecasting TechniquesDocument25 paginiForecasting TechniquesAshraf S. Youssef100% (3)

- 5 S TrainingDocument10 pagini5 S TrainingAshraf S. YoussefÎncă nu există evaluări

- Customer Behavior TrainingDocument15 paginiCustomer Behavior TrainingAshraf S. YoussefÎncă nu există evaluări

- Ashraf S. Youssef ResumeDocument10 paginiAshraf S. Youssef ResumeAshraf S. YoussefÎncă nu există evaluări

- Effective Presentation Skills Skills: Course IntroductionDocument23 paginiEffective Presentation Skills Skills: Course IntroductionAshraf S. Youssef100% (2)

- Awarness of ISO 9001: 2008Document19 paginiAwarness of ISO 9001: 2008Ashraf S. YoussefÎncă nu există evaluări

- Guru Guide Six Thought Leaders Who Changed The Quality World ForeverDocument8 paginiGuru Guide Six Thought Leaders Who Changed The Quality World ForeverJose Luis Moncada100% (4)

- Academic Ref StandardsDocument6 paginiAcademic Ref StandardsAshraf S. YoussefÎncă nu există evaluări

- Quote of The WeekDocument14 paginiQuote of The WeekAshraf S. YoussefÎncă nu există evaluări

- Ashraf S. Youssef ResumeDocument9 paginiAshraf S. Youssef ResumeAshraf S. YoussefÎncă nu există evaluări

- Continuous Improvement ToolsDocument61 paginiContinuous Improvement ToolsAshraf S. YoussefÎncă nu există evaluări

- Laboratory Quality Control and Assurance: An Integrated ApproachDocument34 paginiLaboratory Quality Control and Assurance: An Integrated ApproachAshraf S. YoussefÎncă nu există evaluări

- An Expert Diagnostic Quality Control SystemDocument16 paginiAn Expert Diagnostic Quality Control SystemAshraf S. YoussefÎncă nu există evaluări

- Lean Manufacturing Fundamentals and ApplicationsDocument13 paginiLean Manufacturing Fundamentals and ApplicationsAshraf S. YoussefÎncă nu există evaluări

- Automated Identification of Basic Control ChartsDocument13 paginiAutomated Identification of Basic Control ChartsAshraf S. YoussefÎncă nu există evaluări

- Integrated Management System " All in One": Action PlanDocument9 paginiIntegrated Management System " All in One": Action PlanAshraf S. YoussefÎncă nu există evaluări

- Lean Managment Fundamentals and Applications (Compatibility Mode)Document17 paginiLean Managment Fundamentals and Applications (Compatibility Mode)Ashraf S. YoussefÎncă nu există evaluări

- Key Factors in Acheiving Education QualityDocument9 paginiKey Factors in Acheiving Education QualityAshraf S. Youssef50% (2)

- Simulation of Engineering SystemsDocument19 paginiSimulation of Engineering SystemsAshraf S. YoussefÎncă nu există evaluări

- Neural Network Applications To Buffer Allocation Problems in Automated Transfer LinesDocument12 paginiNeural Network Applications To Buffer Allocation Problems in Automated Transfer LinesAshraf S. YoussefÎncă nu există evaluări

- Implementing QMS Fast - Track ApproachDocument1 paginăImplementing QMS Fast - Track ApproachAshraf S. YoussefÎncă nu există evaluări

- Facilities Planning and LayoutDocument37 paginiFacilities Planning and LayoutAshraf S. Youssef100% (7)

- Engineering ReliabilityDocument53 paginiEngineering ReliabilityAshraf S. Youssef100% (2)

- The Perspective of Vat Concessions Regime in Tanzania PDFDocument32 paginiThe Perspective of Vat Concessions Regime in Tanzania PDFHandley Mafwenga SimbaÎncă nu există evaluări

- Fire Retardant Research PaperDocument2 paginiFire Retardant Research Paperapi-318759920Încă nu există evaluări

- Safe Food Handlers Course NotesDocument13 paginiSafe Food Handlers Course NotesJinky PradoÎncă nu există evaluări

- Quality Assurance in Medical LaboratoriesDocument69 paginiQuality Assurance in Medical Laboratories"DocAxi" Maximo B Axibal Jr MD FPSP100% (1)

- SASO 1431 (GS 1355) SorbitolDocument5 paginiSASO 1431 (GS 1355) SorbitolakÎncă nu există evaluări

- 004 General Consent English (Front)Document2 pagini004 General Consent English (Front)عبدالله الرعويÎncă nu există evaluări

- 02 2 Internal OrgansDocument1 pagină02 2 Internal OrgansgabrielaÎncă nu există evaluări

- Alvarez 2015Document18 paginiAlvarez 2015Clara RodriguesÎncă nu există evaluări

- Daftar PustakaDocument3 paginiDaftar PustakaErliTa TyarLieÎncă nu există evaluări

- Colegiul National SF - Sava Catedra de Limba Engleza Prof. Speteanu Alexandra GabrielaDocument3 paginiColegiul National SF - Sava Catedra de Limba Engleza Prof. Speteanu Alexandra Gabrielaannem29Încă nu există evaluări

- Buku Koding 1Document74 paginiBuku Koding 1indra_igrÎncă nu există evaluări

- Immunohematology PDFDocument126 paginiImmunohematology PDFNicole Tan Calayca100% (1)

- Marijuana Fact SheetDocument1 paginăMarijuana Fact Sheetapi-355176759Încă nu există evaluări

- Dynamic Learning Plan 2-Lesson 2Document27 paginiDynamic Learning Plan 2-Lesson 2Cyrah OntiverosÎncă nu există evaluări

- Burns Guide: Causes, Types, TreatmentDocument4 paginiBurns Guide: Causes, Types, TreatmentMartin KoaÎncă nu există evaluări

- Spagyria vs Alchemy: Separating Myth from TruthDocument4 paginiSpagyria vs Alchemy: Separating Myth from Truthvas25Încă nu există evaluări

- Igem ListDocument9 paginiIgem ListMilad YadollahiÎncă nu există evaluări

- LAS For Summative Assessment (Written Work Performance Task)Document2 paginiLAS For Summative Assessment (Written Work Performance Task)Angel Dela CruzÎncă nu există evaluări

- Antonella Arrieta LaurentDocument24 paginiAntonella Arrieta LaurentEmanueleÎncă nu există evaluări

- Referral Letter: Client Personal Details Client Identity DetailsDocument2 paginiReferral Letter: Client Personal Details Client Identity DetailsFlorence LinÎncă nu există evaluări

- Main - Factsheet Tacrolimus OintmentDocument4 paginiMain - Factsheet Tacrolimus OintmentSakuranbochanÎncă nu există evaluări

- Les Effets Nutritionnels de La ChlorophylleDocument4 paginiLes Effets Nutritionnels de La ChlorophylleChahinez MansouriÎncă nu există evaluări

- Hospital Administrative Assistant Resume-A4Document2 paginiHospital Administrative Assistant Resume-A4Philip V AlexÎncă nu există evaluări

- Respiratory MechanicsDocument27 paginiRespiratory MechanicsKarla Hernandez100% (1)

- ORA.007 Pharmaceutical Microbiology ManualDocument92 paginiORA.007 Pharmaceutical Microbiology ManualNindyÎncă nu există evaluări