Documente Academic

Documente Profesional

Documente Cultură

DW Abcd Formula 1009

Încărcat de

gnino2Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DW Abcd Formula 1009

Încărcat de

gnino2Drepturi de autor:

Formate disponibile

FLORIDA DEPARTMENT OF ENVIRONMENTAL PROTECTION DRINKING WATER A, B, C & D FORMULA SHEET AND CONVERSION FACTORS 10-09 12 in = 1 ft 3 ft = 1 yd 5280 ft = 1 mi 144

sq. in.= 1 sq. ft. 43,560 sq. ft.= 1 acre 27 cu. ft.= 1 cu. yd 7.48 gal = 1 cu. ft. 8.34 lbs = 1 gal 62.4 lbs = 1 cu. ft. 1 grain / gal = 17.1 mg/L 1000 mg = 1 gm 1000 gm = 1 kg 1000 ml = 1 liter 3.785L = 1 gal 2.31 ft water = 1 psi 0.433 psi = 1 ft water L = Length AREA Rectangle: A = L x W Volume Cylinder: V = R2 x H Rectangle: V=LxWxH Cone: V = 1/3 x R2 x H Triangle: A = 1/2 B x H Circle: Area = x R2 B = Base 60 sec = 1 min 60 min = 1 hour 1440 min = 1 day 10,000 mg/L = 1% 454 gm = 1 lb.

= 3.14

W = Width

H = Height

R = Radius

TEMPERATURE CONVERSIONS Co to F o = C o x 1.8 + (32) F o to C o = (F o 32) 1.8

VELOCITIES and FLOW RATES 1. 2. V= distance, feet time, min Flow rate = (velocity, ft / sec x area, sq. ft.)

Q=VxA

DETENTION TIME 1. 2. Detention Time = (tank, cap.,gal) x (24 hours/day) rate of flow (gal / time) Detention Time, Minutes = (cap.,gal.)(24 hr./day) (60 min./hr.) (Flow, gal./day)

PARTS PER MILLION / POUNDS 1. 2. mg/L = lbs = pounds of chemical (8.34 lbs / gal x MG) 8.34 lbs / gal x mg/L x MG

LOADINGS 1. 2. Weir overflow, gal / day / ft = Surface loading, gal / day / sq.ft. = total flow, gal / day length of weir, ft. flow, gal / day surface area, sq. ft.

3.

Rise rate, ft / min =

surface loading, gal / min / sq. ft. 7.48 gal / cu. ft.

CHEMICAL MIXING & SOLUTION STRENGTHS 1. Polymer, % = (dry polymer, lbs) x (100%) (dry polymer, lbs + water, lbs)

(Water, Lbs)

2. 3. 4. 5. 6. 7. 8.

Dry polymer, lbs = Water, lbs =

/ ((100 / polymer %) -1)

- dry polymer, lbs

dry polymer, lbs x 100% polymer %

Liquid polymer, gal = Scale setting, % = Feeder setting, % = Water added, gal =

(polymer solution, %) (gal of solution) liquid polymer, % (desired feed rate, gal / hr) (100%) maximum feed rate, gal / hr. (desired feed rate, lbs / day) (100%) (maximum feed rate, lbs / day) (hypo, gal) (hypo, %) - (hypo, gal) (desired hypo, %) desired hypo, %

Polymer feed, lbs/day = (polymer conc., mg/L)(vol. pumped, ml)(60 min/hr)(24 hr/day) (time pumped, min.)(1,000 mg/L)(1,000 mg/gm)(454 gm/lb)

ii

FILTRATION 1. 2. 3. 4. 5. 6. Filtration rate, gal / min / sq. ft. = flow, gal / min surface area, sq. ft.

Backwash pumping rate, gal / min = (filter surface area, sq. ft.) (BW rate, gal / min / sq. ft.) Backwash rise, in/min. = (backwash, GPM/sft)(12in/ft) (7.48 gal/cft) Backwash % = (backwash water, gal) (100%) water filtered, gal. UFRV, gal / sq. ft. = volume filtered, gal filter surface area, sq. ft.

UFRV, gal/sq. ft. = (Filtration Rate, GPM/sq ft)(Filter Run, hr)(60 min/hr)

SOFTENING & DEMINERALIZATION 1. Lime feed, mg/L = (A + B + C + D) x 1.15 purity of lime as a decimal (mg/L as CO2) (mg/L as Ca CO3) (mg/L as Ca CO3) (mg/L as Mg2+) x x x x (56 / 44)

A= B= C= D=

carbon dioxide, source water bicarbonate alkalinity, source water hydroxide alkalinity, source water magnesium, source water

(56 / 100) (56 / 100) (56 / 24.3)

If hydrated lime is used instead of quicklime, substitute 74 for 56 in A, B, C, and D. 2. 3. 4. 5. 6. 7. 8. Lime demand, mg/L = [ (2.27 x CO2) + (Total Alkalinity) + (4.12 x Mg) x 0.56] x (excess) Calcium oxide purity (% / 100)

Lime demand, lbs / MG = (lime demand, mg/L) (1 MG) (4.67 lb / MG / mg/L) (excess lime, %/10) Calcium oxide purity (% / 100) Exchange capacity, grains = Water treated, gal = Bypass flow, gal / day = Salt, lbs = Brine, gal = (removal capacity, gr / cu. ft.) (media vol, cu. ft.)

exchange capacity, grains hardness removed, grains / gal (total flow, gal / day) (finished water hardness, grains / gal) raw water hardness, grains / gal (hardness removed, grains)

(salt reqd, lbs / 1000 grains) salt needed, lbs salt soln, lbs / gal

iii

9.

Mineral rejection, %

= 1-

(product TDS, mg/ L feedwater TDS, mg/L

)X

100%

10. 11.

Recovery, %

product flow feed flow

X 100% as CaCO3

Non-Carbonate Hardness =

Mg/L

Total Hardness - Total Alkalinity =

Non-Carbonate Hardness

Raw Non-Carbonate Hardness - Finished Non-Carbonate Hardness = Non-Carbonate Hardness Removed 12. Soda Ash = (Non-Carbonate Hardness)

106 100

)

(100%)

FLUORIDATION 1. 2. 3. Fluoride ion purity, % = Feed rate, lbs / day = Feed rate, gal / day = (molecular wt. of F in compound) molecular wt. of compound

(flow, MGD) (desired F, mg/L) (8.34 lbs / gal) (100%) (acid soln, %) (purity %) feed rate, lbs / day chemical soln, lbs / gal (commercial chemical purity, %) (100%) (100%) (Fluoride ion, % )

4.

Portion of F

5.

Feed rate, lbs / day =

Fluoride, lbs / day fluoride, lbs / lb of commercial chemical

LABORATORY 1. 2. Dilute to mL = (Actual Weight, gm)(1,000 mL) (Desired Weight, gm)

Langelier Index (L.I.) = pH pHs

DISINFECTION Chlorine Demand, mg/L = Chlorine Dosage, mg/L Chlorine Residual, mg/L Chlorine Dosage, mg/L = Chlorine Demand, mg/L + Chlorine Residual, mg/L

iv

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- High Protein FoodsDocument10 paginiHigh Protein Foodsgnino2Încă nu există evaluări

- High Protein FoodsDocument10 paginiHigh Protein Foodsgnino2Încă nu există evaluări

- USDA National Nutrient Database For Standard Reference, Release 25Document25 paginiUSDA National Nutrient Database For Standard Reference, Release 25gnino2Încă nu există evaluări

- Fatty Acids, Mono ListsDocument26 paginiFatty Acids, Mono Listsgnino2Încă nu există evaluări

- Nitrogen Removal Example 5Document1 paginăNitrogen Removal Example 5gnino2Încă nu există evaluări

- Chapter 4 - Nitrogen Removal 101: Example 4.3Document1 paginăChapter 4 - Nitrogen Removal 101: Example 4.3gnino2Încă nu există evaluări

- Dielectric in Electric FieldDocument34 paginiDielectric in Electric FieldBo BogdanÎncă nu există evaluări

- Tri Halomethane SDocument2 paginiTri Halomethane Sgnino2Încă nu există evaluări

- FiltrationDocument2 paginiFiltrationgnino2Încă nu există evaluări

- Wastewater Nitrogen RemovalDocument22 paginiWastewater Nitrogen Removalgnino2Încă nu există evaluări

- Nitrgen Removal Example 1 PDFDocument3 paginiNitrgen Removal Example 1 PDFgnino2Încă nu există evaluări

- Fundamental of Nitrogen RemovalDocument12 paginiFundamental of Nitrogen Removalgnino2Încă nu există evaluări

- Nitrogen Removal Example 2Document1 paginăNitrogen Removal Example 2gnino2Încă nu există evaluări

- Chapter 4 - Nitrogen Removal 85Document2 paginiChapter 4 - Nitrogen Removal 85gnino2Încă nu există evaluări

- Nitrgen Removal Example 1 PDFDocument3 paginiNitrgen Removal Example 1 PDFgnino2Încă nu există evaluări

- SofteningDocument6 paginiSofteninggnino2Încă nu există evaluări

- Taste and OdorDocument2 paginiTaste and Odorgnino2Încă nu există evaluări

- Miscellaneous TreatmentDocument2 paginiMiscellaneous Treatmentgnino2Încă nu există evaluări

- SofteningDocument6 paginiSofteninggnino2Încă nu există evaluări

- Fe & MN RemovalDocument3 paginiFe & MN Removalgnino2Încă nu există evaluări

- FluoridationDocument1 paginăFluoridationgnino2Încă nu există evaluări

- SedimentationDocument6 paginiSedimentationgnino2Încă nu există evaluări

- FiltrationDocument2 paginiFiltrationgnino2Încă nu există evaluări

- Polymer Calculation and Dosage RatesDocument4 paginiPolymer Calculation and Dosage Ratesgnino2Încă nu există evaluări

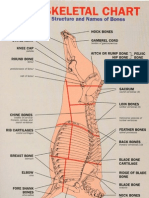

- Beef Skeletal ChartDocument1 paginăBeef Skeletal Chartgnino2Încă nu există evaluări

- DeminerlizationDocument3 paginiDeminerlizationgnino2Încă nu există evaluări

- DisinfectionDocument6 paginiDisinfectiongnino2Încă nu există evaluări

- Corrosion ControlDocument2 paginiCorrosion Controlgnino2Încă nu există evaluări

- Alkalinity and HardnessDocument2 paginiAlkalinity and Hardnessgnino2Încă nu există evaluări

- National Contaminants Level EPADocument6 paginiNational Contaminants Level EPAMohamed WahbyÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- CT Excel Skills Test Revised 12102015Document8 paginiCT Excel Skills Test Revised 12102015Soundarya Ramesh0% (1)

- Belaire Compressor CatalogDocument12 paginiBelaire Compressor CatalogBillÎncă nu există evaluări

- Metal Q Clip System Brochure PDFDocument5 paginiMetal Q Clip System Brochure PDFSunil Dinanath JoshiÎncă nu există evaluări

- EMG 2014 Mechanics of Machines II July 2014 Class WorkDocument3 paginiEMG 2014 Mechanics of Machines II July 2014 Class WorkCharles OndiekiÎncă nu există evaluări

- Bearing SPM Condition Analyser BVT 111Document2 paginiBearing SPM Condition Analyser BVT 111industrialindiaÎncă nu există evaluări

- Operators Manual: TEC-B-0002 REV0 1/09Document117 paginiOperators Manual: TEC-B-0002 REV0 1/09Clay MorrisÎncă nu există evaluări

- Technical Sheet of EI2 60 Handed DoorDocument1 paginăTechnical Sheet of EI2 60 Handed DoorTaoufikAzarkanÎncă nu există evaluări

- Piyush NTPC Training ReportDocument83 paginiPiyush NTPC Training ReportRavi GuptaÎncă nu există evaluări

- Transmission LinesDocument56 paginiTransmission LinesGrace LatÎncă nu există evaluări

- Apf188088 enDocument130 paginiApf188088 enJavier LópezÎncă nu există evaluări

- Bottom Failure - Annex K - en 14015 - Rev 3Document3 paginiBottom Failure - Annex K - en 14015 - Rev 3KP SahuÎncă nu există evaluări

- RGF 1Document4 paginiRGF 1mickymausÎncă nu există evaluări

- Classic Petrol 35 SDocument10 paginiClassic Petrol 35 S5432167890OOOOÎncă nu există evaluări

- Non Traditional MachiningDocument17 paginiNon Traditional MachiningLeo Dev WinsÎncă nu există evaluări

- Casagrande Lecture Recommended Practice For Soft Ground Site Characterization Ladd and de GrootDocument60 paginiCasagrande Lecture Recommended Practice For Soft Ground Site Characterization Ladd and de GrootPavlos VardoulakisÎncă nu există evaluări

- Seismic: VvinuDocument528 paginiSeismic: VvinuLucas ScartonÎncă nu există evaluări

- 03-Application List Moto, ATVDocument97 pagini03-Application List Moto, ATVΗλίας ΓεωργιάδηςÎncă nu există evaluări

- Methodology Well Foundation (R3)Document14 paginiMethodology Well Foundation (R3)jitendra100% (2)

- Experimental Study On The Thermal Performance of R600a PDFDocument9 paginiExperimental Study On The Thermal Performance of R600a PDFEdy MesinÎncă nu există evaluări

- CHAPTER 7: Benchmark Test ResultsDocument10 paginiCHAPTER 7: Benchmark Test Resultsnapoleon_velasc3617Încă nu există evaluări

- MEISER Grating PDFDocument136 paginiMEISER Grating PDFEngr Qaisar NazeerÎncă nu există evaluări

- (L2) - Mole Concept JEEDocument19 pagini(L2) - Mole Concept JEEHYDRA CLAN100% (1)

- MT6592 Android ScatterDocument7 paginiMT6592 Android ScatterÁlvaro López VillegasÎncă nu există evaluări

- PrecastDocument35 paginiPrecastalyssa0% (1)

- Draft SOP For Usage of Tree PrunerDocument2 paginiDraft SOP For Usage of Tree PrunerAkhilesh Kumar Singh100% (1)

- Intake Manifold Air Temperature Is High: TroubleshootingDocument3 paginiIntake Manifold Air Temperature Is High: TroubleshootingPutra JawaÎncă nu există evaluări

- EN VEGASWING 63 Two WireDocument48 paginiEN VEGASWING 63 Two WireLucas FiordelisiÎncă nu există evaluări

- 036 Siga-UmDocument6 pagini036 Siga-UmzezohomeÎncă nu există evaluări

- Computer Architecture and Parallel Processing by Kai Hwang PDFDocument6 paginiComputer Architecture and Parallel Processing by Kai Hwang PDFApoorva ursÎncă nu există evaluări

- DSR Cabos SinteticosDocument28 paginiDSR Cabos SinteticosFabian Andres CelyÎncă nu există evaluări