Documente Academic

Documente Profesional

Documente Cultură

Strength of Materials - Combined Stresses - Hani Aziz Ameen

Încărcat de

Hani Aziz AmeenTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Strength of Materials - Combined Stresses - Hani Aziz Ameen

Încărcat de

Hani Aziz AmeenDrepturi de autor:

Formate disponibile

Strength of Materials

Handout No.12

Combined Stresses

Asst. Prof. Dr. Hani Aziz Ameen Technical College- Baghdad Dies and Tools Eng. Dept.

E-mail:haniazizameen@yahoo.com www.mediafire.com/haniazizameen

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

12-1 Introduction

As should have become apparent from the preceding chapters , a description of the state of stress at a point of a stressed member can be found by using the convential formulas and may involve normal and shearing stresses. In this chapter , the method of redescribing the state of stress in iterms of the combined stressed will be applied to some particular cases of stressed members The curved members , such as crane hooks and machine frames, are often subjected to axial loads and bending moments . Therefore the theory of curved beam will be also discussed in this chapter .

12-2

Stresses due to Combinations of Axial Loads and Bending Moments

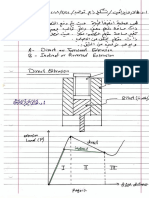

The simple stress formula for the member subjected to axial load P is ............( 12- 1) A as shown in Fig(12-1a)

Fig(12-1a) And for a member subjected to lateral load (bending) the stress is My 12- 2) I as shown in Fig(12-1 b ) .

Fig(12-1b) The stresses produced by axial loads and bending moments are such that stresses are normal to the cross-section of a member . Thus the resulting stresses at any point on the cross-section of the member are added algebraically .

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

The stresses given in Eq(12-1) & Eq(12-2) are both normal to the cross section of the member , therefore the resultant stress acting on the section , due to the simultaneous action of the axial load P and the pure bending moment M , is the algebraic sum of the direct stress and the flexural stress. The equation of resultant stress is generally written in the form ; P My ...................... (12-3) A I The plus and minus signs indicated in Eq(12-3) are assigned

It can be seen that the resultant stress distribution due to the combined action of P & M is obtained by superposing the stress distribution due to P & M . So , in this section it has been assumed that the eccentric load is applied to the member on one of its principal axes, either on the x-axis or on the y axis , thus the two cases are shown in Fig.(12-2).

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

-aFig(12-2) P A where : Myy=P.a Iyy about y-axis tia Ixx M yy. x I yy

-bP A M xx .y I xx

Mxx=P.b about x-axis

12-2-1 Axis

Stresses due to Loads not Applied to Principal

Fig(12-3)

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

In order to position the load P (shown in Fig(12-3)) along the centroidal axis C of the member, we have to move either directly from the point of application of the load to point C or we have to move through the distance ( a ) towards the Y axis and then through the distance (b) towards the X- axis . In order to obtain the equation of stress ( ) let us move the load through a distance ( a ) and then through a distance ( b ). In moving through a distance (a) , we shall induce a bending movement Myy = P.a . plus the condition shown in Fig(12-2b ) .Thus , the stress acting at any point on the number of Fig.(12-3) is the algebraic sum of the M yy .x P M xx y as indicated below and the I yy A I xx P M xx y M yy .x A I xx I yy X & Y represent the coordinates of the point at which the stress in the member of Fig(12-3) is required .

12-3 Direct Shear Combined with Torsion

The shearing stress due to applied torque acting at any point on a shaft having a circular cross section is computed as T .r J and the shearing stress , due to a direct shearing force acting at any point on a beam of any section is V Ay Ib The resultant shearing stress at the point is given by the algebraic sum as: T.r V A y .......... .......... ..... (12-4) J Ib the plus and minus signs in Eq.(12-4) are assigned to shearing stresses that act along the same line of action and have respectively the same and opposite directions .

12.4 Combined Stresses due to Bending & Torsion

A common application of combined stresses is that of a shaft subjected to bending & twisting and it is often convenient to express the resulting direct and shear stresses directly in terms of the applied moment &torque. If the bending moment is M and the torque T Fig(12-4 a) , then the stresses acting on an element on the upper surface are as shown in the

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

plane view Fig(12- 4 b) ( those on the lower surface are the same , except that x compressive).

-aFig(12-4) My I T.r J M(d 2) 64 T d4 , M 32 d3

-b-

d 16 Assuming solid shaft, the max . principal stress , 1 2 4 2 max x x 2

2 max 2

max

. is given by

1 2

M d3 32

max

M d3 32 1 M 2 M2 T2

T 4 d3 16 T2

i.e.

32

d3

Me = 32

1 M 2

max

M2 Me Me Ze

- - - - equivalent bending moment

d3

max

Me d 32 1 2 1 2

3

and also

2 Max x

4

2

2 2

max

M d3 32

T 4 d3 16

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

16

d3

Max

M2

T2

T2 .. equivalent torque

Te = 16 d3

M2

Max

Te Te.r J

Te

Max 16

d3

12.5 Combined Torsion &

Axial Load

If the axial load P and torque T are applied to the rod as shown in Fig(12-5)

Fig(12-5) Then

tens

P A T.r J

2

P

d2 4

4P d2

for axial load

and

16T d3

2

for torque ,

4p max 2 d2 2 16 T d3 2

max

max

16 d3

Pd 2 8

T2

12.6 Combined Axial Load , Bending & Torsion

If the axial load F, bending moment M and Torsion T are applied to the rod as shown in Fig(12-6 ) . Then 32M 4 F bending direct d3 d2 T.r 16T and and also, J d3 Fig(12-6)

2 2 max

32M

max

4F d2

16T d2

d3

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

12- 7 Examples

The following examples explain the different concepts of the combined stresses problems . Example(12-1) Fig.(12-7) shows a steel chimney is 30m high , 1 m external diameter and 10 mm thick . It is rigidly fixed at the base . It is acted upon by a horizontal wind pressure which is taken to be of a uniform intensity of 1kN/m2 of projected area for the lower 15m and to vary unifor mly from 1 kN/m2 to 2 kN/m2 over the upper 15m. Find the maximum stress in the plates at the base , steel has a density of 7.8 Mg/m3 .

Fig(12-7) Solution The pressure distribution diagram is shown in Fig(12-7). The total wind force can be divided into P1, the force due to a uniform of 1kN/m2 over the whole height and P2 , the force due to the additional pressure over the upper 15 m. P1=1*103*30 = 30 kN

3 P2 = 1 * 10 * 1 * 15 7.5 kN 2 .: moment about base =30*15+7.5*25=637.5 kN.m

I of cross- section =

64

14

0.984

0 .003815 m4

M 637.5 * 103 .: maximum bending stress = *y = * 0.5 83.6 MN/m 2 I 00.03815

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

Direct stress at base = specific weight * height = 7.8 *103 * 9.81 * 30 = 2.3 MN/m2 .: total stress at base = 83.6 +2.3 =85.9 MN/m2 Example(12-2) Fig (12-8) shows a short column of I-section 200mm x160mm . A vertical load W acts through the centroid of the section together with a parallel load W/4 acting through a point on the center line of the web , distance 60 mm from the centroid measured towards the longer flange . Find the greatest allowable value of W if the maximum compressive stress is not to exceed 80 MN/m2. What is the minimum stress in the section?

Fig(12-8) Solution Taking moments about the top edge 160*10*5+180*10*100+120*10*195 =4600 y1 .: y1=91.74mm and y2=108.26mm 160 * 103 10 * 1803 160 * 10 * 86.742 10 * 180 * 8.262 Ixx= 12 12 120 * 103 + 120 * 10 * 103.262 = 29.85*106 mm4 12 Transferring the load ( W/4) to the axis XX, there is then a total direct load of ( 5 W/4 ) ,together with a bending moment about XX of magnitude ( We / 4 ) where ( e ) is the eccentricity of the load From XX. 5W W * 0.06 0.10826 80 * 106 N/ m 2 * max 6 4 * 0.0046 4 29.85 * 10 from which W=245 kN

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

Minimum stress 5 * 245 * 103 245 * 103 * 0.06 0.08674 = * 55.92 MN/m 2 6 4 * 0.0046 4 29.85 * 10 Example(12-3) Fig. (12-9 ) shows a pillar 1.5 m high is of rectangular section 50 mm think and tapers longitudinally from a width of 150 mm at the base to 50mm at the top . A compressive load of 100 kN acts through the centroid at the top end and parallel to the vertical edge. Find the magnitude of the maximum compressive stress and the crosssection at which it will occur.

-aFig(12-9)

-b-

Solution Fig(12-9 b) shows the section of the pillar at a distance x m below the x x * 0.1 0.05 m so that the top, the width of the section is 0.05+ 1.5 15 x m with respect to centroid of the section. load has an eccentricity of 30 100 * 103 30 Direct stress , d MN/m2 x 0.05{0.05 15 } 0.75 x 30 90 22.5 120x .. (i) 2 0.75 x (0.75 x ) (0.75 x ) 2 d 0 x 0.375m For to be a maximum dx Substituting in Eq.(i) yields 67.5 53.33MN / m 2 2 1.125 Bending stress,

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

Example (12- 4) A steel bar of circular section , 100 mm diameter , carries a longitudinal pull whose line of action is parallel to the axis of the bar . At a certain transverse section the longitudinal stresses are measured at the surface of the bar at three points A , B & C . These points being equally spaced round the section the tensile stresses at these points are A , 90 MN/m2; B , 75MN/m2 ; C , 30MN/m2. Find :a) The magnitude & location of the greatest & least stresses at the section b) The magnitude & eccentricity of the applied pull . Make a diagram showing the stresses & their positions relative to the points A, B, & C . Solution It will be evident that the line of action of P lies with in the sector AOB, At A . as in Fig(12-10) . P 4 d

2

P * e * cos

3

P

2

P * e * cos 32 (i) 0.1

3

400P

1 80 * e * cos

0.1 d 4 32 =90 MN/m2 ............... Similarly , at B. 400P 1 80 * e * cos 120 =75 MN/m2 At C , =

400P

1 80 * e *

1 cos 2

3 sin 2

.............. 400P

( ii ) ) 3 sin 2 30MN / m 2 ... (iii)

1 80 * e * cos(120 1 cos 2

400p

1 80 * e * (

These equations simplify to 1 80 * e * cos 1 40 * e * ( cos 9 40P 3 sin ) .................. (iv) 7.5 40P ......... (v)

1 40 * e * ( cos From Eq(v) and Eq(vi)

3 sin )

3 ............... (vi) 40P

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

2 80 e * cos

10.5 ..................... (vii) 40P

From Eq(iv) and Eq(vi) 19.5 P= = 0.51 MN 120 From Eq(v) and Eq(vi) 80 3e * sin And from Eq(iv) 80 e * cos tan 0.693 =1.035 0.386 3 46 9 1 0.386 ........... (ix) 40P 4.5 = 0.693 ........ (viii) 40P

From Eq(viii) or Eq(ix) , e 0.00695m 400P (1 80e) when 0 max =

min

400 * 0.51

(1 80 * 0.00695) 101 MN/m2 when

400P =

(1 80e)

180

400 * 0.51

(1 80 * 0.00695) 28.9 MN/m2

Fig( 12-10)

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

Example(12-5) A steel bar of rectangular section 80mm x 40mm is used as a simply supported beam on a span of 1.4m and loaded at mid-span . If the yield stress is 300 MN/m2 and the long edges of the section are vertical, find the load when yielding first occurs . Solution

-aFig(12-11) Mmax =

-b-

wL (see Fig(12-11a) 4 M max wL 6 = * max = Ze 4 bh 2 w * 1.4 * 6 300*106= w = 36.57 kN 4 * 0.04 * 0.082 After yielding resisting moment =2 F1 * 0.035 F2 * 0.02 ( see Fig(12-11b) ) i.e w * 1.4 = 4 2 * (300 * 106 * 0.01 * 0.04) * 0.035 (150 * 106 * 0.03 * 0.04) * 0.02 w= 44.6 kN If yielding ceases at x m from the center 44.6 * 103 0.04 * 0.082 ( 0.7 x ) = 300*106 * x = 0.126m M= 2 6 Length over which yielding occurs 2x = 0.252 m

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

Example(12-6) Fig (12-12 )shows the section of a beam which is subject to a bending moment of such magnitude that yielding occurs at the lower part of the web over a depth of 50mm. The stress of 300MN/m 2 may be assumed constant over the yield area , while over the remainder of the section the stress is proportional to the distance from the N.A Find : a) The position of the N.A . b) The stress at the top of the section . c) The moment of resistance of the section

-a-

-b Fig(12-12)

Solution The stress distribution diagram is shown in Fig(12-12 b) . If the N.A after yielding is at a depth h mm below the top , then 300 300h MN / m 2 ..................... (i) h 150 h 150 h h 20 Stress at underside of flange = h Therefore equating forces above and below the N.A, gives

h 20 h

2 2 * (h

*120 * 20

h 20 * h 300 * (150 h ) * 20 2

20) * 20 300 * 50 * 20

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

From which :

300( 250h h2 200h

h2) 2000

h = 65.8 mm and 234.5MN / m2 65.8 20 Stress at underside of flange = * 234.5 163.3MPa 65.8 Assuming that the force on the flange acts its geometric center moment about N.A. ( 234.5 163.3) * 106 * 0.12 * 0.02 * (0.0658 0.01) 26650N.m = 2 Moment about N.A of force on web above N.A. From Eq(i) and Eq(ii) 163.3 * 106 * (0.0658 0.02) * 0.02 * 2 (0.0658 0.02) 2285N.m = 3 2 Moment about N.A of force on web below N.A. 300 * 106 * (0.15 0.0658) * 0.02 * 2 (0.15 0.0658) 14170N.m 3 2 Moment about N.A of force on plastic part of web =300*106*0.05*0.02*(0.175 0.0685) = 31950 N.m Total moment of resistance =75055 N.m = Example(12-6) Fig(12-13) shows a steel bar of rectangular section (38 mm)wide by 101.6 mm deep is subjected to compressive force of 53.37 kN acting as shown in Fig. Find the maximum tensile and compressive stresses normal to the cross-section of the bar and sketch stress distribution over the cross section of the bar .

Fig(12-13) Solution The forces can be represented as

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

The compressive stress

P 53.37 = 12.79 MPa A 38 * 101.6 * 10 6 My 53.37 * 103 (0.0508 12.7 * 10 3 ) y bendng I I 3 3 bh 38 * (101.4) 3.33 * 106 mm 4 I= 12 12 3 10 * 53.37 * (0.0508 12.7 *10 3 ) * 0.0508 31.027MPa bending 3.33 *10 6

c

P My A I 12.74 31.07 = 43.817 Mpa (comp.) ( top fiber) (bottem fiber) 12.47 31.07 18.23MPa (tension ) Example(12-7) Fig(12-14) shows a steel beam with an overhang is simply supported at A & B . If the beam is rectangular in section 50.8mm wide by 152.4mm deep . Find the largest stress acting normal to the cross-section of the beam neglect the weight of the beam .

Fig(12.14)

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

Solution Resolving the inclined force of 53.37 kN

Fx = Fy = Fx H Ax Fy

3 * 53.37 * 103 50.707kN 10 1 * 53.37 * 103 16.902kN 2 2 1 3 o Fx o 50.707kN RA RB 40 *103 16.902 *103 0

3

MB

0.2032 * R A

40 *103 *152.4 *10

16.902 *103 * 0.0508 0

RA=25.798 kN RB= 31.136 kN

P A

50.707 * 103 50.8 * 10

3

* 152.4 * 10 )

6.55MPa

Bending stress (

bending

0 x1 50.8 Mx1=25.798x1 At x1 = 0 Mx1=0 At x1=50.8 mm Mx1=25.798*103*50.8*10 3=15.725 kN.m

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

0 x 2 152.4 Mx2=25.798*(0.0508+x2) 40 * x2 At x1=0 Mx2=15.725 kN.m At x2=152.4 Mx2=25.798*0.203 40*0.1524 = 10.302 kN.m 0 x3<50.8 Mx3=25.798* (0.203+x3) 40*(0.1524+x 3) +31.136 x3 AT x3=0 Mx3=25.798*0.203 40*0.1524= 10.302 kN.m At x3= 50.8 Mx3= 25.798 *0.254 40 * 0.203 + 31.136 *0.0508 = 0 Mmax = 15.725 kN.m bh 3 50.8 *152.43 IN.A. = 12 12

14.98 mm 4

My 15.725 * 103 * 76.2 * 10 I 14.98 * 10 6 the largest stress 6.55 79.98 86.53MPa

79.98 MPa

Example(12-8) Fig(12-15) shows the cast iron clamp having the dimensioned cross-section shown . Find the max load P that can be applied . The allowable stresses are 20.68 MPa in tension and 62.05 MPa in compression .

Fig(12-15)

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

Solution y Ai yi Ai

63.5 9.525 9.525) 2 y 17.907mm

9.525 * 50.8 * 4.76 6.35 * (63.5 9.525) * ( (9.525* 50.8 6.35 * (635 9.525) y

50.8 * (17.907) 3 I N .A 3 0.288 * 106 mm 4

(50.8 6.35)(17.907 9.525) 3

6.35(63.5 17.907) 3 / 3

The force acting on the clamp of Fig(12-16) is equivalent to a force P acting along the centroidal axis of the section and to a bending moment of the magnitude M=P(0.1143+ y ) P(0.1143 0.017907) 0.1322 * P as shown in Fig(12-16)

Fig(12-16)

P A

direct stress where A 9.525 * 50.8 6.35 * (63.5 9.525) 825.8mm 2

P My 1210.9 P and bending stress is 6 I 825.8 * 10 The flexure stress at each of the point A & B of Fig(12-16) 0.1322 * P * 17.907 * 10 3 8.219 * 103 P tension A 6 0.288 * 10 0.1322 * (63.5 * 10 3 19.05 * 10 3 ) 20.4 * 103 P comp B 6 0.288 * 10 P My Allowable tensile stress at point A A I 6 20.68*10 = 1210.9 * P 20400 *P P 2.192kN P My Allowable compressive stress at point B A I 62.05*106 = 1210.9 P 20400* P P = 3.144 kN Max. safe load is = 2.192 kN

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

Example(12-9) Fig(12-16) shows a concrete dam has the dimensioned cross section shown, if concrete weighs 23.55 kN/m3 and water weighs 9.796 kN/m3 . Find the max. height (h) of the water that can be maintained behind the dam without causing tension on the foundation of the dam .

Fig(12-16) Solution Firstly to find the centroid of the section to the back of the dam : A i yi y Ai thus , 1.8288*13.716*1.8288+0.5(4.572 1.8288)*13.716* [(4.572 1.8288) /3+1.8288] = [1.8288*13.716+0.5*(4.572 1.8288)*13.716] * y y 1.697m The weight of concrete acting at the foundation is W=volume*23550 =0.5(1.8288+4.572)*13.716*0.3048*23550 =315.25 kN This load acts through the centroid of the dam as shown in Fig(12-17).

Fig(12-17)

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

Force due to average pressure is 1 1 Wh 2 F = average pressure *Area = 0 W h * h * 1 2 2 This force acts through the centroid of the pressure distribution at a distance of ( h/3 ) from the foundation of the dam. The force acting on Fig(12-17) is equivalent to that shown in Fig(12-18)

Fig(12-18) From this figure the direct compressive stress due to the weight of W concrete is , where A is the area of foundation A

Fig(12-19) 315.25 * 10 1.3898

3

226.831kN / m 2

Now applying the flexure formula

My I

M=M2 M1 M! ..... bending moment due to weight W of concrete M2 ..... .due to pressures force F Taken about the of area of Fig(12- 19) (the foundation)

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

M1=Wa =W 4.572 y

315.25 * 103 * ( 2.286 1.697) 185.45kN.m

Fh 1 2 h wh 3 9796 * h 3 M2 = wh . 1632 * h 3 3 2 3 6 6 3 M=1632 h 185.45 The moment of inertia around the N.A of Fig(12-19) bh 3 0.3048 * 4.5723 185.45 m 4 IN.A= 12 12 3 (1632 * h 185.45) * 2.286 2.427

Therefore the resultant stress at point B must be zero hence (1632 * h 3 185.45) * 2.286 0 B 2.427 h=9.509 m 226.185kN / m 2 (comp) (dired )

flexual )

226.185kN / m 2 ten .at B , comp. at A

226.185 226.185 213.021kN / m 2 (comp) &

Example(12-10) Fig(12-20 ) shows a short member having a rectangular section 8 x10 is subjected to a compressive force of P = 180 kN . Find the stresses normal to the cross- section A , B , C and D locate the neutral axis of the cross-section ABCD .

Strength of materials- Handout No.12- Combined Stresses - Dr. Hani Aziz Ameen

Fig(12-20) Solution P 180 * 103 3.5MPa comp .at point A, B, C, D A 0.203 * 0.254 Bending moment about the X-axis is Mxx=P*0.025=180*0.025= 4.572 kN.m this Bending moment cause tension at A & B and comp at C&D 254 * 203.23 177.6 * 106 mm 4 & y 101.6mm I XX 12 My 4.572 * 103 2.586MPa I 177.6 * 10 6 tensile at A & B and comp. at C & D Moment of inertia of the entire section about the y-axis is Iyy=(203.2*103)/12 = 277.48*106 mm4 & X=127 mm M yy .X 6778.2 * 0.127 3.102MPa I yy 277.48 * 10 6 tensile at B & C compression at A& D P A

A=

M xx I xx

M yy I yy

3.5+2.586 3.102 = 4.65 Mpa (comp) B = 3.5+2.586+3.102 = 2.24 Mpa (ten.) C = 3.5 2.586+3.102 = 2.93 Mpa(comp) D = 3.5 2.586 3.102 = 9.13 Mpa (comp) The stress distribution is as shown in Fig(12-21).

Fig(12-21)

Strength of materials- Handout No. 12- Combined Stresses- Dr. Hani Aziz Ameen

Example(12-11) Fig(12- 22) shows a short column of T - section 25cm x 20cm has a cross-sectional area 52 cm2 and max radius of gyration 10.7cm a vertical load W kN acts through the centroid of the section together with a parallel load of ( W/4 ) kN acting through a point on the center line of the web distant 6 cm from the centroid . Find ( a ) the greatest allowable value of W if the max stress is not to exceed 65 MN/m2 (b) what is then the min stress? Solution (a) I = A K2 = 52 (10.7)=5953.48 cm4 (W W ) 4 * 10 0.24W MPa ( dinect ) 52 * 104 M ( W / 4) * 0.06 * 10 3 ( bending ) Ze Ze

( bed )

0.015W * 10 Ze

0.015W * 10 ( I / y)

0.25 0.125m 2 0.015 W * 10 ( bend ) (5953.48* 10- 8 / 0.125) 0.031 W MPa ( bend )

d b

65 0.0315 W 65 Fig(12-22)

0.24 W

65 239.4 kN W= 0.24 0.0315 (b) min d b =W * (0.24 0.0315) = 234.4(0.24 0.015)*10 = 49.9 MPa

Strength of materials- Handout No. 12- Combined Stresses- Dr. Hani Aziz Ameen

Example (12-12) Fig(12-12 ) shows a rectangular plate with a hole drilled in it .Find the greatest and least intensities of stress at the critical cross-section of the plate when subjected to an axial pull of 90 kN.

Fig(12-23) Solution Axial load =90 kN 20 * 20 * 10 80 * 20 * 160 130mm 20 * 20 80 20 y1=200-130=70 mm The moment of inertia about the XX axis. 20 * 803 20 * 203 2 Ixx = 20 * 80 * 70 40 20 * 20 * 130 10 2 12 12 6 4 Ixx = 8.066*10 m Eccentricity, e = 100 y1= 100 70 = 30 mm or e = y2 100= 130 100 = 30 mm P 90 * 10 3 45 MPa (tens) d 3 A 2 * 10 My P*e *y b I I P * e * y2 90 * 30 * 10 3 * 0.13 * 10 3 45 45 max .atuu 6 I xx 8.066 * 10 2 2 = 88.5 kN/m = 88.5 kN/m (tens) P * e * y1 90 * 30 * 10 3 * 0.07 45 45 * 10 3 min at vv 6 I xx 8.066 * 10 = 21.57 MPa. =21.57 MPa (tens.) The location of centroid y2 =

Strength of materials- Handout No. 12- Combined Stresses- Dr. Hani Aziz Ameen

Example(12-13) Fig.(12-24 ) shows a short hollow cast iron column having an external diameter of 600 mm and diameter 400 mm was cast in a factory. On inspection it was found that the bore is eccentric as shown in the figure. If the column carries a load of 1600 kN along the axis of the bore, find the extreme intensities of stress induced in the section.

Fig(12-24) Solution External diameter = 600 mm = 0.6 m Internal diameter = 400 mm = 0.4 m Net area = 4 Load , W =1600 kN To find out the c.g. of the section * 0.6 2 * OG1 4 * 0.4 2 * OG 2 4 OG = x * 0.6 2 4 * 0.4 2 4 0.6 2 0.4 2 0.157m 2

where OG1=0.3 m , OG2=0.34 m x 268mm So GG1 = 0.3 0.268 = 0.032 m GG2 = 0.34 0.268 = 0.072 m Eccentricity = OG2 x =0.34 0.268 = 0.072 m =72 mm Moment M = 1600*0.072 =115.2 kN.m. Iyy = Iyy = 4 64 0.64 4 0 .6 4 4 0.4 4 * 0.6 2 * GG1 4

2

64

* 0.4 4

* 0.4 2

GG 2

0.6 2 * 0.0322

0.4 2 * 0.0722

4.743 * 10 3 m 4

Strength of materials- Handout No. 12- Combined Stresses- Dr. Hani Aziz Ameen

Bending stress (tensile)

bt

MX1 I yy

115.2 * 0.268 * 10 9.743 * 10 3

bt

Bending stress (comp.) bc W 1600 10 3 10.19 MPa .(comp.) direct A 0.157 Max. comp. Stress = d bc 10.19 8.06 18.25 MPa Min. comp. Stress = d bt 10.19 6.51 3.66 MPa Example(12-14) Fig(12-25) shows a steel rod 40 mm diameter passes through a copper tube of 60 mm internal diameter and 80 mm external diameter . Rigid cover plates are provided at each end of the tube and steel rod passes through these cover plates also. Nuts are screwed on the projecting ends of the rod so that the cover plates put pressure on the ends of the tube. If the center of the rod is 10 mm out of the center of the tube, find the max. stress in the copper tube when one of the nuts is tightened to produce a linear strain of 0.002 in the rod. Take Esteel= 210 GN/m2 and Ecopper = 105 GN/m2

6.51 MPa. 8.06 MPa.

Fig(12-25) Solution Diameter of steel rod , ds=40 mm External diameter of the copper tube , Dc=80 mm Internal diameter of the copper tube , dc= 60 mm Area of the cross section of the rod , As = * 402 1256.6mm 2 4 Area of the cross section of the rod , As = * 802 4 Strain in the steel rod , s 0.002 602 2199.1mm 2

S-ar putea să vă placă și

- Strength of Materials - Deformation Due To Axial Load - Hani Aziz AmeenDocument32 paginiStrength of Materials - Deformation Due To Axial Load - Hani Aziz AmeenHani Aziz Ameen91% (32)

- Strength of Materials - Bending Stress in Beam - Hani Aziz AmeenDocument37 paginiStrength of Materials - Bending Stress in Beam - Hani Aziz AmeenHani Aziz Ameen88% (26)

- Strength of MeterialsDocument142 paginiStrength of MeterialsEricJohnDeraferaÎncă nu există evaluări

- Strength of Materials - Torsion of Circular Cross Section - Hani Aziz AmeenDocument31 paginiStrength of Materials - Torsion of Circular Cross Section - Hani Aziz AmeenHani Aziz Ameen80% (15)

- Strength of MaterialsDocument64 paginiStrength of MaterialsMark Anthony Liwag Nama100% (1)

- Strength of Materials - Thermal Stresses - Hani Aziz AmeenDocument24 paginiStrength of Materials - Thermal Stresses - Hani Aziz AmeenHani Aziz Ameen73% (15)

- 41346877859Document5 pagini41346877859Lelouch BlacknightsÎncă nu există evaluări

- Ch3b Load and Stress AnalysisDocument33 paginiCh3b Load and Stress AnalysisagniflameÎncă nu există evaluări

- Strength of MaterialsDocument11 paginiStrength of Materialsjerold_arandiaÎncă nu există evaluări

- Mechanics of Deformable Bodies Solved ProblemsDocument10 paginiMechanics of Deformable Bodies Solved ProblemsYan NieÎncă nu există evaluări

- Mechanics of Materials: Beam DeflectionsDocument69 paginiMechanics of Materials: Beam Deflectionssayqa100% (1)

- Beam DeflectionsDocument33 paginiBeam DeflectionsJoniel Rosal Jayag100% (1)

- Quiz No. 3Document2 paginiQuiz No. 3naikin_1031Încă nu există evaluări

- Engineering Correlation Engineering CorrelationDocument8 paginiEngineering Correlation Engineering CorrelationMarbel PerezÎncă nu există evaluări

- Strength of Materials, 4th Edition (Solutions Manual) - Singer, PytelDocument286 paginiStrength of Materials, 4th Edition (Solutions Manual) - Singer, PytelSamantha CusiÎncă nu există evaluări

- Moren - MODULE 5 - Eccentric ConnectionsDocument13 paginiMoren - MODULE 5 - Eccentric ConnectionsJoshua Espanto MorenÎncă nu există evaluări

- CH-3 Strength of MaterialsDocument33 paginiCH-3 Strength of Materialsethiopia ethiopia100% (2)

- Stress and Strain RenewDocument65 paginiStress and Strain Renewshafarizy100% (1)

- Elementary Theory of StructuresDocument112 paginiElementary Theory of StructuresGodwin AcquahÎncă nu există evaluări

- ECS448 - Topic 4 (Cables)Document54 paginiECS448 - Topic 4 (Cables)dixn__Încă nu există evaluări

- 2 Slope Deflection Method For Statically Indeterminate Portal FrameDocument31 pagini2 Slope Deflection Method For Statically Indeterminate Portal Framezulizwxn100% (1)

- Lecture 2 SLOPE DEFLECTIONDocument38 paginiLecture 2 SLOPE DEFLECTIONLaila Azreen100% (4)

- Determinacy, Indeterminacy and StabilityDocument17 paginiDeterminacy, Indeterminacy and StabilityShepherd NhangaÎncă nu există evaluări

- Flexural Stresses by The Elastic CurveDocument24 paginiFlexural Stresses by The Elastic CurveKristelle Ginez100% (1)

- Strength of MaterialsDocument57 paginiStrength of MaterialsFrancis Dwight Maglinte100% (2)

- Torsion 6th ChapterDocument13 paginiTorsion 6th ChapterakshatbhargavaÎncă nu există evaluări

- 7 - Analysis and Design of T-BeamsDocument16 pagini7 - Analysis and Design of T-BeamsgarhgelhÎncă nu există evaluări

- HydraulicsDocument12 paginiHydraulicsMugiwara Sparrow0% (1)

- Strength of MaterialsDocument29 paginiStrength of Materialsrubyshaji96Încă nu există evaluări

- Statics Problems & SolutionsDocument39 paginiStatics Problems & SolutionsYanli Baltero Cruz100% (1)

- Module 3-1 Stress-Strain RelationshipDocument48 paginiModule 3-1 Stress-Strain RelationshipJersey MagpayoÎncă nu există evaluări

- Shear and MomentDocument70 paginiShear and MomentDhyz Quinquilleria100% (4)

- Design of Compression Members-3Document62 paginiDesign of Compression Members-3eseem0% (1)

- Strength of Materials: Prepared By: Engr. Jeric P. SarteDocument30 paginiStrength of Materials: Prepared By: Engr. Jeric P. SarteGiacomo EllieÎncă nu există evaluări

- Strenght of Mat DR AhmedDocument184 paginiStrenght of Mat DR AhmedAlaomda Albasrawy100% (1)

- Vector Mech 01Document168 paginiVector Mech 01Azahar Bin Hashim0% (1)

- Simple Strain PDFDocument9 paginiSimple Strain PDFCharlene Anne Austria VillarozaÎncă nu există evaluări

- Strength of MaterialDocument105 paginiStrength of MaterialMuhammad Assim Baig80% (10)

- Homework 1 3Document6 paginiHomework 1 3inisdeprawn100% (2)

- Cables and ArchesDocument22 paginiCables and ArchesFouad KehilaÎncă nu există evaluări

- Mechanics of Deformable Bodies Review ProblemsDocument7 paginiMechanics of Deformable Bodies Review ProblemsadrianÎncă nu există evaluări

- Structural Steel Design by Besavilla Download PDFDocument2 paginiStructural Steel Design by Besavilla Download PDFJefferd PaetÎncă nu există evaluări

- Strengths of Materials Simple, Bearing and SHearing Stress Answer KeysDocument13 paginiStrengths of Materials Simple, Bearing and SHearing Stress Answer Keyskitzm67% (3)

- Strength 1 Practice Problems - 240119 - 231420Document7 paginiStrength 1 Practice Problems - 240119 - 231420john patrick punsalanÎncă nu există evaluări

- Solution of Strength of Materials ProblemsDocument12 paginiSolution of Strength of Materials ProblemsPaul Charles Macaling100% (2)

- Strength of Materials Objective and Conventional by S K MondalDocument434 paginiStrength of Materials Objective and Conventional by S K Mondalpadalakirankumar33% (3)

- Arches and CablesDocument21 paginiArches and CablesAriel Dela CruzÎncă nu există evaluări

- ES 64 - EXAM 2 FiNALDocument5 paginiES 64 - EXAM 2 FiNALGlimmer Dawn Loredo OrdanielÎncă nu există evaluări

- Mechanics and Materials: Chapter 6: BendingDocument37 paginiMechanics and Materials: Chapter 6: BendingMuhammad Mumtaz Ahmad100% (1)

- Ce6306 Strength of Materials Lecture NotesDocument34 paginiCe6306 Strength of Materials Lecture NotesRakeshkumarcegÎncă nu există evaluări

- Chapter 5 Flexural MembersDocument40 paginiChapter 5 Flexural MembersAriel Dela CruzÎncă nu există evaluări

- Problems Set 04 With SolutionsDocument10 paginiProblems Set 04 With Solutionsjutt4all100% (1)

- Bending Stresses & Direct Stresses CombinedDocument12 paginiBending Stresses & Direct Stresses Combinedvsathees2350% (2)

- Chapter 05 Compound StressesDocument7 paginiChapter 05 Compound StressesAshish KumarÎncă nu există evaluări

- Circular Shaft em 327: Mechanics of Materials Laboratory: ObjectivesDocument4 paginiCircular Shaft em 327: Mechanics of Materials Laboratory: ObjectivesSumit SharmaÎncă nu există evaluări

- Chapter 2 - Stresses in Machine Elements-1Document8 paginiChapter 2 - Stresses in Machine Elements-1felixnziokiÎncă nu există evaluări

- Transverse Shear Stresses in BeamsDocument6 paginiTransverse Shear Stresses in BeamsMijhael Anatholi Romero MamaniÎncă nu există evaluări

- Torsion of Circular Sections: Recitation #6 October 14, 2003Document12 paginiTorsion of Circular Sections: Recitation #6 October 14, 2003Krm ChariÎncă nu există evaluări

- 1.mechanical Technology A Two Year Course 257 294 - Compressed 20 38Document19 pagini1.mechanical Technology A Two Year Course 257 294 - Compressed 20 38josh harleedÎncă nu există evaluări

- Strength of Material (Stress and Strain)Document31 paginiStrength of Material (Stress and Strain)Mg SicsicÎncă nu există evaluări

- 2-Wire Drawing-Prof - Dr.Hani Aziz Ameen PDFDocument15 pagini2-Wire Drawing-Prof - Dr.Hani Aziz Ameen PDFHani Aziz AmeenÎncă nu există evaluări

- Stess Elasticity Prof - Dr.hani Aziz AmeenDocument53 paginiStess Elasticity Prof - Dr.hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- 7-Blanking and Piercing-Prof - Dr.hani AzizDocument4 pagini7-Blanking and Piercing-Prof - Dr.hani AzizHani Aziz AmeenÎncă nu există evaluări

- 8-High Rate Enfergy Forming-Prof - Dr.haniDocument7 pagini8-High Rate Enfergy Forming-Prof - Dr.haniHani Aziz AmeenÎncă nu există evaluări

- 4-Extrusion Process-Prof - Dr.hani Aziz AmeenDocument42 pagini4-Extrusion Process-Prof - Dr.hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Formability of Laser WeldingDocument9 paginiFormability of Laser WeldingHani Aziz AmeenÎncă nu există evaluări

- Experimental and Theoretical Investigation of Impact Dynamic Plasticity For CK45 - Hani Aziz AmeenDocument9 paginiExperimental and Theoretical Investigation of Impact Dynamic Plasticity For CK45 - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- The Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenDocument21 paginiThe Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Rolling Process-Prof - Dr.hani Aziz AmeenDocument18 paginiRolling Process-Prof - Dr.hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- RESIDUAL ELASTO-PLASTIC STRESSES ANALYSIS OF POLYMERIC THICK - WALLED PRESSURIZED CYLINDER - Hani Aziz AmeenDocument14 paginiRESIDUAL ELASTO-PLASTIC STRESSES ANALYSIS OF POLYMERIC THICK - WALLED PRESSURIZED CYLINDER - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- شهادة تقديرية - دكتور هاني عزيز أمين PDFDocument1 paginăشهادة تقديرية - دكتور هاني عزيز أمين PDFHani Aziz AmeenÎncă nu există evaluări

- Moving and Repeating Load in Ansys APDL - Hani Aziz AmeenDocument4 paginiMoving and Repeating Load in Ansys APDL - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Deep Drawing - Prof - Dr.hani Aziz AmeenDocument17 paginiDeep Drawing - Prof - Dr.hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Finite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenDocument16 paginiFinite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Static and Dynamic Characteristics of Slotted Cylinder SpringDocument12 paginiStatic and Dynamic Characteristics of Slotted Cylinder SpringHani Aziz AmeenÎncă nu există evaluări

- The Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenDocument21 paginiThe Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Effect of Post-Buckling On The Stiffness and Stress of Plate - Hani Aziz AmeenDocument16 paginiEffect of Post-Buckling On The Stiffness and Stress of Plate - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Ansys Analysis of Concrete Planter Round PDFDocument6 paginiAnsys Analysis of Concrete Planter Round PDFHani Aziz AmeenÎncă nu există evaluări

- Professor DR Hani Aziz AmeenDocument1 paginăProfessor DR Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Effect of Loading Path On Stress DistributionDocument12 paginiEffect of Loading Path On Stress DistributionHani Aziz AmeenÎncă nu există evaluări

- Manufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Document19 paginiManufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Hani Aziz AmeenÎncă nu există evaluări

- Manufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Document19 paginiManufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Hani Aziz AmeenÎncă nu există evaluări

- Slotted Cylinder SpringDocument11 paginiSlotted Cylinder SpringHani Aziz AmeenÎncă nu există evaluări

- Finite Element Analysis of The Dish Multi-Point FormingDocument10 paginiFinite Element Analysis of The Dish Multi-Point FormingHani Aziz AmeenÎncă nu există evaluări

- ANSYS of Groundwater Flow Problem-Hani Aziz AmeenDocument10 paginiANSYS of Groundwater Flow Problem-Hani Aziz AmeenHani Aziz Ameen100% (2)

- Hani Aziz Ameen هاني عزيز امينDocument3 paginiHani Aziz Ameen هاني عزيز امينHani Aziz AmeenÎncă nu există evaluări

- Hani Aziz Ameen هاني عزيز امينDocument3 paginiHani Aziz Ameen هاني عزيز امينHani Aziz AmeenÎncă nu există evaluări

- PDF Created With Pdffactory Pro Trial VersionDocument1 paginăPDF Created With Pdffactory Pro Trial VersionHani Aziz AmeenÎncă nu există evaluări

- Hani Aziz Ameen هاني عزيز امينDocument3 paginiHani Aziz Ameen هاني عزيز امينHani Aziz AmeenÎncă nu există evaluări

- PDF Created With Pdffactory Pro Trial VersionDocument1 paginăPDF Created With Pdffactory Pro Trial VersionHani Aziz AmeenÎncă nu există evaluări

- Fluid Mechanics Unit 1 - Question BankDocument2 paginiFluid Mechanics Unit 1 - Question BankVaibhavÎncă nu există evaluări

- Eota TR 068 Design Structural Connections Column ShoesDocument13 paginiEota TR 068 Design Structural Connections Column ShoesthaibinhkxÎncă nu există evaluări

- Second Law of Thermodynamics in Terms of EntropyDocument9 paginiSecond Law of Thermodynamics in Terms of Entropykhandaker raiyanÎncă nu există evaluări

- Corrosion Fatigue of Precipitation-Hardening Martensitic Stainless SteelDocument8 paginiCorrosion Fatigue of Precipitation-Hardening Martensitic Stainless SteelMahsaÎncă nu există evaluări

- Hydraulics 2Document20 paginiHydraulics 2UserÎncă nu există evaluări

- LESSON 4 - General Transport EquationsDocument4 paginiLESSON 4 - General Transport EquationsPamela MendozaÎncă nu există evaluări

- Asme BPVC - Ssc.vii - Ii.v.ix - Xiii-2023Document54 paginiAsme BPVC - Ssc.vii - Ii.v.ix - Xiii-2023mmendozagÎncă nu există evaluări

- Engineering Structures: Qiang Han, Yulong Zhou, Yuchen Ou, Xiuli DuDocument12 paginiEngineering Structures: Qiang Han, Yulong Zhou, Yuchen Ou, Xiuli Duserkanozen80Încă nu există evaluări

- Thermodynamics Steam TableDocument10 paginiThermodynamics Steam Tablependrive80Încă nu există evaluări

- ENSC 13 Course Outline (Sum13-14)Document5 paginiENSC 13 Course Outline (Sum13-14)Maricar MingoyÎncă nu există evaluări

- Finite Element Analysis of The Direct Shear Box Test - Potts (1987) PDFDocument13 paginiFinite Element Analysis of The Direct Shear Box Test - Potts (1987) PDFAlfredo López HernándezÎncă nu există evaluări

- Heat Transfer - Activity 3.1 - Fundamentals of Convection (Cognitive Domain)Document18 paginiHeat Transfer - Activity 3.1 - Fundamentals of Convection (Cognitive Domain)Kamille NayraÎncă nu există evaluări

- Hind ERS 31 (LV)Document2 paginiHind ERS 31 (LV)Rajesh GiriÎncă nu există evaluări

- PLP P-9-2003, Mechanical Refrigeration-2nd Ed-RosenDocument55 paginiPLP P-9-2003, Mechanical Refrigeration-2nd Ed-Rosenivanov5559Încă nu există evaluări

- EMG 2502 - Tutorial Sheet 4Document21 paginiEMG 2502 - Tutorial Sheet 4Mogeni HenryÎncă nu există evaluări

- Critical Review - Feyel FE2 PDFDocument14 paginiCritical Review - Feyel FE2 PDFyusufcatiÎncă nu există evaluări

- CH1101 Physical Chemistry: Dr. Paula Colavita School of ChemistryDocument41 paginiCH1101 Physical Chemistry: Dr. Paula Colavita School of Chemistrydlupu_30Încă nu există evaluări

- Thermal Conductivity of Metal Rod: Instruction ManualDocument8 paginiThermal Conductivity of Metal Rod: Instruction ManualAdityaÎncă nu există evaluări

- Low Speed Aerodynamics ASE 320: Lecture 5: Fluid StaticsDocument15 paginiLow Speed Aerodynamics ASE 320: Lecture 5: Fluid StaticsMert BağrıyanıkÎncă nu există evaluări

- Chap 2 PDFDocument36 paginiChap 2 PDFCemre KuzeyÎncă nu există evaluări

- SC F1 - Chapter 7Document10 paginiSC F1 - Chapter 7Azrul EffindiÎncă nu există evaluări

- Engineering Mathematics-Iii: Visvesvaraya Technological University, BelagaviDocument134 paginiEngineering Mathematics-Iii: Visvesvaraya Technological University, BelagavirameshÎncă nu există evaluări

- Chemical and Mechanical Engineering 2300 / Thermodynamics I: Problem 1Document6 paginiChemical and Mechanical Engineering 2300 / Thermodynamics I: Problem 1Takishima N VovoÎncă nu există evaluări

- TDS - Published - CREEP IN TIMBERDocument17 paginiTDS - Published - CREEP IN TIMBERcenewo7114Încă nu există evaluări

- 18Mee305T - Finite Element Method: SRM Institute of Science and TechnologyDocument20 pagini18Mee305T - Finite Element Method: SRM Institute of Science and TechnologyjumkalakaÎncă nu există evaluări

- Wind Load (NSCP)Document1 paginăWind Load (NSCP)dantevarias100% (4)

- jspd170003 1494449798282Document13 paginijspd170003 1494449798282Biplab DasÎncă nu există evaluări

- Pembahasan To 2020 2021Document32 paginiPembahasan To 2020 2021Samantha Regina HanayoÎncă nu există evaluări

- PHYDocument5 paginiPHYfnadhrahAs ssÎncă nu există evaluări

- HP Steam Turbine StageDocument8 paginiHP Steam Turbine StageTarun ChoudharyÎncă nu există evaluări

- Advanced Modelling Techniques in Structural DesignDe la EverandAdvanced Modelling Techniques in Structural DesignEvaluare: 5 din 5 stele5/5 (3)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDe la EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresEvaluare: 1 din 5 stele1/5 (2)

- Marine Structural Design CalculationsDe la EverandMarine Structural Design CalculationsEvaluare: 4.5 din 5 stele4.5/5 (13)

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (137)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDe la EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsÎncă nu există evaluări

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- Structural Cross Sections: Analysis and DesignDe la EverandStructural Cross Sections: Analysis and DesignEvaluare: 4.5 din 5 stele4.5/5 (19)

- The Long Hangover: Putin's New Russia and the Ghosts of the PastDe la EverandThe Long Hangover: Putin's New Russia and the Ghosts of the PastEvaluare: 4.5 din 5 stele4.5/5 (76)

- Predicting Lifetime for Concrete StructureDe la EverandPredicting Lifetime for Concrete StructureÎncă nu există evaluări

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesDe la EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraEvaluare: 4.5 din 5 stele4.5/5 (4)

- Ukraine: What Everyone Needs to KnowDe la EverandUkraine: What Everyone Needs to KnowEvaluare: 4.5 din 5 stele4.5/5 (117)

- Engineering for Kids: Building and Construction Fun | Children's Engineering BooksDe la EverandEngineering for Kids: Building and Construction Fun | Children's Engineering BooksEvaluare: 3 din 5 stele3/5 (2)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDe la EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingÎncă nu există evaluări

- Pile Design and Construction Rules of ThumbDe la EverandPile Design and Construction Rules of ThumbEvaluare: 4.5 din 5 stele4.5/5 (15)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDe la EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsEvaluare: 4 din 5 stele4/5 (16)

- Built: The Hidden Stories Behind Our StructuresDe la EverandBuilt: The Hidden Stories Behind Our StructuresEvaluare: 4 din 5 stele4/5 (27)

- Design and Construction of Soil Anchor PlatesDe la EverandDesign and Construction of Soil Anchor PlatesEvaluare: 5 din 5 stele5/5 (1)