Documente Academic

Documente Profesional

Documente Cultură

Saph 440

Încărcat de

rinkumax2003Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Saph 440

Încărcat de

rinkumax2003Drepturi de autor:

Formate disponibile

HOT ROLLED STEEL SHEET

JIS G 3113 1990 Hot-Rolled Steel Plates, Sheets and Strip for Automobile Structural Uses

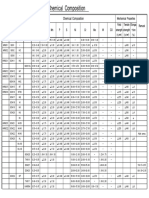

Chemical Composition

Symbol SAPH 310, SAPH370, SAPH400, SAPH440 Chemical Composition P 0.040max. S

Unit : %

0.040max.

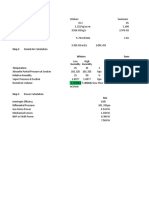

Mechanical Properties

Yield Point N/mm2 Elongation (rolling direction) % No.5 Test Piece Symbol Tensile Thickness Thickness Strength up to 6mm or N/mm2 and excl. over to and excl. 6mm 8mm Thickness 8mm or Thickness Thickness over to 1.6 or 2.0 or and incl. over to over to 14mm and and excl. excl. 2.0mm 2.5mm Thickness 2.5 or over to and excl. 3.15mm Thickness 3.15 or over to and excl. 4.0mm No.1 A Test Piece Bendability Inside Radius

Thickness Bending Test 4.0 or Thickness Thickness Angle Thickness Piece over to up to 6.3mm 2.0mm and and excl. or over or over excl. 2.0mm 6.3mm

Flat on itself Thickness 180 0.5 Thickness 180 1.0 Thickness 180 1.0 180 Thickness 1.0 No.3 Thickness trans 1.0 versely Thickness to rolling 1.0 direction Thickness 1.5

SAPH 310 310min. (185)min. (185)min. (175)min. 33min. 34min. 36min. 38min. 40min. 26min. SAPH 370 370min. 225min. 225min. 215min. 32min. 33min. 35min. 36min. 37min. 25min. SAPH 400 400min. 255min. 235min. 235min. 31min. 32min. 34min. 35min. 36min. 24min. SAPH 440 440min. 305min. 295min. 275min. 29min. 30min. 32min. 33min. 34min. 22min.

Remarks : 1. The values specified in the above table shall no to be applied to the irregular portions of both ends of the steel coil. 2. The figures in ( ) are given for informative reference.

JIS G 3116 2000

Steel sheets, plates and strip for gas cylinders

Unit : %

Chemical Composition

Symbol SG 255 SG 295 SG 325 SG 365 Chemical Composition C 0.20 max. 0.20 max. 0.20 max. 0.20 max. Si

Mn 0.30 max. 1.00 max. 1.50 max. 1.50 max.

P 0.040 max. 0.040 max. 0.040 max. 0.040 max.

S 0.040 max. 0.040 max. 0.040 max. 0.040 max.

0.35 max. 0.55 max. 0.55 max.

Remarks : Alloying elements other than those shown in the table may be added if necessary.

Mechanical Properties

Symbol Yield Point or Tensile Elongation Proof Stress Strength N/ % 2 2 N/mm mm 255min. 295min. 325min. 365min. 400min. 440min. 490min. 540min. 28min. 26min. 22min. 20min. No.5 in rolling direction Tensile Test Piece Bendability Bending Angle 180 180 180 180 Thickness 1.5 Inside Radius Thickness 1.0 No.3 in rolling direction Test Piece

SG 255 SG 295 SG 325 SG 365

Remarks : The values specified shall not be applied for irregular portions on each end of steel strip.

29

Excerpts from public standards

S-ar putea să vă placă și

- 32 Steel PDFDocument1 pagină32 Steel PDFIrfan DzakyÎncă nu există evaluări

- Comparison Table of Cast Aluminum Alloy GradesDocument2 paginiComparison Table of Cast Aluminum Alloy GradesdeanwinshesterÎncă nu există evaluări

- Al. Alloy Chemical CompositionDocument9 paginiAl. Alloy Chemical Compositionketan1965Încă nu există evaluări

- Case HardeningDocument84 paginiCase HardeningMduduzi Magiva Mahlangu100% (1)

- Automotive Grade PDFDocument3 paginiAutomotive Grade PDFGuilhermeDirksenÎncă nu există evaluări

- Aluminum Alloy Specification'Document12 paginiAluminum Alloy Specification'ArjunÎncă nu există evaluări

- Parts Catalogue: Glamour (May, 2012)Document101 paginiParts Catalogue: Glamour (May, 2012)JimJiangÎncă nu există evaluări

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39De la EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Evaluare: 5 din 5 stele5/5 (1)

- Compressor Torque Manual GES089Document93 paginiCompressor Torque Manual GES089Jeff LÎncă nu există evaluări

- 70ZV 2 BrochureDocument12 pagini70ZV 2 BrochurepedrofalfanÎncă nu există evaluări

- Pfaudler Din Be Reactors 1Document42 paginiPfaudler Din Be Reactors 1Nancy GarciaÎncă nu există evaluări

- Gray and Ductile Iron Grade Comparison TableDocument2 paginiGray and Ductile Iron Grade Comparison Tableariefihsan100% (1)

- Blower Power CalculationsDocument7 paginiBlower Power CalculationsMuzzamilÎncă nu există evaluări

- Heat Resistant Alloy Chemical CompositionDocument2 paginiHeat Resistant Alloy Chemical Compositionsusisaravanan100% (1)

- Ductile IronDocument159 paginiDuctile IronPrabhakar KattulaÎncă nu există evaluări

- Jis G3113 1990Document11 paginiJis G3113 1990TUAN NGUYEN VANÎncă nu există evaluări

- Manual MisiaDocument60 paginiManual MisiaErc Nunez VÎncă nu există evaluări

- JIS G 3141 Commercial Cold Rolled SPCC SteelsDocument6 paginiJIS G 3141 Commercial Cold Rolled SPCC SteelsAnonymous 8lxxbNcA0sÎncă nu există evaluări

- Failure of Secondary Reformer RefractoryDocument27 paginiFailure of Secondary Reformer RefractoryZeshanÎncă nu există evaluări

- Analysis On The Cause of Longitudinal Crack On The Hot-Rolled Ribbed Bar SurfaceDocument5 paginiAnalysis On The Cause of Longitudinal Crack On The Hot-Rolled Ribbed Bar SurfaceTanjidul IslamÎncă nu există evaluări

- 2.CH890.02 - IMA - S 223.1422-02.enDocument63 pagini2.CH890.02 - IMA - S 223.1422-02.enJoe Vargas JulcaÎncă nu există evaluări

- Bisalloy's PlatesDocument16 paginiBisalloy's PlatesMarcoÎncă nu există evaluări

- JIS G3521 WIRE SpecificationsDocument2 paginiJIS G3521 WIRE SpecificationsalexgtzlzÎncă nu există evaluări

- C 45Document10 paginiC 45mohsen_267Încă nu există evaluări

- Jis G4052-1979Document39 paginiJis G4052-1979RanjithkumarÎncă nu există evaluări

- HGM410 HGM420 V1.6 enDocument44 paginiHGM410 HGM420 V1.6 enDante Marcelo Obinu HidalgoÎncă nu există evaluări

- Steel CleanlinessDocument22 paginiSteel CleanlinessfondershellÎncă nu există evaluări

- CR StandardsDocument6 paginiCR Standardsalpha_beta48Încă nu există evaluări

- Nisshin Cold-Rolled Special Steel GuideDocument28 paginiNisshin Cold-Rolled Special Steel GuideekopujiantoeÎncă nu există evaluări

- DIN 17022-5 - Heat Treating of Ferrous Materials PDFDocument13 paginiDIN 17022-5 - Heat Treating of Ferrous Materials PDFFelipe FernandesÎncă nu există evaluări

- High Tensile Steel 4340Document2 paginiHigh Tensile Steel 4340CarmenJuliaÎncă nu există evaluări

- General Tolerances For Linear and Angular Dimnsions (Din Iso 2768 t1)Document1 paginăGeneral Tolerances For Linear and Angular Dimnsions (Din Iso 2768 t1)VIVEK UPADHYAYÎncă nu există evaluări

- SPCCDocument10 paginiSPCCDeepak JainÎncă nu există evaluări

- Tabel AISI ASTM (Selected)Document5 paginiTabel AISI ASTM (Selected)Dini Adilah PrabowoÎncă nu există evaluări

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Document5 paginiSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiÎncă nu există evaluări

- Agarwal Fastners Pvt. Ltd.Document1 paginăAgarwal Fastners Pvt. Ltd.satyam nagaichÎncă nu există evaluări

- Riview On Cold Drawing Process PDFDocument7 paginiRiview On Cold Drawing Process PDFAmandeep Singh GujralÎncă nu există evaluări

- 3coated SteelDocument20 pagini3coated Steelalifakash1605Încă nu există evaluări

- Indian Standard Designation of SteelsDocument1 paginăIndian Standard Designation of Steelssushil.vgi75% (4)

- JIS G 3193 steel sheet specsDocument3 paginiJIS G 3193 steel sheet specsAngga KurniawanÎncă nu există evaluări

- PS 1804 (S)Document19 paginiPS 1804 (S)dzilioÎncă nu există evaluări

- Sintered Metal Bush ProductionDocument5 paginiSintered Metal Bush Production124swadeshiÎncă nu există evaluări

- V Groove WheelDocument3 paginiV Groove Wheelthirumalg1981Încă nu există evaluări

- TOOL AND DIE STEEL FinalDocument73 paginiTOOL AND DIE STEEL FinalSapan KansaraÎncă nu există evaluări

- 2370 Ed1 ENDocument5 pagini2370 Ed1 ENanhthoÎncă nu există evaluări

- MSI DC 01 FosecoDocument4 paginiMSI DC 01 FosecoVivek Shrivastava100% (1)

- Jis 3193 PDFDocument3 paginiJis 3193 PDFAngga KurniawanÎncă nu există evaluări

- S355 European Standard SteelDocument7 paginiS355 European Standard SteelmaiquelernÎncă nu există evaluări

- Aisi 1010 Carbon Steel (Uns g10100)Document5 paginiAisi 1010 Carbon Steel (Uns g10100)spiderblackÎncă nu există evaluări

- High Carbon Wire RodDocument9 paginiHigh Carbon Wire Rodninganray6316100% (1)

- About En19Document1 paginăAbout En19ramanamurtytv7176Încă nu există evaluări

- Materials Comparison: Steel Grades in JIS, Foreign, and European StandardsDocument1 paginăMaterials Comparison: Steel Grades in JIS, Foreign, and European Standardswulfgang66Încă nu există evaluări

- Preventing Scale Loss During Heat Treatment & Hot Forging - With ImagesDocument17 paginiPreventing Scale Loss During Heat Treatment & Hot Forging - With ImagesSrikar Shenoy100% (1)

- BS 6615 Iso 8062-CT7Document2 paginiBS 6615 Iso 8062-CT7Purushothama Nanje GowdaÎncă nu există evaluări

- CRCA (Cold Rolled Close Annealed Coils) Specifications: As Per IsDocument2 paginiCRCA (Cold Rolled Close Annealed Coils) Specifications: As Per Isray_k_9177100% (9)

- Weld Wire CatalogDocument50 paginiWeld Wire CatalogMurdock Howling MadÎncă nu există evaluări

- Claw Pole Forging ProcessDocument8 paginiClaw Pole Forging ProcessBhagat SinghÎncă nu există evaluări

- Jis G 3466 - 2006 (JP)Document11 paginiJis G 3466 - 2006 (JP)HongHaiDuongÎncă nu există evaluări

- Stelex ProDocument4 paginiStelex ProRafael TellezÎncă nu există evaluări

- Material Definitions & TermsDocument3 paginiMaterial Definitions & TermsDr_M_SolimanÎncă nu există evaluări

- JIS G4801 SUP10 Steel GuideDocument2 paginiJIS G4801 SUP10 Steel GuideĐình Sỹ TTPÎncă nu există evaluări

- Continuous casting The Ultimate Step-By-Step GuideDe la EverandContinuous casting The Ultimate Step-By-Step GuideÎncă nu există evaluări

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesDe la EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesÎncă nu există evaluări

- Mahindra StandardDocument6 paginiMahindra StandardSuresh Shinde67% (3)

- AS 1397 ZAM Coating StandardsDocument1 paginăAS 1397 ZAM Coating StandardsCao SonÎncă nu există evaluări

- Press q3 Ass 2Document5 paginiPress q3 Ass 2Arslan RaoÎncă nu există evaluări

- Denison Hydraulics Stack Valves Cetop 03 GuideDocument13 paginiDenison Hydraulics Stack Valves Cetop 03 Guideabuzer1981100% (1)

- Cypecad Vs Etabs - En1Document37 paginiCypecad Vs Etabs - En1dskumar49Încă nu există evaluări

- Rao 1961Document10 paginiRao 1961Sãröj ShâhÎncă nu există evaluări

- Frames of reference in physics and their usesDocument6 paginiFrames of reference in physics and their usesPrateek SharmaÎncă nu există evaluări

- Sany Crane-Brochure STC250C5-YR1Document9 paginiSany Crane-Brochure STC250C5-YR1Shayan MehboobÎncă nu există evaluări

- Thermal Management of Electronics Using Phase ChangeDocument9 paginiThermal Management of Electronics Using Phase ChangeRaj kumarÎncă nu există evaluări

- DrillchartDocument5 paginiDrillchartcc6689Încă nu există evaluări

- พอฤทัย วิริยะภาค26 3.5Document2 paginiพอฤทัย วิริยะภาค26 3.55.6 25 [พิงค์แพรว]นางสาวพอฤทัย วิริยะภาคÎncă nu există evaluări

- Manual Termostato Digitall t6812 FancoilDocument4 paginiManual Termostato Digitall t6812 FancoilaarroyofÎncă nu există evaluări

- NR24R Imo InformmationDocument12 paginiNR24R Imo Informmationronny ArdiansyahÎncă nu există evaluări

- MAN L35mc6 S35MC7Document6 paginiMAN L35mc6 S35MC7Shree ChavanÎncă nu există evaluări

- VTU Mechanical Engineering Internship ReportDocument39 paginiVTU Mechanical Engineering Internship ReportNiXx HBÎncă nu există evaluări

- Understanding Wind Power TechnologyDocument14 paginiUnderstanding Wind Power TechnologyDiego ZayasÎncă nu există evaluări

- Mechanical TestingDocument2 paginiMechanical Testinggosaye desalegnÎncă nu există evaluări

- Worksheets LS2 HeatLightSoundDocument4 paginiWorksheets LS2 HeatLightSoundAngeline Panaligan Ansela83% (6)

- Viva QuestionsDocument16 paginiViva Questionsjpsridhar100% (1)

- Effects of Shear Box Size and Silt Content on Strength of Silty SandsDocument7 paginiEffects of Shear Box Size and Silt Content on Strength of Silty SandsJavier MtÎncă nu există evaluări

- Galant CH 2 Engine Electrical PDFDocument14 paginiGalant CH 2 Engine Electrical PDFjustcheerfulÎncă nu există evaluări

- Introduction of Control Systems and Basic TerminologyDocument12 paginiIntroduction of Control Systems and Basic TerminologyShivaji ThubeÎncă nu există evaluări

- Theory of ElasticityDocument719 paginiTheory of ElasticityAlberto Gaxiola HernándezÎncă nu există evaluări