Documente Academic

Documente Profesional

Documente Cultură

Piping Specifications

Încărcat de

smithallenDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Piping Specifications

Încărcat de

smithallenDrepturi de autor:

Formate disponibile

f ESSAR

Essar Engineering Services Limited

Piping Material Specification

.,,

8001-HN-110015

~ 0 1 ~ 1 Revision: 1

Piping Material Specification

1 Rev 1 Date 1

Purpose

1 Prepared By

Checked By Approved BY

8001-HN-110015

Piping Material Specification

Essar Engineering Services Limited

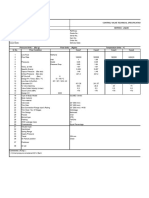

Pipe Class: A01B-1 Revision: 1

Rating Class: Type of Material: Spec Valve Trim: Corrosion Allowance: Type of Service: Type of Service: Type of Service: Type of Service: Type of Service: Type of Service: Type of Service: Type of Service: Type of Service: Type of Service: Special Requirements: Min. Design Temp:

150, ASME B16.5/ASME B16.47 (B) Carbon Steel 13% CR, STELLITED 1.0 mm SWEET TREATED COOLING WATER, T>100 DEG.C COKE QUENCHING WATER STEAM (P<3.5 BAR) CONDENSATE STEAM TRACING TRACERS PROCESS / RAW / UTILITY WATER OIL CONTAMINATED WATER PLANT AIR, NITROGEN INSTRUMENT AIR (BEFORE FILTERS) STORM WATER (U/G) (UNDER CONCRETE PAVING)(COATED AND WRAPPED) PIPING TO BE DESIGNED UNDER FULL VACUUM CONDITION -29 Deg C

PRESSURE-TEMPERATURE RATINGS

SIZE Deg_C Kg/cm2G .5-14 26 20 .5-14 300 10.4 30-30 65 10 .5-14 350 8.6 42-42 65 10.01 .5-14 400 6.6 .5-14 100 18 .5-14 427 5.5 16-16 120 12 20-24 120 12.01 26-26 120 5.5 28-28 120 12.02 32-32 120 3.5 .5-14 150 16.1 18-18 170 3.5 .5-14 200 14.1 .5-14 250 12.3 36-36 280 5.2

PIPE-SCHEDULE RATINGS

NPS SCHED

.5 S-40 12 S-20 32 S-10

.75 S-40 14 S-10 36 S-10

1 S-40 16 S-10 40 CALC

1.5 S-40 18 S-10 42 S-STD

2 S-40 20 S-20 48 CALC

3 S-40 22 CALC

4 S-40 24 S-10

6 S-40 26 S-STD

8 S-20 28 S-STD

10 S-20 30 S-STD

NOTES:

1 2 3 4 5 6 7 8 PRESSURE / TEMPERATURE RATING IS BASED ON FLANGE RATING ACCORDING TO ASME B16.5, GROUP 1.1 FOR VENTS & DRAINS ONLY FOR TESTING VENTS & TESTING DRAINS ONLY FOR ORIFICE FLANGES & CLASS 300 CONNECTIONS ONLY FOR ORIFICE INSTRUMENT CONNECTIONS ONLY. FOR INSTRUMENT CONNECTIONS ON EQUIPMENT ONLY THIS DOCUMENT IS PREPARED BASED ON ABB PIPE SPEC A01B-1 REV. 3 EXTENDED BODY VALVES TO BE FABRICATED AT SITE.

8001-HN-110015

Piping Material Specification

Essar Engineering Services Limited

Pipe Class: A01B-1 Revision: 1

9 10 11 12 13 14 15 16 17 18 19 20

FOR THERMOWELL ONLY, INSULATION THICKNESS UPTO 65MM, THE NOZZLE PROJECTION SHALL BE 150MM, AND FOR ABOVE 65MM, THE NOZZLE PROJECTION SHALL BE 200MM FOR INSTRUMENT CONNECTIONS ONLY. COMMODITY CODES FOR LOCK OPEN AND LOCK CLOSED VALVES USE ONLY IF MENTIONED IN P&ID TEMP LIMITED TO 204 DEG C PIPE OF SCHEDULE XS TO BE USED ONLY FOR THREADED CONNECTIONS. PIPELINE CONNECTOR & STEAM TRAP TO BE USED AS AN ASSEMBLY 45DEG BRANCH TABLE ATTACHED IS APPLICABLE ONLY FOR DESIGN PRESSURE LESS THAN 5 KG/CM2G FOR ORIFICE TAPPING ONLY. THERMOSTATIC TRAP TO BE USED ONLY FOR STEAM TRACER LINES FOR ANY OTHER TEMPERATURE-PRESSURE COMBINATION FOR LINE SIZES 16" & ABOVE, WHICH CALL FOR HIGHER THICKNESS FOR PIPE & PIPING COMPONENTS SHALL BE VALIDATED BY RESPECTIVE DEC. FOR THE SIZES HAVING 'CALC' THICKNESS, DEC TO CALCULATE THE THICKNESS BASED ON DESIGN CONDITION.

Piping Material Specification

Essar Engineering Services Limited

8001-HN-110015 Pipe Class: A01B-1 Revision: 1

ITEM

SIZE 1

SIZE 2

SCH/RAT OPTION COMMODITY CODE

DESCRIPTION

NOTES

Pipes & Tubes

NIPL NIPL NIPL NIPL PIP PIP PIP PIP PIP PIP PIP PIP PIP PIP PIP PIP PIP PIP .5-1.5 .5-1.5 .5-1.5 .5-1.5 .5-1.5 .5-1.5 2-3 4-6 8-12 14-18 20-20 22-22 24-24 26-30 32-36 40-40 42-42 48-48 80 80 80 80 1 725 721 743 1 431 1 1 1 1 1 1 1 1 1 1 1 1 ONIPABQPEACRA1C ONIPABQPTACRA1C ONIPABQTMACRA1C ONIPABQPTACRA1B PPPABQPEACRAAG PPPABQTMACRAAG PPPABQBEACRAAG PPPABQBEAEEAAC PPPABQBEAEEAAC PPPABQBEAEEAAC PPPABQBEAEEAAC PPPABQBEAEEAAC PPPABQBEAEEAAC PPPABQBEAEEAAC PPPABQBEAEEAAC PPPABQBEAEEAAC PPPABQBEAEEAAC PPPABQBEAEEAAC Nipple, B36.10M, PBE, A 106 Gr. B, 3" Long , SMLS Nipple, B36.10M, PE/TE, A 106 Gr. B, 3" Long , SMLS Nipple, B36.10M, TBE, A 106 Gr. B, 3" Long , SMLS Nipple, B36.10M, PE/TE, A 106 Gr. B, 6" Long , SMLS Pipe, B36.10M, PE, A 106 Gr. B, SMLS Pipe, B36.10M, MTE, A 106 Gr. B, SMLS Pipe, B36.10M, BE (ASME B16.25), A 106 Gr. B, SMLS Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW Pipe, B36.10M, BE (ASME B16.25), API 5L Gr. B, ERW

17

14

Forged Fittings

90SOL 90TEE 90TRE CAP CAP CPL CPLR E45 E90 NPL PLG SWGC SWGC SWGC SWGE SWGE TOL 90TEE 90TEE 2 - 48 .5 - 1.5 .75 - 1.5 .5 - 1.5 .5 - 1.5 .5 - 1.5 .75 - 1.5 .5 - 1.5 .5 - 1.5 2 - 48 .5 - 1.5 .75 - 1.5 2-2 .75 - 1.5 .75 - 1.5 2-2 2 - 42 2 - 10 12 - 48 .5 - 1.5 .5 - 1 .5 - 1 .5 - 1.5 .25 - 1 .5 - 1.5 .5 - 1 .5 - 1 .5 - 1.5 .5 - 1.5 CL3000 CL3000 CL3000 CL3000 CL3000 CL3000 CL3000 CL3000 CL3000 S-80 S-80 S-80 S-80 S-80 S-80 CL3000 1 1 1 1 521 1 1 1 1 1 1 1 1 711 1 1 1 1 1 OSOCAM9SSWACGZZZ OETEAB2SSWACGZZZ ORTEAB2SSWACGZZZ OCAPAB2STFACGZZZ OCAPAB2SSWACGZZZ OCPLAB2SSWACGZZZ OCPRAB2SSWACGZZZ OE45AB2SSWACGZZZ OE90AB2SSWACGZZZ ONPLAM9SPEACGZZZ OPLHAB2TMACGZZZ OSGCAM8PEACKXAA OSGCAM8BPACKXAA OSGCAM8PCACKXAA OSGEAM8PEACKXAA OSGEAM8BPACKXAA OTHLAM9STFACGZZZ Sockolet, MSS SP-97, CL3000, SWE, A105 Equal Tee, B16.11, CL3000, SWE, A105 Red. Tee, B16.11, CL3000, SWE, A105 6 Cap, B16.11, CL3000, FTE, A105 Cap, B16.11, CL3000, SWE, A105 Full Cplg., B16.11, CL3000, SWE, A105 Red. Cplg., B16.11, CL3000, SWE, A105 45 Deg. Elbow, B16.11, CL3000, SWE, A105 90 Deg. Elbow , B16.11, CL3000, SWE, A105 Nipolet, MSS SP-97, CL3000, PE, A105 Plug Hex Head, B16.11, MTE, A105 2 Con. Swage, MSS SP-95, PBE, A 234 Gr. WPB, SMLS Con. Swage, MSS SP-95, BLE/PSE, A 234 Gr. WPB, SMLS Con. Swage, MSS SP-95, PLE/TSE, A 234 Gr. WPB, SMLS Ecc. Swage, MSS SP-95, PBE, A 234 Gr. WPB, SMLS Ecc. Swage, MSS SP-95, BLE/PSE, A 234 Gr. WPB, SMLS Threadolet, MSS SP-97, CL3000, FTE, A105 3 Eq. Tee, B16.9, BE, A 234 Gr. WPB, SMLS Eq. Tee, B16.9, BE, A 234 Gr. WPB, Welded

BW Fittings

BTEEABMBEACKABA BTEEABMBEACKAAD

Page 1 of 7

Piping Material Specification

Essar Engineering Services Limited

8001-HN-110015 Pipe Class: A01B-1 Revision: 1

ITEM

SIZE 1

SIZE 2

SCH/RAT OPTION COMMODITY CODE

DESCRIPTION

NOTES

BW Fittings

90TRE 90TRE CAP E45 E45 E90 E90 REDC REDC REDE REDE RPAD 2 - 10 12 - 48 2 - 48 2 - 10 12 - 48 2 - 10 12 - 48 3 - 10 12 - 48 3 - 10 12 - 48 4 - 42 1.5 - 8 10 - 42 1.5 - 8 6 - 42 1.5 - 8 6 - 42 2 - 32 1 1 1 1 1 1 1 1 1 1 1 1 BTERABMBEACKABA BTERABMBEACKAAD BCAPABMBEACKABA BE4LABMBEACKABA BE4LABMBEACKAAD BE9LABMBEACKABA BE9LABMBEACKAAD BRECABMBEACKABA BRECABMBEACKAAD BREEABMBEACKABA BREEABMBEACKAAD BRPAAP1PEAEEEAC Red. Tee, B16.9, BE, A 234 Gr. WPB, SMLS Red. Tee, B16.9, BE, A 234 Gr. WPB, Welded Cap, B16.9, BE, A 234 Gr. WPB, SMLS 45 Deg. Elbow 1.5D, B16.9, BE, A 234 Gr. WPB, SMLS 45 Deg. Elbow 1.5D, B16.9, BE, A 234 Gr. WPB, Welded 90 Deg. Elbow 1.5D, B16.9, BE, A 234 Gr. WPB, SMLS 90 Deg. Elbow 1.5D, B16.9, BE, A 234 Gr. WPB, Welded Con. Reducer, B16.9, BE, A 234 Gr. WPB, SMLS Con. Reducer, B16.9, BE, A 234 Gr. WPB, Welded Ecc. Reducer, B16.9, BE, A 234 Gr. WPB, SMLS Ecc. Reducer, B16.9, BE, A 234 Gr. WPB, Welded Reinforcing Pad, B31.3, PE, API 5L Gr. B, 6MM DIA. TAP HOLE Red Splt Tee wth Flg, B16.9, CL150, BE x RF, A 234 Gr. WPB, SMLS Blind Flg., B16.5, CL150, RF, A105, 125 250 Ra Finish Blind Flg., B16.47 Sr. B, CL150, RF, A105, 125 250 Ra Finish Blind Flg., B16.5, CL300, RF, A105, 125 250 Ra Finish SW Flg., B16.5, CL150, RF, A105, 125 250 Ra Finish WN Flg., B16.5, CL150, RF, A105, 125 250 Ra Finish WN Flg., B16.5, CL300, RF, A105, 125 250 Ra Finish , 150 mm long WN Flg., B16.5, CL300, RF, A105, 125 250 Ra Finish , 200 mm long WN Flg., B16.5, CL600, RF, A105, 125 250 Ra Finish WN Flg., B16.47 Sr. B, CL150, RF, A105, 125 250 Ra Finish SW Flg., B16.5, CL300, RF, A105, 125 250 Ra Finish SW Flg., B16.5, CL600, RF, A105, 125 250 Ra Finish WN Flg., B16.5, CL300, RF, A105, 125 250 Ra Finish WN Flg., B16.5, CL1500, RF, A105, 125 250 Ra Finish WN Flg., B16.47 Sr. B, CL300, RF, A105, 125 250 Ra Finish WN Flg., B16.47 Sr. B, CL300, RF, A105, 125 250 Ra Finish Red. WN Flg., B16.5, CL150, RF, A105, 125 250 Ra Finish Red. WN Flg., B16.5, CL150, RF, A105, 125 250 Ra Finish Red. Thd. Flg., B16.5, CL300, RF, A105, 125 250 Ra Finish Paddle Blank, B16.48, CL150, RFTBE, IS 2062 Gr. B, 125 250 Ra Finish Paddle Blank, As per Dwg.No. AS-8001-000-461000111-01, CL150, RFTBE, IS 2062 Gr. B, 125 250 Ra Finish Spectacle Blind, B16.48, CL150, RFTBE, IS 2062 Gr. B, 125 250 Ra Finish

Cmp. Butt Wld. Fitt

RSPT 3 - 10 2-8 CL150 1 XRTABMDXBACKABA

Flanges

FBL FBL FBL FLG FLG FLG FLG FLG FLG FLG FLG FLG FLG FLG FLG FLGR FLGR FLGR .5 - 24 26 - 48 .5 - 24 .5 - 1.5 2 - 24 1 - 1.5 1 - 1.5 2 - 12 26 - 48 .5 - 1.5 .5 - 1.5 2 - 24 2-2 28 - 28 48 - 48 4-4 3-3 2-2 .75 - .75 2-2 .5 - .5 CL150 CL150 CL300 CL150 CL150 CL300 CL300 CL600 CL150 CL300 CL600 CL300 CL1500 CL300 CL300 CL150 CL150 CL300 1 1 773 1 1 173 174 781 1 773 781 773 797 773 773 1 1 1 FBLABLDRFACGA1A FBLABJDRFACGA1A FBLABLIRFACGA1A FSWABLDRFACGA1A FWNABLDRFACGA1A FWNABLIRFACGEAH FWNABLIRFACGEAK FWNABLLRFACGA1A FWNABJDRFACGA1A FSWABLIRFACGA1A FSWABLLRFACGA1A FWNABLIRFACGA1A FWNABLPRFACGA1A FWNABJIRFACGA1A FWNABJIRFACGA1A FRWABLDRFACGA1A FRWABLDRFACGA1A FRTABLIRFACGA1A

9 9 12

10

Discs

BPAD BPAD 18 - 24 26 - 48 CL150 CL150 1 1 DBPA1ADRTXX7AAC DBPXJBDRTXX7AAC

F8

.5 - 16

CL150

DF8A1ADRTXX7AAC

Page 2 of 7

Piping Material Specification

Essar Engineering Services Limited

8001-HN-110015 Pipe Class: A01B-1 Revision: 1

ITEM

SIZE 1

SIZE 2

SCH/RAT OPTION COMMODITY CODE

DESCRIPTION

NOTES

Discs

SPCR SPCR 18 - 24 26 - 48 CL150 CL150 1 1 DBSA1ADRTXX7AAC DBSXJBDRTXX7AAC Paddle Spacer, B16.48, CL150, RFTBE, IS 2062 Gr. B, 125 250 Ra Finish Paddle Spacer, As per Dwg.No. AS-8001-000-461000111-01, CL150, RFTBE, IS 2062 Gr. B, 125 250 Ra Finish Non Metal Flat Gskt, B16.21, CL150, RF, Graphite, 316 SS mesh tang inserted Non Metal Flat Gskt, B16.21, CL150, RF, Graphite, 316 SS mesh tang inserted, B16.47 Series B dimensions Sp. Wound Gskt, B16.20, CL300, RF, 316 SS, graphite Fill, CS CR Sp. Wound Gskt, B16.20, CL600, RF, 316 SS, graphite Fill, CS CR Sp. Wound Gskt, B16.20, CL1500, RF, 316 SS, graphite Fill, CS CR Sp. Wound Gskt, B16.20, CL300, RF, 316 SS, graphite Fill, CS CR, B16.47 Series B dimensions Std Blt & 2 Hex Nut, B18.2.1, A 193 B7 / A 194 2H

Gaskets

GSK GSK .5 - 24 26 - 48 1.6MM 1.6MM CL150 CL150 1 1 GNMAB7DRFXYRZZZ GNMAB7DRFXYRA1D

GSK GSK GSK GSK

.5 - 24 .5 - 12 2-2 26 - 48

4.5MM 4.5MM 4.5MM 4.5MM

CL300 CL600 CL1500 CL300

773 781 797 773

GSWAB6IRFABEZZZ GSWAB6LRFABEZZZ GSWAB6PRFABEZZZ GSWAB6IRFABEA1D

5 12

Bolts

BLT VGAT .5 - 48 .5 - 1.5 CL800 1 1 LSBABNABIZZZ

Gate Valves

VGREWCMSWAFACGAAGXAA Gate Vlv,ISO 15761, CL800, SWE, Bltd Bonnet, Handwheel Operator, A105, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), OS&Y , Graphite Gland Packing , API 598 , Solid Wedge VGREWCMSWAFACGAAGXCC Gate Vlv,ISO 15761, CL800, SWE, Bltd Bonnet, Handwheel Operator, A105, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), OS&Y , Graphite Gland Packing , API 598 , With Valve locking arrangement , Solid Wedge VGREWCMSFAFACGAAGXAA Gate Vlv,ISO 15761, CL800, SWE x FTE, Bltd Bonnet, Handwheel Operator, A105, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), OS&Y , Graphite Gland Packing , API 598 , Solid Wedge VGREWCIRFAFACGAAGXAB Gate Vlv,ISO 15761, CL300, RF, Bltd Bonnet, Handwheel Operator, A105, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), 125 250 Ra Finish , OS&Y , Graphite Gland Packing , API 598 , Solid Wedge VGRBWFDRFABACDAAGXAC Gate Vlv,BS 1414, CL150, RF, Bltd Bonnet, Gear Operator, A 216 Gr. WCB, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), 125 250 Ra Finish , OS&Y , Graphite Gland Packing , API 598 , Flexible Wedge VGRBWFDRFABACDAAGXEF Gate Vlv,BS 1414, CL150, RF, Bltd Bonnet, Gear Operator, A 216 Gr. WCB, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), 125 250 Ra Finish , OS&Y , Graphite Gland Packing , API 598 , With Valve locking arrangement , Flexible Wedge VGRBWFDRFAFACDAAGXAC Gate Vlv,BS 1414, CL150, RF, Bltd Bonnet, Handwheel Operator, A 216 Gr. WCB, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), 125 250 Ra Finish , OS&Y , Graphite Gland Packing , API 598 , Flexible Wedge VGRBWFDRFAFACDAAGXEF Gate Vlv,BS 1414, CL150, RF, Bltd Bonnet, Handwheel Operator, A 216 Gr. WCB, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), 125 250 Ra Finish , OS&Y , Graphite Gland Packing , API 598 , With Valve locking arrangement , Flexible Wedge VGRBWFDRFABACDAAGXAD Gate Vlv,BS 1414, CL150, RF, Bltd Bonnet, Gear Operator, A 216 Gr. WCB, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), ASME B16.47 Series B , 125 250 Ra Finish , OS&Y , Graphite Gland Packing , API 598 , Flexible Wedge VGRBWFDRFABACDAAGXEL Gate Vlv,BS 1414, CL150, RF, Bltd Bonnet, Gear

VGAT

.5 - 1.5

CL800

68

11

VGAT

.5 - 1.5

CL800

714

VGAT

.5 - 1.5

CL300

773

VGAT

14 - 24

CL150

VGAT

14 - 24

CL150

68

11

VGAT

2 - 12

CL150

VGAT

2 - 12

CL150

68

11, 12

VGAT

26 - 42

CL150

VGAT

26 - 42

CL150

68

11

Page 3 of 7

Piping Material Specification

Essar Engineering Services Limited

8001-HN-110015 Pipe Class: A01B-1 Revision: 1

ITEM

SIZE 1

SIZE 2

SCH/RAT OPTION COMMODITY CODE

DESCRIPTION

NOTES

Gate Valves

Operator, A 216 Gr. WCB, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), ASME B16.47 Series B , 125 250 Ra Finish , OS&Y , Graphite Gland Packing , API 598 , With Valve locking arrangement , Flexible Wedge Gate Vlv,BS 1414, CL300, RF, Bltd Bonnet, 6 Handwheel Operator, A 216 Gr. WCB, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), 125 250 Ra Finish , OS&Y , Graphite Gland Packing , API 598 , Flexible Wedge

VGAT

2-3

CL300

773

VGRBWFIRFAFACDAAGXAC

Globe Valves

VGLB .5 - 1.5 CL800 1 VLREWBMSWAFACGAAGXAC Globe Vlv,ISO 15761, CL800, SWE, Bltd Bonnet, Handwheel Operator, A105, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), Plug Disc , OS&Y , Graphite Gland Packing , API 598 VLRBWEDRFAFACDAAGXAD Globe Vlv,BS 1873, CL150, RF, Bltd Bonnet, Handwheel Operator, A 216 Gr. WCB, Trim 8 to API 600, 602 (13% Cr Hard faced Seat), Plug Disc , 125 250 Ra Finish , OS&Y , Graphite Gland Packing , API 598

VGLB

2 - 12

CL150

Check Valves

VCHK .5 - 1.5 CL800 1 VCPCEWAMSWAACG1AEXAB Pistn Lft Chk Vlv ,EN ISO 15761 , A105 , CL800 , SWE , Bltd Bonnet , Trim 1 to API 594, 602 (13% Cr) , Horiz. and Vert. Installation , API 598 Swing Chk Vlv ,BS 1868 , A 216 Gr. WCB , CL150 , RF , Bltd Bonnet , Trim 1 to API 594, 602 (13% Cr) , 125 250 Ra Finish , API 598 Butterfly Vlv, API 609 Cat.B, CL150, RF, Gear Operator, A 216 Gr. WCB, Trim 1 to API 594, 602 (13% Cr), ASME B16.47 Series B , 125 250 Ra Finish , Fire safe Per API 6FA , API 598 , Antistatic and Blowout proof , Double Offset Butterfly Vlv, API 609 Cat.B, CL150, RF, Gear Operator, A 216 Gr. WCB, Trim 1 to API 594, 602 (13% Cr), ASME B16.5 , 125 250 Ra Finish , Fire safe Per API 6FA , API 598 , Antistatic and Blowout proof , Double Offset Butterfly Vlv, API 609 Cat.B, CL150, RF, 12 Handwheel Operator, A 216 Gr. WCB, Trim 1 to API 594, 602 (13% Cr), ASME B16.5 , 125 250 Ra Finish , Fire safe Per API 6FA , API 598 , Antistatic and Blowout proof , Double Offset Ball Vlv LP FB, ISO 17292, CL150, RF, Top entry Fltg. ball, Wrench Operator, A 216 Gr. WCB, 13 Cr. Trim , PTFE Seat and Seals, 125 250 Ra Finish , Fire safe Per API 607 , API 598 , Antistatic and Blowout proof Ball Vlv LP FB, ISO 17292, CL800, SWE, Two piece Fltg. Ball, Handwheel Operator, A105, 13 Cr. Trim , PTFE Seat and Seals, 100 mm Nipples at both ends , Fire safe Per API 607 , API 598 , Antistatic and Blowout proof Y- Strainer , Manf. Std (DEC to design) , CL800 , SWE , A105 , Scrd Cover with Drain Plug , SMLS , 40 Mesh , SS 316 (L) Internals , Forged Cover T- Strainer , Manf. Std (DEC to design) , CL150 , BE , A 234 Gr. WPB , Flgd Cover with Drain Plug , SMLS , 40 Mesh , SS 316 (L) Internals , Forged Cover T- Strainer , Manf. Std (DEC to design) , CL150 , BE , A 234 Gr. WPB , Flgd Cover with Drain Plug , Welded , 40 Mesh , SS 316 (L) Internals , Forged 13, 12

VCHK

2 - 24

CL150

VCSCBWDDRFAACD1AEXAC

Butterfly Valves

VBFY 26 - 30 CL150 1 VYBAA2DRFBACD1AEXAC

VBFY

8 - 24

CL150

VYBAA2DRFBACD1AEXAB

VBFY

4-4

CL150

VYBAA2DRFFACD1AEXAB

Ball Valves

VBAL 2-6 CL150 1 VBLEAADRFVEACDXABXAD

VBAL

1.5 - 1.5

CL800

VBLEAAMSWYFACGXABXAP

13, 12

Miscellaneous

STR .5 - 1.5 CL800 1 MPSYAP2MSWAAACGAAB

STR

2 - 10

CL150

MPSFAP2DBEABACKAAB

STR

12 - 24

CL150

MPSFAP2DBEABACKAAE

7 Page 4 of 7

Piping Material Specification

Essar Engineering Services Limited

8001-HN-110015 Pipe Class: A01B-1 Revision: 1

ITEM

SIZE 1

SIZE 2

SCH/RAT OPTION COMMODITY CODE

DESCRIPTION

NOTES

Miscellaneous

THTRAP .5 - 1 CL150 1 MPTTAP2DSWZZX1GAAL Cover Thdynamic Steam Trap , Manufacturer Std , CL150 , SWE , A105 Body \ SS Internals , As per Drawing No. AS-8001-000-461-000115-00 , SPIRAX MARSHALL PC01N with UTD3 or equivalant Thstatic Steam Trap , Manufacturer Std , CL150 , SWE , A105 Body \ SS Internals , As per Drawing No. AS-8001-000-461-000115-00 , SPIRAX MARSHALL PC01N with UBP21CV or equivalant 15

TSTRAP

.5 - 1

CL150

MPTSAP2DSWZZX1GAAK

15, 18

7 Page 5 of 7

Piping Material Specification

Essar Engineering Services Limited

8001-HN-110015 Pipe Class: A01B-1 Revision: 1

90 Degree BRANCH CONNECTION Legend and chart

48 44 42 40 36 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 3 2 1-1/2 1 3/4 1/2

TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE RWE SOC SOC SOC SOC TEE TER RWE RWE SOC SOC SOC SOC TEE TER RWE SOC SOC SOC SOC TEE TER SOC SOC SOC SOC TEE TER SOC SOC SOC ETE RTE RTE RTE ETE RTE RTE ETE RTE ETE

B R A N C H S I Z E

48

44

42

40

36

32

30

28

26

24

22

20

18

16

14

12

10

1-1/2

3/4

1/2

HEADER SIZE

TEE ETE RTE NPL NIP TER RWE SOC L45 RWX RPA THL WEL LRE RPA L45 LEE ETS RTR

Equal Tee Equal Tee Reducing Tee Nipolet Nipple Reducing Tee Reinforcing Weld - Design to Check if Reinforcement is Reqd Sockolet Latrolet 45 degree Reinforcing Weld Rpad Threadolet Weldolet Reducing Lateral Tee (45 Degree) Reinforcing Pad 45 Deg Latrolet Equal Lateral Tee (45 Degree) Equal Tee + Swage Reducing Tee + Reducer

7 Page 6 of 6

Piping Material Specification

Essar Engineering Services Limited

8001-HN-110015 Pipe Class: A01B-1 Revision: 1

90 45 Degree BRANCH CONNECTION Legend and chart

48 44 40 36 32 28 24 20 18 16 14 12 10 8 6 4

RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX RWX

B R A N C H S I Z E

48

44

40

36

32

28

24

20

18

16

14

12

10

HEADER SIZE

45DEG BRANCH TABLE ATTACHED IS APPLICABLE ONLY FOR DESIGN PRESSURE LESS THAN 5 KG/CM2G

TEE ETE RTE NPL NIP TER RWE SOC L45 RWX RPA THL WEL LRE RPA L45 LEE ETS RTR

Equal Tee Equal Tee Reducing Tee Nipolet Nipple Reducing Tee Reinforcing Weld - Design to Check if Reinforcement is Reqd Sockolet Latrolet 45 degree Reinforcing Weld Rpad Threadolet Weldolet Reducing Lateral Tee (45 Degree) Reinforcing Pad 45 Deg Latrolet Equal Lateral Tee (45 Degree) Equal Tee + Swage Reducing Tee + Reducer

7 7 Page 6 of 6

S-ar putea să vă placă și

- TEM-En-001-00 - Spring Support Data SheetDocument2 paginiTEM-En-001-00 - Spring Support Data SheetPhilippe AlexandreÎncă nu există evaluări

- Air Release ValveDocument17 paginiAir Release Valvevikaskatheria100% (1)

- Hazen - William Coeficiente FBEDocument10 paginiHazen - William Coeficiente FBEOrlandoÎncă nu există evaluări

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Yanbu: Export Refinery ProjectDocument8 paginiYanbu: Export Refinery ProjectJanakiraman MalligaÎncă nu există evaluări

- PG 6 - 14 Basis of Support StandardDocument10 paginiPG 6 - 14 Basis of Support StandardPankaj SahuÎncă nu există evaluări

- A537 4010 1005 Enq Rev0Document293 paginiA537 4010 1005 Enq Rev0jayakumar100% (1)

- Gas supply pig launcher datasheetDocument9 paginiGas supply pig launcher datasheetOlusayoÎncă nu există evaluări

- Air Tools and Air Consumption PDFDocument13 paginiAir Tools and Air Consumption PDFNEDALÎncă nu există evaluări

- NZ-NZOS Pressure RegulatorDocument12 paginiNZ-NZOS Pressure Regulatorravirebba96950% (1)

- Flange Pipe Support for 4-36Document1 paginăFlange Pipe Support for 4-36indeskeyÎncă nu există evaluări

- Dilating Disk Valve White PaperDocument11 paginiDilating Disk Valve White PaperDeltaflyer47Încă nu există evaluări

- C2quick PDFDocument34 paginiC2quick PDFJose Maria PedrazasÎncă nu există evaluări

- Data Sheet 26 - Fig FT702 150 T StrainerDocument1 paginăData Sheet 26 - Fig FT702 150 T StrainerSteve NewmanÎncă nu există evaluări

- PIPING CODES AND STANDARDS GUIDEDocument299 paginiPIPING CODES AND STANDARDS GUIDENaresh Sharma0% (1)

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 paginiDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoÎncă nu există evaluări

- Pipe Stress Analysis - 4Document23 paginiPipe Stress Analysis - 4Ismail Magdy Ismail100% (1)

- Welding SymbolsDocument23 paginiWelding SymbolsgaurangÎncă nu există evaluări

- Actuated Ball Valve 357 D - BDKDocument4 paginiActuated Ball Valve 357 D - BDKfarhanakhtar ansariÎncă nu există evaluări

- Tendernotice - 1 (Kolkata Spurline)Document742 paginiTendernotice - 1 (Kolkata Spurline)dineshhindujaÎncă nu există evaluări

- IR HL Heatless DryerDocument1 paginăIR HL Heatless DryerYing Kei ChanÎncă nu există evaluări

- Is 14845-2000 (Air Relief Valves) PDFDocument18 paginiIs 14845-2000 (Air Relief Valves) PDFSarbendu PaulÎncă nu există evaluări

- Static Mixer Datasheet for Water, Iron Chloride, and Sodium Hypochlorite MixingDocument1 paginăStatic Mixer Datasheet for Water, Iron Chloride, and Sodium Hypochlorite Mixingaras aliÎncă nu există evaluări

- Load flange supportDocument4 paginiLoad flange supportxkokarcaxÎncă nu există evaluări

- A 1 KDocument5 paginiA 1 KSumantrra ChattopadhyayÎncă nu există evaluări

- Joint Efficiency - EDocument6 paginiJoint Efficiency - EPaul NeedhamÎncă nu există evaluări

- ARTICLE - Tubular Drag Conveyors (R Sutton) 09-06Document12 paginiARTICLE - Tubular Drag Conveyors (R Sutton) 09-06Darko MarjanovicÎncă nu există evaluări

- Category Sheet DescriptionDocument96 paginiCategory Sheet DescriptionNguyen TaiÎncă nu există evaluări

- Tie-In List Osbl: Doc. No.: 26071-203-P0-000-00001 Job No.: 26071Document14 paginiTie-In List Osbl: Doc. No.: 26071-203-P0-000-00001 Job No.: 26071Inggit PrillasariÎncă nu există evaluări

- List of Participants: Update As of 15 September 2017Document9 paginiList of Participants: Update As of 15 September 2017kiranvar13Încă nu există evaluări

- SR Piping Designer/checkerDocument4 paginiSR Piping Designer/checkerapi-78715367Încă nu există evaluări

- Cycle of Absorption MachineDocument4 paginiCycle of Absorption MachineMajid SattarÎncă nu există evaluări

- Restriction Orifice Final CalculationDocument1 paginăRestriction Orifice Final CalculationJasperTanÎncă nu există evaluări

- Ansi B16.9-16.28-MSS SP-43Document3 paginiAnsi B16.9-16.28-MSS SP-43vangie3339515Încă nu există evaluări

- ASME B16.10 FaceToFace Dimension of FlangesDocument41 paginiASME B16.10 FaceToFace Dimension of FlangesPedro OfogbaÎncă nu există evaluări

- ANSI B16.25 Butt Welding Pipe DimensionsDocument4 paginiANSI B16.25 Butt Welding Pipe DimensionsFernandoÎncă nu există evaluări

- Mueller Gate Valve OS&Y 2365Document1 paginăMueller Gate Valve OS&Y 2365wilfredoruizÎncă nu există evaluări

- Pressure Rating ClassesDocument2 paginiPressure Rating ClassesDonPulubi Prokopyo100% (1)

- Data Sheet S7 - 2020 - ENG - Light - CavagnaDocument12 paginiData Sheet S7 - 2020 - ENG - Light - CavagnaWND PRTMÎncă nu există evaluări

- Cs Globe Valve 600#Document1 paginăCs Globe Valve 600#Vijay GaikwadÎncă nu există evaluări

- Especificación Tecnica de Materiales de PipingDocument61 paginiEspecificación Tecnica de Materiales de PipingDaniel Lopez100% (1)

- Iocl TenderDocument22055Document769 paginiIocl TenderDocument22055dineshhindujaÎncă nu există evaluări

- SPE 76-002 (2006) Flange MaterialsDocument6 paginiSPE 76-002 (2006) Flange Materials김창배Încă nu există evaluări

- Iso 9001 CertifiedDocument4 paginiIso 9001 CertifiedLuis R. Salas SotoÎncă nu există evaluări

- Sample Calculating For Piping Wall Thickness CalculationDocument8 paginiSample Calculating For Piping Wall Thickness CalculationsubhashÎncă nu există evaluări

- Pipe SizeDocument9 paginiPipe SizezniperxÎncă nu există evaluări

- DIxonDocument172 paginiDIxonRio WitcandraÎncă nu există evaluări

- FVC Standard Connections Class 1500 Bore SizesDocument1 paginăFVC Standard Connections Class 1500 Bore SizesvincentÎncă nu există evaluări

- Data Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary UnitsDocument10 paginiData Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1Încă nu există evaluări

- Spe 77-105 Gate Globe and Check Valves To Bs 5154Document9 paginiSpe 77-105 Gate Globe and Check Valves To Bs 5154awisakipÎncă nu există evaluări

- HDPE Blow Molding Properties OverviewDocument2 paginiHDPE Blow Molding Properties Overviewtayyabmubarik2417Încă nu există evaluări

- LiquidDocument2 paginiLiquidsiddhesh_guessÎncă nu există evaluări

- External/Internal Painting Specification for Carbon Steel VesselsDocument11 paginiExternal/Internal Painting Specification for Carbon Steel VesselsgaurangÎncă nu există evaluări

- Diaphragm ValveDocument10 paginiDiaphragm Valveshganesh81Încă nu există evaluări

- Tutorial - IsO 14692 FRPDocument36 paginiTutorial - IsO 14692 FRPEugene DerkachÎncă nu există evaluări

- Class 1CB1S01 (Pip PN01CB1S01 - 2005)Document5 paginiClass 1CB1S01 (Pip PN01CB1S01 - 2005)Zvonko Bešlić100% (2)

- Yanbu: Export Refinery ProjectDocument8 paginiYanbu: Export Refinery ProjectJanakiraman MalligaÎncă nu există evaluări

- Yanbu: Export Refinery ProjectDocument8 paginiYanbu: Export Refinery ProjectJanakiraman MalligaÎncă nu există evaluări

- Piping Class DatasheetDocument5 paginiPiping Class Datasheetcyno21100% (2)

- Class 1CB2S01 (Pip PN01CB2S01 - 2005)Document6 paginiClass 1CB2S01 (Pip PN01CB2S01 - 2005)Zvonko BešlićÎncă nu există evaluări