Documente Academic

Documente Profesional

Documente Cultură

Oil Storage Tank Foundation Design Spreadsheet - 2

Încărcat de

Vince26Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Oil Storage Tank Foundation Design Spreadsheet - 2

Încărcat de

Vince26Drepturi de autor:

Formate disponibile

March 12, 2002

Rev: 0

API 650 Storage Tank

FOUNDATION DESIGN:

Per API 650 (Appendix E)

Tank is unanchored, use equations pertaining to unanchored tanks,

for seismic loading.

DATA GIVEN:

Seismic Zone;

Zone Coefficient

Importance Factor

Diameter of Tank

Height of Liquid Content (Design)

Shell Height

Design Specific Gravity

Thickness of Bottom PL Under Shell

Yeild Strength of Bottom PL

Weight of Shell

Weight of Roof + Live Load = 107.4 + 210.4

PI()/4(94.5)2 (44.5)(.79)(62.4)

Weight of Product

Z=

I =

D=

H=

Hs =

G=

tb =

3

0.3

1.0

125.3

45.43

46

0.9

0.5000

Fby =

Ws =

Wy =

Wt =

36,000

373.4

210.4

31,460

PSI

Kips

Kips

Kips

CALCULATIONS:

Seismic Coefficients:

Xs =

C1 =

D/H =

21 Ft

0.60

2.76

Per Fig. E-2

W1 / Wt =

0.4

W1 =

12,584.1

W2 / Wt =

0.52

W2 =

16,359.3

X1 /H =

0.36

X1 =

16.4

X2 /H =

0.56

X2 =

25.4

Per Fig. E-3

Per Fig. E-4

K = 0.62

Lateral Force Coefficients:

E-3.3

T =K (D 0.5 ) =.6 *(94.5 0.5) =

If Greater Than 4.5 seconds

6.72 Seconds

3.375 (s/T2) = 3.375*1.5/5.832 =

Page 1 of 5

0.112 Seconds

FileName: 69757972.xls.ms_office

WorkSheet: Foundation Design - 1

March 12, 2002

Rev: 0

API 650 Storage Tank

FOUNDATION DESIGN:

Seismic Loads:

M = (Z)(I) { (C1)(Ws)(Xs)+(C1)(Wr)(Ht)+(C1)(W)(X)+(C2)(W 2)(X2)}

(0.3)*(1.0)[ 0.6(221)(19.685)+ 0.6(317.8)(48.0)+ 0.6(8232)(16.7)+ 0.149(6924)(26.3)]

0.3

4705

5807

123828

46539

54264 Ft-Kips

V = (Z)(I) {(C1)(Ws)+(C1)(Wr)(Ht)+(C1)(W)(X)+(C2)(W2)(X2)}

(0.3)*(1.0)[ 0.6(221)+ 0.6(317.8)+ 0.6(8232)+ 0.149(6924)]

0.3

224.04

126.24

7550.46

1832.2416

2920 kips

Reistance to Overturning:( E.4.1) API 650

W L = 7.9tb Fby G H

(G18)*(G16)*(G14)/(G13)2 )

1471932

7.9

Constant =

4,792

# / ft

4,792

# / ft

6404

# / ft

6404

# / ft

1213

Not to exceed 1.25*GHD

USE

Shell Compression: Per E-5

M=

54264 ft-kips

Wt + W L = 583.8 / (PI()*94.5) + 4.153

M / D2 (Wt + W L)

6.12 Kips

(G76)/(G13)2(6.12)

54264

96085

b = 1.815+1.273*54264/125.3^2

0.565 < 0.785

b =

Max. Longitudinal Compressive Force

6.2

6.2

UnAnchored Longitudinal Compressive Stress

7000 / 6

Allowable Longitudinal Compressive Stress

GHD2/t2

1.255 * 106 = Fa=106 (t) / D =

Anchorage Not Required

Page 2 of 5

1167

3.99 Kips

FileName: 69757972.xls.ms_office

WorkSheet: Foundation Design - 1

Page 3

FOUNDATION DESIGN:

Max. Overturning Moment Due To Seismic Loads.

Compression or Tension Due To Moment:

Seismic Base Shear:

54,264 Kips

7.74 kpf

0.27 kips

RINGWALL DESIGN:

Use Following Weight Values for Materials

490lb/ft3

110 lb/ft3

150 lb/ft3

50 lb/ft3

Wt. of Steel

Wt. Of Compacted Soil

Wt. Of Concrete Wall

Wt. Of Product in Tank

Horizontal Pressure on Ring Wall:

F=Kah(g*p*H+1/2 soh)+270

0.3*6.0[(50*44.5+0.5*110*6.0)]+270

4,953 kips

Hoop Tension:

1/2FD= 1/2(4869)(94.5)

310 kips

As= 310/24.0

9.63 in.

USE - 6 # 9 Bars Ea. Face

USE - # 4 Bars at 12" on Center

Minimum RingWall Thickness:

T = 2W / g *p*h - 2h ( gc - gso)

W = 1100

(2)(1100)/50(44.5)-2(6.0)(150-110)

1.23

Use 16" Thick Concrete Wall

12"

Top of Ground Elevation

16"

48"

12"

Page 3 of 5

FileName: 69757972.xls.ms_office

WorkSheet: Foundation Design - 2

Page 4

Concrete Tensile Stress:

fct = c(Es)(As)+T / Ac + n (As)

.0003(29*106)(10)+231000/(16*72)+(9*10)

318000

1242

.15(3000)

256 psi

450 psi

OK

Soil Bearing:

Try 3'- 6" Footing

Weight. of Wall = 1.33*5.0*.150

Weight of Footing = 3.5*1.0*.150

Weight of Fill = 2.17*4.0*.110

1.0

0.525

0.95

2.48

kips

kips

kips

kips

Case 1

Load from Shell + Roof + Live Load =

Weight of Wall +Footing + Fill =

Bearing Pressure =

3.58/3.50

1.1 kips

2.48 kips

1.0 kips

Case 2

Dead + Live Load + Earthquake Load =

P = 3.58 + 5.19 =

H=

Moment at Base of Footing =

.270(6.0)

Bearing Pressure Under Footing =

8.77/3.5*1

2.51+.79

Allowable Pressure = 3.0*1.33

8.77 kips

0.270 kips

1.62 kips

2.51 kips

3.30 kips

3.99

OK

USE -4 # 9 Bars in Footing

USE - # 4 Bars at 12" Horizontal

Page 4 of 5

FileName: 69757972.xls.ms_office

WorkSheet: Foundation Design - 2

March 12, 2002

Rev: 0

API 650 Storage Tank

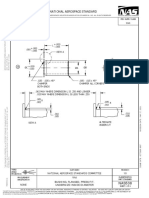

DETAILED FOUNDATION DESIGN:

62' - 8"

Center Line of Tank

4'-0"

12"

6 # 9 Bars Each Face Eq.

Slope 1" per ft.

10"

10" Pad of Sand

Well-Compacted Gravel

95% Compacted

50 / 100 % Passing # 4 Sieve

# 4 Bars 12" O/C Each Face

95 % Compacted Subgrade or fill Material

12"

1'-4" Wall

(4) # 9 Bars Eq. Spaced

3' - 6"

NOTES:

1. Oiled sand to be mixture of sand and liquid asphalt (mc70):

2. Use 10 gallons of asphalt per cubic yard of sand:

3. Top of concrete to be smooth and level with 1/8" +/- in any 30 feet of circumferential length:

4. Maximum Deiation to be less than 1/4" overall:

Page 5 of 5

FileName: 69757972.xls.ms_office

WorkSheet: Foundation Design - 3

S-ar putea să vă placă și

- Oil Storage Tank Foundation DesignDocument5 paginiOil Storage Tank Foundation Designsugianto100% (2)

- API 650 Tank Design CalculationDocument8 paginiAPI 650 Tank Design Calculationmail_younes659283% (29)

- Ring Wall Tank Foundation DESIGNDocument6 paginiRing Wall Tank Foundation DESIGNanandamÎncă nu există evaluări

- Contents Specific Gravity: Calculation SheetDocument3 paginiContents Specific Gravity: Calculation SheetHui Liu100% (4)

- Ring WallDocument17 paginiRing WallYunanto WidiÎncă nu există evaluări

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)Document25 paginiAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)AVBP100% (3)

- Design of Storage Tank FoundationDocument14 paginiDesign of Storage Tank Foundationkoyahassan100% (1)

- Tank Ring Wall Foundation DesignDocument6 paginiTank Ring Wall Foundation DesignanandamÎncă nu există evaluări

- Tank Foundation Design and Load CalculationsDocument3 paginiTank Foundation Design and Load CalculationsdantevariasÎncă nu există evaluări

- Project Equipment Load AnalysisDocument54 paginiProject Equipment Load Analysisrajeshmk2002100% (6)

- Ring Wall Foundation PDFDocument18 paginiRing Wall Foundation PDFAbhaysinh Shinde85% (13)

- Tank Foundation & Ring Beam DesignDocument8 paginiTank Foundation & Ring Beam Designpsconsultants100% (2)

- Vertical Vessel Foundation Design GuideDocument52 paginiVertical Vessel Foundation Design GuideIsrael AGÎncă nu există evaluări

- Tank Ring Wall Foundation+&+Annular+RaftDocument12 paginiTank Ring Wall Foundation+&+Annular+Raftasghar750% (2)

- Tank Foundation Rev 01Document10 paginiTank Foundation Rev 01AnbalaganV100% (1)

- STAAD - Foundation Tank Ringwall Calculation SheetDocument9 paginiSTAAD - Foundation Tank Ringwall Calculation Sheetdumbadumba100% (4)

- Storage Tank Ringwall Foundation DesignDocument7 paginiStorage Tank Ringwall Foundation DesignSana Ullah100% (1)

- 3000 MT Storage Tank Foundation DesignDocument15 pagini3000 MT Storage Tank Foundation DesignDeny AristyaÎncă nu există evaluări

- Tank Foundation Design GuideDocument44 paginiTank Foundation Design GuideMichelle Baker65% (23)

- STAAD Tank FoundationDocument17 paginiSTAAD Tank Foundationiuliandurdureanu100% (2)

- Storage Tank DesignDocument21 paginiStorage Tank Designravi456compÎncă nu există evaluări

- Tank Foundation Design ProcedureDocument53 paginiTank Foundation Design ProcedureMichael Teo82% (11)

- 42 Pile Foundation (Water Tank Foundation)Document10 pagini42 Pile Foundation (Water Tank Foundation)Harish Kumar Mahavar100% (1)

- Fuel Tank Ring Beam Design CalculationDocument11 paginiFuel Tank Ring Beam Design CalculationDawson Preethi EA94% (16)

- Bottom Corrosion PreventionDocument16 paginiBottom Corrosion PreventionMayuresh Kudve100% (1)

- Molasses Tank Design Sheet CalculationsDocument9 paginiMolasses Tank Design Sheet CalculationsGautam Paul100% (2)

- R.C. Foundation Design for Oil Storage TankDocument17 paginiR.C. Foundation Design for Oil Storage Tanknerioalfonso100% (2)

- API 650 Tank Design CalculationsDocument8 paginiAPI 650 Tank Design Calculationsツ ツÎncă nu există evaluări

- 1000MT Cap DesignDocument5 pagini1000MT Cap Designrbalmodal100% (1)

- API 650 Tank Design CalculationDocument8 paginiAPI 650 Tank Design CalculationHoracio RodriguezÎncă nu există evaluări

- API 650 Tank Design CalculationDocument8 paginiAPI 650 Tank Design CalculationNorazlan Shah Mahadi100% (1)

- Oil Storage Tank Foundation Design Spreadsheet 1Document2 paginiOil Storage Tank Foundation Design Spreadsheet 1ronyÎncă nu există evaluări

- API 650 Tank Design CalculationDocument9 paginiAPI 650 Tank Design CalculationSunday PaulÎncă nu există evaluări

- Design of Concrete Ring Type Foundation For Storage TankDocument5 paginiDesign of Concrete Ring Type Foundation For Storage TankFadli PunyeÎncă nu există evaluări

- Tank Design As Per IS803 and API650Document36 paginiTank Design As Per IS803 and API650Vikk Suriya100% (1)

- Tank Design As Per IS803 and API650Document36 paginiTank Design As Per IS803 and API650Vikash Kumar Singh100% (1)

- TDI13 Storage Tank Design As Per IS803 and API650Document36 paginiTDI13 Storage Tank Design As Per IS803 and API650zefiloÎncă nu există evaluări

- TDI13 Storage Tank Design As Per IS803 and API650Document36 paginiTDI13 Storage Tank Design As Per IS803 and API650Faizal Sattu100% (3)

- API 650 Tank Design CalculationsDocument8 paginiAPI 650 Tank Design CalculationsMohammed EljammalÎncă nu există evaluări

- API 650 Storage Tank DesignDocument8 paginiAPI 650 Storage Tank DesignCarey Rich67% (3)

- Design Calculation TankDocument28 paginiDesign Calculation Tankibiceng100% (4)

- Tank Design As Per IS803 and API650Document36 paginiTank Design As Per IS803 and API650Mani Vannan100% (3)

- Design Tanks Menurut API 650Document80 paginiDesign Tanks Menurut API 650irbar.darmansyah.alwiÎncă nu există evaluări

- WIND MOMENT (Per API-650 SECTION 5.11)Document9 paginiWIND MOMENT (Per API-650 SECTION 5.11)ramu karri100% (1)

- Foundation DesignDocument2 paginiFoundation DesignrabzihÎncă nu există evaluări

- Orica Tank Design Calculation AWWADocument8 paginiOrica Tank Design Calculation AWWAmohanuma100% (2)

- 2x4.5mx3.5m Fill 1000mmDocument46 pagini2x4.5mx3.5m Fill 1000mmmtuanlatoi9704Încă nu există evaluări

- Desain Pondasi PileDocument9 paginiDesain Pondasi PilegembulflowÎncă nu există evaluări

- API 650 Crude Oil Storage Tank DesignDocument8 paginiAPI 650 Crude Oil Storage Tank Designlecongdinh100% (1)

- 2.TankSurge Plate FOundationDocument2 pagini2.TankSurge Plate FOundationdanjidÎncă nu există evaluări

- Skirt Support TrialDocument11 paginiSkirt Support TrialAbhishek Nag0% (1)

- Mill Feed Silo-10!09!08Document120 paginiMill Feed Silo-10!09!08Umer AziqÎncă nu există evaluări

- Transmission Tower Foundation DesignDocument26 paginiTransmission Tower Foundation Design14pcash100% (1)

- CalculationDocument15 paginiCalculationTohid Karimi67% (3)

- API 650 Tank Design CalculationsDocument8 paginiAPI 650 Tank Design CalculationsVinoth Rajendra50% (4)

- Timber DesignDocument18 paginiTimber Designshaina mae omandacÎncă nu există evaluări

- Tank Calc - Api650Document90 paginiTank Calc - Api650kamleshyadavmoney100% (3)

- SLRB Pipe CulvertDocument22 paginiSLRB Pipe CulvertBoppineti Naga Raju100% (1)

- Transmission Tower Foundation DesignDocument26 paginiTransmission Tower Foundation DesignSara Nuon86% (7)

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesDe la Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesÎncă nu există evaluări

- SCI-BRE-BCSA Wind Guidance PDFDocument28 paginiSCI-BRE-BCSA Wind Guidance PDFrina2393Încă nu există evaluări

- SCI-BRE-BCSA Wind Guidance PDFDocument28 paginiSCI-BRE-BCSA Wind Guidance PDFrina2393Încă nu există evaluări

- Storage Tank Design CalculationDocument12 paginiStorage Tank Design CalculationVince26Încă nu există evaluări

- Box Culvert Design ManualDocument40 paginiBox Culvert Design ManualAnil Kumar Kothamacha71% (21)

- Sample Questions For HaadDocument15 paginiSample Questions For HaadBrian Balan79% (14)

- USMLE Step I Comp Review Term ListDocument170 paginiUSMLE Step I Comp Review Term ListeÎncă nu există evaluări

- Design of Box Culvert (AASHTO)Document12 paginiDesign of Box Culvert (AASHTO)Sudhir Reddy Nallamilli76% (25)

- Joints in Concrete Buildings: Planning, Design and PerformanceDocument8 paginiJoints in Concrete Buildings: Planning, Design and PerformanceHossam Al-Dein Mostafa Helmy100% (1)

- SP16-Design Aid For RC To IS456-1978Document252 paginiSP16-Design Aid For RC To IS456-1978sateeshsingh90% (20)

- Slope Deflection MethodDocument87 paginiSlope Deflection MethodFian ArdiyanaÎncă nu există evaluări

- Appendix B SettlementDocument24 paginiAppendix B SettlementVince26100% (1)

- Thrust Block and Anchor BlockDocument8 paginiThrust Block and Anchor Blockwikoboy50% (4)

- EDI Brochure 2008Document15 paginiEDI Brochure 2008RamezSabetÎncă nu există evaluări

- Mod 2 BA PhysicsDocument412 paginiMod 2 BA PhysicsBenitoKameloÎncă nu există evaluări

- Inorganic ChemistryDocument7 paginiInorganic ChemistryJopie ArandaÎncă nu există evaluări

- DME ProcessDocument5 paginiDME ProcessAndres FragosoÎncă nu există evaluări

- Ucalgary 2020 Du StevenDocument65 paginiUcalgary 2020 Du StevenmnasiroleslamiÎncă nu există evaluări

- Form Checklist Civil.Document91 paginiForm Checklist Civil.Iki Hendro100% (2)

- D4B807E3B5B-Body Repairs General Body RepairsDocument54 paginiD4B807E3B5B-Body Repairs General Body Repairsderp derpissimoÎncă nu există evaluări

- Osborn Guide PDFDocument228 paginiOsborn Guide PDFThái Mai ĐìnhÎncă nu există evaluări

- M-Phi Singly Reinforced Rectangular Concrete SectionDocument26 paginiM-Phi Singly Reinforced Rectangular Concrete SectionRishabh LalaÎncă nu există evaluări

- Manage Waste & Resources with WastivityDocument21 paginiManage Waste & Resources with WastivitybhishmÎncă nu există evaluări

- Enclosure Mansonry Wall Systems WorldwideDocument229 paginiEnclosure Mansonry Wall Systems Worldwidexxxxx8086Încă nu există evaluări

- Polymers 14 02684Document18 paginiPolymers 14 02684Hira KarimÎncă nu există evaluări

- Compaction RegisterDocument73 paginiCompaction Registersuraj ChinttuÎncă nu există evaluări

- CHM 1025c Final Exam Practice WCDocument5 paginiCHM 1025c Final Exam Practice WCMiguel SuarezÎncă nu există evaluări

- 2) Data Sheet VDek-703 Standard 2021 FTDocument1 pagină2) Data Sheet VDek-703 Standard 2021 FTJean CausilÎncă nu există evaluări

- SCOPEDocument5 paginiSCOPEMel FÎncă nu există evaluări

- Tankguard StorageDocument5 paginiTankguard StorageBiju_PottayilÎncă nu există evaluări

- L3-Ch15 - Thermal Energy (Lesson 1)Document35 paginiL3-Ch15 - Thermal Energy (Lesson 1)Jamal RamadanÎncă nu există evaluări

- Design and Analysis of Interpretation For Orthopedic Plate With Titanium AlloyDocument9 paginiDesign and Analysis of Interpretation For Orthopedic Plate With Titanium AlloyIJRASETPublicationsÎncă nu există evaluări

- Thermal Oxidation of Anhydride Cured Epoxies. 1 - Mechanistic AspectsDocument10 paginiThermal Oxidation of Anhydride Cured Epoxies. 1 - Mechanistic AspectsIgor SilvaÎncă nu există evaluări

- Stain Removal GuideDocument1 paginăStain Removal Guidekhamid arifÎncă nu există evaluări

- Keswick School 1Document12 paginiKeswick School 1api-25909541Încă nu există evaluări

- Georgia Department of Public Health Environmental Health SectionDocument8 paginiGeorgia Department of Public Health Environmental Health Sectionjclark13010Încă nu există evaluări

- Propriedades Quânticas de Nanomateriais Utilizando A Teoria Do Funcional Densidade (DFT)Document13 paginiPropriedades Quânticas de Nanomateriais Utilizando A Teoria Do Funcional Densidade (DFT)Leandro Costa Sobrinho MutucÎncă nu există evaluări

- National Aerospace Standard: Fed. Supply ClassDocument4 paginiNational Aerospace Standard: Fed. Supply ClassGlenn CHOU100% (1)

- Duplex Stainless Steel 2304 Spec Sheet for Weight Savings & Corrosion ResistanceDocument2 paginiDuplex Stainless Steel 2304 Spec Sheet for Weight Savings & Corrosion ResistanceDeepak TdÎncă nu există evaluări

- VFDH PRSH enDocument3 paginiVFDH PRSH enOmar JarwanÎncă nu există evaluări

- Dokumen - Tips NFL Bathinda Training FileDocument53 paginiDokumen - Tips NFL Bathinda Training FileNitish BhardwajÎncă nu există evaluări

- Geotechnics With GeosyntheticsDocument24 paginiGeotechnics With GeosyntheticsAnonymous VeDNBhÎncă nu există evaluări

- 10 - Equipment Damage Curves Motors PDFDocument5 pagini10 - Equipment Damage Curves Motors PDFMoulay m'hammed LOUKILIÎncă nu există evaluări

- Horiba - XGT 9000 IIDocument1 paginăHoriba - XGT 9000 IIAmanah WatiiÎncă nu există evaluări