Documente Academic

Documente Profesional

Documente Cultură

Tube Size (MM) : BS 6891 Table

Încărcat de

Kevin TraynorDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tube Size (MM) : BS 6891 Table

Încărcat de

Kevin TraynorDrepturi de autor:

Formate disponibile

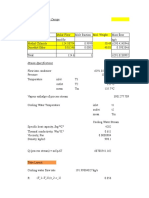

Tube Size (mm)

10 x 0.6 12 x 0.6 15 x 0.7 22 x 0.9 28 x 0.9

3 0.84 1.52 2.9 8.7 18

6 0.56 1.01 1.9 5.8 12

Length of pipe run (m) Discharge (m/hr) 9 12 15 20 0.51 0.36 0.31 0.22 0.84 0.82 0.67 0.51 1.5 1.3 1.1 0.95 4.6 3.9 3.6 2.8 9.4 8 7.2 6

25 0.17 0.39 0.92 2.6 5.4

30 0.14 0.33 0.88 2.3 4.8

BS 6891 Table Approximate flow of gas (m/hour) in straight horizontal copper tube. Flow rates are for low pressure supplies with 1 mbar differential pressure between and of pipe for gas of relative density of 0.6 To obtain the effective length of the pipework take the actual pipe length and add:0.3 For each 90 bend 0.5 For each elbow 0.5 For each tee To get the gas flow rate divide the appliance heat input by the calorific value (CV) of the gas Natural gas CV is 38.5MJ/m. Example: For a 10kW appliance Flow rate will be: 1038.5=0.26 litres/second, This can be converted to m/hour By multiplying by 3.6 to get 0.936m/hour

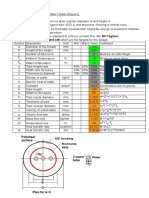

Col 1

Pipe Section

Col 2

Col 3

Flow Rate

Col 4

Assumed Diameter

Col 5

Measured Length

Col 6

Extra for fittings

Col 7

Effective length

Col 8

Maximum length

Col 9

Actual pressure drop

Col 10

Progressive pressure drop

Power

(kW)

(m/hr)

(mm)

(m)

(m)

(m)

(m)

(mbar)

(mbar)

Working out pipe sizing.

Tube Size (mm)

10 x 0.6 12 x 0.6 15 x 0.7 22 x 0.9 28 x 0.9

3 0.84 1.52 2.9 8.7 18

6 0.56 1.01 1.9 5.8 12

Length of pipe run (m) Discharge (m/hr) 9 12 15 20 0.51 0.36 0.31 0.22 0.84 0.82 0.67 0.51 1.5 1.3 1.1 0.95 4.6 3.9 3.6 2.8 9.4 8 7.2 6

25 0.17 0.39 0.92 2.6 5.4

30 0.14 0.33 0.88 2.3 4.8

Col 1

Pipe Section

Col 2

Col 3

Flow Rate

Col 4

Assumed Diameter

Col 5

Measured Length

Col 6

Extra for fittings

Col 7

Effective length

Col 8

Maximum length

Col 9

Actual pressure drop

Col 10

Progressive pressure drop

Power

(kW)

(m/hr)

(mm)

(m)

(m)

(m)

(m)

(mbar)

(mbar)

S-ar putea să vă placă și

- Equilibrium LineDocument8 paginiEquilibrium Linedhea novitaÎncă nu există evaluări

- Cooling Tower ComparisonDocument4 paginiCooling Tower ComparisonKiran DasÎncă nu există evaluări

- CalculationDocument13 paginiCalculationajit kumarÎncă nu există evaluări

- Heat Exchanger Input Correction FactorDocument11 paginiHeat Exchanger Input Correction FactorTrần Tuấn VũÎncă nu există evaluări

- Gas Line Pressure LossesDocument4 paginiGas Line Pressure Lossesyash saragiyaÎncă nu există evaluări

- XSteam V2aDocument9 paginiXSteam V2aPRABU PERUMALÎncă nu există evaluări

- Txy Diagram For Ethanol/Water at 760Mmhg: Model, Bubble Point Model, Dew Point Data, Bubble Point Data, Dew PointDocument3 paginiTxy Diagram For Ethanol/Water at 760Mmhg: Model, Bubble Point Model, Dew Point Data, Bubble Point Data, Dew PointjunomarsÎncă nu există evaluări

- Values Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesDocument7 paginiValues Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesaltruismÎncă nu există evaluări

- Spray Nozzles Total STDDocument3 paginiSpray Nozzles Total STDDylan RamasamyÎncă nu există evaluări

- Psychrometric CalculatorDocument4 paginiPsychrometric CalculatorArie Emmanuel ListonÎncă nu există evaluări

- 4.4 Heat Ex ChangersDocument7 pagini4.4 Heat Ex Changersmukesh kaushikÎncă nu există evaluări

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocument6 paginiSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareÎncă nu există evaluări

- Part 1 Answer Below Here: Calculate The Head Loss in A Pipe With FittingsDocument1 paginăPart 1 Answer Below Here: Calculate The Head Loss in A Pipe With FittingsRafael ReyesÎncă nu există evaluări

- Eleactrical Tracing Calc - Filter TankerDocument28 paginiEleactrical Tracing Calc - Filter TankerAjay TiwariÎncă nu există evaluări

- Basic Control Valve Sizing and SelectionDocument38 paginiBasic Control Valve Sizing and SelectionmohamedÎncă nu există evaluări

- Design of Heat ExchangersDocument23 paginiDesign of Heat ExchangersKhalid Turki100% (2)

- FormulasDocument31 paginiFormulasJL PerezÎncă nu există evaluări

- Pressure Drop Within DuctsDocument6 paginiPressure Drop Within DuctskasvikrajÎncă nu există evaluări

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 paginiWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Thermal Design - 2 Effect Forward-Feed Evaporator Nama Aristya Kurniawan NIM 114 152 5005 Design BasisDocument4 paginiThermal Design - 2 Effect Forward-Feed Evaporator Nama Aristya Kurniawan NIM 114 152 5005 Design BasisAristya KurniawanÎncă nu există evaluări

- CFM and Capacity Calcs 4.9Document14 paginiCFM and Capacity Calcs 4.9hvacrmedicÎncă nu există evaluări

- Heat Conduction Pipe InsulationDocument1 paginăHeat Conduction Pipe InsulationJogender DhayalÎncă nu există evaluări

- Mixer CalcDocument10 paginiMixer CalchadiÎncă nu există evaluări

- Sizing Calculation - AC214312UJ - R0 PDFDocument1 paginăSizing Calculation - AC214312UJ - R0 PDFPavendhan PavÎncă nu există evaluări

- Type k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarDocument3 paginiType k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarRobinÎncă nu există evaluări

- LV 3 PH Fault CurveDocument1 paginăLV 3 PH Fault Curveyadav_sctÎncă nu există evaluări

- Length Power Dynamic Viscosity Heat FluxDocument9 paginiLength Power Dynamic Viscosity Heat FluxAnubhav KhandelwalÎncă nu există evaluări

- Pump Selection SH BoilersDocument4 paginiPump Selection SH BoilersAnith kumar ReddyÎncă nu există evaluări

- App 6 CalculationsDocument2 paginiApp 6 CalculationsNizarHamrouniÎncă nu există evaluări

- ChE450 TBWS15.28Document6 paginiChE450 TBWS15.28HaematomaÎncă nu există evaluări

- Ejector User GuideDocument2 paginiEjector User GuidehaseebÎncă nu există evaluări

- All HVAC CalculationDocument52 paginiAll HVAC CalculationSlam HassanÎncă nu există evaluări

- Linear Mixing CalcDocument12 paginiLinear Mixing CalcClarence AG YueÎncă nu există evaluări

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDocument20 paginiExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsLeonardo Ramirez GuzmanÎncă nu există evaluări

- Norgren Sizing Calculations Cylinder Sizing Calculations Force Pressure X Area of Piston (F PA)Document5 paginiNorgren Sizing Calculations Cylinder Sizing Calculations Force Pressure X Area of Piston (F PA)navneetÎncă nu există evaluări

- Sewer Pumpstation Design Calculations For AlqiDocument7 paginiSewer Pumpstation Design Calculations For AlqiTahirJabbarÎncă nu există evaluări

- Performance Thermo CompressorsDocument8 paginiPerformance Thermo CompressorsclintoncÎncă nu există evaluări

- Louver and Pump SizeDocument1 paginăLouver and Pump SizeShabeer HamzaÎncă nu există evaluări

- Bell Method Example 7 5Document9 paginiBell Method Example 7 5jnmanivannanÎncă nu există evaluări

- Native File For Pump (Example)Document2 paginiNative File For Pump (Example)Venturindo SiteÎncă nu există evaluări

- Fdocuments - in Separator Sizing SpreadsheetDocument31 paginiFdocuments - in Separator Sizing SpreadsheetGabrielito PachacamaÎncă nu există evaluări

- Heat Capacity Ratio of Real GasesDocument2 paginiHeat Capacity Ratio of Real GasesilyesinÎncă nu există evaluări

- Tube Side Velocity CalculationDocument20 paginiTube Side Velocity CalculationNitin KurupÎncă nu există evaluări

- Chimney Draught Calculations: //vboxsrv/conversion - Tmp/scratch - 4/195995390.xls - Ms - OfficeDocument1 paginăChimney Draught Calculations: //vboxsrv/conversion - Tmp/scratch - 4/195995390.xls - Ms - OfficemohdnazirÎncă nu există evaluări

- Psuextension Particle Size 4mm MetricDocument8 paginiPsuextension Particle Size 4mm MetricRed RedÎncă nu există evaluări

- Case - 2.6 Ef (Star TCC)Document1 paginăCase - 2.6 Ef (Star TCC)joshÎncă nu există evaluări

- Zfactor Spreadsheet VersionDocument35 paginiZfactor Spreadsheet VersionCHANADASÎncă nu există evaluări

- Heat CalcDocument13 paginiHeat Calciese027Încă nu există evaluări

- Voltage Drop CalculatorDocument1 paginăVoltage Drop Calculatorpandi27Încă nu există evaluări

- Packed Column DesignDocument6 paginiPacked Column Designyamen-691904Încă nu există evaluări

- JR Heat Exchanger DesignDocument14 paginiJR Heat Exchanger Designjanelle ramdahinÎncă nu există evaluări

- Hydroulics Calculation and Gas PropertiesDocument3 paginiHydroulics Calculation and Gas PropertiesSteve WanÎncă nu există evaluări

- Understanding NPSHDocument34 paginiUnderstanding NPSHeliyanto budiartoÎncă nu există evaluări

- 3ph Isc at LV InstallationDocument7 pagini3ph Isc at LV InstallationbambangÎncă nu există evaluări

- Total Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Document41 paginiTotal Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Anonymous 1fyKr9XSeGÎncă nu există evaluări

- Water Heater DesignDocument4 paginiWater Heater DesignKaushik SahaÎncă nu există evaluări

- Natural Gas Conversion Guide PDFDocument52 paginiNatural Gas Conversion Guide PDFTinuoye Folusho OmotayoÎncă nu există evaluări

- Perhitungan Pipa Gas CustomerDocument13 paginiPerhitungan Pipa Gas CustomerFah RoziÎncă nu există evaluări

- Gas Pipe SizingDocument10 paginiGas Pipe SizingSanthosh Kumar100% (1)

- Gas Pipe SizingDocument17 paginiGas Pipe Sizingcentaury2013100% (2)