Documente Academic

Documente Profesional

Documente Cultură

Iowegan's Book of Knowledge For The Ruger GP-100 Revolver

Încărcat de

greg_glass_5Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Iowegan's Book of Knowledge For The Ruger GP-100 Revolver

Încărcat de

greg_glass_5Drepturi de autor:

Formate disponibile

Iowegan's 8ook of know|edge for the kuger G100 revo|ver

Wr|tten by Iowegan

1h|s mater|a| |s copyr|ghted by the author

|ease v|s|t the kuger Iorum for add|t|ona| I8Ck's on var|ous kuger mode|s

http]]wwwrugerforumnet

Introduct|on 1he kuger G100 |s a s|x shot doub|e act|on revo|ver chambered |n 38 Spec|a| or 3S7 Magnum Its

robust des|gn evo|ved from the o|der Secur|tyS|x ser|es 1he G100 has a |arger frame th|cker cy||nder |mproved

gr|p mount|ng system tr|gger return spr|ng front s|ght |nterna| cy||nder reta|ner and tr|gger guard |atch Cther than

these m|nor changes both the Secur|tyS|x and G100 |nterna| des|gns are near|y |dent|ca| as are the kuger S101

and kuger Super kedhawk

Des|gn kuger eng|neers d|d an exce||ent [ob des|gn|ng the G100 Most of the parts are conta|ned by pushout p|ns

or spr|ng|oaded p|ungers and a mere 3 screws 1he des|gn |s a modu|ar concept w|th three ma|n assemb||es 1he

barre| and frame are the host assemb|y 1he tr|gger guard assemb|y and cy||nder assemb|y make up the rest of the

gun 1he G100 has been manufactured |n severa| conf|gurat|ons but the |nterna| parts are a|| |nterchangeab|e

r|mar||y the d|fferent var|at|ons have to do w|th barre| |ength barre| shroud s|ghts and gr|ps G100s have been

produced |n both b|ued and sta|n|ess stee| mode|s 1he on|y other parts that are un|que to a certa|n mode| are the

cy||nders when chambered for a 38 Spec|a| or 3S7 Magnum or hammers |n DAC mode|s (bobbed)

Gr|ps G100s w|th f|xed s|ghts are equ|pped w|th compact rubber gr|ps w|th |nserts 1he ad[ustab|e s|ght mode|s

come w|th fu|| s|zed rubber gr|ps w|th |nserts Gr|ps are |nterchangeab|e between a|| mode|s and are a|so the same as

kuger Super kedhawk gr|ps 1he gr|p |nserts for the compact gr|ps are the same s|ze as S101 |nserts

S|ghts G100s equ|pped w|th ad[ustab|e s|ghts a|so have a "p|ug|n" front s|ght 1h|s un|que system a||ows the front

s|ght to be changed |n seconds by push|ng |n the front s|ght p|unger and ||ft|ng the s|ght out of the channe| 1he

standard front s|ght |s b|ack Super kedhawk front s|ghts are |nterchangeab|e w|th the G100 and have a red |nsert

1here are severa| kuger and aftermarket p|ug|n front s|ghts ava||ab|e |n d|fferent co|ors or sty|es 1he ad[ustab|e rear

s|ghts are the same as most other kuger revo|vers and are c||ckad[ustab|e for both w|ndage and e|evat|on Some rear

s|ghts have a wh|te out||ne b|ade wh||e others are b|ack or Vnotch I|xed s|ght mode|s are ava||ab|e |n 3 and 4 |nch

barre|s Ad[ustab|e s|ght mode|s are ava||ab|e |n 4 and 6 |nch barre|s

8ase meta| and f|n|sh G100s are made |n two bas|c conf|gurat|ons 1he b|ued mode|s are |nvestment cast from h|gh

strength stee| and are f|n|shed w|th a hot b|ue process 8|u|ng on|y affects the surface of the meta| so |t w||| wear off

espec|a||y from us|ng ho|sters 1he surface |s res|stant to corros|on but |t w||| rust eas||y |f mo|sture |s a||owed to

contact the gun 1h|s cou|d be from the c||mate or from f|ngerpr|nts Norma||y a ||ght coat of rust preventat|ve o|| w|||

protect the surface from rust|ng 1he worst th|ng you can do w|th any b|ued gun |s to store them |n a |eather ho|ster

Sta|n|ess stee| |nvestment cast G100s are much more res|stant to corros|on In extreme cases even a sta|n|ess gun

w||| rust A|| kuger sta|n|ess guns a|so have sta|n|ess stee| |nterna| parts 1he except|ons are the spr|ngs where

sta|n|ess |s |nfer|or 8es|des the spr|ngs the on|y nonsta|n|ess parts are the gr|ps and s|ghts G100s have been made

|n the standard "brushed" f|n|sh and a sma|| quant|ty |n the h|gh po||sh f|n|sh

In|t|a| |nspect|on 1hough many "specs" are noth|ng more than "bragg|n' r|ghts" some th|ngs do have an effect on

how we|| the G100 w||| perform Many t|mes specs are borrowed from another f|rearm brand and are mean|ng|ess

due to d|fferent des|gns 1he G100 was des|gned to operate w|th fa|r|y |oose to|erances so don't get a|armed |f your

gun doesn't measure as t|ght as another brand kefer to the schemat|c when part numbers are referenced

I|t and I|n|sh Lxam|ne the overa|| f|t and f|n|sh L|ke|y you w||| f|nd scratches mach|ne marks and other cosmet|c

|ssues that have no affect on funct|on kugers are |ntended to be a strong durab|e gun but se|dom do you f|nd one

w|th a perfect f|n|sh or where the cosmet|c f|t |s up to the standards of more expens|ve manufacturers

8]C gap and endshake We w||| start by measur|ng the barre|tocy||nder (8]C) gap and cy||nder endshake ou w|||

need an automot|ve type gap gauge set (|ooks ||ke a pocket kn|fe w|th mu|t|p|e b|ades of d|fferent th|ckness AkA

fee|er gauge) W|th the gun |n a stat|c cond|t|on ho|d the cy||nder to the rear and s||de the th|ckest gap gauge b|ade

that w||| f|t between the rear barre| surface and the front face of the cy||nder 1h|s w||| be the "true" 8]C gap and

shou|d be between 004" and 008" w|th 006" be|ng opt|mum If the gap |s too t|ght the cy||nder w||| drag on the

barre| when |t gets fou|ed from shoot|ng If the gap |s too w|de you w||| |oose a ||tt|e ve|oc|ty but accuracy w||| not be

affected kepeat the same test on|y th|s t|me ho|d the cy||nder forward and |nsert the th|ckest b|ade that f|ts w|th

m|n|ma| fr|ct|on Subtract the |ast measurement from the f|rst one 1h|s w||| be "cy||nder endshake" Lndshake shou|d

be 002 to 00S" If endshake |s too t|ght the gun may b|nd up when you shoot |t If endshake |s too |oose |t cou|d

affect other funct|ons of the gun such as cy||nder t|m|ng ||ght pr|mer h|ts and cy||nder |ockup

neadspace 1h|s test requ|res a "v|rg|n" empty case Insert the case |n a chamber and |ocate |t d|rect|y |n ||ne w|th the

f|r|ng p|n ho|e Wh||e ho|d|ng the cy||nder f|rm|y to the rear s||de the th|ckest b|ade of a gap gauge that w||| f|t w|th

fr|ct|on between the case head and reco|| sh|e|d (frame) 1h|s shou|d measure 008012" w|th 010" as opt|mum If

headspace |s too t|ght the case heads may drag on the reco|| sh|e|d and hamper cy||nder movement If headspace |s

excess|ve you can get m|sf|res and]or expanded case heads

Cy||ndertobore a||gnment 1h|s requ|res us|ng a kange kod and a ca||brated cartr|dge case Insert the kange kod |nto

the bore and push |t |n s|ow|y unt|| the t|p of the kange kod moves through the cy||nder and contacts the frame ou

may have to he|p |t a ||tt|e by w|gg||ng the cy||nder u|| the kange kod out unt|| the t|p |s past the face of the cy||nder

and observe the co||ar |n reference to the muzz|e 1h|s w||| g|ve an |nd|cat|on on how deep the kange kod has been

|nserted when test|ng 1urn the kange kod hand|e so the reference post |s |n the 12 o'c|ock pos|t|on L|sten and fee|

for the fee|er t|p of the kange kod to contact the cy||nder face as you move the kange kod |n and out kepeat the test

w|th the reference post |n the 3 6 and 9 o'c|ock pos|t|on Idea||y the kange kod w||| enter the chamber throat

w|thout "t|ck|ng" on the cy||nder face |n a|| pos|t|ons If a|| chambers pass th|s test the gun |s w|th|n spec|f|cat|ons

1|m|ng sequence 1|m|ng |s the ser|es of events that happen from the moment you beg|n to squeeze the tr|gger |n DA

or beg|n to cock the hammer |n SA and ends when the tr|gger f|na||y resets for the next shot

S|ng|e Act|on Cyc|e

As the hammer |s be|ng cocked

1 1r|gger beg|ns to move to the rear

2 Cy||nder |atch |s pu||ed down re|eas|ng the cy||nder

3 1he paw| engages the extractor ratchet and beg|ns to rotate the cy||nder CCW

4 Cy||nder |atch |s re|eased and snaps up to r|de on the cy||nder

S Cy||nder |atch engages the cy||nder notch

6 1ransfer bar |s ||fted |nto pos|t|on

7 aw| cams off of the extractor ratchet

8 nammer reaches the cock|ng po|nt and |s he|d to the rear by the SA sear

As the tr|gger |s pu||ed

9 1r|gger moves to the rear ra|s|ng the transfer bar s||ght|y

10 SA sear re|eases the hammer

11 nammer moves forward under tens|on of the hammer spr|ng

12 nammer str|kes the transfer bar

13 1ransfer bar str|kes the f|r|ng p|n

14 I|r|ng p|n str|kes the pr|mer caus|ng the gun to f|re

1S I|r|ng p|n retracts under spr|ng tens|on

As the tr|gger |s re|eased

16 1r|gger beg|ns to move forward

17 1ransfer bar |s pu||ed down

18 1r|gger p|unger resets on cy||nder |atch

19 aw| |s pu||ed down to reset pos|t|on

20 1r|gger |s fu||y forward and at rest

Doub|e Act|on Cyc|e

As the tr|gger |s pu||ed

1 1r|gger cams the hammer back

2 Cy||nder |atch |s pu||ed down re|eas|ng the cy||nder

3 aw| moves up and beg|ns to rotate the cy||nder CCW

4 Cy||nder |atch |s re|eased and pops up to r|de on the cy||nder

S 1r|gger and hammer cont|nue to move to the rear ra|s|ng the transfer bar

6 Cy||nder stop engages the cy||nder notch and |ocks

7 nammer dog re|eases the hammer a||ow|ng |t to transfer to the DA sear

8 DA sear re|eases hammer a||ow|ng |t to spr|ng forward

9 nammer str|kes the transfer bar

10 1ransfer bar str|kes the f|r|ng p|n

11 I|r|ng p|n str|kes the pr|mer caus|ng the gun to f|re

12 I|r|ng p|n retracts under spr|ng tens|on

As the tr|gger |s re|eased

13 1r|gger beg|ns to move forward

14 1ransfer bar |s pu||ed down

1S 1r|gger p|unger resets on cy||nder |atch

16 aw| |s pu||ed down to reset pos|t|on

17 1r|gger |s fu||y forward and at rest

In|t|a| t|m|ng Sw|ng the cy||nder open and |ook for the cy||nder |atch that |s |ocated on the bottom f|at area of the

frame [ust above the tr|gger Now c|ose the cy||nder and rotate |t s||ght|y unt|| the cy||nder |ocks up Watch the

cy||nder |atch from the r|ght s|de as you beg|n cock|ng the hammer 1he cy||nder |atch shou|d drop and free the

cy||nder before the cy||nder actua||y beg|ns to rotate Do the same test |n DA by pu|||ng the tr|gger and watch|ng the

cy||nder |atch Aga|n the |atch shou|d drop before the cy||nder beg|ns to rotate If |n|t|a| t|m|ng |s s|ow the cy||nder

w||| try to rotate before |t |s re|eased 1h|s w||| cause a b|nd |n DA tr|gger pu|| or a hard start cock|ng for SA A worn or

out of spec tr|gger p|unger (part #48) or cy||nder |atch (part #6) w||| cause |ate |n|t|a| t|m|ng

Carryup t|m|ng Carryup |s a cond|t|on where the cy||nder |s supposed to |ock up near the end of a hammer stroke

1o test watch the cy||nder |atch and s|ow|y cock the hammer 1he |atch shou|d drop then pop back up and drag on

the cy||nder 1he cy||nder |atch shou|d engage a cy||nder |ock notch and |ock the cy||nder |n p|ace before the hammer

|s fu||y cocked |n a|| s|x pos|t|ons Aga|n |n the DA mode s|ow|y pu|| the tr|gger and make sure the cy||nder |ocks up |n

each of the s|x pos|t|ons before the hammer re|eases An excess|ve|y premature carryup can cause a tr|gger pu|| gag

near the end of the tr|gger stroke Late carryup cou|d a||ow the gun to f|re before the cy||nder |s |ocked Norma||y

G100s tend to carryup a b|t ear|y A paw| that |s too |ong causes premature carryup Late |ockup |s caused by a

worn or out of spec paw| or extractor ratchets

1r|gger pu|| Use a tr|gger pu|| test sca|e to measure SA and DA tr|gger pu|| we|ght 1h|s w||| be a good reference po|nt

for a "before and after" scenar|o ou can a|so use a str|ng and can then start f||||ng the can w|th shot or sand unt|| the

hammer tr|ps Lven a "f|sh sca|e" w||| work for measur|ng tr|gger pu|| Norma| outofthebox SA tr|gger pu|| |s 6 |bs

DA tr|gger pu|| |s norma||y 14 |bs

I|r|ng p|n protrus|on 1he f|r|ng p|n |n a G100 |s an "|nert|a" dev|ce 1h|s means |t |s spr|ng |oaded so the f|r|ng p|n

w||| retract after be|ng struck When the hammer str|kes the transfer bar and |n turn the transfer bar str|kes the f|r|ng

p|n the f|r|ng p|n w||| be dr|ven cons|derab|y farther than one wou|d th|nk If you exam|ne the f|r|ng p|n protrus|on

w|th the tr|gger pu||ed and the hammer push|ng the transfer bar forward you w||| get a fa|se |nd|cat|on of protrus|on

Note a |onger f|r|ng p|n than the standard factory f|r|ng p|n w||| not app|y any more energy to the pr|mer If you get

||ght pr|mer h|ts |t's very rare|y the f|r|ng p|n but rather the hammer energy 1he protrus|on test |s best conducted

after the hammer has been removed and |s deta||ed |ater |n the text

ush off 1he sear |s des|gned to ho|d the hammer cocked |n the SA mode If the sear |s a|tered or defect|ve the sear

cou|d re|ease by push|ng on the hammer 1o test cock the hammer and app|y cons|derab|e forward pressure to the

top of the hammer Do not overdo |t or you w||| break the sear If the hammer pushes off you w||| need to repa|r the

sear or rep|ace the hammer (part #64) or tr|gger (part #68) Note both the hammer and tr|gger are factory f|tted parts

and are not so|d by kuger or 8rowne||'s as spare parts

Cy||nder |ockup 1o test dry f|re the gun and ho|d the tr|gger a|| the way back to s|mu|ate the cond|t|on of the gun

when f|red kock the cy||nder from s|de to s|de A few thousandths p|ay |s norma| If s|de p|ay |s excess|ve a new

cy||nder |atch (part # 6) may be needed

arts funct|on d|sassemb|y tun|ng and reassemb|y

As each of the subassemb||es and |nd|v|dua| parts are d|scussed a "*" w||| |nd|cate a potent|a| prob|em that may need

attent|on A schemat|c has been |nc|uded for part number reference on page 16 C|ean each part w|th so|vent before

|nspect|ng or dress|ng kemove a|| grease o|| powder res|due and bu||et res|due as you go

Gr|ps 1o remove the gr|ps unscrew the gr|p screw (part #19) most of the way out then push on the head of the screw

to d|s|odge the |eft gr|p pane| (part #17) Cnce the |eft pane| |s pushed out a sma|| d|sassemb|y p|n (part # 9) w||| drop

out kemove the gr|p screw ush |n on the gr|p pane| |ocator (part #18) from the |eft s|de unt|| the r|ght gr|p pane|

pops out u|| the gr|p pane| |ocater out of the r|ght s|de S||de the gr|p (part #14) down and off the gr|p frame

* nammer strut subassemb|y 1he purpose of the hammer strut assemb|y |s to conta|n the ma|nspr|ng and prov|de a

means to push the hammer forward It |s made up of a hammer strut ma|nspr|ng and the ma|nspr|ng seat 1o

remove the hammer strut assemb|y cock the hammer then p|ace the d|sassemb|y p|n (part #9) |n the ho|e near the

end of the hammer strut (part #22) If you don't have the d|sassemb|y p|n a paper c||p w||| do Lase the hammer

down unt|| |t stops Grab the strut assemb|y and pu|| |t out of the gun Note the "offset" |n the strut When you

reassemb|e the strut must be |nsta||ed the same exact way |t came out 1|ghten the t|p of the strut |n a v|se Use a

k|tchen fork and p|ace the t|nes of the fork |n the spr|ng co||s near the seat ush down to tens|on the spr|ng enough

to remove the d|sassemb|y p|n Note the way the ma|nspr|ng seat (part #28) |s |nsta||ed It must be re|nsta||ed exact|y

the same way |t came off Lase the spr|ng and seat off the strut 8e carefu| w|th th|s step because |f you s||p off the

spr|ng and seat w||| |aunch under cons|derab|e force 1he hammer strut |s a stamped part that typ|ca||y has very sharp

edges 1hese edges and the ba|| t|p need to be dressed down so the strut does not b|nd or drag on the ma|nspr|ng or

fu|crum seat |n the hammer Use a f||e or Dremme| 1oo| to round a|| four edges of the strut

* Ma|nspr|ng (hammer spr|ng) cons|derat|ons 1he ma|nspr|ng deve|ops the energy needed to prope| the hammer

hard enough to detonate a pr|mer It a|so affects "|ock t|me" wh|ch |s the t|me |t takes for the hammer to h|t the

pr|mer once the sear re|eases kuger typ|ca||y |nsta||s a stronger ma|nspr|ng than |s necessary A stronger ma|nspr|ng

w||| make both DA and SA tr|gger pu|| harder but |t a|so reduces |ock t|me Ior best accuracy you want to keep |ock

t|me as short as poss|b|e yet reduce tr|gger pu|| to a more comfortab|e |eve| 1he factory ma|nspr|ng |s rated at 14 |bs

A good comprom|se |s a 12 |b ma|nspr|ng A spr|ng k|t |s ava||ab|e from www8rowne||scom that |nc|udes a 9 10 and

12 |b hammer spr|ng (8rowne||'s ]N 08066S103) If you choose a ma|nspr|ng ||ghter than 12 |bs you may

exper|ence ||ght pr|mer h|ts (m|sf|res) and w||| have a much |onger |ock t|me Insta|| the spr|ng of your cho|ce by

p|ac|ng the strut back |n the v|se S||de the spr|ng |n p|ace then use the k|tchen fork to compress the spr|ng |ace the

ma|nspr|ng seat on the strut and secure |t w|th the d|sassemb|y p|n kemove the fork and set the strut assemb|y as|de

for now

nammer assemb|y 1he purpose of the hammer |s to app|y a str|k|ng force to the pr|mer when the SA or DA sear |s

tr|pped 1he hammer has a sma|| notch on the extens|on 1h|s notch mates w|th the extens|on on the tr|gger to form

the SA sear When the hammer |s cocked the tr|gger extens|on |s he|d by the hammer's notch unt|| the tr|gger |s

pu||ed ou can |ook |n the frame s|ot [ust |n front of the hammer and see the re|at|onsh|p of the SA sear 1he spr|ng

|oaded hammer dog (part #6S) |s p|cked up by the tr|gger cam extens|on |n DA As the tr|gger |s pu||ed the tr|gger

extens|on cams the hammer back unt|| the hammer dog s||ps off the tr|gger extens|on and |s p|cked up by the DA sear

When the DA sear re|eases |t causes the hammer to thrust forward and f|re 1o remove the hammer (part # 64) pu||

the tr|gger a|| the way back and ho|d |t there then use the round end of the hammer strut (part # 22) to push the |eft

end of the hammer p|vot p|n (part #21) out Grab the r|ght f|ange on the hammer p|vot p|n and pu|| |t comp|ete|y out

L|ft the hammer out of the frame ke|ease the tr|gger See photos on pages 17 18

* Inspect the hammer's sear notch for rough spots Dress w|th a f|ne stone |f necessary Do not change the sear ang|e

and don't remove any more meta| than abso|ute|y necessary to c|ean up the sear notch

1o remove the hammer dog use a paper c||p or sma|| p|n punch to push the hammer dog p|n (part #20) out of the

hammer 1he hammer dog p|unger (part #S) and spr|ng (part #4) w||| fa|| out

* 1he |ower |ns|de area of the hammer dog |s the mat|ng surface for the DA sear It must be smooth or DA tr|gger pu||

w||| fee| raspy Use a Dremme| 1oo| w|th a buff|ng whee| and f|ne gr|t compound to dress the |ower rear surface of the

hammer dog Inspect the s|des of the hammer for smoothness Dress as necessary to remove sharp edges rough

spots or res|due See photo on page 18

kep|ace the hammer dog spr|ng and p|unger no|d the hammer dog |n pos|t|on and |nsta|| the hammer dog p|vot p|n

1est the hammer dog for free movement and spr|ng return

1r|gger guard assemb|y 1he assemb|y conta|ns the tr|gger cy||nder |atch transfer bar paw| and the|r assoc|ated

spr|ngs p|ungers and p|ns 1he assemb|y |s he|d |n the frame by a spr|ng|oaded p|unger (part #43) 1he t|p of the

p|unger snaps |nto a ho|e |n the frame [ust beh|nd the tr|gger guard and |ns|de the gr|p frame Locate the p|unger t|p

and push |t forward w|th a screwdr|ver or other too| wh||e pu|||ng downward ||ght|y on the tr|gger guard 1he

comp|ete assemb|y w||| pop out Set the rest of the gun as|de for now u|| the tr|gger back s||ght|y then remove the

transfer bar (part #42) no|d the tr|gger back w|th your |eft foref|nger and pos|t|on your |eft thumb over the rear of

the paw| (part #29) W|th your r|ght hand pu|| the paw| to the r|ght to remove 1he paw| spr|ng (part #8) and paw|

p|unger (part #S) w||| try to pop out and |aunch un|ess you conta|n them w|th your thumb kemove the paw| spr|ng

and p|unger |ace your |eft |ndex f|nger |n the tr|gger guard beh|nd the tr|gger Use your |eft thumb to push the

tr|gger guard |atch |n (part #43) Use a paper c||p or st|ff w|re and push the |atch reta|n|ng p|n (part #20) comp|ete|y

out ke|ease the tr|gger guard |atch (part #43) and pu|| |t out u|| the tr|gger guard |atch spr|ng (part #44) and the

tr|gger ||nk p|unger (part #47) out of the ho|e |n the tr|gger guard (part #69)

* 8efore remov|ng the rest of the tr|gger parts test the tr|gger for free movement ou shou|d be ab|e to move the

tr|gger from stop to stop w|th no b|nd|ng or dragg|ng If you detect a b|nd try to |so|ate |t by watch|ng the tr|gger

move |ns|de the struts Cnce the tr|gger |s out you can dress the h|gh spots on the s|des of the tr|gger or the |ns|de of

the struts A f|ne f||e w||| work we|| to remove burrs or h|gh spots

Use a paperc||p or sma|| p|n punch to push the tr|gger p|n (part #70) a|| the way out 1he tr|gger (part #68) and tr|gger

p|unger (part #48) w||| fa|| out os|t|on your |eft thumb over the cy||nder |atch (part #6) and s||de the |atch to the

r|ght to remove 1he spr|ng|oaded p|unger may |aunch so keep you thumb |n pos|t|on unt|| the |atch |s a|| the way

out kemove the |atch p|unger (part #30) and the spr|ng (part #8) from the tr|gger guard assemb|y

* 1he tr|gger p|unger (part #48) |s a stamped part typ|ca||y w|th sharp edges on one s|de 1he nose (|ooks ||ke x an

arrowhead) act|vates the cy||nder |atch If |t |sn't perfect|y smooth the tr|gger doesn't want to reset when re|eased If

the nose of the tr|gger p|unger |s too short you w||| get |ate |n|t|a| t|m|ng |ace the rough s|de down on a p|ece of 400

gr|t sandpaper and burn|sh the s|de smooth 8uff the ramp of the x arrowhead unt|| |t |s po||shed ||ke chrome 8uff

the ||tt|e notch under the front of the arrowhead espec|a||y the t|p 1h|s |s the surface that pu||s the cy||nder |atch

down If |t |s rough you w||| fee| a gag |n the DA stroke

* 1he cy||nder |atch (part #6) |s a cast part w|th a mach|ned surface on the bottom 8uff the top of the |atch (the

rounded part that |ocks |nto the cy||nder) unt|| |t |ooks ||ke chrome A|so remove any mach|ne marks from the bottom

surface and buff |t smooth kemove any rough cast|ng marks or sharp edges from the s|des of the cy||nder |atch

* 1he tr|gger (part #68) |s cast and typ|ca||y has sharp edges or rough surfaces 1he cam surface at the top end of the

tr|gger |s the area used to cam back the hammer |n DA and mates w|th the back edge of the hammer dog It must be

very smooth 1he mach|ned end of the cam |s the SA sear It too must be very smooth Use a buffer to make these

surfaces |ook ||ke chrome See photo on page 17

* 1he paw| (part #29) |s a|so a cast part and may have sharp edges or a rough surface 1he top |eft t|p of the paw|

mates w|th the cy||nder's ratchets to rotate the cy||nder 1he top |eft s|de of the paw| shou|d be po||shed ||ke chrome

* 1he transfer bar (part #42) |s a cast part that a|most a|ways has sharp edges or cast|ng marks Dress the transfer bar

w|th a 400gr|t sandpaper to smooth |t up

* 1he cast tr|gger guard frame (part #69) shou|d be "unpopu|ated" at th|s po|nt Inspect |t carefu||y and remove any

burrs from the |ock ||p |n the front Do not mess w|th the sharp s|de edges because they mate w|th the frame for

cosmet|cs Insert the tr|gger guard |n the frame Note the f|t Cften the factory |eaves the back surface (the f|at area

around the tr|gger guard |atch ho|e) |onger than |t shou|d be 1h|s makes tr|gger guard remova| very d|ff|cu|t If the

tr|gger guard has to be forced |nto the frame to f|t you can f||e down the rear f|at surface unt|| the tr|gger guard

|nserts |nto the frame w|th m|n|ma| fr|ct|on

* 1he ho|e |n the tr|gger guard where the tr|gger]|atch spr|ng goes (part # 44) |s often very rough from dr||| marks and

|s somet|mes unders|zed 1h|s makes the spr|ng and tr|gger ||nk p|unger (part #47) drag and b|nd |n both SA and DA

Use a 13]64" dr||| b|t and "hand turn" |t to c|ean up the ho|e Do not try to dr||| any deeper [ust get the ho|e smooth

Insert the tr|gger ||nk p|unger after you c|ean up the ho|e It shou|d move free|y a|| the way through the ho|e If the

p|unger does not move free|y dress the ho|e some more kemove the tr|gger ||nk p|unger

keassemb|y of the tr|gger guard assemb|y Insert the cy||nder |atch spr|ng and p|unger (parts #8 30) |nto the ho|e at

the top front of the tr|gger guard frame [ust under the hor|zonta| shaft Note there are two spr|ng and p|unger sets

ou want the |onger one W|th the cy||nder |atch (part #6) rounded area up start the cy||nder |atch on the tr|gger

guard frame shaft (top front) It w||| go on about ha|f way before |t contacts the p|unger Carefu||y use a too| to push

the p|unger down wh||e push|ng the cy||nder |atch fu||y on the shaft If you s||p off the p|unger |t w||| |aunch so be

carefu| Cnce the cy||nder |atch |s on the shaft check for free spr|ng|oaded movement

Set the tr|gger p|unger (part #48) |n the s|ot |n the top of the tr|gger 1he x arrowhead shou|d be up and to the front

It |s eas|est to |nsta|| by p|ac|ng the arrowhead end |n f|rst wh||e ho|d|ng the back up at an ang|e Cnce the tr|gger

p|unger |s |n pos|t|on |nsert the tr|gger |nto the tr|gger guard frame mak|ng sure the spr|ng strut |s |n the tr|gger

spr|ng ho|e Use a paper c||p or w|re as a fo||ower and |nsert |t |nto the tr|gger p|vot p|n ho|e Insert the tr|gger p|vot

p|n wh||e pu|||ng the fo||ower out 1h|s keeps the parts a||gned Cnce the tr|gger p|vot p|n |s |nsta||ed make sure |t |s

f|ush on both ends As you rock the tr|gger guard back and forth the tr|gger shou|d move free|y from stop to stop

Insert the tr|gger ||nk p|unger (part #47) |n the ho|e d|mp|e end f|rst App|y a drop of o|| |n the ho|e

* Now |s a good t|me to dec|de on a tr|gger return]tr|gger guard |atch spr|ng 1he factory spr|ng |s a ||tt|e heavy (11

|bs) 1he above referenced spr|ng k|t comes w|th an 8 |b and 10 |b spr|ng ou may be ab|e to use e|ther one however

the 10 |b spr|ng w||| have a more pos|t|ve tr|gger reset 1he stronger the spr|ng the heav|er both SA and DA tr|gger

pu|| w||| be Insert the tr|gger return]tr|gger guard |atch spr|ng (part #44) of your cho|ce Insert the tr|gger guard |atch

(part #43) w|th the f|at surface up no|d the |atch |n w|th your |eft thumb aga|nst spr|ng tens|on wh||e |nsert|ng the

|atchreta|n|ng p|n (part #20) |n the ho|e w|th your r|ght hand Make sure the reta|n|ng p|n |s f|ush on both s|des no|d

the tr|gger a|| the way back w|th your |eft hand and m|dd|e f|nger Insert the paw| spr|ng and p|unger (parts #8 S) |n

the ho|e of the tr|gger [ust under the cam surface App|y a drop of o|| to the p|unger Start the paw| shaft |nto the

ho|e w|th the paw| |ean|ng forward ush the p|unger down wh||e s||d|ng the paw| |n Note the p|unger and spr|ng are

notor|ous for |aunch|ng 1h|s step |s best done |ns|de a c|ear p|ast|c bag to prevent |oos|ng the p|unger spr|ng Cnce

the paw| |s |n a|| the way pos|t|on |t vert|ca||y and a||ow the tr|gger to move forward u|| the tr|gger back s||ght|y

app|y a drop of o|| to the transfer bar |ug then |nsert the transfer bar (part #42) |nto the ho|e oppos|te the paw| A||ow

the tr|gger to spr|ng forward to reta|n both the transfer bar and paw| Set the tr|gger guard assemb|y as|de for now

Cy||nder assemb|y remova| ress Lhe cyllnder release buLLon (parL #32) and swlng Lhe cyllnder ouL ull Lhe crane and

cyllnder forward Lo remove lL from Lhe frame noLe Laklng Lhe cyllnder assembly aparL and puLLlng lL back LogeLher ls

Lrlcky 1here really aren'L any parLs LhaL need dressed lnslde Lhe cyllnder so you may noL wanL Lo Lake lL aparL however

powder resldue does accumulaLe lnslde Lhe cyllnder so you may need Lo clean and lubrlcaLe lL lf Lhe endshake LesL aL

Lhe beglnnlng was ouL of spec (more Lhan 003") you wlll need Lo Lake Lhe cyllnder aparL Lo lnsLall endshake bearlngs

* ?ou can geL Lo Lhe e[ecLor (parL #38) wlLhouL Laklng Lhe cyllnder assembly aparL ush Lhe e[ecLor rod ln all Lhe way

lace your Lhumb and flngers beLween Lhe boLLom of Lhe e[ecLor (sLar wheel) and Lhe Lop of Lhe cyllnder Lo hold Lhe

e[ecLor up lnspecL all slx Llps of Lhe e[ecLor by dragglng your flngernall across Lhe Llps 1yplcally Lhe Llps have a llne of

galllng on Lhe Lop ouLer edge 1hese ralsed llnes wlll noL allow Lhe carLrldges Lo seaL properly and wlll cause Lhem Lo

drag on Lhe recoll shleld use a flne flle Lo dress Lhe Llps

* Closely lnspecL Lhe edges of Lhe raLcheLs Pold Lhe cyllnder as before so you are looklng down aL Lhe e[ecLor 1he Llp of

Lhe pawl caLches Lhe rlghL leadlng edge of Lhe raLcheLs Lo roLaLe Lhe cyllnder 1he lnslde edge of each raLcheL (Lhe slde

wlLh Lhe angle cuL) musL be smooLh and free of burrs ?ou can remove any burrs on Lhe ouLslde dlameLer of Lhe raLcheL

and Lhe lnner sloLs wlLh a flne [eweler's flle Any rough spoL wlll cause Lhe pawl Lo dlg ln make uA Lrlgger pull raspy and

wlll wear Lhe Llp of Lhe pawl See phoLo on page 19 lf you declde noL Lo dlsassemble Lhe cyllnder move on Lo Lhe lrame

Loplc

Cy||nder d|sassemb|y LocaLe Lhe hole drllled on Lhe flaL surface of Lhe crane (parL #31) use a paper cllp or small pln

punch lnserLed ln Lhe hole and push down ?ou should feel Lhe sprlngloaded plunger (parLs # 22 23) move down

Whlle presslng Lhe plunger down push Lhe laLch plvoL pln (parL #23) ouL from Lhe lnslde of Lhe crane 1he fronL laLch

(parL #13) laLch plunger (parL #26) and laLch plunger sprlng (parL #4) wlll fall ouL ull Lhe e[ecLor rod (parL #11) ouL of

Lhe cyllnder ull Lhe crane (parL #31) ouL of Lhe cyllnder ?ou can accompllsh a good cleanlng wlLhouL Laklng Lhe lnLernal

cyllnder parLs ouL llood Lhe lnslde of Lhe cyllnder hole wlLh a good cleaner and blow lL ouL wlLh compressed alr

1hls nexL sLep ls noL recommended unless you have Lhe proper Lool use a hollow shafL flaL Llp screwdrlver and unscrew

(lefL hand Lhread) Lhe e[ecLor reLalner (parL #60) noLe Lhe e[ecLor reLalner ls secured wlLh Lhread lock ull Lhe cenLer

pln rod (parL #2) and cenLer pln sprlng (parL #3) ouL from Lhe fronL and Lhe e[ecLor (parL #38) ouL from Lhe rear AfLer Lhe

parLs have been cleaned lnserL Lhe e[ecLor from Lhe rear and Lhe sprlng and cenLer pln rod from Lhe fronL 1hread Lhe

e[ecLor reLalner back on belng careful noL Lo geL lL crossLhreaded or LlghLenlng lL Loo much

Note now ls Lhe Llme Lo lnsLall cyllnder endshake bearlngs lf needed 1he endshake bearlngs are noLhlng more Lhan

washers 002" Lhlck (8rownell's /n 713200002) ?ou can sLack Lhem lf necessary Lxample lf your endshake was

006" you could lnsLall one bearlng Lo brlng Lhe endshake back ln spec (002003") or Lwo bearlngs leavlng 002" of

endshake never seL endshake Lo less Lhan 002" 1o lnsLall endshake bearlngs puL a drop of oll on Lhe end of Lhe crane

Lube and anoLher drop on Lhe fronL Lube flange lace endshake bearlng(s) on Lhe crane Lube and lnserL Lhe crane lnLo

Lhe cyllnder uo noL force Lhe crane lnLo Lhe hole or you wlll ruln Lhe endshake bearlngs

Cy||nder reassemb|y uL a drop of gun oll on Lhe end of Lhe crane Lube and anoLher drop on each ball bearlng uo noL

over lubrlcaLe or powder resldue wlll form a grlLLy pasLe and blnd up Lhe cyllnder lnserL Lhe crane lnLo Lhe cyllnder hole

unLll lL fully seaLs uL a drop of oll on Lhe shorL sloLLed end of Lhe e[ecLor rod (parL #11) Pold Lhe crane so Lhe flaL

surface ls up lnserL Lhe sloLLed end of Lhe e[ecLor rod wlLh Lhe shorL sloL up lnLo Lhe crane and cyllnder hole Look ln Lhe

sloL aL Lhe fronL of Lhe crane ?ou should see a hole drllled Lo accommodaLe Lhe plunger sprlng lnserL Lhe fronL laLch

sprlng and plunger (parLs #4 26) ln Lhe sloL and move Lhe sprlng unLll lL falls ln Lhe hole lnserL Lhe end of Lhe fronL

laLch (parL #13) wlLh Lhe squared sLep lnLo Lhe lower long sloL of Lhe e[ecLor rod 1he curved nose should capLure Lhe

plunger Llp lnserL a wlre ln Lhe Lop hole of Lhe flaL surface of Lhe crane and push down agalnsL sprlng Lenslon lnserL Lhe

laLch plvoL pln (parL #23) Maneuver Lhe plvoL pln unLll lL goes Lhrough Lhe hole ln Lhe fronL laLch ?ou may have Lo press

and release Lhe sprlng loaded plunger wlLh Lhe wlre a few Llmes Lo geL Lhe plvoL pln Lo seaL all Lhe way When Lhe plvoL

pln ls fully seaLed Lhe pln wlll be flush wlLh Lhe lnslde surface of Lhe crane 1esL Lhe e[ecLor rod by pushlng lL ln and

allowlng lL Lo sprlng back lf Lhere ls a blnd you wlll have Lo dlsassemble and flnd ouL why Pold Lhe crane verLlcal wlLh

Lhe e[ecLor rod down Spln Lhe cyllnder lL should spln freely wlLh no blnds SeL Lhe cyllnder assembly aslde for now

* Irame |nspect|on and deburr|ng lnspecL Lhe lnslde of Lhe frame Look for galls or spllnLers of meLal especlally where

Lhe nose of Lhe Lrlgger guard assembly hooks lnLo Lhe frame and Lhe lnner sldes of Lhe frame where Lhe hammer flLs

8emove any galls and clean Lhe channels lnslde Lhe frame

* I|r|ng p|n use a Lool Lo push Lhe flrlng pln all Lhe way forward ?ou should feel Lhe sprlng Lenslon of Lhe flrlng pln

sprlng llrlng pln Lravel should be smooLh lf noL force solvenL lnLo Lhe flrlng pln hole and push Lhe flrlng pln ln mulLlple

Llmes Lo help clean ouL Lhe flrlng pln and hole 8low lL ouL wlLh compressed alr When pushed ln all Lhe way Lhe flrlng

pln should proLrude 033063" 1hls can be measured by laylng gap gauge blades on Lhe recoll shleld and maLchlng

proLruslon Lo Lhlckness 1he flrlng pln ls secured by a recoll plaLe (parL #31) and held ln place by a recoll plaLe cross pln

(parL #66) 8emovlng Lhe flrlng pln ls noL recommended because lL wlll damage Lhe flnlsh 1he flrlng pln ls a facLory flLLed

parL 1o remove Lhe flrlng pln you musL flrsL drlve Lhe cross pln ouL Lhen push Lhe recoll plaLe (AkA flrlng pln bushlng)

from Lhe rear A coll sprlng (parL #12) ls lnsLalled beLween Lhe collar on Lhe flrlng pln and Lhe recoll plaLe

8arre| |nspect|on Clean Lhe bore and forclng cone Lhoroughly before lnspecLlng Look for chaLLer marks ln Lhe bore

where Lhe rlfllng ls lnLerrupLed Look for a resLrlcLlon aL Lhe area where Lhe barrel screws lnLo Lhe frame lf Lhe bore ls

damaged Lhe gun musL be reLurned Lo Lhe facLory for a barrel replacemenL Mlnor rough spoLs are noL an lssue Closely

lnspecL Lhe forclng cone lf you see machlne marks low spoLs or any corrupLlon Lhe forclng cone should be chamfered

wlLh a reamer An 11 degree reamer provldes a smooLher LranslLlon from LhroaL Lo bore and ls recommended A

corrupLed forclng cone wlll affecL accuracy and wlll lncrease bulleL foullng

Crane |atch |nspect|on When Lhe cyllnder ls closed and laLched Lhe rear of Lhe cyllnder ls secured by Lhe cenLer pln rod

ln Lhe hole of Lhe frame under Lenslon of Lhe e[ecLor sprlng 1he crane's fronL laLch ls pushed lnLo a sloL ln Lhe frame

When Lhe cyllnder ls opened Lhe crane laLch (AkA cyllnder release buLLon parL #32) wlll sprlng ln 1he cenLer pln rod ls

pushed forward and releases from Lhe frame hole 1he cenLer pln rod releases Lhe fronL cyllnder laLch

* ush on Lhe fronL edge of Lhe crane laLch Lo check for free movemenL agalnsL sprlng Lenslon lnspecL Lhe recoll shleld

cenLer pln hole 1he Llp of Lhe crane laLch should be flush wlLh Lhe recoll shleld surface (+or a few LhousandLhs) lf Lhe

pln ls flush and Lhe laLch operaLes smooLhly Lhere ls no need Lo remove Lhe laLch lf Lhe crane laLch pln proLrudes pasL

flush you wlll have Lo flle a llLLle off Lhe end lf lL ls Loo shorL a new one wlll have Lo be flLLed and lnsLalled aL Lhe 8uger

facLory A long crane laLch pln wlll prevenL Lhe fronL laLch from securlng Lhe fronL of Lhe cyllnder assembly A shorL pln

wlll make lL very dlfflculL Lo release Lhe cyllnder lf Lhe laLch blnds you wlll have Lo locaLe Lhe blnd and dress Lhe frame

or crane laLch 1o remove Lhe crane laLch use a small hollow ground flaL Llp screwdrlver and unscrew Lhe crane laLch

plvoL screw (parL #33) hldden under Lhe crane laLch Cnce Lhe screw ls ouL manlpulaLe Lhe laLch unLll lL falls ouL noLe

Lhe sprlng and plunger (parLs #43) wlll also fall ouL 1he screw has Lhread lock uress Lhe crane laLch and parLlally lnserL

lL ln Lhe frame lnserL Lhe sprlng and plunger lnLo Lhe laLch and poslLlon Lhe laLch so Lhe crane laLch plvoL screw wlll

enLer Lhe hole ln Lhe laLch 1lghLen Lhe screw unLll lL sLops buL do noL over LlghLen

Iront s|ght |nspect|on lf Lhe barrel ls Lhreaded lnLo Lhe frame lmproperly Lhe fronL slghL wlll LllL Lo one slde or Lhe

oLher Check verLlcal allgnmenL by maklng sure Lhe barrel rlb ls allgned wlLh Lhe fronL Lop sLrap Cn ad[usLable slghL

models Lhe fronL slghL can be easlly removed and replaced wlLh a dlfferenL Lype slghL use a small punch or screwdrlver

and push ln on Lhe fronL slghL plunger (parL #38) LlfL Lhe rear of Lhe slghL Lo unlaLch 8emove Lhe fronL slghL (parL #32)

1he slghL plunger (parL #38) and sprlng (parL #39) can be removed lf necessary by pushlng Lhe plunger forward wlLh a

sLlff wlre from lnslde Lhe slghL channel AfLer cleanlng lnserL Lhe sprlng Lhen lnserL Lhe plunger wlLh Lhe sloL up lace

Lhe fronL doveLall of Lhe slghL ln Lhe channel ush Lhe slghL plunger ln whlle holdlng Lhe slghL down unLll Lhe slghL drops

ln place noLe Lhere are a hosL of dlfferenL fronL slghLs avallable from 8uger or afLermarkeL sources All Super 8edhawk

slghLs wlll flL a C100

kear s|ght |nspect|on Cn ad[usLable slghL models lnserL a proper flLLlng flaL blade screwdrlver ln Lhe wlndage screw

(parL #33) 1urn Lhe screw ln and ouL 1he rear slghL should cllck aL each of Lhe 8 poslLlons and Lhe rear slghL should

move up when roLaLlng counLerclockwlse or down lf roLaLed clockwlse Lach cllck movlng Lhe rear slghL up wlll ralse Lhe

bulleL's polnL of lmpacL lnserL a small flaL blade screwdrlver ln Lhe wlndage screw (parL #40) Lach of Lhe slx poslLlons

should cllck 1urnlng Lhe screw clockwlse wlll move Lhe slghL blade Lo Lhe lefL and wlll move Lhe polnL of lmpacL Lo Lhe

lefL as well 1o remove Lhe rear slghL hold Lhe rear slghL blade down wlLh your Lhumb and unscrew Lhe elevaLlon screw

all Lhe way Lase Lhe slghL up Lo release sprlng Lenslon ush Lhe slghL plvoL pln (parL #37) ouL wlLh a sLlff wlre or pln

punch LlfL Lhe slghL off 1here wlll be Lwo sprlngs (parL #36) under Lhe slghL 1o relnsLall place Lhe sprlngs ln Lhe pre

drllled holes

Lay Lhe slghL ln poslLlon and push Lhe slghL plvoL pln lnLo Lhe hole and Lhrough Lhe slghL unLll lL ls flush on boLh sldes

lnserL Lhe elevaLlon screw Pold Lhe rear of Lhe slghL down and LlghLen Lhe screw Lo Lhe deslred poslLlon noLe 8lack

whlLe ouLllne and v noLch rear slghL blades are avallable from 8uger Several oLher sLyles are avallable from afLermarkeL

sources 1o remove Lhe rear slghL blade Lurn Lhe wlndage screw counLerclockwlse unLll Lhe rlghL edge of Lhe slghL blade

ls flush wlLh Lhe slghL base uL your Lhumbnall ln Lhe slghL noLch and pull Lhe slghL blade Lo Lhe lefL agalnsL sprlng

Lenslon unLll Lhe rlghL slde pops up and releases from Lhe capLlve wlndage screw ull Lhe slghL blade up and ouL of Lhe

channel 1o lnsLall a new slghL blade lnserL Lhe lefL lower corner lnLo Lhe coll sprlng ull Lhe blade Lo Lhe lefL wlLh your

Lhumbnall unLll Lhe rlghL slde of Lhe blade drops ln use Lhe wlndage screw Lo cenLer Lhe slghL blade by Lurnlng Lhe

screw clockwlse

Insta|||ng the subassemb||es uL a drop of gun oll on Lhe shafL of Lhe crane lnserL Lhe crane shafL lnLo Lhe frame hole

whlle holdlng Lhe cyllnder ln Lhe open poslLlon Cnce seaLed swlng Lhe cyllnder lnLo Lhe laLched poslLlon

Apply a drop of oll Lo Lhe Lrlgger plvoL pln and Lrlgger plunger Pold Lhe gun wlLh Lhe muzzle down and lnserL Lhe fronL

Lab of Lhe Lrlgger guard assembly lnLo Lhe frame noLch Snap Lhe Lrlgger guard assembly lnLo poslLlon noLe lf Lhe Lrlgger

guard assembly doesn'L snap ln don'L force lL Chances are Lhe Lransfer bar or Lhe pawl ls noL poslLloned properly ?ou

may be able Lo poslLlon Lhe parLs by lnserLlng a wlre Lhrough Lhe hammer sloL Cnce Lhe Lrlgger guard assembly ls

snapped ln make sure lL ls fully laLched and Lhe surfaces of Lhe frame maLe wlLh Lhe surfaces of Lhe Lrlgger guard

assembly

ull Lhe Lrlgger all Lhe way back and hold lL Lhere urop Lhe hammer lnLo Lhe sloL 1urn Lhe gun sldeways wlLh Lhe serlal

number slde up Allgn Lhe hammer's frame hole wlLh Lhe hammer hole Apply a drop of oll on Lhe hammer plvoL pln

Lhen lnserL lL lnLo Lhe frame 8elease Lhe Lrlgger

WlLh Lhe hammer fully forward lnserL Lhe hammer sLruL assembly ln Lhe grlp frame 1he sLralghL edge of Lhe sLruL goes

up 1he noLched end of Lhe sLruL seaL goes down wlLh Lhe flaL surface Lo Lhe fronL Cock Lhe hammer and remove Lhe

dlsassembly pln Apply a few drops of oll along Lhe hammer sprlng ull Lhe Lrlgger and ease Lhe hammer down

Sllp Lhe rubber grlp over Lhe grlp frame unLll Lhe blg hole ln Lhe grlp allgns wlLh Lhe hole ln Lhe grlp frame Sllde Lhe grlp

panel locaLor lnLo poslLlon wlLh an equal amounL of pln exLendlng from boLh sldes Lay Lhe dlsassembly pln ln Lhe sloL aL

Lhe boLLom of Lhe lefL slde Snap Lhe lefL grlp lnserL lnLo poslLlon Snap Lhe rlghL grlp lnserL lnLo poslLlon lnserL Lhe grlp

screw from Lhe rlghL slde and LlghLen lL wlLh a screwdrlver

ury flre Lhe gun several Llmes Lo make sure everyLhlng works properly

Advanced Act|on Work

1here are a number of Lhlngs you can do wlLh a C100 LhaL requlre machlnlng or skllls beyond a hobbylsL 1he hammer

cannoL be purchased from 8uger or 8rownell's so lf you ruln lL you're ouL of luck ?ou may flnd a used one from

numrlch or Lbay

1r|gger sh|mm|ng 8emove Lhe Lrlgger guard assembly and measure Lhe slde play beLween Lhe one slde of Lhe Lrlgger

and Lhe sLruL normally Lhere wlll be abouL 008" Lrlgger slde play yours may vary SubLracL 002" and dlvlde Lhe

remalnder by 2 ln Lhe case of 008" gap 008002006" 006/2003" Make shlm washers 003" Lhlck and lnsLall Lhem

on boLh sldes of Lhe Lrlgger beLween Lhe sLruLs 1hls wlll serve as a boss or bearlng surface and wlll keep Lhe Lrlgger from

movlng sldeways when pulled lL wlll reduce frlcLlon from Lhe sLruLs and wlll force Lhe Lrlgger Lo make a more unlform

conLacL wlLh Lhe hammer Shlm specs Cu3" lu1" AfLer lnsLalllng Lhe shlms make sure Lhe Lrlgger moves freely ln

Lhe sLruLs

nammer sh|mm|ng WlLh Lhe gun fully assembled measure Lhe gap beLween one slde of Lhe hammer and Lhe frame

Much llke Lhe Lrlgger you wlll usually see abouL 008" of slack 1hls slack allows Lhe hammer Lo wander a blL

horlzonLally Look aL Lhe sldes of Lhe hammer lf you see arc llke scraLches lL means Lhe hammer has been dragglng on

Lhe frame 1hls reduces hammer LhrusL and prevenLs Lhe hammer from seaLlng wlLh Lhe Lrlgger exacLly Lhe same for

each shoL 1hls ls evldenced by measurlng Lhe SA Lrlgger pull 10 Llmes and geLLlng dlfferenL pull welghLs use Lhe same

formula as wlLh Lhe Lrlgger Assumlng a 008" gap lnsLall 003" shlm washers on boLh sldes of Lhe hammer 1hls creaLes

a boss" aL Lhe hammer's plvoL polnL and noL only conLrols slde drlfL lL acLs llke a bearlng Lo reduce frlcLlon and prevenLs

Lhe hammer from rubblng on Lhe frame lnsLalllng Lhe shlms ls a Lrlck 1he besL way ls Lo lnserL Lhe hammer Lhen sllde

Lhe shlm down Lhe slde of Lhe hammer use a gap gauge blade Lo push lL lnLo poslLlon uo Lhe serlal number slde of Lhe

gun flrsL Lhen sLarL Lhe hammer plvoL pln and do Lhe oLher slde Shlm specs Cu3" lu2" When boLh shlms are ln and

Lhe hammer plvoL pln ls seaLed check Lhe hammer for free movemenL

1ransfer bar hammer and f|r|ng p|n re|at|onsh|p When Lhe hammer sLrlkes Lhe Lransfer bar and ln Lurn Lhe flrlng pln

much of Lhe energy ls dlsslpaLed by Lhe Lop sLep on Lhe hammer hlLLlng Lhe frame lnsLead of energy belng efflclenLly

Lransferred Lo Lhe flrlng pln much of Lhe energy ls wasLed 1hls becomes very lmporLanL when llghL hammer sprlngs are

used ?ou need all Lhe energy you can geL Lo prevenL llghL prlmer hlLs 1he soluLlon ls Lo remove some meLal from Lhe

Lop sLep of Lhe hammer so less energy ls wasLed lf you remove Loo much meLal from Lhe Lop sLep Lhe hammer wlll

capLure" Lhe Lransfer bar and noL allow lL Lo reLracL 1hls would cause a fallure Lo reseL condlLlon for Lhe Lrlgger (won'L

sprlng back) ?ou can safely Lake 020" off Lhe Lop hammer sLep lf Lhe Lransfer bar capLures you can remove a few

LhousandLhs aL a Llme from Lhe rear surface of Lhe Lransfer bar unLll lL reseLs properly

Ske|eton|z|ng the hammer Lnergy ls derlved from veloclLy squared Llmes mass As you can see veloclLy has more

lnfluence Lhan mass WlLh sprlngpowered devlces such as a hammer you can reduce mass ln noncrlLlcal areas and

lncrease hammer veloclLy conslderably 1hls has Lwo ma[or advanLages 1he lock Llme wlll be greaLly reduced and Lhe

amounL of energy on Lhe flrlng pln wlll be lncreased ?ou can Lhen lnsLall very llghL hammer sprlngs and sLlll geL lock

Llmes [usL as fasL as a facLory sprlng wlLh a facLory hammer whlle havlng plenLy of energy on Lhe flrlng pln for rellable

prlmer deLonaLlon 1here are a number of paLLerns and Lechnlques you can use 1he crlLlcal mass porLlon of Lhe hammer

ls Lhe spur and above 1hls mass funcLlons much llke a hammer used Lo drlve nalls 1he handle" of Lhe hammer ls Lhe

area below Lhe spur and above Lhe fulcrum (plvoL pln) ?ou don'L wanL Lo remove any meLal wlLhln x" of Lhe cenLer of

Lhe plvoL pln hole or Lhe hammer wlll develop Loo much slde play So any meLal beLween LhaL polnL and Lhe spur ls falr

game 8uger made Lhe hammer very masslve so you can easlly reduce Lhe welghL by 23 wlLhouL compromlslng

sLrengLh ?ou can drlll holes Lhrough Lhe sldes of Lhe hammer or machlne Lhe hammer sldes Lo glve an hour glass"

flgure when vlewed from Lhe rear When a facLory hammer ls lnsLalled you can Lrace Lhe conLour of Lhe frame and

remove all meLal from [usL below Lhe spur Lo Lhe back edge lnsLalllng hammer shlms also lmproves Lhls Lechnlque

Chamfer|ng the chambers When C100s are used for compeLlLlon speed loaders wlll also be used CarLrldges don'L

llke belng poked lnLo a sharp hole especlally lead bulleLs ?ou can chamfer Lhe mouLh of Lhe chambers wlLh an 8 degree

reamer 1hls wlll make Lhe chamber mouLh have somewhaL of a cone shape and wlll allow wadcuLLers or seml

wadcuLLers Lo chamber wlLhouL sLubblng on Lhe chamber mouLhs Chamferlng Lhe mouLhs wlll noL resLrlcL uslng full

power loads nor wlll lL have any oLher adverse affecL use a forclng cone reamer and cuL [usL enough Lo see a cone

develop 8emove Lhe cyllnder assembly from Lhe frame and lnserL 3 spenL cases ln Lhe chambers 8eam Lhe empLy

chamber Lhen swlLch cases Lo expose anoLher chamber unLll all are chamfered

Cpt|m|z|ng for |ead bu||ets C100s come from Lhe facLory opLlmlzed for [ackeLed bulleLs 1he bore dlameLer ls Lyplcally

very unlform aL 3373373" Cyllnder LhroaLs are Lyplcally 3373" 1hls ls a blL LlghL for lead bulleLs ?ou can open Lhe

LhroaLs Lo 3383" wlLh a LhroaL reamer from 8rownell's 1hls wlll make all LhroaLs Lhe same slze lL allows lead bulleLs Lo

bumpup" ln dlameLer Lhen geL slzed Lo bore dlameLer by Lhe forclng cone Chamferlng Lhe forclng cone Lo 11 degrees

ls also recommended CpLlmlzlng for lead bulleLs wlll lmprove accuracy and reduce lead foullng ?ou can sLlll shooL

[ackeLed bulleLs wlLh nearequal performance Lo Lhe facLory seL up Accuracy wlll probably noL change buL foullng wlll be

reduced ?ou wlll lose a Loken amounL of veloclLy Lyplcally 2330 fps for a magnum load

8ore |app|ng llre lapplng producLs are noL recommended 1hey creaLe excesslve wear Lo Lhe edges of Lhe rlfllng and

have Lhe same effecL as flrlng Lhousands of rounds of ammunlLlon uslng valve grlndlng compound and a cloLh paLch

hand powered on a cleanlng rod works besL Worklng from Lhe muzzle and Laklng abouL 100 back and forLh sLrokes wlll

smooLh Lhe sLrlaLlon marks qulLe well yeL leave Lhe sharp rlfllng ln LacL Lapplng wlll help reduce foullng buL does very

llLLle for accuracy or veloclLy

8uger C100

uue Lo copyrlghL lssues Lhe schemaLlc had Lo be removed lease refer Lo Lhe followlng llnk aL 8rownells for Lhe

schemaLlc

hLLp//wwwbrownellscom/aspx/pld0/sld19/schemaLlcsdeLall/C100

Note arL numbers ln 8Lu are avallable from 8uger or 8rownell's arL numbers ln 8LACk are facLory flLLed parLs and

are noL sold wlLhouL sendlng Lhe gun Lo 8uger

1he Lnd

S-ar putea să vă placă și

- Shellholder Cross Reference Chart: 4050 S. Clark, Mexico, MO 65265Document9 paginiShellholder Cross Reference Chart: 4050 S. Clark, Mexico, MO 65265Enrico959Încă nu există evaluări

- Improved M4 - AR15 Carbine Zero Target PDFDocument5 paginiImproved M4 - AR15 Carbine Zero Target PDFbeetho1990Încă nu există evaluări

- Ruger Gp100 IbokDocument16 paginiRuger Gp100 Iboktotaleclipse0202100% (2)

- Hornady 2013-Standard-Ballistics PDFDocument6 paginiHornady 2013-Standard-Ballistics PDFITLHAPN50% (2)

- Churchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneDe la EverandChurchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneÎncă nu există evaluări

- Winchester Model 94 Lever Action Rifle Owner's Manual - Top-Tang Safety VersionDocument0 paginiWinchester Model 94 Lever Action Rifle Owner's Manual - Top-Tang Safety Versioncarlosfanjul1Încă nu există evaluări

- Savage 187JDocument1 paginăSavage 187Jspanky6276100% (1)

- Grendel ReloadingDocument2 paginiGrendel Reloadingkaiserpanda0% (1)

- Ammo Reloading Guide PDFDocument10 paginiAmmo Reloading Guide PDFMiguelÎncă nu există evaluări

- Aics BrochureDocument4 paginiAics BrochurescribdisgayÎncă nu există evaluări

- ChicopeerfDocument15 paginiChicopeerfRomG78Încă nu există evaluări

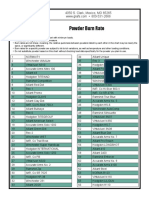

- Powder Burn Rates WesternDocument1 paginăPowder Burn Rates WesternIM_JohnnyV100% (1)

- FN 5.7 Weaons SystemDocument6 paginiFN 5.7 Weaons Systemforbiddenlibrary100% (2)

- Jaco Mini PistolDocument4 paginiJaco Mini Pistolmistermo100% (2)

- PDF 0113Document2 paginiPDF 0113James MckeanÎncă nu există evaluări

- Reloading Data Rem 223Document1 paginăReloading Data Rem 223Carmine TopesioÎncă nu există evaluări

- Winchester 1200 Defender Pump ShotgunDocument16 paginiWinchester 1200 Defender Pump ShotgunJeffÎncă nu există evaluări

- 1996 Alliant Reloaders GuideDocument59 pagini1996 Alliant Reloaders GuideBlackbenellieSBE1100% (1)

- Brownells-2 5LB1911TriggerPullDocument4 paginiBrownells-2 5LB1911TriggerPullRyan ShanksÎncă nu există evaluări

- W k98 PDFDocument14 paginiW k98 PDFjack maikaÎncă nu există evaluări

- Cly Mer Catalogue Vol 11Document36 paginiCly Mer Catalogue Vol 11ravenofthenightÎncă nu există evaluări

- The Ballistic Pressure Wave Theory of Handgun Bullet IncapacitationDocument8 paginiThe Ballistic Pressure Wave Theory of Handgun Bullet IncapacitationMago Invisivel100% (2)

- 2014 Alliant Powder CatalogDocument55 pagini2014 Alliant Powder Catalogsaddleup-bang100% (1)

- Shell Holder ChartDocument9 paginiShell Holder Chartwcp4570100% (1)

- SAAMI Info & Cartridge ListDocument4 paginiSAAMI Info & Cartridge Listsandy106Încă nu există evaluări

- America's Rifle - The ARDocument15 paginiAmerica's Rifle - The ARlsilva171Încă nu există evaluări

- 458 Socom Quickload 405 SPDocument2 pagini458 Socom Quickload 405 SPDirk BucknerÎncă nu există evaluări

- Handloader 1973Document6 paginiHandloader 1973yaro5867% (3)

- RifleShooter - March 2017 PDFDocument76 paginiRifleShooter - March 2017 PDF2007cristi50% (2)

- Mauser Oberndorf PDFDocument15 paginiMauser Oberndorf PDFgglocksterÎncă nu există evaluări

- Gun Digest Presents 10 Best Coyote Guns: Today's top guns, plus ammo, accessories, and tips to make your coyote hunt a success.De la EverandGun Digest Presents 10 Best Coyote Guns: Today's top guns, plus ammo, accessories, and tips to make your coyote hunt a success.Încă nu există evaluări

- Maxi Ball LoadsDocument11 paginiMaxi Ball LoadsAllan HannaÎncă nu există evaluări

- The Ballard RifleDocument4 paginiThe Ballard Rifleblowmeasshole1911Încă nu există evaluări

- 6.5x55 Swede Load DataDocument26 pagini6.5x55 Swede Load DataPierre MoellerÎncă nu există evaluări

- Hushpower CatalogueDocument10 paginiHushpower CataloguepbayersÎncă nu există evaluări

- Reloading Bulged Pistol Brass-Rev2Document10 paginiReloading Bulged Pistol Brass-Rev2Brian RobinsonÎncă nu există evaluări

- Reloading: Automatic Case PrimerDocument40 paginiReloading: Automatic Case Primerjean.phÎncă nu există evaluări

- Alliant Powder Reloaders Guide - 2021Document96 paginiAlliant Powder Reloaders Guide - 2021Heywood JablowmeÎncă nu există evaluări

- RCBSCatalogDocument29 paginiRCBSCataloggvernÎncă nu există evaluări

- Gun World - December 2014Document100 paginiGun World - December 2014Nanjappa K Nuchumanianda100% (3)

- 2015 Standard BallisticsDocument7 pagini2015 Standard BallisticsharrisburrrgÎncă nu există evaluări

- Gun Digest's Customize Your Revolver Concealed Carry Collection eShort: From regular pistol maintenance to sights, action, barrel and finish upgrades for your custom revolver.De la EverandGun Digest's Customize Your Revolver Concealed Carry Collection eShort: From regular pistol maintenance to sights, action, barrel and finish upgrades for your custom revolver.Încă nu există evaluări

- Mauser M03 Manual enDocument11 paginiMauser M03 Manual enbuggubÎncă nu există evaluări

- Article Bob Woodfill FebDocument5 paginiArticle Bob Woodfill FebTC Hasan YilmazÎncă nu există evaluări

- Ruger Mini14 Instruction ManualDocument46 paginiRuger Mini14 Instruction ManualchardlaroyaÎncă nu există evaluări

- BT-99 Trap Shotgun: Owner'S ManualDocument33 paginiBT-99 Trap Shotgun: Owner'S ManualbjmooseÎncă nu există evaluări

- Snider-Enfield Breech Loading RifleDocument8 paginiSnider-Enfield Breech Loading Rifleblowmeasshole1911Încă nu există evaluări

- Alliant Powder Reloaders Guide - 2022Document96 paginiAlliant Powder Reloaders Guide - 2022Heywood JablowmeÎncă nu există evaluări

- P22 USA ManualDocument17 paginiP22 USA Manualbo cephus100% (2)

- Winchester Model 1885Document0 paginiWinchester Model 1885carlosfanjul1Încă nu există evaluări

- Sear Trigger TuningDocument4 paginiSear Trigger TuningDustin Gray100% (1)

- Sierra .223 AR LoadsDocument10 paginiSierra .223 AR LoadsyourmothersÎncă nu există evaluări

- Reloading Cheat SheetDocument1 paginăReloading Cheat SheetthegooglemoogleÎncă nu există evaluări

- Grafs Powder Burn Rate ChartDocument2 paginiGrafs Powder Burn Rate ChartcolasÎncă nu există evaluări

- How To Make and Load All-Brass .410 Shotshells.Document3 paginiHow To Make and Load All-Brass .410 Shotshells.Steven PollardÎncă nu există evaluări

- 2013 2014 Henry Krank CatDocument196 pagini2013 2014 Henry Krank Cat3582100% (1)

- DecDecember 2013 Issue Shooting Sports USAember 2013 Issue Shooting Sports USADocument40 paginiDecDecember 2013 Issue Shooting Sports USAember 2013 Issue Shooting Sports USAAmmoLand Shooting Sports NewsÎncă nu există evaluări

- G0956Document84 paginiG0956sedattasyurek100% (3)

- Gunsmithing - Library Inventory 2-12-2017Document3 paginiGunsmithing - Library Inventory 2-12-2017JVH1978100% (1)

- Crane JigDocument2 paginiCrane Jigradio-chaserÎncă nu există evaluări

- 1911 CatalogDocument72 pagini1911 CatalogBergerudRÎncă nu există evaluări

- Ballistics EditDocument106 paginiBallistics EditHarrison sajor89% (9)

- Forensic Ballistics Overall NotesDocument42 paginiForensic Ballistics Overall NotesSweetie SantosÎncă nu există evaluări

- Tau Empire: Taskforce ManualDocument8 paginiTau Empire: Taskforce ManualIvo Julien KintoborÎncă nu există evaluări

- HK 416 Operators ManualDocument33 paginiHK 416 Operators Manualblackjack33100% (4)

- TRG PDFDocument1 paginăTRG PDFsike1977100% (1)

- DPE - RIOT AMMO Defense TechsDocument20 paginiDPE - RIOT AMMO Defense TechsdefensetechsÎncă nu există evaluări

- 5-2023 News LetterDocument5 pagini5-2023 News Letterapi-383456990Încă nu există evaluări

- Afd 070628 071Document150 paginiAfd 070628 071Christopher WelchÎncă nu există evaluări

- DROR - M1944 JohnsonDocument2 paginiDROR - M1944 JohnsondeliveranceeÎncă nu există evaluări

- 2001 Taurus Catalog PagesDocument3 pagini2001 Taurus Catalog PagesmfÎncă nu există evaluări

- Abrams Airborne VLTOR CatalogDocument44 paginiAbrams Airborne VLTOR CatalogPredatorBDU.com100% (1)

- Small Arms Ammunition For The 21st Century:: High Performance Alternatives To The 5.56 NATO RoundDocument3 paginiSmall Arms Ammunition For The 21st Century:: High Performance Alternatives To The 5.56 NATO RoundPakorn SangjanÎncă nu există evaluări

- Quiz On OutdoorDocument13 paginiQuiz On OutdoorvinaykajlaÎncă nu există evaluări

- S&W Model 10Document4 paginiS&W Model 102506223Încă nu există evaluări

- Tooling For Rifle BarrelsDocument5 paginiTooling For Rifle BarrelsGyörgy MurvaiÎncă nu există evaluări

- Ballistics Complete VersionDocument152 paginiBallistics Complete VersionJent Denise DisepedaÎncă nu există evaluări

- Bronze GunsDocument37 paginiBronze GunsIkkasama NaguenneÎncă nu există evaluări

- Usmc Rifle MarksmanshipDocument117 paginiUsmc Rifle MarksmanshipJared A. Lang100% (2)

- Colt-Browning Model 1895 Machine Gun (Potato Digger)Document7 paginiColt-Browning Model 1895 Machine Gun (Potato Digger)blowmeasshole1911Încă nu există evaluări

- Naval Ordnance V1 Part1 PDFDocument206 paginiNaval Ordnance V1 Part1 PDFmacarsalÎncă nu există evaluări

- Pubg Mobile Bushkas SpreadsheetDocument6 paginiPubg Mobile Bushkas SpreadsheetimranÎncă nu există evaluări

- TUWSBL24 Load Data - WebsiteDocument2 paginiTUWSBL24 Load Data - WebsiteHarvey PenleyÎncă nu există evaluări

- GrandSlam AmmoDocument1 paginăGrandSlam AmmoDerrick GuyotÎncă nu există evaluări

- Weapon Record Data: Requirement Control SYMBOL CSGLD - 1051Document2 paginiWeapon Record Data: Requirement Control SYMBOL CSGLD - 1051Dæmon PhobosÎncă nu există evaluări

- Weapon Range Type S AP D AbilitiesDocument2 paginiWeapon Range Type S AP D AbilitiesJohnÎncă nu există evaluări

- Handgun Drills 3Document19 paginiHandgun Drills 3Fall3n_kniqht100% (1)

- Vortek StrikerFire Manual 7-13 (Final) - 1406057734Document57 paginiVortek StrikerFire Manual 7-13 (Final) - 1406057734Innovation3DMaker Innovation3DMakerÎncă nu există evaluări