Documente Academic

Documente Profesional

Documente Cultură

Din en 12517 - 2006

Încărcat de

marcelogf74Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Din en 12517 - 2006

Încărcat de

marcelogf74Drepturi de autor:

Formate disponibile

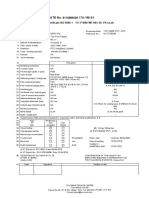

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

DEUTSCHE NORM

June 2006

DIN EN 12517-1

ICS 25.160.40

{

Supersedes DIN EN 12517:2003-01

Non-destructive testing of welds Part 1: Evaluation of welded joints in steel, nickel, titanium and their alloys by radiography Acceptance levels English version of DIN EN 12517-1:2006-06

Zerstrungsfreie Prfung von Schweiverbindungen Teil 1: Bewertung von Schweiverbindungen in Stahl, Nickel, Titan und ihren Legierungen mit Durchstrahlung Zulssigkeitsgrenzen Englische Fassung DIN EN 12517-1:2006-06

Document comprises 17 pages

No part of this standard may be reproduced without prior permission of DIN Deutsches Institut fr Normung e. V., Berlin. Beuth Verlag GmbH, 10772 Berlin, Germany, has the exclusive right of sale for German Standards (DIN-Normen).

English price group 10 www.din.de www.beuth.de

!,o-?"

11.06 9761028

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

DIN EN 12517-1:2006-06

National foreword

This standard has been prepared by CEN/TC 121 Welding (Secretariat: Germany). The responsible German body involved in its preparation was the Normenausschuss Materialprfung (Materials Testing Standards Committee), Technical Committee NMP 822 Durchstrahlungsprfung und Strahlenschutz. Amendments This standard differs from DIN EN 12517:2003-01 as follows: a) The standard now consists of two parts, Part 1 dealing with welded joints in steel, nickel, titanium and their alloys and Part 2 with welded joints in aluminium and its alloys. b) Table 2 has been completely revised taking into account the specifications of EN ISO 5817:2003. c) Annexes B and C have been added. d) Annex ZA has been dropped. Previous editions DIN EN 12517: 1998-03, 2003-01

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EUROPEAN STANDARD NORME EUROPENNE EUROPISCHE NORM

ICS 25.160.40

EN 12517-1

March 2006

Supersedes EN 12517:1998

English Version

Non-destructive testing of welds - Part 1: Evaluation of welded joints in steel, nickel, titanium and their alloys by radiography Acceptance levels

Essais non destructifs des assemblages souds - Partie 1: valuation par radiographie des assemblage souds en acier, nickel, titane et leurs alliages - Niveaux d'acceptation Zerstrungsfreie Prfung von Schweiverbindungen Teil 1: Bewertung von Schweiverbindungen in Stahl, Nickel, Titan und ihren Legierungen mit Durchstrahlung Zulssigkeitsgrenzen

This European Standard was approved by CEN on 6 February 2006. CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the Central Secretariat or to any CEN member. This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official versions. CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION COMIT EUROPEN DE NORMALISATION EUROPISCHES KOMITEE FR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels

2006 CEN

All rights of exploitation in any form and by any means reserved worldwide for CEN national Members.

Ref. No. EN 12517-1:2006: E

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Contents

Page

Foreword......................................................................................................................................................................3 1 2 3 4 5 Annex A.1 A.2 A.3 Scope ..............................................................................................................................................................4 Normative references ....................................................................................................................................4 Radiographic technique ................................................................................................................................4 General............................................................................................................................................................5 Acceptance levels..........................................................................................................................................5 A (informative) Guide to the limitations of radiographic testing ............................................................10 Volumetric imperfections in butt welds.....................................................................................................10 Cracks in butt welds ....................................................................................................................................10 Planar imperfections in butt welds ............................................................................................................10

Annex B (informative) Examples for determination of area percentage (%) of imperfections........................11 Annex C (normative) Sum of acceptable areas ....................................................................................................13 Bibliography ..............................................................................................................................................................15

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Foreword

This document (EN 12517-1:2006) has been prepared by Technical Committee CEN/TC 121 Welding, the secretariat of which is held by DIN. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by September 2006, and conflicting national standards shall be withdrawn at the latest by September 2006. This document supersedes EN 12517:1998. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). EN 12517 comprises a series of European Standards for industrial radiographic films which is made up of the following: EN 12517-1 Non-destructive testing of welds Part 1: Evaluation of welded joints in steel, nickel, titanium and their alloys by radiography Acceptance levels EN 12517-2 Non-destructive testing of welds Part 2: Evaluation of welded joints in aluminium and its alloys by radiography Acceptance levels According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Scope

This document specifies acceptance levels for indications from imperfections in butt welds of steel, nickel, titanium and their alloys detected by radiographic testing. If agreed, the acceptance levels may be applied to other types of welds or materials. The acceptance levels may be related to welding standards, application standards, specifications or codes. This European Standard assumes that the radiographic testing has been carried out in accordance with EN 1435. When assessing whether a weld meets the requirements specified for a weld quality level, the sizes of imperfections permitted by standards are compared with the dimensions of indications revealed by a radiograph made of the weld.

Normative references

The following referenced documents are indispensable for the application of this European Standard. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 1435, Non-destructive examination of welds Radiographic examination of welded joints EN ISO 5817, Welding Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding excluded) Quality levels for imperfections (ISO 5817:2003) EN ISO 6520-1, Welding and allied processes Classification of geometric imperfections in metallic materials Part 1: Fusion welding (ISO 6520-1:1998)

Radiographic technique

Depending on the weld quality level, radiographic technique A or B in accordance with EN 1435 is used as shown in Table 1.

Table 1 Radiographic testing

Quality levels in accordance with EN ISO 5817 Testing techniques and classes in accordance with EN 1435 B Ba A Acceptance levels in accordance with EN 12517 1 2 3

B C D

a However, the minimum number of exposure for circumferential weld testing may correspond to the requirements of class A of EN 1435.

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

General

Welded joints should be visually tested and evaluated in accordance with EN 970 before radiographic testing. The acceptance levels in this European Standard are basically valid for evaluation of imperfections which cannot be detected and evaluated by visual testing. Surface imperfections (such as undercut and excessive penetration, surface damage, weld spatter etc.) which, due to object geometry, cannot be evaluated, but where the interpreter suspects the EN ISO 5817 quality levels are not fulfilled, shall be subject to more specific testing. When quantification of undercut and/or excessive penetration by radiographic testing is required, specific procedures using test exposures may be applied in order to establish a basis for approximate quantification in accordance with the requirements of EN ISO 5817. This shall be specified.

Acceptance levels

The acceptance levels for indications are shown in Table 2 and Table 3. The types of imperfections are selected from EN ISO 5817 and defined in EN ISO 6520-1. The symbols used in Table 2 and Table 3 are the following: l length of indication, in millimetres;

s nominal butt weld thickness, in millimetres; t material thickness, in millimetres;

L any 100 mm testing length, in millimetres; wp width of the weld, or cross surface imperfection, in millimetres h width of indication, the width or height of surface imperfection, in millimetres; d diameter of pore; in millimetres; b width of excess penetration of weld, in millimetres; A sum of projected areas of indications related to L x wp, in %; l summary length of imperfections within L, in millimetres. Indications shall not be divided into different ranges L.

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Table 2 Acceptance levels for internal indications in butt welds

Type of internal imperfections in accordance with EN ISO 6520-1 Cracks (100)

No.

Acceptance level 3 a

Acceptance level 2 a

Acceptance level 1

1 2a

Not permitted

Not permitted A 1,5 % d 0,3s, max. 4 mm L = 100 mm A3% d 0,3s, max. 4 mm L = 100 mm A 8% d 0,3s, max. 3 mm L = 100 mm A4% d 0,3s, max. 3 mm L = 100 mm A8% d 0,3s, max. 3 mm L = 100 mm h < 0,3s, max. 3 mm

Not permitted A1% d 0,2s, max. 3 mm L = 100 mm A2% d 0,2s, max. 3 mm L = 100 mm A 4% d 0,2s, max. 2 mm L = 100 mm A2% d 0,2s, max. 2 mm L = 100 mm A4% d 0,2s, max. 2 mm L = 100 mm h < 0,2s, max. 2 mm

Porosity and gas pores A 2,5 % (2012, 2011) d 0,4s, max. 5 mm Single layer L = 100 mm Porosity and gas pores A 5 % (2012, 2011) d 0,4s, max. 5 mm Multilayer L = 100 mm Clustered (localized) A 16% porosity (2013) d 0,4s, max. 4 mm L = 100 mm

2b

3b

4ac

Linear porosity (2014) Single layer

A8% d 0,4s, max. 4 mm L = 100 mm A 16 % d 0,4s, max. 4 mm L = 100 mm

4bc

Linear porosity (2014) Multilayer

5d

Elongated cavities h < 0,4s, max. 4 mm (2015) and wormholes l s, max. 75 mm, (2016) L=100 mm Shrinkage cavity (202) (other than crater pipes) h < 0,4s, max. 4 mm l 25 mm h 0,2t, max. 2 mm l 0,2t, max. 2 mm

l s, max. 50 mm,

L=100 mm Not permitted

l s, max. 25 mm,

L=100 mm Not permitted

6e

Crater pipe (2024)

Not permitted h < 0,3s, max. 3 mm

Not permitted h < 0,2s, max. 2 mm

8d

Slag inclusions (301), flux inclusions (302) and oxide inclusions (303)

h < 0,4s, max. 4 mm

l s, max. 75 mm

L = 100 mm

l s, max. 50 mm

L = 100 mm l 0,3s, max. 3 mm

l s, max. 25 mm

L = 100 mm l 0,2s, max. 2 mm

Metallic inclusions (304) l 0,4s, max. 4 mm (other than copper)

(to be continued)

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Table 2 (concluded)

Type of internal imperfections in accordance with EN ISO 6520-1 Copper inclusions (3042) Lack of fusion (401)

No.

Acceptance level 3 a

Acceptance level 2 a

Acceptance level 1

10

Not permitted

Not permitted

Not permitted

11e

Permitted, but only intermittently and not breaking the surface l 25 mm, L = 100 mm l 25 mm, L = 100 mm

Not permitted

Not permitted

12e

Lack of penetration (402)

Not permitted

Not permitted

a b c d e

Acceptance levels 3 and 2 may be specified with suffix X, which denotes that all indications over 25 mm are unacceptable. See Annex C, Figure C.1 and Figure C.2 (normative) See Annex C, Figure C.3 and Figure C.4 (normative) See Annex C, Figure C.5 and Figure C.6 (normative) If the length of the weld is below 100 mm, then the maximum length of indications shall not exceed 25% of that weld.

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Table 3 Surface imperfections: The acceptance levels are those defined for visual testing. These defects are normally evaluated by visual testing

Type of imperfections accordance EN ISO 6520-1 surface in with

No.

Acceptance level 3 a

Acceptance level 2 a

Acceptance level 1

13 14a

Crater cracks (104)

Not permitted

Not permitted is Smooth transition required For t > 3 mm

Not permitted is Smooth transition required For t > 3 mm is

Smooth transition Undercut, continues and required intermittent (5011,5012) For t > 3 mm

h 0,2t, max. 1 mm For 0,5 mm t 3 mm l 25 mm, h 0,2t

h 0,1t, max. 0,5 mm For 0,5 mm t 3 mm l 25 mm, h 0,1t

h 0,05t, max. 0,5 mm For 0,5 mm t 3 mm not permitted

14b

Shrinkage groove (root Smooth transition undercut 5013) required For t > 3 mm l 25 mm, h 0,2t, max. 2 mm, For 0,5 mm t 3 mm h 0,2 mm + 0,1t

transition is Smooth required For t > 3 mm l 25 mm, h 0,1t, max. 1 mm For 0,5 mm t 3 mm l 25 mm, h 0,1t h 1 mm + 0,3 b

transition is Smooth required For t > 3 mm l 25 mm, h 0,05t, max. 0,5 mm For 0,5 mm t 3 mm Not permitted h 1 mm + 0,1 b

is

15a

Excess penetration (504) 0,5 mm t 3 mm

h 1 mm + 0,6 b

15b

Excess penetration (504) t > 3mm

h 1 mm + 1,0 b, max. 5 mm Permitted, if the properties of the parent metal are not affected

h 1 mm + 0,6 b, max. 4 mm

h 1 mm + 0,2 b, max. 3 mm

16

Stray arc (601)

Not permitted

Not permitted

17 18a

Spatter (602)

Acceptance depends on application, e.g. material, corrosion protection l 25 mm: Not permitted h 0,1 t (to be continued)

Root concavity (515) h 0,2 mm + 0,1 t 0,5 mm s 3 mm

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Table 3 (concluded)

Type of imperfections accordance EN ISO 6520-1 surface a in Acceptance level 3 with l 25 mm, h 0,2 t, max. 2 mm

No.

Acceptance level 2 a

Acceptance level 1

18b

Root concavity (515) s > 3 mm

l 25 mm, h 0,1 t, max. 1 mm

l 25 mm, h 0,05 t, max. 0,5 mm

19

Poor restart (517) s 0,5 mm

Permitted, The limit depends on the type of imperfection (see EN ISO 5817) l 25 mm, Not permitted Not permitted

20a

Sagging (509)

l 25 mm, h 0,1 t Not permitted

Incompletely filled groove h 0,25 t (511) 0,5 mm s 3 mm 20b Sagging (509) l 25 mm,

l 25 mm, h 0,1 t, max. 1 mm

l 25 mm, h 0,05 t, max. 0,5 mm

Incompletely filled groove h 0,25 t, (511) max. 2 mm s > 3 mm 21a Linear misalignment (507) 0,5 mm s 3 mm 21b Linear misalignment, longitudinal welds (507) s > 3 mm 21c Linear misalignment, circumferential welds (507) s 0,5 mm

a

h 0,2 mm + 0,25 t

h 0,2 mm + 0,15 t

h 0,2 mm + 0,1 t

h 0,25 t, max. 5 mm

h 0,15 t, max. 4 mm

h 0,1 t, max. 3 mm

h 0,5 t, max. 4 mm

h 0,5 t, max. 3 mm

h 0,5 t, max. 2 mm

Acceptance levels 3 and 2 may be specified with suffix X, which denotes that all indications over 25 mm are unacceptable.

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Annex A (informative) Guide to the limitations of radiographic testing

NOTE

The numbers between brackets conform to those used in EN ISO 6520-1.

A.1 Volumetric imperfections in butt welds

Porosities and gas pores (2011, 2013, 2015 and 2017) Wormholes and elongated cavities (2016 and 2015) Solid inclusions (300) Copper inclusions (3042) The above imperfections listed in Table 2 will be readily detected using radiographic technique A or B of EN 1435 as shown in Table 1 of this European Standard.

A.2 Cracks in butt welds

Crater cracks (104) Cracks (100) The detectability of cracks by radiographic testing depends on the crack height, the ramification (presence of branching parts), opening width, direction of the X-ray beam to crack orientation and radiographic technique parameters. Reliable detection of all cracks is therefore limited. The use of radiographic technique B or better, as specified in EN 1435, will provide better crack detectability than radiographic technique A.

A.3 Planar imperfections in butt welds

Lack of fusion (401) Lack of penetration (402) The detection of lack of fusion and lack of penetration depends on characteristics of imperfections and radiographic technique parameters. Lack of side-wall fusion will probably not be detected (except it is associated with other imperfections such as slag inclusions) unless it is radiographed in direction of the side-wall.

10

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Annex B (informative) Examples for determination of area percentage (%) of imperfections

The following figures give a presentation of different area percentage (%) of imperfections. This should assist the assessment of imperfections on radiographs and fracture surfaces.

Figure B.1 1 %

Figure B.2 1,5 %

Figure B.3 2 %

Figure B.4 2,5 %

11

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Figure B.5 3 %

Figure B.6 4 %

Figure B.7 5 %

Figure B.8 8 %

Figure B.9 16 %

12

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Annex C (normative) Sum of acceptable areas

Figure C.1 Clustered porosity, D > dA2

Figure C.2 Clustered porosity, D < dA2 The sum of the different pore areas (A1+A2.) related to the evaluation area L X wp (Figure C.1). If D is less than dA1 or dA2, whatever is smaller, an envelope surrounding the porosity area A1+A2 shall be considered as one area of imperfection (Figure C.2).

Figure C.3 Linear porosity, D > d2

13

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Figure C.4 Linear porosity, D < d2

d12 d 2 2 The sum of the different pore areas + + ... related to the evaluation area L X wp (Figure C.3). 4 4

If D is smaller than the smaller diameter of one of the neighbouring pores, the full connected area of the two pores is to be taken into the sum of imperfections (Figure C.4).

Figure C.5 Elongated cavities and wormholes, D > l3

Figure C.6 Elongated cavities and wormholes, D < l3

The sum of the length of indications l shall be determined for each testing length L (Figure C.5). If D is smaller than the shorter length of one of the neighbouring imperfections, the full connection of the two imperfections is to be taken into the sum of imperfections (Figure C.6).

14

Licena de uso exclusivo para DEDINI S/A INDUSTRIAS DE BASE

EN 12517-1:2006 (E)

Bibliography

[1] [2] [3]

EN 970, Non-destructive examination of fusion welds Visual examination EN 12062, Non-destructive examination of welds General rules for metallic materials IIW catalogue of reference radiographs for assessment of weld imperfections according to ISO 5817

15

S-ar putea să vă placă și

- DIN EN 12517-1: Deutsche NormDocument17 paginiDIN EN 12517-1: Deutsche Normmarcos crisostoÎncă nu există evaluări

- Application for Certification according to DIN 18800-7Document9 paginiApplication for Certification according to DIN 18800-7gorgika papandÎncă nu există evaluări

- BPVC Ix QW-482Document2 paginiBPVC Ix QW-482ganesh82Încă nu există evaluări

- BS EN 1090-2:2008 Non-destructive testing requirementsDocument1 paginăBS EN 1090-2:2008 Non-destructive testing requirementseghashangzadehÎncă nu există evaluări

- T.C.L. Co. - Test & Control LaboratoriesDocument2 paginiT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταÎncă nu există evaluări

- List of Questions EN 13445 - 2014Document11 paginiList of Questions EN 13445 - 2014kamal615Încă nu există evaluări

- WPQR SBM 029Document3 paginiWPQR SBM 029HoJienHauÎncă nu există evaluări

- CV of Engineer MD Sazid Alam1Document8 paginiCV of Engineer MD Sazid Alam1Alam MD SazidÎncă nu există evaluări

- KTA 3201 - 3e 2007editionDocument163 paginiKTA 3201 - 3e 2007editionlram70Încă nu există evaluări

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 paginiWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniÎncă nu există evaluări

- Reduce Hydrogen Cracking with Proper PreheatDocument3 paginiReduce Hydrogen Cracking with Proper PreheatVJG369Încă nu există evaluări

- Din 54109-2-89 PDFDocument2 paginiDin 54109-2-89 PDFAndres Afanador MuñozÎncă nu există evaluări

- Iso 17640 2017 en PDFDocument11 paginiIso 17640 2017 en PDFTanveer Ahmed Quadri100% (1)

- NDE of BoilersDocument6 paginiNDE of Boilersshabbir626100% (1)

- E 310 - 99 - Rtmxma - PDFDocument4 paginiE 310 - 99 - Rtmxma - PDFUpul Eranda AbeyrathnaÎncă nu există evaluări

- Din en 12680-1Document33 paginiDin en 12680-1vafavafaÎncă nu există evaluări

- Welder Certificate ISO 9606-1 QualificationDocument1 paginăWelder Certificate ISO 9606-1 QualificationDeepak Das100% (1)

- ISO 9606-1 Cor1-2012Document1 paginăISO 9606-1 Cor1-2012Flaah92Încă nu există evaluări

- Er 100 S 1Document1 paginăEr 100 S 1Oliver Quezada Inostroza100% (1)

- WPQR TIG Fillet Welding ProcedureDocument3 paginiWPQR TIG Fillet Welding ProcedureDimitris NikouÎncă nu există evaluări

- DIN 17175-79 Seamless Steel Tubes Chemical CompositionsDocument0 paginiDIN 17175-79 Seamless Steel Tubes Chemical CompositionsAhmed SaadÎncă nu există evaluări

- Astm A 450Document10 paginiAstm A 450Telmo VianaÎncă nu există evaluări

- 096 SelDocument3 pagini096 SelPiyush SrivastavaÎncă nu există evaluări

- Electroslag & Electrogas PDFDocument5 paginiElectroslag & Electrogas PDFRobin GuÎncă nu există evaluări

- Hardness Test Report: Test Details Machine DetailsDocument1 paginăHardness Test Report: Test Details Machine DetailsESHWAR CHARYÎncă nu există evaluări

- 2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDocument22 pagini2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDadaso Baburao JamdarÎncă nu există evaluări

- Comparison of Welding Inspector Qualification or Certification SchemesDocument7 paginiComparison of Welding Inspector Qualification or Certification Schemeswahyu santosoÎncă nu există evaluări

- 1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pagini1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh Binh0% (1)

- 234 D7091 344Document7 pagini234 D7091 344Ivan AlanizÎncă nu există evaluări

- ATTAR Phased Array Visualisation ToolDocument3 paginiATTAR Phased Array Visualisation ToolGOUTHAM RATHINAMÎncă nu există evaluări

- ASME VIII-2-Service Restrictions, Joint Efficiencies, RadiographyDocument34 paginiASME VIII-2-Service Restrictions, Joint Efficiencies, RadiographyMohammed AnshafÎncă nu există evaluări

- RT Standards NotesDocument4 paginiRT Standards NotesprabhuÎncă nu există evaluări

- Tangential RadiographyDocument9 paginiTangential Radiographykirubha_karan2000Încă nu există evaluări

- Conformity of Structural Steel Products and StructuresDocument5 paginiConformity of Structural Steel Products and StructuresStephen HicksÎncă nu există evaluări

- Is 9902 2004 PDFDocument11 paginiIs 9902 2004 PDFAgniva DuttaÎncă nu există evaluări

- PDS Na GTS65 PDFDocument2 paginiPDS Na GTS65 PDFMoaatazz NouisriÎncă nu există evaluări

- Ultrasonic Phased Array Inspection of Welded Pipes Using Mode Converted WavesDocument8 paginiUltrasonic Phased Array Inspection of Welded Pipes Using Mode Converted WavesMohsin IamÎncă nu există evaluări

- 121 T BW FPDocument4 pagini121 T BW FPA. ΒρατσισταÎncă nu există evaluări

- Aws D 1Document15 paginiAws D 1WagnerTarossiÎncă nu există evaluări

- NDT-Verify Steel WeldsDocument1 paginăNDT-Verify Steel Weldskinglordofato100% (1)

- QCF312 WPQRDocument2 paginiQCF312 WPQRminhnnÎncă nu există evaluări

- GGG40CI WeldingDocument13 paginiGGG40CI WeldingA K NairÎncă nu există evaluări

- ISO Specifications for Non-Destructive TestingDocument4 paginiISO Specifications for Non-Destructive Testingskynyrd75Încă nu există evaluări

- Operating Manual CrxvisionDocument45 paginiOperating Manual CrxvisionChandrashekhar ThiramdasuÎncă nu există evaluări

- ts203 PDFDocument45 paginits203 PDFSergio AlejandroÎncă nu există evaluări

- Bsen ISO-10675-1-2016Document9 paginiBsen ISO-10675-1-2016SamsuÎncă nu există evaluări

- B H e L Limited RTDocument13 paginiB H e L Limited RTbhavin17850% (2)

- Liquid Penetrant (Lev1el-I-level - II''Document100 paginiLiquid Penetrant (Lev1el-I-level - II''Chandresh100% (1)

- Rererence - PIM-SC-2505-N - CS PIPING FABRICATIONDocument14 paginiRererence - PIM-SC-2505-N - CS PIPING FABRICATIONaslam.ambÎncă nu există evaluări

- Asme 1325-18 (2007)Document1 paginăAsme 1325-18 (2007)Matthew TaylorÎncă nu există evaluări

- Iso 3834-2Document16 paginiIso 3834-2NONNE NaineÎncă nu există evaluări

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- En 12517Document15 paginiEn 12517Nguyen Huu TriÎncă nu există evaluări

- 036 - 12517-1.Non-Destructive Testing of Welds-Part 1 Evaluation of Welded Joints in Steel, Nickel, Titanium and Their Alloys by Radiography.Document15 pagini036 - 12517-1.Non-Destructive Testing of Welds-Part 1 Evaluation of Welded Joints in Steel, Nickel, Titanium and Their Alloys by Radiography.OktayKulÎncă nu există evaluări

- 12517-2 - BS en 12517-2-2008 - Acceptance Levels - RadiographyDocument16 pagini12517-2 - BS en 12517-2-2008 - Acceptance Levels - RadiographyengdanielmorenoÎncă nu există evaluări

- Draft: European Standard Norme Europeenne Europaische NormDocument39 paginiDraft: European Standard Norme Europeenne Europaische Normjohn_progecoÎncă nu există evaluări

- Bs+en+12517-2-2008 NDT PDFDocument16 paginiBs+en+12517-2-2008 NDT PDFPham CongÎncă nu există evaluări

- En10272-01 (2008)Document42 paginiEn10272-01 (2008)kpurnimaÎncă nu există evaluări

- EN 1043-1 Hardness TestDocument23 paginiEN 1043-1 Hardness TestMadley Rock100% (1)

- Tubos de Aço Carbono com e sem costura até 40Document4 paginiTubos de Aço Carbono com e sem costura até 40Bruno OliveiraÎncă nu există evaluări

- ASME B36.19M Stainless Steel PipesDocument14 paginiASME B36.19M Stainless Steel Pipesdssscarface50% (2)

- Alumínio Cold ASM Material Data SheetDocument2 paginiAlumínio Cold ASM Material Data Sheetmarcelogf74Încă nu există evaluări

- Dacromet Coating: World Class Corrosion ProtectionDocument6 paginiDacromet Coating: World Class Corrosion Protectionmarcelogf74Încă nu există evaluări

- MFL Tank Bottom Scanner PDFDocument2 paginiMFL Tank Bottom Scanner PDFmarcelogf74Încă nu există evaluări

- AWS API 1104 Study Book PDFDocument60 paginiAWS API 1104 Study Book PDFmarcelogf74Încă nu există evaluări

- Engineering Welding Handbook99 PDF TigDocument48 paginiEngineering Welding Handbook99 PDF TigSorin Stanescu100% (1)

- Details of The Louis M. Brown and Forrest S. Mosten International Client Consultation Competition (National Round)Document5 paginiDetails of The Louis M. Brown and Forrest S. Mosten International Client Consultation Competition (National Round)Bar & BenchÎncă nu există evaluări

- Law On Obligation and Contract: Here Is Where Your Presentation BeginsDocument35 paginiLaw On Obligation and Contract: Here Is Where Your Presentation BeginsKent Giane GomezÎncă nu există evaluări

- 2007 Political Law - Atty AlobbaDocument4 pagini2007 Political Law - Atty AlobbaMark PiadÎncă nu există evaluări

- NFA Citizen's CharterDocument53 paginiNFA Citizen's CharterpastorjeffgatdulaÎncă nu există evaluări

- Frequently Ask Question - BudgetingDocument28 paginiFrequently Ask Question - BudgetingNrf Frn100% (1)

- Critical Analysis of NHRC's Role in Protecting Human Rights in IndiaDocument2 paginiCritical Analysis of NHRC's Role in Protecting Human Rights in IndiaShra19Încă nu există evaluări

- Donor's Tax: Requisites of A Valid DonationDocument55 paginiDonor's Tax: Requisites of A Valid DonationYvonne Ryss Batuigas MendeÎncă nu există evaluări

- Non-Leasehold CovenantsDocument1 paginăNon-Leasehold CovenantssrvshÎncă nu există evaluări

- LabRel Batch 3Document30 paginiLabRel Batch 3Andrea Nicole Paulino RiveraÎncă nu există evaluări

- Valone v. Michigan Dep't of Treasury, Docket No. 385120 (Mich. Tax Tribunal August 18, 2011)Document7 paginiValone v. Michigan Dep't of Treasury, Docket No. 385120 (Mich. Tax Tribunal August 18, 2011)Paul MastersÎncă nu există evaluări

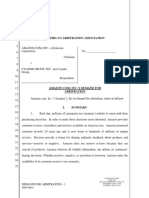

- Arbitration Demand Cyande Group PDFDocument9 paginiArbitration Demand Cyande Group PDFjustice2019Încă nu există evaluări

- Sri Lanka Procurement ManualDocument163 paginiSri Lanka Procurement ManualvihangimaduÎncă nu există evaluări

- Letter From St. John's Terminal Developers' Lawyers To City Planning CommissionDocument6 paginiLetter From St. John's Terminal Developers' Lawyers To City Planning CommissionDNAinfoNewYorkÎncă nu există evaluări

- XXX - Optional IrishliteratureDocument168 paginiXXX - Optional IrishliteratureMada AnandiÎncă nu există evaluări

- Trespass to Land: Definition, Elements and Types of InterferenceDocument5 paginiTrespass to Land: Definition, Elements and Types of InterferenceMUHAMAD ALIF IZZUDIN AZMALEÎncă nu există evaluări

- Mabry v. Klimas, 448 U.S. 444 (1980)Document3 paginiMabry v. Klimas, 448 U.S. 444 (1980)Scribd Government DocsÎncă nu există evaluări

- Special Proceedings Brondial DoctrinesDocument54 paginiSpecial Proceedings Brondial DoctrinesFaith Alexis Galano50% (2)

- Act 156 Industrial Co Ordination Act 1975Document20 paginiAct 156 Industrial Co Ordination Act 1975Adam Haida & CoÎncă nu există evaluări

- Demonitizatin On Consumer Behaviour FMCGDocument52 paginiDemonitizatin On Consumer Behaviour FMCGMohit Agarwal88% (8)

- Revocable Living TrustDocument14 paginiRevocable Living TrustJack100% (7)

- Access To Buildings For People With DisabilitiesDocument4 paginiAccess To Buildings For People With DisabilitiesJÎncă nu există evaluări

- Deed of Grant of Usufructuary RightsDocument3 paginiDeed of Grant of Usufructuary Rightssharmine_ruiz100% (2)

- D - Internet - Myiemorgmy - Intranet - Assets - Doc - Alldoc - Document - 5762 - Jurutera July 2014 PDFDocument47 paginiD - Internet - Myiemorgmy - Intranet - Assets - Doc - Alldoc - Document - 5762 - Jurutera July 2014 PDFDiana MashrosÎncă nu există evaluări

- Frauds and Scams in Banking Sector in India PR DishaDocument72 paginiFrauds and Scams in Banking Sector in India PR Dishajyoti raghuvanshi100% (2)

- 6 World Bull 1Document22 pagini6 World Bull 1Shinji NishikawaÎncă nu există evaluări

- Course Outline - As of Feb 2 15Document5 paginiCourse Outline - As of Feb 2 15pulithepogiÎncă nu există evaluări

- Code of ConductDocument6 paginiCode of ConductdrpkdhakaÎncă nu există evaluări

- Lacsona Land Co., Inc. v. CIRDocument11 paginiLacsona Land Co., Inc. v. CIRMingÎncă nu există evaluări

- Module 1 - Law of Contract IIDocument30 paginiModule 1 - Law of Contract IIAnkitÎncă nu există evaluări

- Revised Penal Code of The PhilippinesDocument57 paginiRevised Penal Code of The PhilippinesPB D GallegoÎncă nu există evaluări