Documente Academic

Documente Profesional

Documente Cultură

Six Sigma - FMEA - Detection Criteria

Încărcat de

gmichalDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Six Sigma - FMEA - Detection Criteria

Încărcat de

gmichalDrepturi de autor:

Formate disponibile

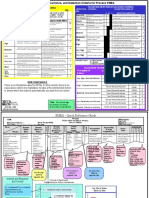

TABLE 14.

Detection Evaluation Criteria Example for Process FMEA

Inspection Type

Detection Almost impossible Very remote Remote Very low Low Moderate

Criteria Absolute certainty of nondetection. Controls will probably not detect. Controls have poor chance of detection. Controls have poor chance of detection. Controls may detect. Controls may detect.

C X X X X

Suggestion Range of Detection Methods Cannot detect or is not checkeq. Control is achieved with indirect or random checks only. Control is achieved with visual inspection only. Control is achieved with double visual inspection only.' Control is achieved with charting methods, such as SPC (Statistical Process Control). Control is based on variable gauging after parts have left the station, or Go/No Go gauging performed on 100% of the parts after parts have left the station. . Error detection in subsequent operations, OR gauging . performed on setup and first-piece check (for setup causes only). Error detection in-station, or error detection in subsequent operations by multiple layers of acceptance: supply, select, install, verify. Cannot accept discrepant part. Error detection in-station (automatic gauging with automatic stop feature). Cannot pass discrepant part. Discrepant parts cannot be made because item has been error-proofed by process/product design.

Ranking 10 9 8

7

6 5

Moderately high

Controls have a good chance to detect. Controls have a good chance to detect.

x

x

High

x

x

X

Very high Very high

Controls almost certain to detect. Controls certain to detect.

2

1

Inspection Types: A. Error-proofed; B. Gauging; C. Manual Inspection. Source: Reprinted with permiSSion from the FMEA Manual (DaimlerChrysler, Ford Motor Company, General Motors Supplier Quality Requirements Task Force).

S-ar putea să vă placă și

- PFMEA Reference CardDocument2 paginiPFMEA Reference Cardkeyoor_pat100% (2)

- Suggested Pfmea Evaluation CriteriaDocument2 paginiSuggested Pfmea Evaluation Criteriatrfcprop100% (1)

- CBIP Publication No 295Document422 paginiCBIP Publication No 295Pravin Narkhede100% (7)

- Root Cause TemplateDocument19 paginiRoot Cause TemplateFiroz Khan100% (3)

- P30 Drivetrain Repair - Sports CarDocument104 paginiP30 Drivetrain Repair - Sports CarAllan Cancino100% (1)

- Error Proofing TechniquesDocument38 paginiError Proofing TechniquesDeepali ParmarÎncă nu există evaluări

- FMEA TemplateDocument5 paginiFMEA TemplateLeonardoViannaÎncă nu există evaluări

- Icm U1d7 Simplifying Exponential Expressions 1Document2 paginiIcm U1d7 Simplifying Exponential Expressions 1kazamÎncă nu există evaluări

- Sampling PlansDocument16 paginiSampling PlanssamadmsinÎncă nu există evaluări

- Severity, Occurrence, and Detection Criteria For Design FMEADocument2 paginiSeverity, Occurrence, and Detection Criteria For Design FMEAtejashraj93Încă nu există evaluări

- How To Troubleshoot Ecu Controlled Systems: Repair Manual SystemDocument17 paginiHow To Troubleshoot Ecu Controlled Systems: Repair Manual SystemOscar AcevedoÎncă nu există evaluări

- Multiple Choice QuestionsDocument12 paginiMultiple Choice QuestionsSarath Bhushan Kaluturi85% (13)

- PFMEA Ranking Table Rating Criteria Action GuidelineDocument10 paginiPFMEA Ranking Table Rating Criteria Action GuidelineEnrico Miguel AquinoÎncă nu există evaluări

- Building a Successful Board-Test StrategyDe la EverandBuilding a Successful Board-Test StrategyEvaluare: 4 din 5 stele4/5 (1)

- Pe Pipelines Pressure Testing Handbook En805Document26 paginiPe Pipelines Pressure Testing Handbook En805Alin Dumitru100% (1)

- PFMEA Reference Card PDFDocument2 paginiPFMEA Reference Card PDFRajesh Yadav100% (6)

- PFMEADocument10 paginiPFMEAsmallik3100% (1)

- Galileo Basic CommandsDocument9 paginiGalileo Basic Commandsbharatstar85% (13)

- Mercer 9100Document16 paginiMercer 9100dtmgoÎncă nu există evaluări

- Fmeca: Failure Modes, Effects and Criticality AnalysisDocument30 paginiFmeca: Failure Modes, Effects and Criticality AnalysisGledson Diniz100% (1)

- FMEADocument10 paginiFMEAlibyanleopardÎncă nu există evaluări

- FMEADocument7 paginiFMEAnishuÎncă nu există evaluări

- Practical Approaches to Method Validation and Essential Instrument QualificationDe la EverandPractical Approaches to Method Validation and Essential Instrument QualificationÎncă nu există evaluări

- Chapter 5 Final A5 EditDocument8 paginiChapter 5 Final A5 EditkINGÎncă nu există evaluări

- TestStand Computer MotherboardDocument8 paginiTestStand Computer MotherboardGeorge RobuÎncă nu există evaluări

- Advanced Process Control: Beyond Single Loop ControlDe la EverandAdvanced Process Control: Beyond Single Loop ControlÎncă nu există evaluări

- MeasureDocument51 paginiMeasureAshwani KumarÎncă nu există evaluări

- Properties of C-Purlins Adopted From Aisc Steel Construction Manual 13Th EditionDocument51 paginiProperties of C-Purlins Adopted From Aisc Steel Construction Manual 13Th EditionD MÎncă nu există evaluări

- Poka Yoke: WE School P.G.E-Biz 2009-11Document7 paginiPoka Yoke: WE School P.G.E-Biz 2009-11urvithakkar86Încă nu există evaluări

- Control ChartDocument50 paginiControl ChartAnand Dubey0% (1)

- BUILDING SERVICES-I Sanitary Fixtures, Fittings & Wellness-1Document48 paginiBUILDING SERVICES-I Sanitary Fixtures, Fittings & Wellness-1Vidya Hitti100% (2)

- PFMEA EncodeDocument4 paginiPFMEA EncodeBooniz-bonice EliasÎncă nu există evaluări

- 6sigma - Control PhaseDocument130 pagini6sigma - Control Phasesathya_145Încă nu există evaluări

- Detection Table - AIAG-VDA Process FMEADocument1 paginăDetection Table - AIAG-VDA Process FMEARaajha MunibathiranÎncă nu există evaluări

- Cisco CCNA 640-607 CompleteDocument30 paginiCisco CCNA 640-607 CompleteAnkit OswalÎncă nu există evaluări

- Semi-Markov Models: Control of Restorable Systems with Latent FailuresDe la EverandSemi-Markov Models: Control of Restorable Systems with Latent FailuresÎncă nu există evaluări

- User Manual For Standard F200 Analyzer: Manufactured byDocument64 paginiUser Manual For Standard F200 Analyzer: Manufactured byAbderrahmen ACHOU100% (1)

- Work Instruction For Error ProofingDocument4 paginiWork Instruction For Error ProofingBALAJI100% (1)

- Detection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionDocument1 paginăDetection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionaslamÎncă nu există evaluări

- Severity Ranking (Sev) : Score Criteria 10 9 8 7 6 5 4 3 2 1Document2 paginiSeverity Ranking (Sev) : Score Criteria 10 9 8 7 6 5 4 3 2 1Sushil Kr ChaurasiaÎncă nu există evaluări

- Copia de FORMATO AmefDocument2 paginiCopia de FORMATO AmefDavid SaucedoÎncă nu există evaluări

- Fmea TableDocument4 paginiFmea TableAfzal RÎncă nu există evaluări

- PFMEA AIAG VDA Detection Rating PDFDocument1 paginăPFMEA AIAG VDA Detection Rating PDFRamdas PaithankarÎncă nu există evaluări

- Detection ScaleDocument1 paginăDetection ScaleSergio LoayzaÎncă nu există evaluări

- Detection RankingDocument1 paginăDetection RankingAbinash KumarÎncă nu există evaluări

- Severity Evaluation CriteriaDocument2 paginiSeverity Evaluation CriteriakhmortezaÎncă nu există evaluări

- The 7 Steps of Process-FMEA: Step 1: Planning and PreparationDocument2 paginiThe 7 Steps of Process-FMEA: Step 1: Planning and PreparationTarun PrabhakarÎncă nu există evaluări

- Table P3 For Detection RatingDocument2 paginiTable P3 For Detection RatingAhmad Bin Ismail KhanÎncă nu există evaluări

- Fmea Detection TableDocument1 paginăFmea Detection TableR.BalasubramaniÎncă nu există evaluări

- FMEA Ranking RRDocument1 paginăFMEA Ranking RRclementiÎncă nu există evaluări

- FMEA Rating ScaleDocument2 paginiFMEA Rating ScaleSridharan VenkatÎncă nu există evaluări

- Failure Mode and Effect AnalysisDocument25 paginiFailure Mode and Effect AnalysislokelooksÎncă nu există evaluări

- QCAR QuizDocument4 paginiQCAR QuizVenkat ReddyÎncă nu există evaluări

- Installation VH20Document21 paginiInstallation VH20Cuong VuÎncă nu există evaluări

- The 4 Components of ZDQDocument37 paginiThe 4 Components of ZDQMuhammad Gullraiz ChohanÎncă nu există evaluări

- BTH 780 Reliability Engineering: Topic: Maintenance, Maintainability & AvailabilityDocument38 paginiBTH 780 Reliability Engineering: Topic: Maintenance, Maintainability & AvailabilityNeuky ElsÎncă nu există evaluări

- How To Monitor Performance in Proficiency Testing: MR Philip BriggsDocument3 paginiHow To Monitor Performance in Proficiency Testing: MR Philip BriggsAdmer Rey C. DablioÎncă nu există evaluări

- 4200 Performance Verification Manual 2020.2.0Document14 pagini4200 Performance Verification Manual 2020.2.0Ana Gabriela OjedaÎncă nu există evaluări

- Mistake Proofing Information N ExampleDocument4 paginiMistake Proofing Information N ExampleeddiekuangÎncă nu există evaluări

- Analisis de Modalidades Y Efectos de Fallas Potenciales (Amef)Document19 paginiAnalisis de Modalidades Y Efectos de Fallas Potenciales (Amef)Juana RivasÎncă nu există evaluări

- CPHQ ControlDocument26 paginiCPHQ ControlibmÎncă nu există evaluări

- Lecture 6 - FMEADocument6 paginiLecture 6 - FMEACherie DiazÎncă nu există evaluări

- Amef - Risk AnalysisDocument8 paginiAmef - Risk AnalysisUSUIEÎncă nu există evaluări

- Test Result Status 13 Apr 17:02 Aulispro Something To TestDocument5 paginiTest Result Status 13 Apr 17:02 Aulispro Something To Testhulk87Încă nu există evaluări

- Basics of A Five Point CalibrationDocument2 paginiBasics of A Five Point Calibrationavandetq15Încă nu există evaluări

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 paginiUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- Failure Modes and Effect Analysis of Electro-Pneumatics SystemDocument9 paginiFailure Modes and Effect Analysis of Electro-Pneumatics SystemmutluÎncă nu există evaluări

- FMEA TemplateDocument6 paginiFMEA TemplateHiếu Trần100% (1)

- DFMEArefcard PDFDocument2 paginiDFMEArefcard PDFIgor PÎncă nu există evaluări

- Software Error Detection through Testing and AnalysisDe la EverandSoftware Error Detection through Testing and AnalysisÎncă nu există evaluări

- Intelligent Technologies for Automated Electronic SystemsDe la EverandIntelligent Technologies for Automated Electronic SystemsÎncă nu există evaluări

- Electromagnetic FlowmeterDocument10 paginiElectromagnetic FlowmeterAjjay KumarÎncă nu există evaluări

- Syllogism IIDocument8 paginiSyllogism IIanon_293252604100% (1)

- Manual - Book-Vektor Ablerex - MsiiDocument24 paginiManual - Book-Vektor Ablerex - MsiiIndonesian's LOVEÎncă nu există evaluări

- g-12 p-1 TestDocument5 paginig-12 p-1 TestDev SethiÎncă nu există evaluări

- A Mathematical Model For The Spatiotemporal Epidemic Spreading of COVID19Document13 paginiA Mathematical Model For The Spatiotemporal Epidemic Spreading of COVID19Barbara BusanelloÎncă nu există evaluări

- IMO 2019 NotesDocument13 paginiIMO 2019 NotesAndrei346Încă nu există evaluări

- Important Gate Topics For Mechanical Engineering (Me) - Mechanical Gate Basic ConceptsDocument9 paginiImportant Gate Topics For Mechanical Engineering (Me) - Mechanical Gate Basic ConceptsSatheesh ChandranÎncă nu există evaluări

- Paper 1: Year 9 Mathematics TestDocument32 paginiPaper 1: Year 9 Mathematics TestMa XóÎncă nu există evaluări

- Biology Final Exam - Print - QuizizzDocument5 paginiBiology Final Exam - Print - QuizizzrubelliteÎncă nu există evaluări

- H61M HVSDocument55 paginiH61M HVSXì DầuÎncă nu există evaluări

- Traffic Flow Theory and Delay - Part6Document5 paginiTraffic Flow Theory and Delay - Part6Sai Kumar0% (1)

- Edge Crush Test-Tappi-2007Document13 paginiEdge Crush Test-Tappi-2007김강형Încă nu există evaluări

- Thermowax Issues Reparation Autochoke Som fastnat-GCV140-160-190Document6 paginiThermowax Issues Reparation Autochoke Som fastnat-GCV140-160-190coyote556Încă nu există evaluări

- Datos JeanDocument8 paginiDatos JeanJean Carlo GuarenasÎncă nu există evaluări

- Multimeter Parts and Functions PDFDocument15 paginiMultimeter Parts and Functions PDFmarkÎncă nu există evaluări

- P521 OrderForm - V18 - 09 - 2014Document11 paginiP521 OrderForm - V18 - 09 - 2014Pakde NdokÎncă nu există evaluări

- Line Matching Unit For PLC: Features and ApplicationsDocument2 paginiLine Matching Unit For PLC: Features and ApplicationsLaurentiuÎncă nu există evaluări

- Of Intrinsic Validity - A Study On The Relevance of Pūrva Mīmā SāDocument29 paginiOf Intrinsic Validity - A Study On The Relevance of Pūrva Mīmā SāDanillo Costa LimaÎncă nu există evaluări

- RN Nemo Outdoor 7 6 0 7 30th June 2015Document55 paginiRN Nemo Outdoor 7 6 0 7 30th June 2015yatishjainkotaÎncă nu există evaluări