Documente Academic

Documente Profesional

Documente Cultură

CF680E

Încărcat de

cf34Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CF680E

Încărcat de

cf34Drepturi de autor:

Formate disponibile

ENGINE YEARBOOK 2006

CF6-80E: Past, present and future

Paolo Lironi, senior technical manager and head of powerplant consulting at IASG, investigates the latest derivative of arguably one of the most successful current build powerplants in the industry. He considers its composition, development, maintenance costs, values and future prospects.

he CF6-80E1 engine model was developed for the A330 family and is the highest thrust and most modern version of the CF6-80 family of engines to have been produced by General Electric (GE). The CF6 family represents the most successful project within GE and most probably within the whole aero-engine industry. The CF6-80E1 is a third generation derivative which has benefited from previous family applications, in particular from the CF680C2 engine model that has accumulated in excess of 120 million flying hours.

Powerplant description

The -E1 engine model has a classic two-shaft, high bypass-ratio, axial-flow turbofan design. The engine is composed of five main modules: The fan module consists of a 96-inch diameter fan frame, aluminium fan blades and a 4 stage booster. The fan frame is one of the two main structural parts of the engine; The core module is composed of a 14 stage high-pressure compressor

driven by the high-pressure turbine, while the low-pressure shaft is driven by the low-pressure turbine. The high-pressure stator, the compressor rear frame, the combustion chamber and the stage 1 nozzle guide vanes are also part of the same module; The high-pressure turbine module has two stages and blades are made of different materials based on the same standard. The nozzle guide vanes are also part of the module; The low-pressure turbine module has five stages, one more than the C2 model. The turbine frame is the second structural part of the engine; Through the inlet gearbox, which is part of the fan module, torque is transferred to the accessory gearbox module where the engine-mounted components are installed. The accessory gearbox module is mounted on the bottom of the HP compressor to reduce engine ground clearance when the engine is installed. The engine is equipped with a second-generation full authority

digital electronic control (FADEC II). The main component in the computerised control system is the engine control unit (ECU). The ECU receives inputs from several sensors located on the engine, the air intake and the aircraft. These inputs are analysed and engine actuators are activated by the ECU to improve engine fuel consumption and to optimise engine airflow efficiency.

Technical development

The first version to be produced was the -E1A2, which was installed on the A330-300. The second version was the -E1A4, while the -E1A3 model was launched in 2002. In 2004, the -E1A4B was then proposed to customers. The latest version to be made available is the -E1A4B which has the capability to provide additional power for short periods of time (thrust bump). The launch operator of the -E1A2 was Air Inter of France which ordered 19 aircraft and then reduced its order to only four aircraft. The -E1 version shares 60 per cent of core parts with the -C2 version. The

24

Engine Yearbook 2006

ENGINE YEARBOOK 2006

Table 1: Engine applications

Engine model

CF6-80E1A2 CF6-80E1A3 CF6-80E1A4 CF6-80E1A4B

Thrust rating (lbs)

68,000 72,000 70,000 70,000

Number of Engines

42 62 48 4

Number of aircraft

21 31 24 2

Types of aircraft

A330-300 A330-200/300 A330-300/-200 A330-300/-200

Table 2: Airbus A330 engine models

Engine model

CF6-80E1A2 CF6-80E1A4 CF6-80E1A3 PW4168A TRENT 772B-60 CF6-80E1A2 CF6-80E1A4 CF6-80E1A3 PW4164 PW4168 PW4168A TRENT 768-60 TRENT 772-60 TRENT 772B-60

No. of engines

8 26 62 102 138 38 6 8 16 52 58 12 36 70

No. of aircraft

4 13 31 51 69 19 3 4 8 26 29 6 18 35

Aircraft types

A330-201 A330-202 A330-203 A330-223 A330-243 A330-301 A330-302 A330-303 A330-321 A330-322 A330-323 A330-341 A330-342 A330-343

Table 3:CF6-80E1 operators

Airline

Aer Lingus Air Calin Air France Air France Air Inter Aer Inter Europe China Airlines Continental Airlines Eva Air GE Capital Aviation Services ILFC KLM Royal Dutch Airlines Philippine Airlines QANTAS QATAR Airways QATAR Amiri Flight TAM Linhas Aereas Turkish Airlines (THY) AIR Madrid Etihad

Total

14 4 16 14 4 0 16 0 15 1 3 6 16 25 37 2 8 5 2 2

Ordered

7 2 8 8 15 0 14 13 10 3 4 6 8 17 28 1 4 5 0 0

Delivered Cancelled

7 2 8 6 4 0 2 0 5 0 0 0 8 11 10 1 4 0 2 2 0 0 0 0 9 0 0 13 0 2 1 0 0 3 1 0 0 0 0 0

core section of the -E1A2 is the same of the -C2 engines. This particular engine model has the same strengths and problems as the C2 model, namely: HP compressor spool cracking; NGV cracking and sagging; and HP turbine disk cracking. With the experience gained with E1A2, when GE contemplated the increased thrust -E1A4 engine it realised that the hot section needed to be improved upon and modified to offer better levels of reliability. GE designed and tested a new highpressure turbine module and this consisted of a revised design including a new HPT stage 1 disk and a new stage 2 disk and blades. Once tests were complete, GE proposed to operators that the name for the engine should become R88, after the new material used in the turbine section. This new turbine design was also installed on the CF6-80C2B8F engine model, powering the latest version of Boeing 767, the -400, operated by Delta Air Lines and Continental. The HP compressor of the -E1A4 also had to be modified. Original production engines were manufactured with a twopart stage 10 - 14 HP compressor spool (a stage 10 HP compressor disk and an 11-14 HP compressor spool). Once the new one-part HP compressor stage 1014 spool was introduced on the CF680C2 engine, it was transferred to the -E1 model.

Applications

The -E1 engine model can be installed on the Airbus A330-200 and -300 aircraft: The same aircraft can be powered by a Rolls-Royce engine or a Pratt & Whitney engine. Fifteen airlines currently operate the -E1 engine model. In 2004 the largest operator of the -E1 was Air France, while Qatar Airways and Qantas were jointly second largest. If the orders and options are converted to orders, the biggest operators (Qatar, Air France/KLM and Qantas) will operate 48 per cent of the total fleet. During early development, operators preferred the RR Trent 700 and PW4100 engine models to the CF680E1 on the A330 application. At the

26

Engine Yearbook 2006

ENGINE YEARBOOK 2006

end of 2004, Rolls-Royce was leading on the A330 with 41 per cent of the market with P&W in second place and the CF6-80E1 in third position. But during 2004, GE won the largest percentage of A330 orders. Also, Air France and Qatar have significantly increased their orders, and KLM and China Airlines have been added to the customer list. This will mean that over the coming five years the majority of newly delivered A330s will be GE powered. It is evident from Figure 2 that GE has been pushing hard to increase sales of this engine model, in order to increase the operator base and fleet size. By the end of 2009, the picture could be very different to what it is today.

proposed to operators has not had sufficient feedback to confirm its validity, although first indications are encouraging. GE has requested operators to perform an on-wing inspection to monitor the deterioration of the VSV bushings. Two main problems are: wearing and fracture of lever arms whereby an uncontrolled vane could rotate freely and create an engine surge; and wear in the internal & external bushing

VSV bushings which permitted vanes to liberate. 2 Fan mid shaft Teflon seal: Several CF6-80C2 engines have suffered from oil leakage at the fan midshaft seal. Since the basic design is similar to the CF6-50 engine model, the nature of the problem and the means of controlling it have been read across to the -80C2. There have been no problems of this

Main technical issues

Since entry into service the engine has shown few significant problems. The core -80C2 engine has been extended to its design limit with an increase of 10 per cent in thrust on the largest thrust engines, the CF6-80C2B7F and CF6-80C2D1F. Typically, first run engines were accumulating 1,300 cycles / 5,200 hours. The main causes for removal were: 1 High vibration: Several operators experienced problems with vibration. Cabin comfort was the main issue. 2 Nozzle guide vanes (NGVs): This was a common problem on -80C2 engines. On the E1 fleet, one particular involved the severe sagging of stage 2 NGVs causing the HP turbine stage 2 blades to fail, and an uncontained failure on the LP turbine Module. Subsequently, the AD applicable to C2 engines was read across to E1 engines. Inspection and re-inspection intervals for borescope inspection were subsequently revised twice to ensure that the intervals were at their correct levels. While the above problems have almost completely been eradicated, the following problems are still persisting: 1 Variable stator vanes (VSVs): This has been an ongoing problem for the CF6-80 family. The latest solution

Rely on the repair and overhaul experts who know the product best the original designer and manufacturer. Woodwards value-added custom solutions lower your cost of ownership. Our technical expertise, engineering and analysis, unmatched environmental test facility, and global support network provide increased component on-wing time, the highest quality levels, fastest turn times, and most cost-effective service in the industry. Dedicated customer service managers Flexible cost and inventory management options Service bulletin and modification programs tailored to your needs Traceable repair maintenance history 24-hour AOG service

INSIST ON GENUINE WOODWARD.

Rockford | Rockton | Zeeland | Prestwick | Beijing | Tomisato | Campinas

+1 815 877 7441 www.woodward.com

Engine Yearbook 2006

27

ENGINE YEARBOOK 2006

Figure 1: Number of A330 aircraft delivered divided by engine model

77 24%

133 41%

nature on CF6-80E engines although magnetic chip detector inspection has been specified and if Teflon is found, the engine has to be repaired. Also, a Commercial engine service memorandum has been issued by GE defining the threshold for inspections and parts replacement. 3 Turbine rear frame (TRF) cracking: Some of the highest cycle engines have experienced cracks in the TRF. Some parts had to be scrapped and GE has been working to increase allowable crack limits and to better understand the cause of the cracking. On-wing inspections are now requested. No final solution is available at this stage.

115 35%

Rolls-Royce Pratt & Whitney GE Delivered at end of 2004

source: IASG

Maintenance costs

For several reasons IASG believes that the costs of maintenance for this

Figure 2: Future A330 deliveries

30

25

20

Undisclosed GE PW RR

15

10

0 2005 2006 2007 2008 2009

source: IASG

engine are going to decrease over the coming years. First of all, there will be an increase in the number of flying engines. Then there will be other MROs offering maintenance on this engine model and competition will most likely drive costs down. Presently, only GE West Coast Operations and GE Caledonian have the complete capability of repairing CF6-80E1 engines. It should be noted, however, that the GE Caledonian test cell is not as yet certified to test the 80E1 and that engines therefore have to be transported to Snecma Paris for testing. IASG understands that GE is currently considering the possibility of having a third engine shop in Asia, possibly in cooperation with Eva Air. There are no significant Airworthiness Directives or repetitive maintenance burdens affecting the E1 variant. Even though the -E1 model shares a lot of parts with the more common -C2 engine, the -E1 version has not received significant interest from the MROs, probably because of the low fleet size. It is understood that part of the Air France - KLM deal for GE powered A330s was to create a fleet size which would allow Air France Industries (AFI) or KLM Maintenance to enter into the -E1 MRO market. The KLM engine shop has recently started performing work on the -E1 engine, while AFI has been designated a GE90 repair station. IASG believes that, based on scheduled removal rates, future shop visits should be sufficient to guarantee enough work for three shops worldwide. However, based on IASG estimations, no additional MRO will enter the market due to lack of work. GE, with KLM as an alternative to the OEM, will most probably dominate the future aftermarket. From its experience, IASG notes the typical cost of a shop visit for this engine model is 10 per cent higher than a -C2 version. A typical shop visit is therefore in the region of $1.8 to $2.1 million, depending on shop loadings and prevailing commercial arrangements. GE is

28

Engine Yearbook 2006

ENGINE YEARBOOK 2006

believed to be promoting the upgrading of existing engines to the latest standard of HP turbine and HP compressor. Costs for the upgrades are being kept under wraps at this time although they will obviously apply to spare engines also. Maintenance costs per flight hour are in the region of $150 to $190 per hour plus $340 to $350 per cycle depending on sector lengths, thrust de-rate policy, operating weights and operating environment. LLP costs are likely to remain high because of the absence of a tertiary market.

Spare engines

Spare engines are owned by big operators and by GECAS. The cost of a new engine is around $12 million and small airlines within the A330 fleet cannot afford to carry such high capital costs. While there have been attempts to create spare engine pools they have been unsuccessful. Information on lease rates is difficult to come by but IASG has seen documented lease rates in the high $80,000 per month, depending upon the length of the lease and the number of engines involved. This is not an engine that IASG would advise engine lessors to invest in unless it is on a full payout basis with a view to part out values at the end of a long lease term.

IASG believe that the introduction of the Boeing 787 and Airbus A350 will threaten the longevity of the A330 to some degree. Boeing has selected the Rolls-Royce Trent 1000 and General Electric GEnx engine models on the B787 and Airbus has specified the GEnx engine for the A350. Consequently the -E1 will be a less interesting product and will be at the end of its technical life cycle within the next seven years. The residual value of the A330 and the installed -E1 powerplants will come under continued downward pressure when the B787 and A350 deliveries come on line.

Figure 3: Deliveries at the end of 2009

150 31% 183 37%

128 26%

28 6%

Conclusions

IASG notes the engine has had only minor problems during the introductory phase. General Electric has been marketing the engine heavily to increase the installed base. As a result, all recent disclosed orders of the A330 are going GEs way and the majority of those that are undisclosed are likely to be GE powered. The customer base will increase and, in all probability, GE will dominate the associated spare engine and engine maintenance business. Operators will need to agree longterm rates with GE or any other MRO that chooses to enter the -E1 market, to prevent prices from inflating unduly in years to come. Owners need to be vigilant with respect to future values and those engines on operating leases should not to be exposed to refurbishment costs without suitable terms and conditions being agreed with GE or the engine MRO. IASG is of the opinion that the CF6 family represents the most successful programme in GE history. The current installed base, the number of orders in GE books and the new versions released will guarantee GE leadership of this market segment. The CF6 family market is stable and broad which may appear to be a guarantee for many investors. However, the powerful, technically competent and reliable CF6-80-E1 engines may be too niche for some investors, and operators need to be vigilant of aftermarket issues.

Undisclosed Rolls-Royce Pratt & Whitney GE

source: IASG

Future

Over the coming years, the number of operators will increase but fleet size will remain relatively small. This should enable increased pooling of spare engines if airlines and alliances can come to a point where they share common ground. As can be seen from the deliveries to date and the predicted future deliveries, the -E1 is still in the first part of its product life cycle, even though it may be halfway through its technical life cycle. Based on the application and on the current fleet, IASG estimates that the engine model will be seen in future airports for at least the next 15 years, since it is compliant with the associated emissions and noise legislation up to that point and probably beyond.

Engine Yearbook 2006

29

S-ar putea să vă placă și

- Toaz - Info Fan Removal PRDocument111 paginiToaz - Info Fan Removal PROsman ParlakÎncă nu există evaluări

- Bobcat 853 Service Manual SN 512816001 Up Sn508418001 Up SN 509718001 UpDocument439 paginiBobcat 853 Service Manual SN 512816001 Up Sn508418001 Up SN 509718001 UpEduardo Ariel Bernal80% (5)

- EngineDocument2 paginiEnginesyahirazaihadÎncă nu există evaluări

- Aerospace Actuators 2: Signal-by-Wire and Power-by-WireDe la EverandAerospace Actuators 2: Signal-by-Wire and Power-by-WireÎncă nu există evaluări

- Quality Assurance in DialysisDocument11 paginiQuality Assurance in DialysisHaribabu ArumugamÎncă nu există evaluări

- Six Essential Skills For Managing ConflictDocument4 paginiSix Essential Skills For Managing ConflictErdi Karatepe100% (2)

- 71-0008 Issue 002Document9 pagini71-0008 Issue 002Panneer Selvam0% (1)

- Cfm56 5b C SeriesDocument10 paginiCfm56 5b C SeriesRobertÎncă nu există evaluări

- Oxford Reading Tree: What Dogs LikeDocument12 paginiOxford Reading Tree: What Dogs LikeKanja100% (1)

- CFM DebrisGuideBoeingProgramsGEK11919307 2017 (Incoming)Document81 paginiCFM DebrisGuideBoeingProgramsGEK11919307 2017 (Incoming)Andrian Putranto EdogawaÎncă nu există evaluări

- Datasheet CF6 80C2 PDFDocument2 paginiDatasheet CF6 80C2 PDFbbarry138Încă nu există evaluări

- CFM56 7B SB Rev 72-0859 TSN.01 N 20130128Document5 paginiCFM56 7B SB Rev 72-0859 TSN.01 N 20130128Mohamad Hazwan Mohamad JanaiÎncă nu există evaluări

- Borescope Inspection Report PK-TWXDocument8 paginiBorescope Inspection Report PK-TWXGranita pru24Încă nu există evaluări

- CFM Doc Leap 1B Cid Nac Eb 3 V1Document29 paginiCFM Doc Leap 1B Cid Nac Eb 3 V1Paulo SanzÎncă nu există evaluări

- ENGINEDocument21 paginiENGINEaliÎncă nu există evaluări

- B Trent41368ATDocument81 paginiB Trent41368ATArabyAbdel Hamed SadekÎncă nu există evaluări

- 70 Power Plant CFM 56 PDFDocument392 pagini70 Power Plant CFM 56 PDFAnonymous 298xlo3uU100% (2)

- Cataloag (Cfm56-5a)Document2 paginiCataloag (Cfm56-5a)hÎncă nu există evaluări

- 1 - Cowling&EBU (CF6-80E1)Document9 pagini1 - Cowling&EBU (CF6-80E1)Chabou_r1627100% (3)

- Choice Global Support Capability: Flight HoursDocument9 paginiChoice Global Support Capability: Flight HoursGenaro Rodriguez100% (2)

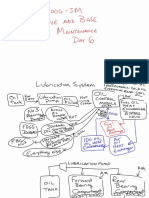

- LBM Day8Document9 paginiLBM Day8Genaro RodriguezÎncă nu există evaluări

- Fuel cfm56Document12 paginiFuel cfm56aliÎncă nu există evaluări

- PW1100G-JM Oil ServicingDocument3 paginiPW1100G-JM Oil ServicingJan Tomašević100% (1)

- EMC 1-STN-Level 2 3-ATA 46 PDFDocument10 paginiEMC 1-STN-Level 2 3-ATA 46 PDFbasid911Încă nu există evaluări

- 4 Power Generation and DistributionDocument51 pagini4 Power Generation and DistributionFanhang ZhangÎncă nu există evaluări

- Airbus T1+T2 CFM56 Tech Doc M8 - PP1Document226 paginiAirbus T1+T2 CFM56 Tech Doc M8 - PP1doga dumanÎncă nu există evaluări

- The CFM56-5A Turbofan EngineDocument2 paginiThe CFM56-5A Turbofan EngineVijayMaradimathÎncă nu există evaluări

- Fan Lub CFM56-7 - HandbookDocument44 paginiFan Lub CFM56-7 - HandbookANDRAÎncă nu există evaluări

- PowerplantDocument14 paginiPowerplantOSCARDELTA100% (2)

- TSFCDocument5 paginiTSFCRohit RaviÎncă nu există evaluări

- Pages From 70 Power Plant Iae v2500Document2 paginiPages From 70 Power Plant Iae v2500AldoÎncă nu există evaluări

- I. Models CF34-10E5 CF34-10E5A1 CF34-10E6 CF34-10E6A1: Maximum ContinuousDocument6 paginiI. Models CF34-10E5 CF34-10E5A1 CF34-10E6 CF34-10E6A1: Maximum ContinuousEstevam Gomes de AzevedoÎncă nu există evaluări

- CF34-3 Engine Notes Chapter 72 Course NotesDocument30 paginiCF34-3 Engine Notes Chapter 72 Course NotesinternetsurfingÎncă nu există evaluări

- 757 PW2 CH 71 2004 SingleDocument9 pagini757 PW2 CH 71 2004 SingleDiego Ruddy Arcaine ZegarrundoÎncă nu există evaluări

- GTCP331 Componentes PDFDocument19 paginiGTCP331 Componentes PDFKevin Arteaga100% (1)

- ATA 49 06.08.2008 - B2 Ready To PrintDocument130 paginiATA 49 06.08.2008 - B2 Ready To PrintDmitryÎncă nu există evaluări

- Carlson.geDocument41 paginiCarlson.gepapaye3712100% (1)

- 49 Apu PDFDocument238 pagini49 Apu PDFIvan Fauzi100% (1)

- Narrative ReportDocument67 paginiNarrative ReportElla ParadoÎncă nu există evaluări

- Fdocuments - in Engine Removal and Installation Cfm56 7 BDocument191 paginiFdocuments - in Engine Removal and Installation Cfm56 7 BpraveenÎncă nu există evaluări

- ATA 36 PneumaticsDocument58 paginiATA 36 PneumaticsBao HuynhÎncă nu există evaluări

- Ata 49 Auxiliary Power Unit (Apu)Document34 paginiAta 49 Auxiliary Power Unit (Apu)svyat_k100% (1)

- B737-3 ATA 52-30 QC L3 REVB New Original PDFDocument33 paginiB737-3 ATA 52-30 QC L3 REVB New Original PDFTharrmaselan VmanimaranÎncă nu există evaluări

- Ground Support Equipment Manuals Index CFM56 - CFM 2019Document4 paginiGround Support Equipment Manuals Index CFM56 - CFM 2019Ibnu AhmadÎncă nu există evaluări

- Pw11000-Jm: Line and BaseDocument14 paginiPw11000-Jm: Line and BaseGenaro RodriguezÎncă nu există evaluări

- V2500 Line and Base Maintenance Engine OverviewDocument24 paginiV2500 Line and Base Maintenance Engine OverviewHENIGUEDRI100% (2)

- B737NG - 27 60 A3 01 PDFDocument1 paginăB737NG - 27 60 A3 01 PDFMuhammed MudassirÎncă nu există evaluări

- Regtronic Eh EngDocument44 paginiRegtronic Eh Enggogame2014100% (1)

- CFM56 C PDFDocument1 paginăCFM56 C PDFhamidrezachamaniÎncă nu există evaluări

- Line and Base: Pw1100G-JMDocument16 paginiLine and Base: Pw1100G-JMGenaro Rodriguez100% (1)

- 2016: Living From Your Center: Sanaya and Duane MessageDocument24 pagini2016: Living From Your Center: Sanaya and Duane MessageELVIS100% (1)

- Gearbox SB NEODocument3 paginiGearbox SB NEOAnkit KaushikÎncă nu există evaluări

- CF680E Engine Ratings (Thrust)Document5 paginiCF680E Engine Ratings (Thrust)Orlando PérezÎncă nu există evaluări

- ATA 06decoded PDFDocument52 paginiATA 06decoded PDFraiday840% (1)

- Sreejith S Quality Assurance 5 Years ExpDocument6 paginiSreejith S Quality Assurance 5 Years ExpRamakrishna GÎncă nu există evaluări

- 27 Flight ControlDocument221 pagini27 Flight ControlHamidreza AhanzadehÎncă nu există evaluări

- ATA 70 CFM56 B2: A318/19/20/21 Single Aisle FamilyDocument86 paginiATA 70 CFM56 B2: A318/19/20/21 Single Aisle FamilyZbor ZborÎncă nu există evaluări

- What Is The Shopify Partner ProgramDocument17 paginiWhat Is The Shopify Partner ProgramAvada CommerceÎncă nu există evaluări

- GEnx Development Emphasizes Composites, Combustor TechnologyDocument3 paginiGEnx Development Emphasizes Composites, Combustor TechnologySiva KumarÎncă nu există evaluări

- Trent 1000 Bsi 23122016Document1 paginăTrent 1000 Bsi 23122016Mohamed AbdelSalamÎncă nu există evaluări

- CFM Flight Ops Support A320Document143 paginiCFM Flight Ops Support A320MarcinÎncă nu există evaluări

- CF34-8C1/-8C5 Turbofan Technical Manual Index October 1, 2019Document11 paginiCF34-8C1/-8C5 Turbofan Technical Manual Index October 1, 2019Oscar Alexander PérezÎncă nu există evaluări

- a320-A321-Refuel-Defuel System - Task Supporting DataDocument15 paginia320-A321-Refuel-Defuel System - Task Supporting Data553486151Încă nu există evaluări

- AIRBUS A320 Operations Circular No. DT / A320 / 816 C. T.E., Hyd Era BadDocument2 paginiAIRBUS A320 Operations Circular No. DT / A320 / 816 C. T.E., Hyd Era BadYogish Katagihallimath100% (2)

- A318/A319/A320/A321: Service BulletinDocument58 paginiA318/A319/A320/A321: Service BulletinPradeep K sÎncă nu există evaluări

- Leap-1A Program Status Program Status: June 2015 June 2015Document11 paginiLeap-1A Program Status Program Status: June 2015 June 2015bnmmauricioÎncă nu există evaluări

- Airbus AC A320 Jan16Document390 paginiAirbus AC A320 Jan16simon100% (1)

- Enhanced Avionics System A Complete Guide - 2020 EditionDe la EverandEnhanced Avionics System A Complete Guide - 2020 EditionÎncă nu există evaluări

- CF6-80C2 Engine History and Evolution: Paolo Lironi, Senior TechnicalDocument5 paginiCF6-80C2 Engine History and Evolution: Paolo Lironi, Senior TechnicalAnonymous kluQX93vÎncă nu există evaluări

- Easa Ad Us-2020-04-15 1Document11 paginiEasa Ad Us-2020-04-15 1cf34Încă nu există evaluări

- Lentil SoupDocument1 paginăLentil Soupcf34Încă nu există evaluări

- MLS®: 8598868 For Sale: $375,000Document3 paginiMLS®: 8598868 For Sale: $375,000cf34Încă nu există evaluări

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 paginiAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)cf34Încă nu există evaluări

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument3 paginiNotification of A Proposal To Issue An Airworthiness Directivecf34Încă nu există evaluări

- Airworthiness Direct Ive: Number: Ata: Effective Date: Type Certificate: SubjectDocument2 paginiAirworthiness Direct Ive: Number: Ata: Effective Date: Type Certificate: Subjectcf34Încă nu există evaluări

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 paginiAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)cf34Încă nu există evaluări

- Easa Ad Us-2020-04-11 1Document7 paginiEasa Ad Us-2020-04-11 1cf34Încă nu există evaluări

- Easa Ad Us-2019-22-01 1Document7 paginiEasa Ad Us-2019-22-01 1cf34Încă nu există evaluări

- Easa Pad 20-055 1Document3 paginiEasa Pad 20-055 1cf34Încă nu există evaluări

- Easa Ad 2020-0048 1Document6 paginiEasa Ad 2020-0048 1cf34Încă nu există evaluări

- Easa Ad Us-2020-03-16 1Document11 paginiEasa Ad Us-2020-03-16 1cf34Încă nu există evaluări

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument3 paginiNotification of A Proposal To Issue An Airworthiness Directivecf34Încă nu există evaluări

- Easa Ad 2020-0052 1Document3 paginiEasa Ad 2020-0052 1cf34Încă nu există evaluări

- Easa Ad 2020-0053 1Document3 paginiEasa Ad 2020-0053 1cf34Încă nu există evaluări

- Easa Ad 2020-0050 1Document3 paginiEasa Ad 2020-0050 1cf34Încă nu există evaluări

- Easa Ad 2020-0054 1Document3 paginiEasa Ad 2020-0054 1cf34Încă nu există evaluări

- Easa Pad 20-032 1Document3 paginiEasa Pad 20-032 1cf34Încă nu există evaluări

- Easa Ad 2020-0051 2Document4 paginiEasa Ad 2020-0051 2cf34Încă nu există evaluări

- Easa Ead 2019-0298-E 1Document2 paginiEasa Ead 2019-0298-E 1cf34Încă nu există evaluări

- Easa - Ad - Isr I 53 2019 12 6R1 - 1Document1 paginăEasa - Ad - Isr I 53 2019 12 6R1 - 1cf34Încă nu există evaluări

- Easa Ad Us-2020-03-22 1Document7 paginiEasa Ad Us-2020-03-22 1cf34Încă nu există evaluări

- Easa Ad Us-2019-22-06 1Document7 paginiEasa Ad Us-2019-22-06 1cf34Încă nu există evaluări

- Easa Pad 19-208 1Document3 paginiEasa Pad 19-208 1cf34Încă nu există evaluări

- Easa Pad 19-209 1Document4 paginiEasa Pad 19-209 1cf34Încă nu există evaluări

- Easa Ad 2019-0289 1Document2 paginiEasa Ad 2019-0289 1cf34Încă nu există evaluări

- Easa Ad 2019-0285 1Document4 paginiEasa Ad 2019-0285 1cf34Încă nu există evaluări

- Easa Ad 2019-0289 1Document2 paginiEasa Ad 2019-0289 1cf34Încă nu există evaluări

- Easa Ad CF-2018-01R2 1Document2 paginiEasa Ad CF-2018-01R2 1cf34Încă nu există evaluări

- @A1B696147 16AD8AEF64 GG7:6A 5E6 C C C C C C C: 1:7 4HI J 7 KLMN? MM? LO P P QRS T UQ7:VS QJ 7 LW7 4hui 7 KLMNDocument3 pagini@A1B696147 16AD8AEF64 GG7:6A 5E6 C C C C C C C: 1:7 4HI J 7 KLMN? MM? LO P P QRS T UQ7:VS QJ 7 LW7 4hui 7 KLMNcf34Încă nu există evaluări

- ANSI-ASME B16.5 Blind Flange 150lbDocument1 paginăANSI-ASME B16.5 Blind Flange 150lbVishal MistryÎncă nu există evaluări

- Welcome To OU Training!: Key Event DetailsDocument4 paginiWelcome To OU Training!: Key Event Detailsaercio manuelÎncă nu există evaluări

- Presentation - EsbDocument30 paginiPresentation - EsbPooja RanganathanÎncă nu există evaluări

- HR Chapter13 PDFDocument30 paginiHR Chapter13 PDFDee WangÎncă nu există evaluări

- International RA472 Front Rear Axle Parts ManualDocument5 paginiInternational RA472 Front Rear Axle Parts ManualHéctor Perez SÎncă nu există evaluări

- PL7 Installation On Windows 7-64bitDocument2 paginiPL7 Installation On Windows 7-64bitsyeadtalhaaliÎncă nu există evaluări

- Opcua PDFDocument33 paginiOpcua PDFmfruge7Încă nu există evaluări

- Prius 2004 - Brakes - BleedingDocument17 paginiPrius 2004 - Brakes - Bleedingburvi20011186Încă nu există evaluări

- Technical Tips - KLEI™Harmony Binding PostDocument1 paginăTechnical Tips - KLEI™Harmony Binding PostJoseph MismoÎncă nu există evaluări

- Siwes Report GoogleDocument28 paginiSiwes Report GoogleelvisÎncă nu există evaluări

- Andhra Pradesh Public Service CommissionDocument3 paginiAndhra Pradesh Public Service Commissionb.veenasriÎncă nu există evaluări

- Brownall Plant Room ValvesDocument4 paginiBrownall Plant Room ValvesPedro QuintalÎncă nu există evaluări

- Indian Ray OneDocument96 paginiIndian Ray Oneધ્રુવ પટેલÎncă nu există evaluări

- Spare Parts Supply ChainDocument8 paginiSpare Parts Supply ChainRaj ChoudharyÎncă nu există evaluări

- Low Impact Development Manual For Michigan September 2008Document512 paginiLow Impact Development Manual For Michigan September 2008Yadir Rodrìguez NùñezÎncă nu există evaluări

- Write Up of EmlDocument7 paginiWrite Up of EmlNeeraj GuptaÎncă nu există evaluări

- 40RUM 60Hz PDC V6Document36 pagini40RUM 60Hz PDC V6hgogoriyaÎncă nu există evaluări

- Benchmarking Study of Strategic Sourcing PracticesDocument2 paginiBenchmarking Study of Strategic Sourcing PracticesPepe CMÎncă nu există evaluări

- CV Equations Used in HysysDocument3 paginiCV Equations Used in HysysBesan LaduÎncă nu există evaluări

- CImg ReferenceDocument193 paginiCImg ReferenceculitabÎncă nu există evaluări

- Group1: Refrigeration and Air Conditioning Course ProjectDocument67 paginiGroup1: Refrigeration and Air Conditioning Course Projectdamola2realÎncă nu există evaluări