Documente Academic

Documente Profesional

Documente Cultură

Manufacture of Alkyd Resin from Castor Oil

Încărcat de

Sandip AgrawalDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Manufacture of Alkyd Resin from Castor Oil

Încărcat de

Sandip AgrawalDrepturi de autor:

Formate disponibile

World Academy of Science, Engineering and Technology 48 2008

Manufacture of Alkyd Resin from Castor Oil

Nway Nay Hlaing1, Mya Mya Oo2

Abstract Oil-modified alkyd resin was prepared from crude castor oil. The experiment started with investigating the optimum conditions for neutralization of crude castor oil and bleaching of neutralized oil. Then the characteristics (iodine value, viscosity, acid value, refractive index and color) of oils were determined. Refined oil has iodine value of 90, kinemetic viscosity of 4 St, free fatty acid value of 1, refractive index of 1.474 and color number of 8. These results showed that the refined oil was qualified to prepare dehydrated castor oil. Dehydration of refined oil was carried out at 210-220C under 600-640mmHg with the help of 1% (wt%) NaHSO4 catalyst. The dehydrated castor oils were analyzed for iodine value, viscosity and its set to touch time and drying time were also investigated. Dehydrated castor oil has iodine value of 140, kinemetic viscosity of 1.6 St, set to touch time of 4 hr and drying time of 5 days. And then , oil modified alkyd resin (acid value 6.6) was prepared from dehydrated castor oil by alcoholysis method in excess of glycerol and phthalic anhydride in the presence of 0.3% (wt%) NaOH catalyst. The obtained resin was characterized by Fourier Transform Infrared Spectrophotometer (FTIR) and the properties were determined.

Keywords Alcoholysis method, Alkyd resin, Castor oil, Dehydrated castor oil, Polymerization

I.

INTRODUCTION

Polymerization is one of the most important industrial processes. Resins and emulsion are two main classes of polymer. Alkyd resins are by far the most important class of coating resins. It is estimated that alkyd resins contribute about 70% to the conventional binders used in surface coating today. The popularity of alky resins as vehicle for coatings is largely due to their unique properties such as film hardness, durability gloss and gloss retention, resistance to abrasion, etc. impacted on them through modification with drying oil [1]. Alkyd resins are used in both clear and pigmented, industrial and trade coating to protect and decorate a wide variety of substances. The industrial coatings or finishes generally are applied during the manufacturing process of the item which they cover. Often they are specifically formulated to meet both conditions desired for their application and the

1.Department of Chemical Engineering, Mandalay technological University, Patheingyi Township, Mandalay, Myanmar, Myanmar 11011, email: nway.nay5@gmail.com 2.Yangon Technological University, Gyongone, Insein, Yangon, Myanmar 11011, e-mail : most7@gmail.com

endless use of the article of manufacture. The industrial finishes include primers and top coats for refrigerators, furniture, and electrical equipment. In view of the development of these items and sectors, the positive growth is expected for paint industry [2]. Further the paint industry envisages a future expansion in view of development in Automobile Industry, utility in Nuclear Power Station, development in Corrosion Resistant Coatings, expansion in housing activity and other industry uses. The demand of alkyd resin being an ingredient in Paint, Varnish and Printing ink industry would be linked with the Paint industry. There are many significant efforts that have been made to increase alkyd resin production. Many researchers have attempted to search the different sources for alkyd resin preparation. Airegumen I Aigbodion et al [3] studied enhancing the quality of alkyd resins using methyl esters of rubber seed oil in 2004. A lot of alkyd resins were imported to Myanmar Paint Industries every year. In order to save foreign currency outflow, it is needed to produce alkyd resin in Myanmar. The oils that are mostly employed for alkyd resin synthesis are linseed oil, soybean oil, dehydrated castor oil, fish oil and tall oil. Myanmar being rich in aquatic and terrestrial resources, every state and division is pursuing the target of putting 500,000 acres under physic nut (castor oil) in three years. Rural development tasks are included in the national development endeavors that are being carried out by the Nation target. Castor oil is useful directly in protective coatings as a plasticizer in alkyd systems, and blown castor oil is an important nitrocellulose plasticizer. In commercial manufacture of dehydrated castor oil, the aim is to produce the most valuable material for use as a drying oil. By far the most important coatings use of castor oil is in the form of dehydrated castor. Dehydrated castor oil is now recognized as an individual drying oil with its own characteristic properties and advantages. The drying oils owe their value as raw materials for decorative and protective coatings to their ability to polymerize or dry after they have been applied to a surface to form tough, adherent, impervious, and abrasion resistance films. The advantages claimed in surface coating applications include excellent odor and heat bleachability, good drying properties, more uniform polymer structure, and lack of after-yellowing. The dehydrated castor oil is nonyellowing oil and so this can give requirements of coating industries [2,4,5,6,7]. 2. Materials and Methods 2.1. Neutralization of Crude Castor Oil

155

World Academy of Science, Engineering and Technology 48 2008

Oil (100g) was heated to 55C. Then, the calculated amount of strong (45Be, 2N NaOH) lye was added to neutralize the free fatty acids exactly, with constant stirring. Completion of neutralization reaction was determined by testing the mixture with phenolphthalein indicator. When the indicator color of the sample mixture turned to pink, neutralization was completed. Then NaCl solution was heated to 90C and 20ml of hot NaCl solution was added to the mixture to ensure adequate salting or graining out of soapstock. After that the mixture was poured into separating funnel. Three hours later, the mixture was separated into two distinct layers. Then the lower layer or soap layer was drain out. The upper layer or oil layer was washed with hot water. Washing was carried out until color of phenolphthalein indicator did not change to pink. After complete washing, the oil was dried at 100C in oven to evaporate the moisture. Drying and cooling was carried out until the weight of dried oil remained unchanged. The neutralized oils were weighed to calculate oil loss and then their free fatty acid content (FFA) were determined [8]. The characteristics of crude oil and neutralized oil were determined by American Society of Testing and Materials (ASTM) standard methods. 2.2. Bleaching of Neutralized Oil The neutralized oils were heated to 100C and different amounts of activated charcoal were added. After the mixture was stirred for 45 minutes, the mixture was cooled to room temperature and activated charcoal was removed by filtering with filter paper. The neutralized oils were also bleached with different amounts of bentonite and a mixture of activated charcoal and bentonite (1:1 ratio). Then the process was carried out above procedure. The colors of bleached oil samples were determined by a spectrophotometric method [11]. In this method, optical densities were measured at the wavelength of 460nm, 550nm, 620nm and 670nm. Then the photometric colors were calculated by the following equation. Photometric color = 1.29D460 + 69.7D550 + 41.2D650 [4] 56.4D670 2.3. Dehydration of Castor Oil Bleached oil (50g) and 2% (wt%) of NaHSO4 catalyst were placed into round bottom flask and the apparatus was set up as shown in figure (1). The system was heated to 210-220C for dehydration time were taken for 15, 30, 45, 60, 75 minutes. Dehydration was also carried out under 600-640 mmHg (vacuum) as described in the above process. In this process, the effect of NaHSO4 catalyst amount on the properties of dehydrated castor oil was also investigated. Then, the iodine values of dehydrated castor oil were determined by ASTM D1541-86 and viscosities were determined by ASTM D 1545-63 method. The drying time and set to touch time were also determined by ASTM D 195370 [9].

Figure 2.1.Dehydration of Castor Oil 2.4. Preparation of Alkyd Resin Oil modified alkyd resin was prepared with dehydrated castor oil, glycerol and phthalic anhydride using NaOH catalyst. The preparation was done in a 4-neck round bottom flask fitted with a motorized stirrer, a nitrogen inlet, a thermometer pocked and a hold for sampling. The system was shown in Fig. 2. In the preparation of alkyd resin, two stages were involved. The first stage was alcoholysis stage and the second stage was esterification stage. Raw material Weight (g) Weight (%) Dehydrate castor oil 114.27 60.437 (DCO) Phthalic anhydride (PA) 43.364 22.935 Glycerol (G) 31.44 16.63 Total 189.074 100 Stage 1 (alcoholysis): In this stage, monoglyceride was first prepared by reacting the oil with glycerol. Alcoholysis of oil was carried out with different percentages of (0.03%, 0.05%, 0.1%) (by weight) PbO catalyst and (0.1%, 0.2%, 0.3%)(by weight) NaOH catalysts. In alcoholysis reaction, the oil was heated with agitation speed of (700 rpm) and N2 sparging rate of about (0.06ft3/sec) to 230-240C. Glycerol and selected catalyst was added and alcoholysis reaction was carried out at 230-240C. The reaction was continued until a sample of the reaction mixture became soluble in two to four volumes of anhydrous methanol. After alcoholysis reaction was completed, the reaction mixture was cooled to 140C. Stage 2 (esterification): In this stage, phthalic anhydride was added to the monoglyceride mixture. The temperature was maintained at the range of 230-240C and maintained at this temperature. The sparging rate of N2 was increased to (0.1ft3/sec). The reaction was monitored by periodic determination of the acid value of the mixture until acid value dropped to nearly 5. The acid value of alkyd resin was determined by ASTM D 1639-90 and the chemical resistances also determined. The prepared resin was standardized by FTIR [12, 13].

Fig.3.3.Alkyd Resin Preparation

156

World Academy of Science, Engineering and Technology 48 2008

3. Results and Discussion 3.1. Results 3.1.1. Characterization of Crude Castor Oil The characteristics of crude castor oil are shown in Table 3.1. Table 3.1. The Characteristics of Crude Castor Oil Characteristics Crude castor oil Free fatty acid value Color, photometric Refractive index Specific gravity Viscosity(Stroke) Iodine value, wijis 19 0.9633 4.5 89.5

3.1.2. Neutralization of Crude Castor Oil Table 3.2 show the FFA content of neutralized oil. Initial weight of crude castor oil = 100g FFA (%) of crude oil = 19% Neutralization temperature = 55C 20% NaCL solution = 40ml Sr. 2N Neutralization FFA (%) Weight of no NaOH time(minutes) of Neutralized Neutralized oil (g) oil 1 15.2 5 8.448 65.09 2 30 10 0.987 60.43 3 30 10 0.988 51.79

Bleaching time = 45 minutes *Photometric color = 1.29D460 + 69.7D620 + 41.2D650 Sample Bleaching (wt%) of Photometric Wt. of no. agents bleachin color Refined oil g agent number (g) A1 Activated 3 7.25 57.437 A2 charcoal 5 6.35 57.400 A3 (A) 7 7.16 57.36 A4 9 8.32 57.254 A5 11 9.29 57.217 B1 Bentonite 3 3.80 58.118 B2 (B) 5 3.40 57.386 B3 7 4.40 57.380 B4 9 4.47 57.311 C1 Activated 3 4.0 57.405 C2 charcoal 5 3.0 57.342 C3 and 7 4.46 57.254 bentonite (1:1 ratio) (C) 56.4D670 [4]. 3.1.5. Dehydration of Refined Castor Oil Table 3.5 present the yield of dehydrated castor oil at different dehydration conditions. The changes of iodine value and viscosity by dehydration of castor oil at different dehydration conditions are shown in Fig. 3.1 and Fig. 3.2. Table 3.5. Yield of Dehydrated Castor Oil at Different Dehydration Conditions Initial weight of sample C2 = 50g

4.1.3. Characterization of Refined Castor Oil The characteristics of refined castor are described in Table 3.3 by comparing with ASTM standard castor oil. Table 3.3.Characteristics of Refined Castor Oil Characteristics Free fatty acid value Color, photometric Refractive index Specific gravity Viscosity(Stroke) Iodine value, wijis Refined castor oil 1 8 1.474 0.9614 4 90 Castor oil (ASTM D 960-79) 1.00 1.476 to 1.4778 0.957 to 0.961 6.3 to 8.9 83 to 88

Source [6] 3.1.4. Bleaching of Neutralized Castor Oil Effect of bleaching on color and yield of neutralized castor oil is shown in Table 3.4. Oil was bleached with 0-11% of activated carbon, 0-9% of bentonite and 0-7% of 1:1 mixture of activated charcoal and bentonite Table 3.4. Effect of Bleaching On Color and Yield of Neutralized Castor Oil Initial weight of neutralized oil = 100 g Bleaching temperature = 100C

157

World Academy of Science, Engineering and Technology 48 2008

NaHSO4 catalyst (%)

cu um )

V.P (mm Hg) 760 600640 600640

Dehydration time (minutes)/Yield (%) 15 0.5 90.9 90.2 30 90.37 90.11 90.035 45 89.88 89.5 89.67 60 89.56 89.13 5 89.39 75 89.55 89.06 89.28

2 2

m)

140 135 130

2%

Na

HS

0 (60

-6 4

0m

, Hg

va

Iodine Value

125 120 115 110 105 100 10 20

1%

Na

(60 SO 4

0 -6 4

mm

Hg

,v

u acu

ho S O 4(w it % N aH

uu ut vac

m)

30

40

50

60

70

80

Dehydration Time(min)

Fig. 3.1.Change of Iodine Value with Reaction Time for Dehydration Temperature at 210-220C

4 .6 4 .4 4 .2 4 .0 3 .8 3 .6

2%

Na

HS

(w

it h

ou

tv ac

uu

3 .4 3 .2 3 .0 2 .8 2 .6 2 .4 2 .2 2 .0 1 .8 1 .6 1 .4 10

2%

aH

SO

1% Na (6 HS 00 O -6 40 m m

(6

00

-6

Hg

40

,v a

cu

Hg

um

,v ac

)

50

uu

)

60 70 80

20

30

40

D e h y d r a t io n T im e ( m in )

Fig.3.2. Change of Viscosity with Reaction Time for Dehydration Temperature at 210-220C 4.1.6. Characterization of Dehydrated Castor Oils The characteristics of typical dehydrated castor were presented in Table 3.6 by comparing with ASTM standard dehydrated castor oil. Table 3.6.Characteristics of Typical Dehydrated Castor Oils Vacuum pressure = 600-640 mmHg Characteristics Dehydrated Dehydrated Standard castor oil 2 dehydrated castor oil1 castor oil (ASTM D961-86) Iodine value 140.01 139.05 125-145 Viscosity (Stroke) Set to touch time (hour) Drying time (hour) 1.600 4 5 1.686 3.5 5 1.5-1.8 2.5,approxi mately -

dehydration with 1% NaHSO4 catalyst for 60 minutes dehydration with 2% NaHSO4 catalyst for 45 minutes 3.1.7. Preparation of Alkyd Resin Reaction condition of alcoholysis reaction condition in alkyd resin preparation is described in Table 3.7. Fig. 3.3 shows the acid value control of esterification reaction. Yield of dehydrated castor oil-modified alkyd resin and the calculation for percentage of reaction complection are presented in Table 3.8. The appearances of gel type resin, dehydrated castor oil-modified alkyd resin are shown in Fig. 3.4. Table 3.7. 1st Stage Alcoholysis Reaction Conditions Reaction temperature = 230-240C Agitation speed = 500 rpm = 0.06 ft3/minutes N2 sparging rate Alcoholysi Catalyst Reaction Completion of s catalysts % (wt%) time (hr) alcoholysis reaction* PbO 0.03 4 Not complete 0.05 4 Not complete 0.1 4 Not complete NaOH 0.1 4 Not complete 0.2 4 Not complete 0.3 2 complete *It was determined by testing the solubility of alcoholysis mixture in anhydrous methanol.

2

Viscosity(Stroke)

100

acid value

10

1 30 60 90 120 150 reaction time (minutes)

Fig.3.3. Acid Value Control of Esterification Reaction Table 3.8. Yield of Dehydrated Castor Oil-Modified Alkyd Resin

158

World Academy of Science, Engineering and Technology 48 2008

I.W-initial weight F.W-final weight Y-yield IAV-initial acid value FVA-final acid value P-degree of reaction complection

DCO alkyd resin (100% solid) 5

I..W(g)

F.W (g) 140

Y (%) 73.85

IAV

FAV 6.6

P (%) 97.72

189.58 2 1125.26

298.58 8

1150-1060

O=C-O-C3.1.8. Characterization of Alkyd Resin The physico-chemical properties of alkyd resin are presented in Table 3.9. The chemical resistances of alkyd resin film are shown in Table 3.10. Table 3.11 show FTIR absorption band of dehydrated castor oil-modified alkyd resin. Table 3.9. Characteristics of Dehydrated Castor Oil-modified Alkyd Resin Properties DCO RSO alkyd DCO alkyd resin* alkyd resin resin Acid value 6.6 12.7 4-11 Iodine 80.24 66.3 value Color Yellow Brown Refractive 1.477 1.5050 index Gouge HB HB hardness Scratch F H hardness RSO- rubber seed oil Source [1, 14] Table 3.10. Chemical Resistances of Alkyd Resin Films Media Immersion Appearance of time (hours) film* Distilled water 18 Not effect 8 Whitening 3 N NaOH 16 Blistering 24 Removal *It was examined after the films were air dried for 30 minutes. Table 3.11. FTIR Absorption Band of Dehydrated Castor OilModified Alkyd Resin Remark Band Experimental Literature frequency No. frequency (cm-1) (cm-1) 1 3008.99 Near 3030 =C-H 2926.74 2 3514.21 3570-3200 O-H 1169.21 Near 1100 O-H 3 2855.67 2926-2850 C-H 1460.43 1485-1440 CH2 CH3COOCH3 4 1738.64 1750-1735 1730.30 1730-1717 COO

3.2. Discussion 3.2.1. Discussion on Characteristics of Crude Castor Oil According to Table 4.1 FFA content of crude castor oil was high and it was not within the ASTM specification limit. The color and refractive index of crude oil can not be determined because the transparency of crude oil was very poor. The viscosity of crude oil was slightly lower than that of ASTM standard oil [6]. Even though, the specific gravity and iodine value of crude oil were in the range of ASTM specification limit, the FFA content of crude oil was differed from ASTM standard. The only reason to reduce the FFA content of oil was to neutralize the crude oil. 4.2.2. Discussion on Neutralization of Crude Castor Oil In neutralization process, it was found that 30 ml of 2 N NaOH per 100g of oil was required to obtain neutralized oil with an acceptable FFA content and to be a minimum of oil loss. The neutralization time of 10 minutes was sufficient to reduce FFA content from 19% to 1%. In neutralization of oil, free fatty acid content of oil was converted in oil soluble soaps. Small amount of impurities such as phosphotides, proteins or protein fragments, and gummy or mucilaginous substances were also removed by neutralization process. Therefore, the initial weight of oil was decreased as well as the yield of oil was decreased. In neutralization process, there was a difficulty to separate the soap and oil layer because FFA content in crude oil was very high. The two layers can be easily separated when NaCL solution was added to the neutralized mixture because NaCL can help to ensure adequate salting or graining out of the soapstock. Other impurities in oil were removed by washing with hot water. In washing step, there has a little loss of oil. So, the average yield of oil was 64%. 3.2.3. Discussion on Characteristic of Neutralized Castor Oil From Table 3.3., it can be seen that the neutralization process can reduce the FFA content of crude oil from 19% to 1%. Then, it can give the refined oil color of 8 and refractive index of 1.474. Therefore, neutralization process can offer great effect on FFA content, color and refractive index of oil. Moreover, the refined oil has specific gravity of 0.9614, viscosity of 4 and iodine value of 90. These results were nearly the same as that of the crude oil. Although the neutralization technique reduced significantly FFA content in

159

World Academy of Science, Engineering and Technology 48 2008

oil, it gave slightly effect on specific gravity, viscosity and iodine value of oil. 3.2.4. Discussion on bleaching of neutralized oil In Table 3.4, it can be seen that the highest color removal efficiency was obtained by bleaching with 5% of bleaching agents. 5% of activated carbon, 5% of bentonite and 5% of (1:1) mixture of activated charcoal and bentonite can give the oil with photometric color of 6.35, 3.4 and 3.0 respectively. Bleaching with (1:1) mixture of activated charcoal and bentonite can offer better result. So, it can be chosen as bleaching agents in bleaching of neutralized oil. Beside decoloring, bleaching of neutralized oil served the important function of largely removal of trace amount of soap. After bleaching process, the average oil yield was 69%. The oil yield was decreased during the bleaching process due to the adsorption of oil on the surface of adsorbents and the filtration of oil with filter paper. 4.2.5. Discussion on Dehydration of Castor Oil According to the Table 3.5, the yield of dehydrated castor oil decreased with increasing the dehydration time. Then, there was a slightly different in yield of dehydrated castor oil although the dehydration process was carried out different dehydration conditions. In Fig. 3.1 and 3.2, it was observed that the dehydrated castor oil with a maximum iodine value and a minimum viscosity could be obtained at the proper reaction time. The iodine values of dehydrated castor oil increased with the reaction time and reached a maximum value. Then, it decreased because prolong heating leads to polymerization with a consequence drop in iodine value and a step rise in viscosity. The minimum viscosity occurs at or near the point of maximum iodine value. From Fig. 3.1, the dehydration of oil without vacuum system could not give acceptable iodine value to qualify as drying oil because the iodine value of oil was below 125 (the lower limit of ASTM dehydrated castor oil) . In this process, a lot of fumes were evolved during dehydration of oil and these fumes were condensed and dripped back into the dehydrated oil. It was undesirable effect. Therefore, it is required to use a current of inert gas such as carbon dioxide or nitrogen in order to remove the decomposition products. The most effective way of removing of fume is by using the vacuum pressure. By this means, the problem of condensing the fume into the dehydrated oil was largely avoided. Therefore, dehydration of refined castor oil was carried out under vacuum system. When dehydration of oil was done by using 1% of NaHSO4 catalyst and vacuum pressure of 600-640 mmHg and the optimum reaction time is 60 minutes, this system could give dehydrated castor oil with iodine value of 140. When dehydration of oil was done by using 2% of catalyst and vacuum pressure of 600-640 mmHg and the optimum reaction time is 45 minutes, this system could give the dehydrated castor oil with iodine value of 139.05. Although the dehydration time was decreased with increasing the amount of catalyst percent, the refractive index of the dehydrated oil was increased.

4.2.6. Discussion on Characteristics of Dehydrated Castor Oils The iodine value and viscosity control the extent of reaction and set to touch time and drying time show the drying properties of dehydrated castor oil. Table 4.7 described that the iodine value and viscosity of dehydrated castor oils were in the limit of ASTM standard dehydrated castor oil. Then the drying time and set to touch time also gave satisfactory result. Therefore, these dehydrated castor oils were acceptable to prepare drying oil-modified alkyd resin. 4.2.7. Discussion on Preparation of Alkyd Resin According to the literature [3], the alcoholysis reaction is usually completed within an hr or two hrs after the batch had reached operating temperature. In Table 4.8, it was found that the samples of the alcoholysis mixture did not completely soluble in anhydrous methanol although the alcoholysis reactions were carried out for 4hr by using different amount of litharge catalysts (0.03%, 0.05%, 0.1%) and NaOH catalysts (0.1%, 0.2%). It should not be tried to use the amount of PbO catalyst more than 0.1% (wt%) because the preferred PbO catalyst percent for alcoholysis reaction is 0.010.1 in literature. Then, large quantities of catalyst lead to dark the color of alkyd resin and detract from the water and alkali resistances of alkyd resin. In alcoholysis of oil with 0.1% (wt%) and 0.2% (wt%) NaOH catalyst, it cannot also give complete alcoholysis mixture after reaction was carried out for 2 hrs. The degree of alcoholysis has an important bearing on the properties of the resulting resin. During the final reaction with phthalic anhydride, esterification of the free hydroxyl groups of the monoglyceride must compete with any unreacted or excess glycerol. The latter reaction leads to glyceryl phthalate which is insoluble in the oil-acid-glyceryl phthalate and unreacted glyceride oil. Unless sufficient monoglyceride is present prior to the addition of the phthalic anhydride, the reaction product will be unsoluble gel of glyceryl phthalate suspended in oily mixed glycerides. Such a product is worthless. In esterification reaction, it was observed that the longer the reaction time, the more viscous the mixture is. In this stage, adequate agitation was necessary for complete mixing of monoglyceride mixture and phthalic anhydride. Unless adequate mixing was supplied in this stage, the unqualify alkyd resin would be resulted. So, the N2 sparging rate was increased in order to remove liberated reaction product and to increase the heat and mass transfer of chemical reaction. In Fig. 3.3, the oil-modified alkyd resin with acid number of 6.6 was obtained after the esterification reaction was carried out for 150 minutes. It should not try to proceed the reaction after the acid number of alkyd resin had dropped to 6.6 because the reaction was closed to gel point. In Table 3.8, it was observed that 97.72 % of reaction was completed when the final acid number of alkyd resin was 6.6. Then, the yield of alkyd resin was 73.87%. 3.2.8. Discussion on Characteristics of Alkyd Resin In Table 3.9, there is no common standard to compare alkyds resins. Each alkyd resin has its own properties. The alkyd resin that has acid number of less than 15 is suitable for application of paint, according to literature [1, 7, 8]. The scratch hardness of alkyd resin was F and gouge hardness was

160

World Academy of Science, Engineering and Technology 48 2008

HB. The refractive index of alkyd resin was 1.447 and color was yellow. 4.2.9. Discussion on Chemical Resistance of Alkyd Resin Film The resistance of alkyd film was determined in two media, distilled water and NaOH solution. Table 3.10 described that there was no effect on alkyd film after immersion in distilled water for 18 hours. The immersion of alkyd film in water for 18 hours was sufficient time to examine the water resistance. When the alkyd film was immersed in strong alkali solution, 3N NaOH, the film got whitening after immersion time for 8 hours, blistering after immersion time for 16 hours and removal after immersion time for 24 hours. So, these results show that the prepared alkyd resin has high chemical resistance. 4.2.10. Discussion on FTIR Adsorption of Dehydrated Castor Oil-Modified Alkyd Resin The FTIR spectrum of prepared alkyd resin exhibits a characteristic of straight chain ester band at 1738.64 cm-1 and aromatic ring ester band at 1730.09 cm-1. The present of O=CO-C- also exhibit a characteristic ester band at 1125.26 cm-1. The appearance of CH2, -CH- confirms the present of methyl group at 1460.43 cm-1 and 2856.67 cm-1. The adsorption band at 3008.99 cm-1 is characteristic of alkene carbon (=C-H) according to literature [12, 13]. 4. Conclusion The characteristics of refined castor oils were found to be standardized with ASTM standard castor oils and it was suitable to carry out the next step. The refined castor oil was done by using NaHSO4 catalyst to carry out the dehydration process. Dehydration under vacuum pressure system was effective processing method and this pressure influenced the quality of dehydrated castor oil. A typical dehydrated castor oil (iodine value 140, viscosity 1.6 stroke, set to touch time 3.5 hr and drying time 5 day) was prepared with 1% NaHSO4 catalyst under vacuum of 600-640 mmHg at 210-220C. In alcoholysis of oil by using 0.3% (wt%) NaOH catalyst, it gave complete alcoholohysis mixture to preceed the esterification reaction after reaction time for 2 hrs. Dehydrated castor oil has been used in the preparation alkyd resin. Dehydrated castor oil-modified alkyd resin (acid value 6.6) was prepared by alcoholysis method from dehydrated castor oil, glycerol and phthalic anhydride with a help of 0.3% NaOH catalyst. The physico-chemical properties and high chemical resistance of alkyd resin film showed that they were promising in formulating of paint. Acknowledgements The financial support of Ministry of Science and Technology is gratefully acknowledged. The author wishs to extend her gratitude to Prof. Dr. Mya Mya Oo for stimulating discussion. REFERENCES

[1]Patton, T.C. 1962. Alkyd Resin Technology. NewYork: Interscience Publishers, Inc. A Division of John Wiley and Sons, Inc. [2] Waters, R.T. Resins-Synthetic, Alkyd Resins. Section 2. London: Wyman and Sons, Ltd. 1955. [3] Ikhuoria, E.U., Aigbodion, A.I., and Okieimen, F.E. Enhancing the quality of Alkyd Resins Using Methyl Esters of Rubber Seed Oil. Tropical Journal of Pharmaceutical Research. 3 (No.1): 2004, 311-317. [4] Formo, M.W. et al. Baileys Industrial Fats and Oils Products. Vol 1. 4th Edition. New York: John Wiley and Sons, Inc, 1965. [5] Kirk, R.F and Othmer, D.F. Alkyd Resin: Encyclopedia of Chemical Technology. Vol 9. New York: John Wiley and Sons, Inc, 1947.

[6] Mark, H.F. Alkyd Resin: Encyclopedia of Polymer Science and Technology. Volume 1. New York: Interscience Publishers. A Division of John Wiley and Sons, Inc, 1964. [7] Mark, H., Proskauer, E.S., and Frilette, V.J. Resins, Rubbers, Plastics Yearbook. New York: Interscience Publishers, Inc. A Division of John Wiley and Sons, Inc, 1954. [8] Mehlenbacher, V.C. Official and Tentative Methods for the American Oil Chemists Society. Second Edition. American Oil Chemists Society (AOCS). Chicago: 35 East Wacker Drive, 1950. [9] Anonymous. Annual Book of American Society for Testing and Materials (ASTM). Part 27, 1975.28, 29. USA. . [10] Pecsok, R.L. Methods of Chemical Analysis. Second Edition. New York: Interscience Publishers, Inc. John Wiley and Sons, Inc, 1980. [11] Branch, R.F. Application of Infraced and Ultraviolet Spectra to Organic Chemistry: Practical Organic Chemistry, 1946. [12] Grasselli, J.G., Mocadlo, S.E., and Mooney, J.R. Applied Polymer Analysis and Characterization, Analysis of Polymers by Fourier Transform Infrared Spectroscopy. Vol. 2. New York: Oxford University Press. [13] Sanler, S.R. et al. Polymer Synthesis and Characterization. A Laboratory Manual. USA: Academic Press. A Division of Harcourt Brace and Company, California, 1998.

161

S-ar putea să vă placă și

- Alkyd Resin ManufacturerDocument5 paginiAlkyd Resin ManufacturerDonald_12Încă nu există evaluări

- Alkyd Resin 2Document5 paginiAlkyd Resin 2Pace AjjaÎncă nu există evaluări

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesDe la EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesÎncă nu există evaluări

- 海名斯特殊化學-Acrylic ResinDocument53 pagini海名斯特殊化學-Acrylic ResinEmilio Hipola100% (2)

- Handbook of Vinyl FormulatingDe la EverandHandbook of Vinyl FormulatingRichard F GrossmanEvaluare: 3 din 5 stele3/5 (1)

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3De la EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Încă nu există evaluări

- Paints, Varnishes, and Related Products: Bailey's Industrial Oil and Fat Products, Sixth Edition, Six Volume SetDocument45 paginiPaints, Varnishes, and Related Products: Bailey's Industrial Oil and Fat Products, Sixth Edition, Six Volume SetAbbas AliÎncă nu există evaluări

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachDe la EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudEvaluare: 5 din 5 stele5/5 (1)

- Alkyd Resin CalculationsDocument2 paginiAlkyd Resin CalculationsAli RazaÎncă nu există evaluări

- Experiment 1 TITLE: Alkyd Resin Preparation Based On Soya OilDocument3 paginiExperiment 1 TITLE: Alkyd Resin Preparation Based On Soya OilBakar Sulaiman100% (3)

- Paints Pigments and Industrial CoatingsDocument10 paginiPaints Pigments and Industrial CoatingsRaymond FuentesÎncă nu există evaluări

- Production of alkyd resins and their paints: Effect of catalyst on propertiesDocument5 paginiProduction of alkyd resins and their paints: Effect of catalyst on propertiesNhu TranÎncă nu există evaluări

- Calculating Technique For Formulating Alkyd Resins: Progress in Organic Coatings September 1992Document22 paginiCalculating Technique For Formulating Alkyd Resins: Progress in Organic Coatings September 1992Naresh KumarÎncă nu există evaluări

- The Chemistry of Polyurethane Coating PDFDocument15 paginiThe Chemistry of Polyurethane Coating PDFDhruv SevakÎncă nu există evaluări

- Preparation of Styrene Acrylic Copolymer Toner ResinDocument106 paginiPreparation of Styrene Acrylic Copolymer Toner ResinTorquemada PrimeroÎncă nu există evaluări

- Smooth Masonry PaintDocument1 paginăSmooth Masonry Paintvanhung88Încă nu există evaluări

- Mowital: Polyvinyl Butyral of Superior QualityDocument36 paginiMowital: Polyvinyl Butyral of Superior Qualityode3197Încă nu există evaluări

- Increasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionDe la EverandIncreasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionÎncă nu există evaluări

- Curative CalculationDocument2 paginiCurative Calculationamarghumatkar_466819Încă nu există evaluări

- 5 - Body Filler - Polyester Putty - 2019 EditionDocument2 pagini5 - Body Filler - Polyester Putty - 2019 Editiondamax rec100% (1)

- Additives in Water-Borne CoatingsDocument90 paginiAdditives in Water-Borne CoatingsWa Lao Eh100% (1)

- Alkyd CalculationsDocument2 paginiAlkyd CalculationsMarcelo Alexis Fuentes Ortiz100% (10)

- Issue #9 Printing and Graphics Science Group NewsletterDe la EverandIssue #9 Printing and Graphics Science Group NewsletterÎncă nu există evaluări

- Pigment Volume Concentration Part IDocument5 paginiPigment Volume Concentration Part IEmilio HipolaÎncă nu există evaluări

- Water-Based Paint Formulations, Vol. 3De la EverandWater-Based Paint Formulations, Vol. 3Evaluare: 4.5 din 5 stele4.5/5 (6)

- Recommended Epoxy FormulationsDocument2 paginiRecommended Epoxy Formulationsuzzy2Încă nu există evaluări

- Epoxy Resins: Manufacturing Process of With FormulationDocument48 paginiEpoxy Resins: Manufacturing Process of With FormulationSivanesh KumarÎncă nu există evaluări

- How to Name an Inorganic Substance: A Guide to the Use of Nomenclature of Inorganic Chemistry: Definitive Rules 1970De la EverandHow to Name an Inorganic Substance: A Guide to the Use of Nomenclature of Inorganic Chemistry: Definitive Rules 1970Evaluare: 5 din 5 stele5/5 (1)

- Resins For Architectural Coatings - Arkema AmericasDocument12 paginiResins For Architectural Coatings - Arkema AmericasLong An Do100% (1)

- The Basics of - Solvents and Thinners PDFDocument20 paginiThe Basics of - Solvents and Thinners PDFJosé Avendaño100% (3)

- Handbook of Waterborne CoatingsDe la EverandHandbook of Waterborne CoatingsPeter ZarrasÎncă nu există evaluări

- Analysis of Alkyd ResinsDocument22 paginiAnalysis of Alkyd ResinsHimanshu PanchalÎncă nu există evaluări

- ExtendersDocument33 paginiExtenderssbttbsÎncă nu există evaluări

- Polyurethanes: Science, Technology, Markets, and TrendsDe la EverandPolyurethanes: Science, Technology, Markets, and TrendsEvaluare: 1 din 5 stele1/5 (1)

- Alkyd Resin PlantDocument1 paginăAlkyd Resin PlantVarun MalhotraÎncă nu există evaluări

- Problems of Moisture Contamination in Polyurethane CoatingsDocument2 paginiProblems of Moisture Contamination in Polyurethane CoatingsJeffrey Bempong100% (1)

- Polishes, Coatings and SealersDocument30 paginiPolishes, Coatings and SealersIdkaÎncă nu există evaluări

- Equivalent Weight: Technical Center Guide To Urethane CalculationsDocument4 paginiEquivalent Weight: Technical Center Guide To Urethane CalculationsAbdullah SahlyÎncă nu există evaluări

- T6TYskLrXGMCXL93cXXEH9Ev9Document1 paginăT6TYskLrXGMCXL93cXXEH9Ev9Sidrah RasoolÎncă nu există evaluări

- Pigment Volume ConcentrationDocument4 paginiPigment Volume ConcentrationEmilio Hipola100% (1)

- 2.2e Coating Formulation CalculationDocument6 pagini2.2e Coating Formulation CalculationSwapnil SononeÎncă nu există evaluări

- Polymer BlendsDe la EverandPolymer BlendsD.R. PaulÎncă nu există evaluări

- Cymel® 303 LF: Product Description Typical PropertiesDocument2 paginiCymel® 303 LF: Product Description Typical Propertiesهیمن مÎncă nu există evaluări

- New Approach For Developing Epoxy-Amine Adductcurative With Modified Epoxy ResinsDocument13 paginiNew Approach For Developing Epoxy-Amine Adductcurative With Modified Epoxy Resinsvipin1222Încă nu există evaluări

- Paint AdditivesDocument3 paginiPaint AdditivesAnonymous yy8In96j0rÎncă nu există evaluări

- 2K-PU Flooring, Flexible, Self-Leveling, Solvent-Free, 50-65-75 Shore A (V 44409 - 0)Document2 pagini2K-PU Flooring, Flexible, Self-Leveling, Solvent-Free, 50-65-75 Shore A (V 44409 - 0)Oswaldo Manuel Ramirez MarinÎncă nu există evaluări

- Additives in PaintsDocument18 paginiAdditives in PaintsShahri GhaniÎncă nu există evaluări

- Four Steps to Effective Pigment Dispersions: Starting from ScratchDocument5 paginiFour Steps to Effective Pigment Dispersions: Starting from ScratchEyad AlsheiikhÎncă nu există evaluări

- To Control Stability and Compatibility of Pigment PastesDocument3 paginiTo Control Stability and Compatibility of Pigment PastesChinmoy DholeÎncă nu există evaluări

- MODAFLOWDocument24 paginiMODAFLOWuzzy2100% (1)

- Alkyd Resins: Properties, Manufacture and ApplicationsDocument16 paginiAlkyd Resins: Properties, Manufacture and Applicationssomesh bhagure100% (1)

- Preparation of Styrene Acrylic Copolymers for Toner ResinsDocument21 paginiPreparation of Styrene Acrylic Copolymers for Toner ResinsTorquemada PrimeroÎncă nu există evaluări

- Brochure Water Based Adhesives WebDocument9 paginiBrochure Water Based Adhesives WebManu WoodÎncă nu există evaluări

- Brochure Matting Agents EDocument60 paginiBrochure Matting Agents Efrox123Încă nu există evaluări

- POLYURETHANE COATING MATERIALSDocument13 paginiPOLYURETHANE COATING MATERIALSAkash Honnappa100% (1)

- Addage Plast VMA - 911 Viscosity Modifying Admixture for Highly Fluid ConcreteDocument1 paginăAddage Plast VMA - 911 Viscosity Modifying Admixture for Highly Fluid ConcreteSandip AgrawalÎncă nu există evaluări

- Glycol TestDocument4 paginiGlycol TestSandip AgrawalÎncă nu există evaluări

- Addage Plast ESNDocument2 paginiAddage Plast ESNSandip AgrawalÎncă nu există evaluări

- DensifierDocument1 paginăDensifierSandip AgrawalÎncă nu există evaluări

- Addage CLC - FaDocument1 paginăAddage CLC - FaSandip AgrawalÎncă nu există evaluări

- Addage Plast PCE 811Document1 paginăAddage Plast PCE 811Sandip AgrawalÎncă nu există evaluări

- Gps VulnerabilityDocument28 paginiGps VulnerabilityaxyyÎncă nu există evaluări

- XHLE Long Coupled Centrifugal Pump EnglishDocument8 paginiXHLE Long Coupled Centrifugal Pump Englishgagi1994brahimÎncă nu există evaluări

- Module 1: Introduction Introduction To Tribology: Fig. 1.1: Carbon Graphite SealDocument18 paginiModule 1: Introduction Introduction To Tribology: Fig. 1.1: Carbon Graphite Sealbansalmohit01Încă nu există evaluări

- Studio GPGL LogDocument5 paginiStudio GPGL LogCarlos Julian LemusÎncă nu există evaluări

- Antena Eh para 10 MetrosDocument3 paginiAntena Eh para 10 Metros10sd156Încă nu există evaluări

- BTS Training Fiber Optic Advanced SplicingDocument5 paginiBTS Training Fiber Optic Advanced Splicingjama99Încă nu există evaluări

- The Shand CCS Feasibility Study Public ReportDocument124 paginiThe Shand CCS Feasibility Study Public ReportSai RuthvikÎncă nu există evaluări

- Heat Exchanger Systems en PPL 2015-03-01Document59 paginiHeat Exchanger Systems en PPL 2015-03-01corneltincuÎncă nu există evaluări

- List of Linkages2016Document74 paginiList of Linkages2016engrwho0% (1)

- Support Orca3D HelpDocument281 paginiSupport Orca3D Helplavrik100% (1)

- Ps 1 SolDocument3 paginiPs 1 SolPang XsÎncă nu există evaluări

- كتاب الهيدروديناميكا-4 The HydrodynamicDocument25 paginiكتاب الهيدروديناميكا-4 The HydrodynamicHocine Gherbi FaycelÎncă nu există evaluări

- XZX ZX ZXDocument4 paginiXZX ZX ZXWong VoonyeeÎncă nu există evaluări

- 050, 051Document28 pagini050, 051kefaja67% (3)

- HalideDocument195 paginiHalidejadecolourÎncă nu există evaluări

- Siremobil Compact PDFDocument108 paginiSiremobil Compact PDFhector anguiano100% (2)

- STN Cat Novelties Vol.i 2023Document89 paginiSTN Cat Novelties Vol.i 2023ruba herbawiÎncă nu există evaluări

- Galvanize Galvanize Business Unit: Trust Us To GalvanizeDocument6 paginiGalvanize Galvanize Business Unit: Trust Us To GalvanizeAdet WildanÎncă nu există evaluări

- Civil Engineering Reference BooksDocument2 paginiCivil Engineering Reference Booksdevbrat boseÎncă nu există evaluări

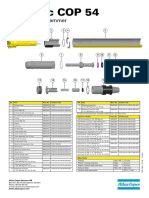

- 9853 1239 01 - COP 54 Service Poster - LOWDocument1 pagină9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasÎncă nu există evaluări

- Ford Essex V6 EngineDocument8 paginiFord Essex V6 EngineJoakamaster 16Încă nu există evaluări

- Operating Instructions, FormulaDocument35 paginiOperating Instructions, FormulaandymulyonoÎncă nu există evaluări

- LDX2101 Spec SheetDocument2 paginiLDX2101 Spec SheetGaurav NarulaÎncă nu există evaluări

- ETN2A ElectromechanicsDocument64 paginiETN2A ElectromechanicsEinstein's VanderbijlparkÎncă nu există evaluări

- Catálogo King LaiDocument144 paginiCatálogo King LaiJason Salas FloresÎncă nu există evaluări

- The Tallest Buildings in The WorldDocument2 paginiThe Tallest Buildings in The WorldW4G8989Încă nu există evaluări

- SW-TS40T Sub-Miniature Toggle SwitchesDocument4 paginiSW-TS40T Sub-Miniature Toggle SwitchesVALTERÎncă nu există evaluări

- Minor Project Report On Efficiency Improvement of A Combined Cycle Power PlantDocument40 paginiMinor Project Report On Efficiency Improvement of A Combined Cycle Power PlantArpit Garg100% (1)

- 2:4 Decoder: DECODER: A Slightly More Complex Decoder Would Be The N-To-2n Type Binary Decoders. These TypesDocument6 pagini2:4 Decoder: DECODER: A Slightly More Complex Decoder Would Be The N-To-2n Type Binary Decoders. These TypesPavithraRamÎncă nu există evaluări

- Lotus 1-2-3 For WindowsDocument75 paginiLotus 1-2-3 For Windowskennedy_saleh100% (1)