Documente Academic

Documente Profesional

Documente Cultură

LT DC Shunt Motor

Încărcat de

Radha Krishnan PDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

LT DC Shunt Motor

Încărcat de

Radha Krishnan PDrepturi de autor:

Formate disponibile

LT- Shunt Motor LOAD TEST ON DC SHUNT MOTOR AIM: To conduct a load test on a given DC shunt motor and

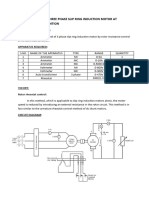

to obtain its performance characteristics. Apparatus required: Sl.No 1 2 3 4 PRECAUTIONS: 1. DC shunt motor should be started and stopped under no load condition. 2. The field rheostat should be at minimum position, the armature rheostat should be at maximum position 3. The spring balances should be at zero and the rotor should rotate free during start. 4. No load should be connected to motor at the time of starting and stopping. PROCEDURE: 1. Connections are made as per the circuit diagram. 2. After checking minimum position of motor field rheostat DPST switch or MCB is closed. 3. Start the motor using a 3 point starter.( used to reduce the starting current) 4. By adjusting the motor field rheostat, the motor is brought to rated speed and is verified using a tachometer. 5. The no load readings are observed and recorded. 5. The load is added to the motor in steps by adjusting the spring balance and the readings are tabulate at regular intervals. 7. The load is increased up till the rated current reaches its 80% of the max value. 8. To switch off the motor, release load in steps by adjusting the spring balance, bring the filed rheostat of the motor to minimum position. 9. Switch off the DPST switch or MCB. 10. It is observed that the 3 point starter handle is released automatically after a certain time. 3 point starter is used only for the purpose of starting. There is no any manual switch off. Apparatus required Ammeter Voltmeter Rheostat Tachometer Range (0-2)A (0-300) V 360 , 1.5A Digital Type MC MC Qty 1 1 2 1

LT- Shunt Motor

Connection diagram for load test on dc shunt motor:-

Model Graph :

Result: - On conducting the experiment it was found that the efficiency was maximum at a certain load and is less for any other load.

Formula:-

LT- Shunt Motor

S-ar putea să vă placă și

- Ac Servo MotorDocument14 paginiAc Servo MotorJeyanthÎncă nu există evaluări

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDe la EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetEvaluare: 2 din 5 stele2/5 (1)

- Sample Busduct SpecsDocument15 paginiSample Busduct SpecsONILEDA1970Încă nu există evaluări

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDe la EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetÎncă nu există evaluări

- HendrixACS - 2. Application & Design PDFDocument40 paginiHendrixACS - 2. Application & Design PDFJaime Orlando SantamariaÎncă nu există evaluări

- Electrical ConstructionDocument41 paginiElectrical ConstructionJayam Harinatha Guptha100% (2)

- Setting Co-Ordination Chart & Graph Relay Setting Calculation 0.415 KV Panel - Ecr-2Document90 paginiSetting Co-Ordination Chart & Graph Relay Setting Calculation 0.415 KV Panel - Ecr-2susovan bIswasÎncă nu există evaluări

- Variable Speed AC Drives with Inverter Output FiltersDe la EverandVariable Speed AC Drives with Inverter Output FiltersÎncă nu există evaluări

- Electrical Machines I Lab ManualDocument54 paginiElectrical Machines I Lab ManualThangam Mahesh89% (18)

- 2301A Load Sharing & Speed ControlDocument24 pagini2301A Load Sharing & Speed Controlgrand_ammar100% (1)

- Brake Test On DC Compound MotorDocument4 paginiBrake Test On DC Compound Motorkudupudinagesh90% (10)

- XR 0408 RectifierDocument2 paginiXR 0408 RectifierСлободан ИлићÎncă nu există evaluări

- Solar Labeling Requirements DatasheetDocument2 paginiSolar Labeling Requirements Datasheetguillermoanaya100% (1)

- Experiment 2 - Iduction Motor Drive Using Slip Power RecoveryDocument6 paginiExperiment 2 - Iduction Motor Drive Using Slip Power RecoveryDeepak BansalÎncă nu există evaluări

- Manual Tecnico PDFDocument6 paginiManual Tecnico PDFMENANI ZineddineÎncă nu există evaluări

- STATCOMDocument17 paginiSTATCOMAbdel-Rahman Saifedin ArandasÎncă nu există evaluări

- Load Char of Self ExcitedDocument3 paginiLoad Char of Self ExcitedRadha Krishnan PÎncă nu există evaluări

- Load Char of Separately ExcitedDocument3 paginiLoad Char of Separately ExcitedRadha Krishnan PÎncă nu există evaluări

- Speed ControlDocument3 paginiSpeed ControlRadha Krishnan PÎncă nu există evaluări

- OCC SeparatelyDocument2 paginiOCC SeparatelyRadha Krishnan PÎncă nu există evaluări

- (EM 2) - Lab Manual 4th SemDocument43 pagini(EM 2) - Lab Manual 4th SemTime LapserÎncă nu există evaluări

- Benn Machine Lab ManualDocument14 paginiBenn Machine Lab ManualRahatullah Khan100% (1)

- Me 2209 Electrical Engineering Lab ManualDocument45 paginiMe 2209 Electrical Engineering Lab ManualSai Karthi100% (1)

- Brake Test On DC Shunt MotorDocument5 paginiBrake Test On DC Shunt MotorkudupudinageshÎncă nu există evaluări

- Driver Motor BrushlesDocument48 paginiDriver Motor BrushlesGONAJ2008Încă nu există evaluări

- Emlab 2Document21 paginiEmlab 2hafizrahimmitÎncă nu există evaluări

- Exp 12 PDFDocument7 paginiExp 12 PDFDhyanÎncă nu există evaluări

- ST Motor Controller 1878Document22 paginiST Motor Controller 1878Ali ErÎncă nu există evaluări

- Ch6 - A Stepper MotorDocument5 paginiCh6 - A Stepper MotorEdward Conal100% (2)

- Lab 8Document6 paginiLab 8Malissa ClarkÎncă nu există evaluări

- Lab Info. - Synchronous Machine ExperimentsDocument3 paginiLab Info. - Synchronous Machine ExperimentsmikeÎncă nu există evaluări

- Experiment Laboratory Report No.3 DraftDocument8 paginiExperiment Laboratory Report No.3 DraftSherwin CaringalÎncă nu există evaluări

- Dcservo NewkitDocument11 paginiDcservo NewkitNikita MalikÎncă nu există evaluări

- 3 - Starter, Braking, EtcDocument22 pagini3 - Starter, Braking, EtcAtul Jaysing PatilÎncă nu există evaluări

- Experiment No Object:-Requirement:-: S.N. Apparatus Type Range Qty. RemarkDocument2 paginiExperiment No Object:-Requirement:-: S.N. Apparatus Type Range Qty. RemarkAkhilesh Kumar MishraÎncă nu există evaluări

- BPM24RT100BL Specspecifications UpdateDocument8 paginiBPM24RT100BL Specspecifications UpdatemalleÎncă nu există evaluări

- EG3000 ManualDocument7 paginiEG3000 ManualJose Armando Perez AcostaÎncă nu există evaluări

- Lab 09 - Synchronous MotorgDocument8 paginiLab 09 - Synchronous Motorgdev2191Încă nu există evaluări

- Giri 1Document18 paginiGiri 1GiridharÎncă nu există evaluări

- EM Lab For ECEDocument24 paginiEM Lab For ECEAnbalagan GuruÎncă nu există evaluări

- Solution Manual For Electric Motor Control 10th EditionDocument38 paginiSolution Manual For Electric Motor Control 10th Editionperrierfoalvbi3hr100% (16)

- Induction1 PDFDocument2 paginiInduction1 PDFAkhilrajscribdÎncă nu există evaluări

- Me 2209 Electrical Engineering Lab Manua EitlDocument45 paginiMe 2209 Electrical Engineering Lab Manua EitlRagunathan NarayananÎncă nu există evaluări

- Variador Yanwa AcerosDocument9 paginiVariador Yanwa Acerosjuan Carlos GonzalezÎncă nu există evaluări

- Electrician QuestionsDocument12 paginiElectrician QuestionsTAHRI BELGACEMÎncă nu există evaluări

- Automatic Restart of Essential Motors Using Micro Processor Based RelaysDocument21 paginiAutomatic Restart of Essential Motors Using Micro Processor Based RelaysJasa R ChoudharyÎncă nu există evaluări

- 5 Simple DC Motor Speed Controller Circuits ExplainedDocument18 pagini5 Simple DC Motor Speed Controller Circuits Explainedlasser22832165Încă nu există evaluări

- EACM-1-ELEC-50-Load Test On Single Phase Induction Motor (Kavita Dhamal)Document3 paginiEACM-1-ELEC-50-Load Test On Single Phase Induction Motor (Kavita Dhamal)Kavita DhamalÎncă nu există evaluări

- Starting and Braking of Induction MotorDocument15 paginiStarting and Braking of Induction MotorSOURABH MONGRAÎncă nu există evaluări

- Experiment 1: Simulation of A Three Phase Full Bridge Inverter AIMDocument11 paginiExperiment 1: Simulation of A Three Phase Full Bridge Inverter AIMSoumiya SrinivasanÎncă nu există evaluări

- ELP332 SecCyc 23-24 1Document15 paginiELP332 SecCyc 23-24 1satyamsinghgour2002Încă nu există evaluări

- College of Engineering, Ambajogai.: Unit Ii Control of Electrical Drives Unit Ii Control of Electrical DrivesDocument27 paginiCollege of Engineering, Ambajogai.: Unit Ii Control of Electrical Drives Unit Ii Control of Electrical Driveslvb123Încă nu există evaluări

- Automatic Station Stop CircuitDocument7 paginiAutomatic Station Stop CircuitRajesh DashÎncă nu există evaluări

- Using A DC Motor As A TachometerDocument5 paginiUsing A DC Motor As A Tachometerumer_0101Încă nu există evaluări

- Controlling Stepper Motors With A PIC MicrocontrollerDocument16 paginiControlling Stepper Motors With A PIC Microcontrollervasudeva yasasÎncă nu există evaluări

- Autotransformer Starter - A Reduced Voltage Motor Starting Method - Voltage DisturbanceDocument12 paginiAutotransformer Starter - A Reduced Voltage Motor Starting Method - Voltage Disturbancemark amthonyÎncă nu există evaluări

- C6.6 ENGINE - GENERATOR SET Operation & Maintenance Manuals - PARALLEL OPERATIONDocument4 paginiC6.6 ENGINE - GENERATOR SET Operation & Maintenance Manuals - PARALLEL OPERATIONsuperteffyÎncă nu există evaluări

- 3350904-Microprocessor and Controller Applications Date: - / - / - Experiment No-02Document3 pagini3350904-Microprocessor and Controller Applications Date: - / - / - Experiment No-02Ashfaq QureshiÎncă nu există evaluări

- FSK-628D Gobernador Electronico de MotorDocument35 paginiFSK-628D Gobernador Electronico de Motorsoldadores motoresÎncă nu există evaluări

- Em-176 Dc-Motor Controller 12/24Vdc 10ADocument2 paginiEm-176 Dc-Motor Controller 12/24Vdc 10AMarco Taype FelixÎncă nu există evaluări

- Braking Schemes of TractionDocument7 paginiBraking Schemes of TractionSuraj BhushanÎncă nu există evaluări

- Direct Load Test On A DC Shunt MotorDocument5 paginiDirect Load Test On A DC Shunt MotorYAKALA RAVIKUMARÎncă nu există evaluări

- Speed Control of 3 Phase Slip Ring Induction MotorDocument2 paginiSpeed Control of 3 Phase Slip Ring Induction Motoraditya aryaÎncă nu există evaluări

- Controlling Stepper Motor Using 8051 MicrocontrollerDocument14 paginiControlling Stepper Motor Using 8051 MicrocontrollerAnkush AgarwalÎncă nu există evaluări

- Induction Motor For Crane ApplicationDocument5 paginiInduction Motor For Crane ApplicationPankaj KumarÎncă nu există evaluări

- Experiment No:3 Load Test On Three Phase Alternator Aim: To Predetermine The Efficiency and Percentage Regulation of A Three Phase Alternator by Apparatus Required: S.No Apparatus Range QuantityDocument5 paginiExperiment No:3 Load Test On Three Phase Alternator Aim: To Predetermine The Efficiency and Percentage Regulation of A Three Phase Alternator by Apparatus Required: S.No Apparatus Range QuantityBodhayan PrasadÎncă nu există evaluări

- Induction Motor GK DubeyDocument13 paginiInduction Motor GK Dubeysakshamnegi40069Încă nu există evaluări

- No Load Test & Blocked Rotor Test of 3 Phase Induction MotorDocument12 paginiNo Load Test & Blocked Rotor Test of 3 Phase Induction MotorPavan Dakore100% (1)

- Power System Analysis and StabilityDocument22 paginiPower System Analysis and StabilityRadha Krishnan PÎncă nu există evaluări

- Beee Motor FigsDocument3 paginiBeee Motor FigsRadha Krishnan PÎncă nu există evaluări

- R2013 Eee I ViiiDocument108 paginiR2013 Eee I Viiisanthosiyal751Încă nu există evaluări

- 2015-16 ODD Sem Academic ScheduleDocument1 pagină2015-16 ODD Sem Academic ScheduleRadha Krishnan PÎncă nu există evaluări

- Electrical Drives and Controls (Nov, Dec2013)Document2 paginiElectrical Drives and Controls (Nov, Dec2013)Surbhi SinghÎncă nu există evaluări

- Subject Code Grade ResultDocument4 paginiSubject Code Grade ResultRadha Krishnan PÎncă nu există evaluări

- Ai (II, Viii Semester & Higher SemesterDocument3 paginiAi (II, Viii Semester & Higher SemesterRadha Krishnan PÎncă nu există evaluări

- Occ Self ExcitedDocument3 paginiOcc Self ExcitedRadha Krishnan PÎncă nu există evaluări

- Swinburnes TestDocument4 paginiSwinburnes TestRadha Krishnan PÎncă nu există evaluări

- LT On TransformerDocument2 paginiLT On TransformerRadha Krishnan PÎncă nu există evaluări

- OC & SC TransformerDocument4 paginiOC & SC TransformerRadha Krishnan PÎncă nu există evaluări

- LT DC Series MotorDocument3 paginiLT DC Series MotorRadha Krishnan PÎncă nu există evaluări

- Tidal Energy 2Document14 paginiTidal Energy 2Radha Krishnan PÎncă nu există evaluări

- Dare To Leave Harbour?....... Join SailDocument7 paginiDare To Leave Harbour?....... Join SailYogesh KumarÎncă nu există evaluări

- M-3425A All Setpoints: Setup SystemDocument5 paginiM-3425A All Setpoints: Setup SystemSenousyIbrahimÎncă nu există evaluări

- Unit V Circuit Breakers 9Document25 paginiUnit V Circuit Breakers 9Prathap VuyyuruÎncă nu există evaluări

- Electrostatics: Related StoriesDocument5 paginiElectrostatics: Related StoriesmadhurÎncă nu există evaluări

- Virtex-6: FPGA Data Sheet: DC and Switching CharacteristicsDocument65 paginiVirtex-6: FPGA Data Sheet: DC and Switching CharacteristicsAntonio DíazÎncă nu există evaluări

- Operation Manual LST900 900DDocument12 paginiOperation Manual LST900 900DLizMarquezÎncă nu există evaluări

- FINAL Haiti Electricity Report March 2018Document44 paginiFINAL Haiti Electricity Report March 2018Djorkaeff FrancoisÎncă nu există evaluări

- Service Manual: STR-DG500/DG600Document102 paginiService Manual: STR-DG500/DG600boroda2410Încă nu există evaluări

- DrucktrxiiDocument8 paginiDrucktrxiiRichard bangcayaÎncă nu există evaluări

- Expt 8 - Design of MSA Using Simulation Software Using CSTDocument4 paginiExpt 8 - Design of MSA Using Simulation Software Using CSTShreesh ParteÎncă nu există evaluări

- Service Manual: Active Subwoofer Speaker SystemDocument16 paginiService Manual: Active Subwoofer Speaker SystemJonathan Vasquez ConeoÎncă nu există evaluări

- Solar Power Tree - An Artistic DesignDocument7 paginiSolar Power Tree - An Artistic DesignEditor IJTSRDÎncă nu există evaluări

- Tutorial 2 KKEE1133Document2 paginiTutorial 2 KKEE1133AimanKPGÎncă nu există evaluări

- C700 User ManualDocument77 paginiC700 User Manualdanh voÎncă nu există evaluări

- Intelligent Control LED Integrated Light Source: Features and BenefitsDocument8 paginiIntelligent Control LED Integrated Light Source: Features and BenefitsjoseantoniooÎncă nu există evaluări

- TES CBdoc PG VCB 1 (EN) 1.12Document92 paginiTES CBdoc PG VCB 1 (EN) 1.12Medo SoroÎncă nu există evaluări

- Very Simple DIY Battery Tester - Schematics & ConstructionDocument5 paginiVery Simple DIY Battery Tester - Schematics & Constructionbnc1Încă nu există evaluări

- Organic Molecules in ElectronicsDocument32 paginiOrganic Molecules in ElectronicsRachelle McKeownÎncă nu există evaluări

- Automated Drip Irrigation System Using Cloud Computing: Prof. P. S. Bangare, Ruturaj Patil, Zia Khatib, Indrajit KaduDocument4 paginiAutomated Drip Irrigation System Using Cloud Computing: Prof. P. S. Bangare, Ruturaj Patil, Zia Khatib, Indrajit Kaduzia khatibÎncă nu există evaluări

- New Construction FIRE ALARM ChecklistDocument2 paginiNew Construction FIRE ALARM ChecklistThein TunÎncă nu există evaluări

- Superbar Final 2019Document32 paginiSuperbar Final 2019Firoj Al HasanÎncă nu există evaluări

- DGW200MS/UK: Operator'S ManualDocument36 paginiDGW200MS/UK: Operator'S ManualthuanÎncă nu există evaluări

- Cat - N BOOK 2019-20Document66 paginiCat - N BOOK 2019-20achyut kumarÎncă nu există evaluări