Documente Academic

Documente Profesional

Documente Cultură

3m Window Film Prestige Nanotechnology D Prestige

Încărcat de

larconeDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

3m Window Film Prestige Nanotechnology D Prestige

Încărcat de

larconeDrepturi de autor:

Formate disponibile

SOLAR CONTROL FILMS

08 87 13

Window Films

1. Product Name Prestige Window Films 2. Manufacturer 3M Building Safety Solutions Window Film 3M Center, Building 0223-02-5-24 Saint Paul, MN 55144-1000 (800) 430-1704 www.3m.com/windowfilm 3. Product Description BASIC USE 3M offers a large selection of window films to meet a variety of requirements. 3M window films reject heat and block nearly all of the suns harmful ultraviolet rays, and many are recommended by The Skin Cancer Foundation as effective UV protectants. 3M window films resist peeling, bubbling, scratching and abrasion and are backed by warranties that are among the most comprehensive available. 3Ms premium Prestige Window Films are specifically designed to increase indoor comfort, lower energy costs and reduce the harmful effects of the suns rays on interior furnishings in both commercial and residential applications. With 4 film styles from which to choose, Prestige films were tested using the Total Solar Energy Rejected - On Angle test and were proven to perform their best at the hottest part of the day when the sun is high. They reject up to 97% of the suns infrared light and block 99.9% of the suns harmful ultraviolet rays. This helps to keep buildings and homes cool, reduces energy demands and prevents premature refinishing or replacement of carpet, hardwood floors, furniture, art and window coverings due to sun and UV damage. Prestige Window Films have low reflectivity, with 2 styles being less reflective than the glass they cover. Because they are manufactured without metals, these films are not susceptible to corrosion in coastal environments and do not interfere with mobile phone reception. COMPOSITION & MATERIALS Prestige Window Films have a nominal thickness of 2 mil and are composed of optically clear polyester. They contain at least 220 layers and

SPEC-DATA and MANU-SPEC are registered trademarks of Reed Elsevier Inc. The ten part SPEC-DATA format conforms to the editorial style of The Construction Specifications Institute and is used with their permission. The manufacturer is responsible for technical accuracy. 2007 Reed Construction Data. All Rights Reserved.

3M Building Safety Solutions Window Film have an acrylic pressure sensitive adhesive on one side and an acrylic abrasion resistant coating on the other. The film incorporates infraredabsorbing carbon and is uniform without noticeable pinholes, streaks, thin spots, scratches, banding or other optical defects. The variation in total transmission across the width at any portion along the length does not exceed 2% over the average. TYPES & SIZES Prestige 70 - Clear film Prestige 60 - Clear film Prestige 50 - Lightly tinted film Prestige 40 - Lightly tinted film Prestige Window Films are available in 100' (30 m) rolls, in widths of 40", 50" and 72" (1016, 1270 and 1829 mm). BENEFITS Helps protect products from fading caused by UV rays Rejects solar heat even during the hottest part of the day, increasing comfort and saving energy Metal-free composition helps to prevent film corrosion in coastal environments and prevents interference with mobile phone reception Tinted and clear film options are available Available in 2 models that reflect less light than glass Resists abrasion 4. Technical Data APPLICABLE STANDARDS ASTM International (ASTM) ASTM E84 Standard Test Method for Surface Burning Characteristics of Building Materials ASTM E308 Standard Practice for Computing the Colors of Objects by Using the CIE System ASTM E903 Standard Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres (Withdrawn 2005) ASTM G26 Practice for Operating LightExposure Apparatus (Xenon-Arc Type) With and Without Water for Exposure of Nonmetallic Materials (Withdrawn 2000) APPROVALS The Skin Cancer Foundation PHYSICAL PROPERTIES Emissivity and u-value properties are determined based upon the established calculation procedure defined by the 1997 ASHRAE

(American Society of Heating, Refrigerating and Air-Conditioning Engineers) Handbook of Fundamentals. See Table 1 for details concerning the physical properties of Prestige Window Films. FIRE PERFORMANCE Prestige Window Films meet Class A requirements for surface burning characteristics when tested in accordance with ASTM E84: Flamespread - 25 maximum Smoke developed - 450 maximum 5. Installation PREPARATORY WORK Deliver products in manufacturers original, unopened, undamaged containers with identification labels intact. Store materials protected from exposure to harmful environmental conditions and at temperature and humidity conditions recommended by the manufacturer. Provide clear access to work areas. Verify that site conditions are acceptable for installation. Do not proceed with installation until unacceptable conditions are corrected. Examine glass surfaces to receive the new film and verify that they are free from defects and imperfections that will affect the final appearance. Correct and/or note all such deficiencies prior to applying the film. Use protective tarps or drop cloths to cover interior furnishings, floor, carpet, window ledges and walls near the window(s) receiving the film installation. Turn off or cover heating, air conditioning and ventilation ducts to reduce dirt and dust in the air or on the glass.

SOLAR CONTROL FILMS

08 87 13

Place toweling or other absorbent material on the window sill or sash to absorb moisture generated by the cleaning and film application process. Clean the window and window framing thoroughly with a neutral cleaning solution. If the window putty or seal is old and cracked, tape or seal it prior to washing the glass. Using a solution comprised of 90% water to 10% ammonia, clean glass with a blade scraper or industrial razor to ensure the removal of contaminants. Thoroughly rinse the glass from top to bottom with water from a pressure spray tank. Squeegee the entire glass surface. Dry the glass edges and window frames using a lint-free towel. METHODS Measure the glass and cut the film edges neatly and squarely to fit, or cut the film 1" (25.4 mm) wider and longer for trimming to size after positioning. No edge seal is required. Mix a film slip solution comprised of 1 capful of baby shampoo or dishwashing liquid to 1 gallon (3.8 L) of water. Spray the solution on the glass and film to facilitate proper film positioning. Use no more soap than is needed to provide slip. Apply film to the glass and lightly spray it with the slip solution. Use polyplastic bladed squeegees to remove excess water and to maximize the bonding of the pressure sensitive adhesive. Trim the film to size if needed before using the squeegee a second time, making sure to use a new blade tip after 3 - 4 cuts. Spray the slip solution to the film and squeegee a second time. Bump the film edge with a lint-free towel wrapped around the edge of a 5-way tool. Wipe the frame edge dry. After installation, the film may have a dimpled appearance from residual moisture. Under reasonable weather conditions, the film will dry flat within 30 days. PRECAUTIONS Use all necessary means to protect the film before, during and after installation. BUILDING CODES Installation must comply with the requirements of all applicable local, state and federal code jurisdictions. 6. Availability & Cost AVAILABILITY Contact 3M Building Safety Solutions Window Film for information on local availability, or reference the 3M online tool under

SPEC-DATA and MANU-SPEC are registered trademarks of Reed Elsevier Inc. The ten part SPEC-DATA format conforms to the editorial style of The Construction Specifications Institute and is used with their permission. The manufacturer is responsible for technical accuracy. 2007 Reed Construction Data. All Rights Reserved.

3M Building Safety Solutions Window Film Customer Support - Where to Buy at http://solutions.3m.com COST Budget installed cost information may be obtained from 3M Building Safety Solutions Window Film. 7. Warranty Prestige Window Films are warranted by 3M for a period of 15 years in that the film will maintain solar reflective properties without cracking, crazing, delaminating, bubbling, peeling or discoloring. In the event that the product is found to be defective under warranty, the seller will replace such quantity of the film proved to be defective, and will additionally provide the removal and reapplication labor free of charge. 3M also warrants against glass failure due to thermal shock glass fracture. This is warranted to a maximum value of $500 per window, provided the film is applied to recommended types of glass and the failure occurs within 60 months from the start of application. Any glass failure must be reviewed by 3M prior to replacement. Complete warranty terms and conditions are available from the manufacturer. For details, consult 3M Building Safety Solutions Window Film. TABLE 1 PHYSICAL PROPERTIES

Model Thickness Emissivity (ASHRAE) U-value (ASHRAE) Visible light transmission (ASTM E308) Visible reflection Exterior (ASTM E903) Visible reflection Interior (ASTM E903) Ultraviolet rejected (ASTM E903) Infrared energy rejected (ASTM E308, E903) Luminous efficacy (ASTM E903) Shading coefficient at 90 degrees (normal incidence) (ASTM E903) Total solar energy rejected (TSER) at 90 degrees (normal incidence) (ASTM E903) TSER 60 degree angle (ASTM E903) PR 70 > 2 mil 0.78 0.99 68% 9% 9% > 99.9% 97% 1.17 PR 60 > 2 mil 0.78 0.99 61% 8% 8% > 99.9% 97% 1.11 PR 50 > 2 mil 0.78 0.99 50% 8% 7% > 99.9% 97% 0.98 PR 40 > 2 mil 0.78 0.99 39% 7% 6% > 99.9% 97% 0.83

8. Maintenance The film may be washed 30 days after application using common window cleaning solutions, including ammonia solutions. Abrasive cleaning agents and bristle brushes that could scratch the film must not be used. These films may also be cleaned with a mild dishwashing soap. Synthetic sponges, squeegees or soft cloths are recommended. 9. Technical Services Technical assistance, including more detailed information, product literature, test results, project lists, assistance in preparing project specifications and arrangements for application supervision, is available by contacting 3M Building Safety Solutions Window Film. 10. Filing Systems Reed First Source MANU-SPEC Additional product information is available from 3M Building Safety Solutions Window Film upon request.

0.58 50% 59%

0.55 52% 61%

0.51 56% 63%

0.47 59% 66%

Note: Performances are based upon 1/4" (6.4 mm) clear glass.

S-ar putea să vă placă și

- Safety S70 Sample Card 082011Document2 paginiSafety S70 Sample Card 082011Sharon SunasseeÎncă nu există evaluări

- MSDS For 3M Auto Glass UrethaneDocument6 paginiMSDS For 3M Auto Glass UrethanejsdoodnathÎncă nu există evaluări

- Specifications For 3M™ Safety S70Document5 paginiSpecifications For 3M™ Safety S70Sergio Javier EspinozaÎncă nu există evaluări

- Color Stable BrochureDocument8 paginiColor Stable BrochureAlperTokayÎncă nu există evaluări

- Palmair Design ManualDocument37 paginiPalmair Design ManualAlfred Harvey ElacionÎncă nu există evaluări

- 3M Optically Clear AdhesivesDocument5 pagini3M Optically Clear AdhesivesPanagiotis ArgyropoulosÎncă nu există evaluări

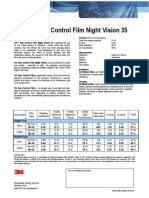

- Night - Vision - Series - NIGHT VISION 35Document2 paginiNight - Vision - Series - NIGHT VISION 35tiuchicoÎncă nu există evaluări

- Your Ideas. Our Technologies: 3M Products For Solar EnergyDocument8 paginiYour Ideas. Our Technologies: 3M Products For Solar EnergymarkotronicÎncă nu există evaluări

- 3M 9731RWDocument4 pagini3M 9731RWcbol91311Încă nu există evaluări

- 3M Vikuiti RPFilm Application InstructionsDocument5 pagini3M Vikuiti RPFilm Application InstructionsCityadvertising ConstantaÎncă nu există evaluări

- 3M 8979 TDSDocument2 pagini3M 8979 TDSmaimonides76Încă nu există evaluări

- 2K005E Tech Data (June.2011)Document2 pagini2K005E Tech Data (June.2011)Giang TúÎncă nu există evaluări

- General Purpose Polyester/ Silicone Tape: 8952 8952L (Linered)Document2 paginiGeneral Purpose Polyester/ Silicone Tape: 8952 8952L (Linered)Hardware 02Încă nu există evaluări

- 3M 3015 VP Vapor Permeable Air Barrier TDS v8!18!17Document4 pagini3M 3015 VP Vapor Permeable Air Barrier TDS v8!18!17Hari SantosoÎncă nu există evaluări

- Water Guard Epdm MembraneDocument4 paginiWater Guard Epdm MembranefairmatechemicalÎncă nu există evaluări

- 3M Crystalline Sun Control Window Films: Product Description Physical PropertiesDocument2 pagini3M Crystalline Sun Control Window Films: Product Description Physical PropertieswarutsgsÎncă nu există evaluări

- Safety Residential WarrantyDocument1 paginăSafety Residential WarrantyJanan AhmadÎncă nu există evaluări

- ANZ Glass Building CodesDocument3 paginiANZ Glass Building CodesTrue Value Glass MichealÎncă nu există evaluări

- 3M SolarFilm1100 - DMRDocument2 pagini3M SolarFilm1100 - DMRasritaipÎncă nu există evaluări

- Ventureshield™ Paint Protection Film 7510Cc/Cs-Ld: Technical Data Sheet April 2011Document2 paginiVentureshield™ Paint Protection Film 7510Cc/Cs-Ld: Technical Data Sheet April 2011Димитър ПетровÎncă nu există evaluări

- Prestige Exterior Family Card 98-0150-07572 112219Document2 paginiPrestige Exterior Family Card 98-0150-07572 112219Diego Ramirez FuentesÎncă nu există evaluări

- All Ultrex Window InstuctionsDocument10 paginiAll Ultrex Window Instuctionssloth185Încă nu există evaluări

- Silicon Sealant Asmaco 2540Document3 paginiSilicon Sealant Asmaco 2540rimshadtpÎncă nu există evaluări

- 2K010 Tech Data (June.2011)Document2 pagini2K010 Tech Data (June.2011)Giang TúÎncă nu există evaluări

- Nitoseal 125Document2 paginiNitoseal 125Hantu TuahÎncă nu există evaluări

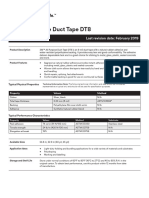

- 3M Duct Tape 8979Document2 pagini3M Duct Tape 8979Jun Xian WaiÎncă nu există evaluări

- Brand 7135 BDocument5 paginiBrand 7135 BNancy ManerpÎncă nu există evaluări

- 3M-425 Foil TapeDocument2 pagini3M-425 Foil TapeSon N Heather NguyenÎncă nu există evaluări

- 3M Anti-Graffiti AG-4Document1 pagină3M Anti-Graffiti AG-4Faith_No_MoreÎncă nu există evaluări

- ACFInterconnect 6000575Document4 paginiACFInterconnect 6000575mazacotesÎncă nu există evaluări

- Glass Cloth Tape: Technical DataDocument2 paginiGlass Cloth Tape: Technical DataАндрей МошкинÎncă nu există evaluări

- Ficha Tecnica - Microseal - DSDocument2 paginiFicha Tecnica - Microseal - DSedocducÎncă nu există evaluări

- 3M Filament Tape 897Document2 pagini3M Filament Tape 897German CalvoÎncă nu există evaluări

- 766 Safety TapeDocument2 pagini766 Safety TapeAch Dja'far SÎncă nu există evaluări

- Ficha 218Document2 paginiFicha 218Victor Javier Reyes NavarroÎncă nu există evaluări

- 3M™ Scotch-Seal™ Mastic Tape and Pads 2229: Data Sheet May 2013Document2 pagini3M™ Scotch-Seal™ Mastic Tape and Pads 2229: Data Sheet May 2013peloquin1349391Încă nu există evaluări

- Product Data Sheet Asmacryl 52Document3 paginiProduct Data Sheet Asmacryl 52Mohsin RazaÎncă nu există evaluări

- Technical Data Sheet: PermacolorDocument2 paginiTechnical Data Sheet: PermacolordjossÎncă nu există evaluări

- Spec 3m 375Document2 paginiSpec 3m 375Thích Rong ChơiÎncă nu există evaluări

- ImpactProtectAdh Spec DataDocument2 paginiImpactProtectAdh Spec DataGregÎncă nu există evaluări

- General Purpose Vinyl Tape: Technical Data April, 2014Document2 paginiGeneral Purpose Vinyl Tape: Technical Data April, 2014ismail mijasÎncă nu există evaluări

- Product Data Sheet Asmacoat WP 810 Liquid Applied Polyurethane Waterproofing MembraneDocument3 paginiProduct Data Sheet Asmacoat WP 810 Liquid Applied Polyurethane Waterproofing MembraneVaittianathan MahavapillaiÎncă nu există evaluări

- Sika WP Shield-104 P: APP Modified Plain Finished Bituminous MembraneDocument3 paginiSika WP Shield-104 P: APP Modified Plain Finished Bituminous MembraneSouvik DasÎncă nu există evaluări

- Cinta 365 ElectricaDocument2 paginiCinta 365 ElectricamiguelÎncă nu există evaluări

- EpdmDocument2 paginiEpdmParashuram ChauhanÎncă nu există evaluări

- 3M Scotch Transparent Film Tape 600 2Document6 pagini3M Scotch Transparent Film Tape 600 2Deepak LoganathanÎncă nu există evaluări

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDe la EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionÎncă nu există evaluări

- Sunwave™ Prismatic Skylights: Product InformationDocument9 paginiSunwave™ Prismatic Skylights: Product InformationAduanas 1Încă nu există evaluări

- 3M SariDocument23 pagini3M SariMohammad BokhariÎncă nu există evaluări

- Co-Extruded Multi-Polymer Protective Tapes: 2A25 2A26 2A29 (Clear)Document3 paginiCo-Extruded Multi-Polymer Protective Tapes: 2A25 2A26 2A29 (Clear)Mario Daniel ConejoÎncă nu există evaluări

- Fps Clear85cr FTP AnglaisDocument2 paginiFps Clear85cr FTP AnglaisNikolche MitrikjevskiÎncă nu există evaluări

- 3M 5386Document2 pagini3M 5386monkey1929Încă nu există evaluări

- 3M FT-DT8DuctTapeDocument2 pagini3M FT-DT8DuctTapeElviera MphieÎncă nu există evaluări

- HBR XL - Crosslink Closed Cell PDSDocument2 paginiHBR XL - Crosslink Closed Cell PDSHuy ThaiÎncă nu există evaluări

- 3M 08892Document3 pagini3M 08892Susheel WankhedeÎncă nu există evaluări

- Sikaflex PRO 3 WFDocument4 paginiSikaflex PRO 3 WFfrahliaÎncă nu există evaluări

- Spectre M 1 Ds EnglishDocument2 paginiSpectre M 1 Ds EnglishOgbedande Awo OrunmilaÎncă nu există evaluări

- 481 Preservation Sealing TapeDocument2 pagini481 Preservation Sealing TapeSixmonÎncă nu există evaluări

- RTV Is800 SeriesDocument4 paginiRTV Is800 SeriesFaraan KhanÎncă nu există evaluări

- 3M EU PB Prestige 40 Ext 2017 5Document3 pagini3M EU PB Prestige 40 Ext 2017 5Faith_No_MoreÎncă nu există evaluări

- Bgif300782 DDocument2 paginiBgif300782 DlarconeÎncă nu există evaluări

- ADV100800 Halo Recessed Catalog PDFDocument308 paginiADV100800 Halo Recessed Catalog PDFlarconeÎncă nu există evaluări

- AISIN AFW VI Application List Ver 1.02Document1 paginăAISIN AFW VI Application List Ver 1.02larconeÎncă nu există evaluări

- Windows 7 WordPad Keyboard ShortcutsDocument1 paginăWindows 7 WordPad Keyboard ShortcutslarconeÎncă nu există evaluări

- Gsa Fmvrs License Plates License - Plate - Management - 2014ffmtDocument46 paginiGsa Fmvrs License Plates License - Plate - Management - 2014ffmtlarconeÎncă nu există evaluări

- Getting To Know Your 2016 ImpalaDocument16 paginiGetting To Know Your 2016 ImpalalarconeÎncă nu există evaluări

- AMCREST IP Camera Brochure Revision2 - 2017Document26 paginiAMCREST IP Camera Brochure Revision2 - 2017larconeÎncă nu există evaluări

- Proline /proseat Molded Wood Toilet Seat: Model # Color #Document1 paginăProline /proseat Molded Wood Toilet Seat: Model # Color #larconeÎncă nu există evaluări

- Army and Air Force Exchange Regulation r215 - 8Document84 paginiArmy and Air Force Exchange Regulation r215 - 8larconeÎncă nu există evaluări

- Chevrolet Police Technical ManualDocument182 paginiChevrolet Police Technical Manuallarcone100% (1)

- 3m Bumpon ProductsDocument8 pagini3m Bumpon ProductslarconeÎncă nu există evaluări

- 3m Window Film Prestige Nanotechnology BDocument4 pagini3m Window Film Prestige Nanotechnology BlarconeÎncă nu există evaluări

- 3m Ear Hearing Products PeltorDocument4 pagini3m Ear Hearing Products PeltorlarconeÎncă nu există evaluări

- Efi Energy Wholesale Catalog Wholesale - CatalogDocument60 paginiEfi Energy Wholesale Catalog Wholesale - CataloglarconeÎncă nu există evaluări

- The Way of The Modern Marketer: A Short Ebook by Ryan Jay D. CrisostomoDocument45 paginiThe Way of The Modern Marketer: A Short Ebook by Ryan Jay D. CrisostomopabendÎncă nu există evaluări

- I33 PDFDocument51 paginiI33 PDFJonathan HayesÎncă nu există evaluări

- Ein Hoch Auf Uns Sheet Music For Piano (Solo)Document1 paginăEin Hoch Auf Uns Sheet Music For Piano (Solo)heidi.ottitschÎncă nu există evaluări

- The Art of WolfWalkers - TextDocument229 paginiThe Art of WolfWalkers - TextFunarÎncă nu există evaluări

- The Chronograph of 354 Its ManuscriptsDocument53 paginiThe Chronograph of 354 Its ManuscriptsLe CozÎncă nu există evaluări

- Komm Suesser Tod II PDFDocument1 paginăKomm Suesser Tod II PDFantonio cucumazzoÎncă nu există evaluări

- Children of No One - Nicole CushingDocument39 paginiChildren of No One - Nicole CushingHa MzaÎncă nu există evaluări

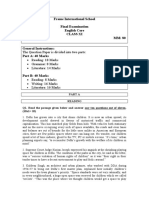

- XI Final ExaminationDocument12 paginiXI Final ExaminationVibha SharmaÎncă nu există evaluări

- Contempo. EditedDocument14 paginiContempo. EditedCristina TumipadÎncă nu există evaluări

- Chop FacsDocument2 paginiChop FacsNoemi Aurora CofanoÎncă nu există evaluări

- Giner y Vidal, Salvador - Grove MusicDocument3 paginiGiner y Vidal, Salvador - Grove MusicSamanosuke7AÎncă nu există evaluări

- List of Colors PDFDocument8 paginiList of Colors PDFWell Wisher And SeekerÎncă nu există evaluări

- EntieaelfuiDocument22 paginiEntieaelfuiKeiber GonzalezÎncă nu există evaluări

- Scroll Down To Read The ArticleDocument16 paginiScroll Down To Read The ArticleSarudzai MutsaÎncă nu există evaluări

- ContemporaryArts12 Q1 Mod3 Contemporary Arts Forms Ver3Document27 paginiContemporaryArts12 Q1 Mod3 Contemporary Arts Forms Ver3Bernadette Reyes100% (2)

- Build Up Rate Format - Precast ConcreteDocument2 paginiBuild Up Rate Format - Precast ConcreteFaiz Ahmad63% (8)

- Joe Raposo - I'm No Girl's Toy Lyrics Genius LyricsDocument1 paginăJoe Raposo - I'm No Girl's Toy Lyrics Genius LyricsmonononononnkumaigÎncă nu există evaluări

- Module 2 QuizDocument1 paginăModule 2 QuizJeyan AmadoÎncă nu există evaluări

- LECIEN MemoireaParis 2018 FreePattern PDFDocument5 paginiLECIEN MemoireaParis 2018 FreePattern PDFSedef Imer Simpson-ZurawÎncă nu există evaluări

- Enga CC6 TuDocument5 paginiEnga CC6 TuLily RoseÎncă nu există evaluări

- Basics of QuillingDocument8 paginiBasics of QuillingTracey Lee BoydÎncă nu există evaluări

- TOWER Hai DuongDocument61 paginiTOWER Hai DuongNguyen Quoc KhanhÎncă nu există evaluări

- Mother Tongue 1Document9 paginiMother Tongue 1Mary Nell AzuraÎncă nu există evaluări

- Landscape and Poetic Identity in Contemporary Caribbean Women's PoetryDocument24 paginiLandscape and Poetic Identity in Contemporary Caribbean Women's PoetryAJ JedidiahÎncă nu există evaluări

- Allspice ToteDocument4 paginiAllspice ToteRogan67% (3)

- Chapter 5 - Elements of ArtsDocument7 paginiChapter 5 - Elements of ArtsJiezl Mae PanaguitonÎncă nu există evaluări

- From Sermon To Parabe Four Conversion Stories in Flannery Oconnor (A. R. Coulthard) PDFDocument18 paginiFrom Sermon To Parabe Four Conversion Stories in Flannery Oconnor (A. R. Coulthard) PDFisabel margarita jordánÎncă nu există evaluări

- Planificare Pe UNITĂȚI DE ÎNVĂȚARE - Engleză - Fairyland Cls. A II-aDocument8 paginiPlanificare Pe UNITĂȚI DE ÎNVĂȚARE - Engleză - Fairyland Cls. A II-aCatalina RusuÎncă nu există evaluări

- Curriculum Plan For Theater Arts 9Document10 paginiCurriculum Plan For Theater Arts 9Raquel Tomas-Nazareno CastilloÎncă nu există evaluări

- University of Cincinnati: July 25, 2005 Jaejin Lee Doctor of Musical Arts Piano PerformanceDocument81 paginiUniversity of Cincinnati: July 25, 2005 Jaejin Lee Doctor of Musical Arts Piano PerformanceKununna FiorentinoÎncă nu există evaluări