Documente Academic

Documente Profesional

Documente Cultură

SSN EPL Mechanical - Manual

Încărcat de

Thejaswar TejaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SSN EPL Mechanical - Manual

Încărcat de

Thejaswar TejaDrepturi de autor:

Formate disponibile

SSN College of Engineering

Rajiv Gandhi Salai, SSN Nagar Kalavakkam 603 110

Certificate

Date: Certified Bonafide Record of work done by . Register number .. of I Semester . Branch during Aug Dec, 2011.

HOD

Faculty

Submitted for the university practical examination held on .

Internal Examiner

External Examiner

CONTENTS

Ex. No.

Date

Title of the Experiment

Page No.

Marks

Faculty Signature

CARPENTRY 1 2 3 4 TEE or Middle Lap Joint Cross Lap Joint Dovetail joint Mortise and Tenon Joint WELDING 1 2 3 Double VEE Butt Joint Tee Joint Lap Joint MACHINING 1 2 3 4 Turing, Facing and Chamfering Step Turning Taper Turning Hole Drilling PLUMBING 1 2 3 Basic pipe connection Mixed pipe connection Connection of G.I pipes SHEET METAL WORK 1 Making of Rectangular Tray

1 13 15 17 19 21 30 32 34 36 51 53 55 57 59 69 71 73 75 81

CARPENTRY

SAFETY PRECAUTIONS FOR CARPENTRY WORK

1. Always keep sufficient distance between the working table and yourself while planning. 2. Boards and other wooden pieces carrying nails should never be allowed to remain on the floor. 3. Chisels and other pointed tools having sharp edges pointing towards the edge of the table should not be kept on the table. 4. Test the sharpness of the cutting edge on wood or paper not by your hand. 5. Tools, which are not being used, should always be kept at their respective places. 6. Care should be taken when you are using your thumb as a guide in cross cutting and ripping. 7. Examine wood for knots and other defects before placing it in the planer. 8. Do not plane against the grain of the wood. 9. Keep the screwdrivers properly pointed to prevent injury to hands.

10

11

12

Ex. No. : 1 Date :

Name of the Job: TEE or Middle Lap Joint

Aim: To make a T-joint of the required dimension from the given wooden piece. Material required: 1. 310 x 45 x 45 mm wooden block Tools required: 1. Metal jackplane 5. Try square 9. Steel rule 2. Mallet 6. Ripsaw 10. Carpentry vice. 2. Planning 5. Sawing or Cutting 3. Right angle checking 6. Chiseling 3. Scriber 7. Firmer chisel 4. Marking gauge 8. C- Clamp

Sequence of Operations: 1. Checking the dimensions 4. Marking 7. Finishing

Procedure: 1. The given job is checked to ensure its correct size. 2. The job is firmly clamped in the carpentry vice and any two adjacent surfaces are planed by Jackplane to get right angle. 3. Using try square, the right angle of the work piece is checked. 4. All the four sides of the wooden pieces are planed to get the smoother and finished surface. 5. The job is cut into two halves using Ripsaw then proper marking is done for T- joint on the two pieces using steel rule and marking gauge. 6. Using tenon saw and firmer chisel the unwanted portions are removed as per the drawing from the two pieces. 7. Now the two pieces are assembled to check proper fitting. 8. The finished job is again checked for its accurate shape and size using try square and steel rule. Result: Thus, the desired T-joint is made.

Signature of Staff

Signature of Instructor

13

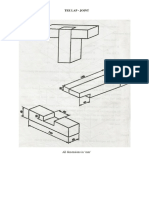

TEE or MIDDLE LAP JOINT

Cutting & Chiseling

Finishing

All dimensions are in mm

14

Ex. No. : 2 Date :

Name of the Job: Cross Lap Joint

Aim: To make a cross lap joint of the required dimension from the given wooden piece. Material required: 1. 310 x 45 x 45 mm wooden block Tools required: 1. Metal jackplane 5. Try square 9. Steel rule 2. Mallet 6. Ripsaw 10. Carpentry vice. 2. Planning 5. Sawing or Cutting 3. Right angle checking 6. Chiseling 3. Scriber 7. Firmer chisel 4. Marking gauge 8. C- Clamp

Sequence of Operations: 1. Checking the dimensions 4. Marking 7. Finishing

Procedure: 1. The given job is checked to ensure its correct size. 2. The job is firmly clamped in the carpentry vice and any two adjacent surfaces are planed by Jackplane to get right angle. 3. Using try square, the right angle of the work piece is checked. 4. All the four sides of the wooden pieces are planed to get the smoother and finished surface. 5. The job is cut into two halves using Ripsaw then proper marking is done for the cross lap joint on the two pieces using steel rule and marking gauge. 6. Using tenon saw and firmer chisel the unwanted portions are removed as per the drawing from the two pieces. 7. Now the two pieces are assembled to check proper fitting. 8. The finished job is again checked for its accurate shape and size using try square and steel rule. Result: Thus, the desired cross lap joint is made.

Signature of Staff

Signature of Instructor

15

CROSS LAP JOINT

Cutting & Chiseling

Finishing

All dimensions are in mm

16

Ex. No. : 3 Date :

Name of the Job: Dovetail Joint

Aim: To make a dovetail joint of the required dimension from the given wooden piece. Material required: 1. 310 x 45 x 45 mm wooden block Tools required: 1. Metal jackplane 5. Try square 9. Steel rule 2. Mallet 6. Ripsaw 10. Carpentry vice. 2. Planning 5. Sawing or Cutting 3. Right angle checking 6. Chiseling 3. Scriber 7. Firmer chisel 4. Marking gauge 8. C- Clamp

Sequence of Operations: 1. Checking the dimensions 4. Marking 7. Finishing

Procedure: 1. The given job is checked to ensure its correct size. 2. The job is firmly clamped in the carpentry vice and any two adjacent surfaces are planed by Jackplane to get right angle. 3. Using try square, the right angle of the work piece is checked. 4. All the four sides of the wooden pieces are planed to get the smoother and finished surface. 5. The job is cut into two halves using Ripsaw then proper marking is done for dovetail joint on the two pieces using steel rule and marking gauge. 6. Using tenon saw and firmer chisel the unwanted portions are removed as per the drawing from the two pieces. 7. Now the two pieces are assembled to check proper fitting. 8. The finished job is again checked for its accurate shape and size using try square and steel rule. Result: Thus, the desired dovetail joint is made.

Signature of Staff

Signature of Instructor

17

DOVETAIL JOINT

Cutting & Chiseling

Finishing

All dimensions are in mm

18

Ex. No. : 4 Date :

Name of the Job: Mortise & Tenon Joint

Aim: To make a mortise and tenon joint of the given dimensions. Material required: 1. 310 x 45 x 45 mm wooden block Tools required: 1. Metal jackplane 5. Try square 9. Steel rule 2. Mallet 6. Ripsaw 10. Carpentry vice. 2. Planning 5. Sawing or Cutting 3. Right angle checking 6. Chiseling 3. Scriber 7. Firmer chisel 4. Marking gauge 8. C- Clamp

Sequence of Operations: 1. Checking the dimensions 4. Marking 7. Finishing

Procedure: 1. The given job is checked to ensure its correct size. 2. The job is firmly clamped in the carpentry vice and any two adjacent surfaces are planed by Jackplane to get right angle. 3. Using try square, the right angle of the work piece is checked. 4. All the four sides of the wooden pieces are planed to get the smoother and finished surface. 5. The job is cut into two halves using Ripsaw then proper marking is done for mortise and tenon joint as per the drawing on the two pieces using steel rule and marking gauge. 6. Using tenon saw and firmer chisel the unwanted portions are removed as per the drawing from the two pieces. 7. Now the two pieces are assembled to check proper fitting. 8. The finished job is again checked for its accurate shape and size using try square and steel rule. Result: Thus, the desired mortise and tenon joint is made.

Signature of Staff

Signature of Instructor

19

MORTISE & TENON JOINT

All dimensions are in mm

20

WELDING

21

GENERAL SAFETY PRECAUTIONS FOR WELDING

To prevent injury to personnel, extreme caution should be exercised when using any types of welding equipment. Injury can result from fire, explosions, electric shock, or harmful agents. Both the general and specific safety precautions listed below must be strictly observed by workers who weld or cut metals.

1. Check the ground connection and insulation of all the wires. 2. The arc produced should be observed only through the shielding glass. 3. Always wear the safety hand gloves, apron and leather shoes. 4. Use proper current capacity cables. 5. Remove all flammable material, such as cotton, oil, gasoline, etc., from the vicinity of welding. 6. Be sure that hot sparks or hot metal will not fall on the operator or on any welding equipment components. 7. Switch off the welding machine when leaving from the work. 8. Do not leave hot rejected electrode stubs, steel scrap, or tools on the floor or around the welding equipment. Accidents and/or fires may occur. 9. Remove the slag by chipping hammer only. 10. To relive strain or irritation on the eyes, eye drops may be applied. 11. Keep a suitable fire extinguisher nearby at all times. Ensure the fire extinguisher is in operable condition.

22

23

24

25

26

27

28

29

Ex. No. : 1 Date :

Name of the Job: Double VEE Butt Joint

Aim: To make a double V-butt joint using arc welding on the given work pieces. Material required: 1. Mild Steel (M.S) plate of size 100 x 50 x 06 mm 02 Nos. Tools required: 1. Power supply (AC/DC) 2. Welding torch 5. Chipping hammer 9. Shield 6. Wire brush 10. Goggles 3. Electrodes 7. Gloves 11. Earth clamp 2. Tacking 6. Cleaning 4. Tongs 8. Apron

Sequence of Operations: 1. Edge preparation (Filing to remove rust, scale, etc.) 3. Welding 4. Cooling 5. Chipping

Procedure: 1. First of all, the workpieces must be thoroughly cleaned to remove any rust, scale and other foreign materials by filing. 2. Then the given workpieces are placed in such a way that it forms a V and an inverted V shape when the plates butt each other (as shown in Fig.). 3. Appropriate power supply should be given to the electrodes and the workpiece. 4. Now, the welding current output may be adjusted as necessary. 5. When the current is passed, arc is produces between the electrode and the workpieces. 6. Set the workpieces in correct position and maintain the appropriate gap of 1-2 mm and start tack welding at both the ends of the workpieces. 7. The welding is carried out throughout the length. 8. Now, the partially welded plates are inverted and the welding is carried out again throughout the length. 9. As soon as the welding process is finished, the current supply is switched off. 10. Leave the workpiece untouched in air for at least 10 minutes for cooling. 11. Slags are removed by chipping process with the help of chipping hammer. 12. Finally using wire brush, welded portions are cleaned. Result: Thus, the desired Double V-butt joint is obtained using arc welding.

Signature of Staff

Signature of Instructor

30

Double Vee Butt Joint

Welding symbol

All dimensions are in mm

31

Ex. No. : 2 Date :

Name of the Job: TEE Joint

Aim: To make a TEE joint using arc welding on the given work pieces. Material required: 1. Mild Steel (M.S) plate of size 100 x 50 x 06 mm 02 Nos. Tools required: 1. Power supply (AC/DC) 2. Welding torch 5. Chipping hammer 9. Shield 6. Wire brush 10. Goggles 3. Electrodes 7. Gloves 11. Earth clamp 2. Tacking 6. Cleaning 4. Tongs 8. Apron

Sequence of Operations: 1. Edge preparation (Filing to remove rust, scale, etc.) 3. Welding 4. Cooling 5. Chipping

Procedure: 1. First of all, the workpieces must be thoroughly cleaned to remove any rust, scale and other foreign materials by filing. 2. Then the given workpieces are placed in such a way that it forms a T-shape (The workpieces are standing at right angles to each other as shown in Fig.) with the help of flat tongs and try square. 3. Appropriate power supply should be given to the electrodes and the workpiece. 4. Now, the welding current output may be adjusted as necessary. 5. When the current is passed, arc is produces between the electrode and the workpieces. 6. Set the workpieces in correct position and maintain the appropriate gap of 1-2 mm and start tack welding at both the ends of the workpieces. 7. The welding is carried out throughout the length on both the sides at the bottom of the vertically standing plate. 8. As soon as the welding process is finished, the current supply is switched off. 9. Leave the workpiece untouched in air for at least 10 minutes for cooling. 10. Slags are removed by chipping process with the help of chipping hammer. 11. Finally using wire brush, welded portions are cleaned. Result: Thus, the desired TEE joint is obtained using arc welding.

Signature of Staff

Signature of Instructor

32

Tee Joint

Welding symbol

All dimensions are in mm

33

Ex. No. : 3 Date :

Name of the Job: LAP Joint

Aim: To make a lap joint using arc welding on the given work pieces. Material required: 1. Mild Steel (M.S) plate of size 100 x 50 x 06 mm 02 Nos. Tools required: 1. Power supply (AC/DC) 2. Welding torch 5. Chipping hammer 9. Shield 6. Wire brush 10. Goggles 3. Electrodes 7. Gloves 11. Earth clamp 2. Tacking 6. Cleaning 4. Tongs 8. Apron

Sequence of Operations: 1. Edge preparation (Filing to remove rust, scale, etc.) 3. Welding 4. Cooling 5. Chipping

Procedure: 1. First of all, the workpieces must be thoroughly cleaned to remove any rust, scale and other foreign materials by filing. 2. Then the given workpieces are placed in such a way that the two workpieces are overlapped one over the other as shown in Fig. 3. Appropriate power supply should be given to the electrodes and the workpiece. 4. Now, the welding current output may be adjusted as necessary. 5. When the current is passed, arc is produces between the electrode and the workpieces. 6. Set the workpieces in correct position and maintain the appropriate gap of 1-2 mm and start tack welding at both the ends of the workpieces as shown in Fig.. 7. The welding is carried out throughout the length. 8. Now, the partially welded plates are inverted and the welding is carried out again throughout the length. 9. As soon as the welding process is finished, the current supply is switched off. 10. Leave the workpiece untouched in air for at least 10 minutes for cooling. 11. Slags are removed by chipping process with the help of chipping hammer. 12. Finally using wire brush, welded portions are cleaned. Result: Thus, the desired lap joint is obtained using arc welding.

Signature of Staff

Signature of Instructor

34

Lap Joint

Welding symbol

All dimensions are in mm

35

MACHINING

36

SAFETY PRECAUTIONS FOR CENTRE LATHE

All lathe operators must be constantly aware of the safety hazards that are associated with using the lathe and must know all safety precautions to avoid accidents and injuries. Carelessness and ignorance are two great menaces to personal safety. Other hazards can be mechanically related to working with the lathe, such as proper machine maintenance and setup. Some important safety precautions to follow when using lathes are: Correct dress is important, remove rings and watches, and roll sleeves above elbows. Always stop the lathe before making adjustments. Do not changes spindle speeds until the lathe comes to a complete stop. Handle sharp cutters, centers, and drills with care. Remove chuck keys and wrenches before operating Always wear protective eye protection. Handle heavy chucks with care and protect the lathe ways with a block of wood when installing a chuck. Know where the emergency stop is before operating the lathe. Use pliers or a brush to remove chips and sward, never your hands. Never lean on the lathe. Never lay tools directly on the lathe ways. If a separate table is not available, use a wide board with a cleat on each side to lay on the ways. Keep tools overhang as short as possible. Never attempt to measure work while it is turning. Never file lathe work unless the file has a handle. File left-handed if possible. Protect the lathe ways when grinding or filing. Use two hands when sanding the work piece. Do not wrap sand paper or emery cloth around the work piece.

37

CENTRE LATHE

Introduction: Lathe is a machine tool which is used to perform several operations on the work piece. Lathe is useful in making several parts which is further assembled to make new machine. I-fence lathe is known as mother of machines. Turning Turning is the machining operation that produces cylindrical parts. In its bathe form, it can be defined as the machining of an external surface: 1. with the work piece rotating. 2. with a single-point cutting tool, 3. And Taper turning is practically the same, except that the cutter path is at an angle to the work axis. Similarly, in contour turning, the distance of the cutter from the work axis is varied to produce the desired shape. Even though a single-point tool is specified, this does no exclude multiple-tool setups, which are often employed in turning. In such setups, each tool operates independently 4 a singlepoint cutter. BASIC WORKING PRINCIPLE OF LATHE

In lathe, the work piece is held in the chuck, a work holding device. The cutting tool is mounted in the tool post. The chuck is rotated by means of power. When the chuck rotates, the work piece also rotates. The tool is moved against the rotating work piece by giving small amount of depth of cut. The material is removed in the form of chips. Continuous feed and appropriate depth of cut is given until the required dimensions of the work piece are obtained. TYPES OF LATHE MACHINES

There are different types of lathe machines. They are 1. Centre lathe 2. Tool room lathe 3. Bench lathe 4. Capstan lathe 5. Turret lathe 6. Automatic lathe

38

DESCRIPTION OF A LATHE

Lathe is a machine which is made up of several parts. They are 1. Bed It is the base of the machine. On its left side, the head stock is mounted. A movable casting called tail stock is mounted on the right side. The legs of the bed have holes to bolt down and grout the lathe. It consists of a spindle, gears and speed change levers. It is used to transmit the motion to the job. There are two types of headstock. 1. Belt driven headstock 2. Geared headstock Tailstock The tailstock is fixed to the right end of the bed. This supports work when turning between centers. It is also used for supporting and feeding drills, reamers etc. The main body is castiron. The barrel of the tailstock has a mores taper hole to accommodate centres, taper sleeves and taper shank drills. In its normal position, the tailstock centre is in line with that of the head stock. An adjustment is provided for setting the tall stock centre to one side for taper turning. The tailstock can be clamped at various positions along the bed to accommodate work pieces of various lengths. The Carriage (or) Saddle The carriage forms the base of the unit which supports the cutting tool. Carriage can be traversed (slide along) along the whole length of the bed by hand control or by power feed. Apron is attached to the front part of the carriage. Apron contains the mechanisms for moving the saddle and cross slide. The combined carriage and apron is called the saddle. Cross slide The cross slide is the part fixed to the top of the carriage. Cross slide is provided for cross traversing. Cross slide moves at right angles to the bed. It is normally used for feeding and facing. The compound slide The compound slide is secured to the cross slide and has two main functions. 1. To provide location and support for the tool post. 2. To enable the tool to be placed at an angle to the axis of the spindle. The compound slide (top slide) is mounted on the cross-slide. The slide is capable of being rotated on a swivel base. The swivel base is marked with a protractor scale. This enables the path of the tool to be inclined to the axis of the lathe. This is simple way of turning tapers and chamfers with a wide range of included angles. The lead screw The lead screw is the top shaft lengthwise at the front of the lathe bed. It ha square thread. When screw cutting, the leads crew is used for causing automatic lengthwise traveled the tool. It gets its drive from the screw-cut gearbox attached to the headstock. The feed shaft is the bottom shaft running length wise at the front of the lathe bed. When the shaft is rotating and when the automatic tray lever is engaged; the whole carriage slides travels automatically along the bed.

39

40

WORK HOLDING DEVICES

Lathe Centres They are used to support work. It has two categories of centres. Live centre is one which is fitted in the headstock spindle. Dead centre is one which is fitted in the tail stock. Chuck It is a device used to hold a job. It is easily fitted on the thread cut on the end of headstock spindle. Various types of chuck are (a) Two jaw chuck (b) Three jaw chuck (c) Four jaw chuck (d) Collet chuck (e) Magnetic chuck Lathe carriers or bogs It is used for transferring the motion from the rotating driving plate to the work held between the centres. Catch plate It is a plain disc of steel or cast iron. It is screwed to the nose of the headstock spindle. It is used to drive the work piece through a carrier or dog when it is held between the centres. Face plate It is a circular plate\and it is screwed to lathe spindle. It is used for mounting the type of jobs which cannot be held by chucks. There are number of holes and slots on the face of the face plate. Steady Rest It supports long work piece when machined between the centres or by a chuck. It is used for cylindrically long jobs. Two types of steady rest are a. Fixed steady rest b. Traveling steady rest Mandrel It is used for holding hollow jobs. It is a hardened piece of round bar for holding bored or reamed jobs. It has drill holes at both the ends. Work piece is mounted over the mandrel and the mandrel is rotated between centres. Follower rest It is made of cast iron and is used for supporting long slender work pieces, against the cutting tool forces. It can be clamped to the carriage of the lathe, to make it travel along with the cutting tool. It has two adjustable jaws to support the work piece the two supporting jaws of the rest, resist the cutting forces. To reduce the damage to the finished surface of the job, the jaws are normally made of brass.

41

42

MARKING AND MEASURING TOOLS

The following table illustrates various marking and measuring tools and their characteristics and uses. 1. Steel Rule It is made of tempered steel about 3/64 inch thick, 3/4 inch wide and 6 inch long with several styles of graduation. It is used to take linear measurements up to accuracy of 0.5mm. 2. Vernier Caliper Graduations are made on both sides of the bar. It is a tool for checking inside and outside measurements. It is also used as depth gauge. 3. Vernier Height Gauge It consists of an upright steel bar fixed to a steel base. On the bar, there is a movable jaw with vernier scale. The screw is used to adjust the vernier scale to a required position. It is used to scribe lines on a work piece to known heights. 4. Scriber A scriber is a sharp pointed steel tool. It is made of carbon tool steel. It is used to scribe or mark lines on metal work pieces. 5. Try square It is a small, light square that has a hardened steel blade without graduations. It has two parts namely blade, beam. Try square is used to check the flatness and square ness of the work piece. 6. Dot Punch It is made of Steel. The angle of the conical point is usually 60. It is used to make dots along marked lines and to provide small centre mark for divider point etc., 7. Surface Plate It is made of grey cast iron and of solid design (or) with ribs. It is used for testing the flatness of work and also used for carrying the work piece while marking.

43

44

CUTTING TOOLS USED

For making a finished job on lathe machine, various types of cutting tools are used. One of them is single point cutting tool which is used to perform several operations on the work piece. Various types of cutting tools are Facing tool: It is used for facing the longitudinal ends of the job. Its shape is like a knife, Rough turning tool: It is used to remove excess material from the work piece in quick time. It can be used to give large depth of cut and works at coarse feed. Radius tool: Jobs which need round cutting are done with this tool. Their types are 1. Concave radius tool 2. Convex radius tool FINISHING TOOL

It is used for getting smooth finish on the work piece. Its point is a little more round. Drill tool: It is used for making holes of various diameters on the job. Drill bit of various sizes of diameter are available. Boring tool: It is used for enlarging the drilled hole. Knurling tool: Drawing slanting or square projecting lines on the surface of a job is known as knurling. It is used for making better grip on the surface of a job. Parting tool: It is used to cut the job into two parts. It is also used for grooving. Form turning tool: It is used for jobs which require both convex and concave turning. Thread cutting tool: It is used for making internal or external threads on the work piece.The tool nose are designed with a definite profile for taking threads. CUTTING TOOLS ANGLES

Top Rake Angle (Back rack angle) If the slope is given to the face or surface of the tool and if this slope is along the tools length then it is called top rake angle. It is usually 15 to 20. Side Rake Angle If the slope is given to the face or top of the tool along the tools width then it is called side rake angle. It lies between 6 and 15. Clearance Angle (Relief angle) Types: (i) Side clearance angle and (ii) End clearance angle. They are provided to keep the surface of the tool clear of the work piece. TOOL MATERIALS

The single point\lathe cutting tools are made of high speed steel (H.S.S.).The main alloying elements in 18-4-1 HSS tools are 18 percent tungsten, 4 percent chromium and 1 percent vanadium. 5 to 10 percent cobalt is also added to improve the heat resisting properties of the tool. General purpose hand cutting tools are usually made from carbon steel or tool steel. Carbide tipped tools fixed in tool holders, are mostly used in production shops

45

46

LATHE OPERATIONS

Facing: It is done for getting fine finish (good surface finish) on the face of the job. Facing tool is set at an angle to the work piece. The tool is fed from the centre of work piece towards the outer surface against the rotating work piece. Depth of cut is low for the facing operation. For getting fine finish, power feed can be used. Plain Turning: It is done for reducing the diameter of the work piece. A cutting tool with 70 setting angle is used for roughing operation. More feed is given for rough turning while less feed is given for finishing. Work piece is held in chuck and tool is set to the centre height of the work piece. Taper turning: Taper turning is different from the turning operation. Taper is defined as the uniform change in the diameter of a work piece measured along its length. Taper = D-d / 2l, = tan-1 (D-d) / 2l D is large diameter, d is small diameter and L is length of taper Taper turning can be done by the following methods Where, 1. Compound rest method 2.Tailstock se over method.3. Using form tool 4. Taper attachment method. Step turning: It is similar to the process of turning but in this case different diameters in step of various sizes are taken on the work piece. In initial stage, roughing tool is used while a knife tool is used for the finishing cut. Boring: It is a process of enlarging a drilled hole. A special type of boring tool is used for this purpose. Tapping: It is a process of making internal threads in small jobs. Tap is held in a tail stock and the job is held in a chuck. Feed is given by rotating tail stock hand wheel. Grooving and Parting off: It is done at the end of the threaded portion. It is fed crosswise against the rotating work piece. Parting off is done by parting tool. Thread cutting: It is a process of making threads on the work piece. Thread cutting tool is used for this operation. Power feed is given to the carriage through lead screw and for one rotation of the job; it covers the distance equal to the pitch. Depth of cut is small for thread cutting. Knurling: It is a process of making serrations on the work piece. Knurling tools of different shape and size are used to make grip on the work piece. It has two hardened steel rollers. The tool is held in the tool post and pressed against the rotating work piece. Work piece is rotated at lower speed and small amount of feed is given. Drilling: It is a process of making a hole on the work piece. Job is held in a chuck while the drill is held in the tailstock sleeve. Feed is given by rotating the hard wheel in the tailstock which pushes the tailstock sleeve. Chamfering: It is a beveling or turning a slope at the end of work piece. It is done for jobs after knurling, rough turning, thread cutting to remove the burrs. It is normally performed on bolts, nuts.

47

48

THE BENCH (SENSITIVE) DRILLING MACHINE

1. The simplest type of drilling machine is the bench drilling machine. 2. It is capable of accepting drills up to 12.5 mm diameter. 3. These machines have the chuck mounted directly on to the spindle nose taper. Variations in spindle speed are achieved by altering the belt position on the stepped pulleys. Drilling: Drilling is the process of machining a round hole in a work piece. Drilling is making a cylindrical hole to a given size in a workspace. Drilling is possible by removing chips of material with a double-edged cutting tool. Twist Drill: A twist drill is machine-rotated tool with cutting edges. The cutting edges produce circular holes in metal, plastics and wood etc.The twist drill is made of high speed steel (HSS) and heat-treated. The twist drill has two spiral grooves. A twist drill has double cutting edges. Twist drill is a spiral, fluted cylinder with cutting lips on one end, The Cutting force is provided by rotating the dill against a stationary work piece. Chips cut at the bottom of the hole a carried away by the flutes as the drill is fed into the work piece to progressively increase the hole depth. The flutes e serves as a passage for cutting fluids. Shank: Shank is the part that fits into the drilling machine is called the shank. There are 1. straight-shank and 2. taper shank twist drills. This taper on shank is called morse taper. Heel: Heel is the tail end of the helix. Land: Land is the narrow part of the body. Land bears on the sides of the hole to give guidance. Lip: Lip is the cutting edge. The two lip lengths must be equal if over size hole are to be avoided. Lead is the same as the pitch of a screw thread. Chisel edge is the cutting edge. The chisel edge angle should be about 130. Drill Point: i) The actual cutting of a hole takes place at the drill point and not at the edges. ii) The drill point geometrics (or) shapes differ according to the demands of the drilling operations and the kind of material being drilled. Point angle is disposed exact equally either side of the drift axis. Point angle is normally 118. Designers arrange the shape of the flute so that when the point angle 118, the lip or cutting edge is a straight line. Clearance angle: For general purposes the clearance angle, measured at the periphery of the drill, should be from 10 to 12. Drill materials: Drills are made of high speed steel. Some drills are tipped with titanium nitride coatings (or) carbide tips improve drilling capabilities. The coatings help to increase the life of drills. A number of different types of drills are employed in industrial production. The section of a specific drill type is dependent on i) The material being drilled ii) Diameter iii) Shape and depth of hole iv) Whether the hole is originated or enlarged v) The type of machinery being used.

49

50

Ex. No. : 1 Date : operations.

Name of the Job: Facing, Turning and Chamfering

Aim: To obtain the required shape and size out of the given workpiece by different lathe

Material required: 1. Cylindrical work piece of diameter 25 mm and length 105 mm mild steel rod. Tools required: 1. Centre lathe 2. Cutting Tool 3. Steel rule 4. Vernier Caliper 5. Vernier Height gauge 6. Surface plate 7. Angle plate Sequence of Operations: 1. Checking the workpiece 2. Work piece setting 3. Tool setting 4. Facing 5. Turning 6. Chamfering 7. Finishing Procedure: 1. The given work piece is checked for its dimensions. 2. The work piece is held in the three-jaw chuck and with the help of chuck key tightens the work piece firmly. Ensure the job is fully centered. 3. The single point cutting tool is held in the tool post and tightens the nuts using spanner. 4. Facing is done with cutting tool moving from the center of work piece towards outside. It is done until the required length of the job is obtained. i.e. movement of the cutting tool is perpendicular to lathe axis 5. Turning is done to reduce the diameter of the job. Sufficient depth of cut is given and

51

it is done until the required diameter of the job is obtained. i.e. movement of the cutting tool is parallel to lathe axis. 6. Chamfering is done on the edges to avoid sharp edges. For that the tool is held 45 to the lathe axis and fed against the rotating work piece. 7. Finally, the dimensions of the work piece are again checked. Result: Thus the required size and shape of the given work piece is obtained and checked for its dimensions.

Signature of Staff

Signature of Instructor

Facing, Turning, and Chamfering

All dimensions are in mm

52

Ex. No. : 2 Date : operations.

Name of the Job: Facing, Step Turning and Chamfering

Aim: To obtain the required shape and size out of the given workpiece by different lathe

Material required: 1. Cylindrical work piece of diameter 25 mm and length 105 mm mild steel rod. Tools required: 1. Centre lathe 2. Cutting Tool 3. Steel rule 4. Vernier Caliper 5. Vernier Height gauge 6. Surface plate 7. Angle plate Sequence of Operations: 1. Checking the workpiece 2. Work piece setting 3. Tool setting 4. Facing 5. Turning 6. Chamfering 7. Finishing Procedure: 1. The given work piece is checked for its dimensions. 2. The work piece is held in the three-jaw chuck and with the help of chuck key tightens the work piece firmly. Ensure the job is fully centered. 3. The single point cutting tool is held in the tool post and tightens the nuts using spanner. 4. Facing is done with cutting tool moving from the center of work piece towards outside. It is done until the required length of the job is obtained. i.e. movement of the cutting tool is perpendicular to lathe axis 5. Turning is done to reduce the diameter of the job. Sufficient depth of cut is given and

53

it is done until the required diameter of the job (different diameter in different length segments) is obtained. i.e. movement of the cutting tool is parallel to lathe axis. 6. Chamfering is done on the edges to avoid sharp edges. For that the tool is held 45 to the lathe axis and fed against the rotating work piece. 7. Finally, the dimensions of the work piece are again checked. Result: Thus the required size and shape of the given work piece is obtained and checked for its dimensions.

Signature of Staff

Signature of Instructor

Facing, Step Turning and Chamfering

All dimensions are in mm

54

Ex. No. : 3 Date : operations.

Name of the Job: Facing, Taper Turning and Chamfering

Aim: To obtain the required shape and size out of the given workpiece by different lathe

Material required: 1. Cylindrical work piece of diameter 25 mm and length 105 mm mild steel rod. Tools required: 1. Centre lathe 2. Cutting Tool 3. Steel rule 4. Vernier Caliper 5. Vernier Height gauge 6. Surface plate 7. Angle plate Sequence of Operations: 1. Checking the workpiece 2. Work piece setting 3. Tool setting 4. Facing 5. Turning 6. Chamfering 7. Finishing Procedure: 1. The given work piece is checked for its dimensions. 2. The work piece is held in the three-jaw chuck and with the help of chuck key tightens the work piece firmly. Ensure the job is fully centered. 3. The single point cutting tool is held in the tool post and tightens the nuts using spanner. 4. Facing is done with cutting tool moving from the center of work piece towards outside. It is done until the required length of the job is obtained. 5. Turning is done to reduce the diameter of the job. Sufficient depth of cut is given and it is done until the required diameter of the job is obtained.

55

6. Taper Turning (changing diameter along the length) is done on the work piece, as per the Taper angle already calculated. Then the compound rest base is swiveled and set at half taper angle. Cutting tool is moved at an angle to the lathe axis. Tool is moved D d by compound rest hand wheel. The taper angle = tan 1 . Here D Major 2L diameter, d Minor diameter and L is length of taper turning. 7. Chamfering is done on the edges to avoid sharp edges. For that the tool is held 45 to the lathe axis and fed against the rotating work piece. 8. Finally, the dimensions of the work piece are again checked. Result: Thus the required size and shape of the given work piece is obtained and checked for its dimensions.

Signature of Staff

Signature of Instructor

Taper angle = tan

24 18 = 0.075 rad or 4.3 2 x 40

Facing, Taper Turning and Chamfering

All dimensions are in mm

56

Ex. No. : 4 Date : machine.

Name of the Job: Drilling of Holes

Aim: To drill the holes of required diameter in the given mild steel plate using a drilling

Material required: 1. Mild steel flat plate of dimension 51 mm x 51 mm x 6 mm Tools required: 1. Steel rule 2. Vernier caliper 3. Surface plate 4. Flat file 5. Scriber 6. Centre 7. Punch 8. Hammer 9. Try square 10. 8 mm and 12 mm drill bits.

Sequence of Operations: 1. Checking the workpiece 2. Filing 3. Work piece setting 4. Tool setting 5. Drilling Procedure: 1. The given work piece is checked for its dimensions. 2. The work piece is fixed in a bench vice and the four sides are filed in order to bring down to the required size and square shape. 3. The work piece is held on the surface plate and using scriber the lines are marked on the plate. 4. At the required positions, the drilling centers are marked using a centre punch and hammer. 5. The plate is then fixed on a drill vice firmly.

57

6. The

8 mm drill bit is fixed in the drill chuck and four holes at the marked places 12 mm drill bit in the

are drilled by manual feed. 7. The edges of the drilled holes are countersunked by using a same drilling machine. Result: Thus, the desired holes are drilled in the given mild steel plate.

Signature of Staff

Signature of Instructor

DRILLING HOLES

All dimensions are in mm

58

PLUMBING

59

SAFETY PRECAUTINS IN PLUMBING

1. Switch off the motor while doing plumbing work. 2. Make sure that there is no leakage after connecting the pipes and other pipe layout. 3. Close the gate valve to prevent the water supply from the main tank and carry out plumbing work. 4. Use proper tool for the job. Never use spanner in place of hammer. 5. Always use proper spanner for proper nut or bolt. 6. File should be used with proper handle. 7. Never use chisels having mushroom heads. 8. Never hold the work in your hand while using a screwdriver. 9. Never strike with hammer on the handle of screwdriver. 10. Handle the plumbing tools with care since they are hard tools.

60

1 Introduction Plumbing is the art of design, installation and maintenance of pipe, pipe fittings and other accessories in a building. It plays a major role in the construction of every building. Plumbing includes the pipes, fixtures and accessories which carry water from the main source of supply to the building. It also conveys the used fluids from a building to other place of local disposal. Water distribution system consists of a supply pipe leading to a fixture and a drain pipe taking the used water away. 2 Purpose of Plumbing Plumbing is installed in a building for the comfort and convenience of the inhabitants as well as sanitation and health. Water is brought by supply pipes and used water is carried away by the drainage pipes. Good plumbing is necessary in houses, apartments, commercial and other public buildings. 3 Tools used by Plumber

3.1 Pipe Vice It is used to hold the pipe during cutting, marking, threading, etc. It consists of a fixed jaw, a movable jaw and a screw handle for adjustment of moving jaw.

Screw handle

Body

Movable jaw Fixed Jaw

Base

3.2 Pipe Wrench It has a fixed bottom jaw (called Heel jaw) attached to a lever handle. The top jaw (called Hook jaw) is a movable by means of an adjustable nut. It is available in different sizes.

61

3.3 Open End Spanner Plain open end spanners are of solid non-adjustable type with openings at each end. These are made in a set.

3.4 Hacksaw Frame with Blade It is bow shaped adjustable or rigid frame with a cutting blade. The blade is made of carbon steel properly tempered and has teeth on one or both the edges.

3.5 Pipe Threading Dies It is also called as stocks and dies Two types of dies are available, namely solid and adjustable. They are fitted into the centre of the frame. Dies are held in position by a block which is adjustable by means of a tommy bar. This stock cuts parallel threads. Separate set of dies are required for each size.

62

4 Pipe Fittings A lot of pipe fittings are used for joining pipes of larger size with flanges, while smaller size pipes are joined by coupling some. 4.1 Coupling Its a short cylindrical sleeve with internal threads throughout its length. It is used for joining two pipes in a straight line and where at least one pipe can be turned. It is available in different materials and different sizes.

4.2 Elbow It is similar to the Coupling. It is used for fitting two pipes at right angles. Internal threads are cut in the elbow. It is also available in different material and different sizes.

4.3 TEE It is used for giving connection from the main pipe line to a branch line. By using it, two more lines can be made from the same supply line. It is available in different materials and different sizes.

63

4.4 Four-way Cross It has a shape of + sign. It is used for fitting a pipe in all four directions. Threads are cut in all its four ends. It is available in different materials and different sizes.

4.5 Pipe Union It connects two pipes Water meter is fitted with union so that they can be removed easily. It provides facility to disconnect pipes. It is available in different material and different sizes.

4.6 Reducer It is used to connect a big pipe to a small pipe or vice versa face to face It is available in different sizes and different materials.

4.7 Plug or Dummy It is a short piece with external threads at one end and square end on another end. Square end enables the use of spanner to fasten it. 64

Used to screw onto a threaded opening for temporary closing. A cap may be used for closing external threaded openings temporarily It is available in different materials and different sizes.

4.8 Valves Pipes can be joined with valves and according to our needs, we can stop or open the flow of water through the pipes. It is available in different materials and sizes.

4.9 Cock It is also called as tap. It serves the purpose of putting off or on the flowing water through pipes. It is made up of copper, plastic, gun metal, etc. At its top, there is a provision for starting the flow of water and insider there is a cock. It is available in different sizes.

65

Types of pipes used in plumbing

66

Study of pipe connections on the suction pipe layouts

1. Laying pipe connection to the suction side of a pump Inlet

67

2. Laying pipe connection to the delivery side of a pump Outlet

68

Ex. No. : 1 Date :

Name of the Job: Basic Pipe Connection

Aim: To make a Basic pipe connection using the given fittings as per the layout Material required: 1. Gate Valve (Brass) 2. G.I Elbow 3. G.I Tee 4. G.I Dummy 5. G.I Coupling 6. M.S. Tap 7. PVC pipe 1 feet 3 Nos. Tools required: 1. Pipe Vice 2. Pipe Wrench 3. Die Set 4. Spanner 10-11 5. Hacksaw frame with Blade Procedure: 1. Assemble the die set with die and diestock correctly. 2. Hold the PVC pipe with use of pipe vice 3. Make the threading operation on both sides 4. Repeat the threading operation in the remaining two pipes 5. Take one PVC pipe and connect the Gate valve (brass) on one side and connect the G.I elbow another side. 6. Take another PVC pipe and connect it to G.I elbow and G.I Tee 7. Take another PVC pipe connect it to G.I Tee and G.I coupling. 8. Plug the G.I Dummy in G.I tee and connect the M.S. Tap with G.I coupling. 9. Tight the all fittings with the use of pipe wrench. Result: The basic pipe connection is done using the given pipes and fittings as per the layout. Signature of Staff Signature of Instructor

69

Basic Pipe Connection

70

Ex. No. : 2 Date :

Name of the Job: Mixed Pipe Connection

Aim: To make a Mixed pipe connection using the given fittings as per the layout Material required: 1. G.I Elbow and Union 2. G.I Cross 3. G.I Reducer 4. G.I. Coupling 5. M.S. Tap 6. PVC pipe 1 feet 3 Nos. 7. PVC pipe 1 feet 1 No. Tools required: 1. Pipe Vice 2. Pipe Wrench 3. Die Set , Die set 4. Spanner 10-11 5. Hacksaw frame with Blade Procedure: 1. Assemble the die set with die and diestock correctly. 2. Hold the PVC pipe with the use of pipe vice 3. Make the threading operation on both sides 4. Repeat the threading operation in the remaining two pipes 5. Assemble the die set with die and diestock correctly 6. Hold the PVC pipe with the use of pipe vice 7. Make the threading operation on both sides 8. Take one PVC pipe and connect the G.I elbow one side and connect the G.I Union another side. 9. Take another PVC pipe and connect it to G.I Union and G.I Cross 10. Take another PVC pipe connect it to G.I Cross and - G.I Reducer. 11. Take another PVC pipe and connect it to G.I Reducer and G.I Coupling 12. Connect the M.S. Tap with G.I Coupling. 13. Tight the all fittings with the use of pipe wrench. Result: The Basic pipe connection is done using the given pipes and fittings as per the layout. Signature of Staff Signature of Instructor

71

Mixed Pipe Connection

72

Ex. No. : 3 Date :

Name of the Job: Connection of Two G.I. Pipes

Aim: To make a G.I pipe connection using the given fittings as per the layout Material required: 1. G.I Coupling 2. G.I. pipe 1 feet 2 Nos. Tools required: 1. Pipe Vice 2. Pipe Wrench 3. Die Set 4. Spanner 10-11 5. Hacksaw frame with Blade Procedure: 1. Assemble the die set with die and diestock correctly. 2. Hold the G.I. pipe with the use of pipe vice 3. Make the threading operation on one side of the pipe. 4. Repeat the threading operation in the remaining pipe. 5. Take one G.I pipe and connect the G.I coupling with it. 6. Take another G.I pipe and connect it to the coupling pipe assembly. 7. Tight all the fittings with the use of a pipe wrench. Result: The Basic pipe connection is done using the given pipes and fittings as per the layout. Signature of Staff Signature of Instructor

73

Connection of Two G.I. Pipes

74

SHEET METAL WORK

75

(i)

76

77

78

79

80

Ex. No. : 1 Date :

Name of the Job: Making of Rectangular Tray

Aim: To make a rectangular tray from given sheet metal as per the given dimensions. Material required: 1. 165 mm x 115 mm of 30 gauge G.I (Galvanized Iron) sheet. Tools required: 1. Steel rule 5. Punch 9. Stakes Sequence of Operations: 1. Checking 4. Marking 7. Hemming 2. Trammel 6. Shears 10. Mallet 3. Scriber 4. Snips 7. Vice 8. Anvil 11. Cross peen hammer

2. Leveling 5. Cutting 8. Riveting

3. Laying out 6. Bending 9. Finishing

Procedure: 1. The size of the given sheet is checked for its dimensions using a steel rule. 2. Then the sheet is leveled on the leveling plate using a mallet. 3. Develop the sheet metal as per the dimension of the tray. 4. The dimensions are marked as shown in fig. 5. The sheet is cut as per the marked dimensions by straight snips. 6. Then a single hemming is made on the four sides of the tray as shown in figure. 7. These four sides of the tray are bent to 90 using stakes anvil. 8. Finally all the corners of the tray are joined by riveting. Result: Thus the required shape of tray is obtained from the given sheet metal.

Signature of Staff

Signature of Instructor

81

Making of Rectangular Tray Marking

All dimensions are in mm

After Cutting

Finishing

82

S-ar putea să vă placă și

- Department of Mechanical Engineering Ge6162 Engineering Practices Lab Laboratory RecordDocument76 paginiDepartment of Mechanical Engineering Ge6162 Engineering Practices Lab Laboratory RecordSathish KÎncă nu există evaluări

- GE 2116 Lab Manual-Rev 2012Document30 paginiGE 2116 Lab Manual-Rev 2012lenojerin3486Încă nu există evaluări

- Sem Workshop ManualDocument22 paginiSem Workshop ManualSaikat BanerjeeÎncă nu există evaluări

- Ep Lab Manual Civil & ElectricalDocument62 paginiEp Lab Manual Civil & ElectricalraghulÎncă nu există evaluări

- Workshop Manual - CorrectedDocument44 paginiWorkshop Manual - CorrectedSaurav KumarÎncă nu există evaluări

- Mannual Narayana 2023-02Document51 paginiMannual Narayana 2023-02pallahemahimaja123Încă nu există evaluări

- Experiment - Arc WeldingDocument5 paginiExperiment - Arc WeldingAl Anood Al AmeriÎncă nu există evaluări

- PRIR11 - Engineering Practice Lab Manual: Tiruchirappalli-620015Document21 paginiPRIR11 - Engineering Practice Lab Manual: Tiruchirappalli-620015pranav kumarÎncă nu există evaluări

- MT-II LabDocument7 paginiMT-II LabAjay Vikram0% (1)

- Airframe and Aero Engine Lab FinalDocument25 paginiAirframe and Aero Engine Lab FinalAravind Phoenix50% (2)

- Workshop - List of Experements and Its Procedure PDFDocument29 paginiWorkshop - List of Experements and Its Procedure PDFAdhi SheshuÎncă nu există evaluări

- MFT Lab Manual 2017-18 Even UpdatedDocument63 paginiMFT Lab Manual 2017-18 Even UpdatedPrakash ThangavelÎncă nu există evaluări

- GE2152 Basic Civil & Mechanical EngineeringDocument30 paginiGE2152 Basic Civil & Mechanical EngineeringThulasi RamÎncă nu există evaluări

- WorkshopDocument5 paginiWorkshopJoseph NjugunaÎncă nu există evaluări

- 1 CarpentryDocument5 pagini1 CarpentryMa NojÎncă nu există evaluări

- Basic Machining Facing and TurningDocument17 paginiBasic Machining Facing and TurningKedar NathÎncă nu există evaluări

- Lab Exp Manual Workshop 2018 19Document32 paginiLab Exp Manual Workshop 2018 19Babeet JaatÎncă nu există evaluări

- Vsa Scholl of Engineering: Iv Semester Mechanical EngineeringDocument43 paginiVsa Scholl of Engineering: Iv Semester Mechanical EngineeringDmj Anbu RajÎncă nu există evaluări

- Lab Manual - BWPDocument23 paginiLab Manual - BWPAneesh KumarÎncă nu există evaluări

- MS-II Lab ManualDocument18 paginiMS-II Lab ManualdibyenindusÎncă nu există evaluări

- Epl RecordDocument63 paginiEpl RecordTishbian MeshachÎncă nu există evaluări

- Central Workshop Manual For Mechanical Workshop CourseDocument60 paginiCentral Workshop Manual For Mechanical Workshop Courseankitbugalia56Încă nu există evaluări

- MP LabDocument14 paginiMP LabJagan RmdÎncă nu există evaluări

- Diploma Workshop Practice IDocument20 paginiDiploma Workshop Practice Ieighteen plusÎncă nu există evaluări

- CASTINGS: The Products Made by Casting Process Are KnownDocument11 paginiCASTINGS: The Products Made by Casting Process Are KnownbernabasÎncă nu există evaluări

- B.Naresh Kumar Workshop - WordDocument61 paginiB.Naresh Kumar Workshop - WordJyotshna DaamagatlaÎncă nu există evaluări

- N 51 e 62 e 9 Ea 2045Document28 paginiN 51 e 62 e 9 Ea 2045TECH RISHABH 07Încă nu există evaluări

- ME 192 Odd Sem Workshop Manual 2013 2014 For 1st YearDocument27 paginiME 192 Odd Sem Workshop Manual 2013 2014 For 1st YearRajib Mandal100% (1)

- M.Kumarasamy: Basic Civil and Mechanical Engineering LaboratoryDocument21 paginiM.Kumarasamy: Basic Civil and Mechanical Engineering LaboratoryAravindÎncă nu există evaluări

- Fitting ShopDocument4 paginiFitting ShopAmarjeet Singh (Assistant Professor- Mechanical Engineer)Încă nu există evaluări

- Assignment 2Document17 paginiAssignment 2AakarshÎncă nu există evaluări

- MT-II LAB ManualDocument44 paginiMT-II LAB ManualGANESH KUMARÎncă nu există evaluări

- C-Clamp: Fundamental of ManufacturingDocument35 paginiC-Clamp: Fundamental of ManufacturingBikash Chandra DasÎncă nu există evaluări

- Co3 WeldingDocument29 paginiCo3 WeldingvarmaÎncă nu există evaluări

- Workshop Hammer ReportDocument14 paginiWorkshop Hammer ReportJoshua Chong67% (3)

- Work Shop Manual I Year-QisDocument69 paginiWork Shop Manual I Year-QisSeshaiah TurakaÎncă nu există evaluări

- Test Project Sheet MetalDocument10 paginiTest Project Sheet MetalSyed Idrus Syed OmarÎncă nu există evaluări

- Aircraft Structure Practical ReportDocument7 paginiAircraft Structure Practical ReportSyamira ZakariaÎncă nu există evaluări

- Ews-Itws Lab ManualDocument167 paginiEws-Itws Lab ManualNetaji GandiÎncă nu există evaluări

- EXP Write UpDocument28 paginiEXP Write UpSoumyajit NandiÎncă nu există evaluări

- Workshop ManualDocument26 paginiWorkshop ManualHarender KumarÎncă nu există evaluări

- Laboratory Manual: MEC 317 Manufacturing Technology LaboratoryDocument27 paginiLaboratory Manual: MEC 317 Manufacturing Technology LaboratorySunil SharmaÎncă nu există evaluări

- Workshop AssignmentDocument11 paginiWorkshop AssignmenttechnologicaluniversityyangonÎncă nu există evaluări

- Mya Myint Mo (Workshop)Document12 paginiMya Myint Mo (Workshop)ytzqddnd58Încă nu există evaluări

- Engineering WorkshopDocument8 paginiEngineering Workshopsteveharrington1418Încă nu există evaluări

- Ews-Itws Lab ManualDocument168 paginiEws-Itws Lab Manualsrinivasallam_259747Încă nu există evaluări

- Workshop Lab: ManualDocument75 paginiWorkshop Lab: ManualNaga KiranÎncă nu există evaluări

- First Year Fall Semester 2020: Ie-115: Material Workshop Report File: Lab WorkDocument45 paginiFirst Year Fall Semester 2020: Ie-115: Material Workshop Report File: Lab WorkMuhammadtayyabaziz KhanÎncă nu există evaluări

- Wa0006Document14 paginiWa0006taiwolateefsamuelÎncă nu există evaluări

- EXP Write UpDocument28 paginiEXP Write UpIndrani ChakrabortyÎncă nu există evaluări

- Chapter 1: Introduction: PKM Smts SPM 2010Document9 paginiChapter 1: Introduction: PKM Smts SPM 2010yeopsagorÎncă nu există evaluări

- Carpentary 2 Workshop LabDocument1 paginăCarpentary 2 Workshop Labsyed azeemÎncă nu există evaluări

- V FittingDocument1 paginăV Fittingkishanreddy KalluÎncă nu există evaluări

- Performing Hand Forging: LO1: Analyze and Plan HandDocument21 paginiPerforming Hand Forging: LO1: Analyze and Plan HandZimbelachew Emawoy100% (2)

- Desempeño Sismico de Una Columna Rectangular Formado en Frio Conectado Al DiafragmaDocument9 paginiDesempeño Sismico de Una Columna Rectangular Formado en Frio Conectado Al DiafragmaSebastian Contreras ContrerasÎncă nu există evaluări

- Ews Lab Manual - Au - 18.1.20241Document47 paginiEws Lab Manual - Au - 18.1.20241Priya SurvacyÎncă nu există evaluări

- Experiment No: 1 Lehigh Restraint TestDocument46 paginiExperiment No: 1 Lehigh Restraint Testpthakar81293279Încă nu există evaluări

- Workshop PracticeDocument87 paginiWorkshop Practiceahmedkhalidhussain100% (2)

- The Art of Sculpture Welding: From Concept to CreationDe la EverandThe Art of Sculpture Welding: From Concept to CreationÎncă nu există evaluări

- UT1 Jan 2011Document2 paginiUT1 Jan 2011Thejaswar TejaÎncă nu există evaluări

- MPCDocument4 paginiMPCThejaswar TejaÎncă nu există evaluări

- 9.implementation of Binary Search Tree and AVL TreeDocument2 pagini9.implementation of Binary Search Tree and AVL TreeThejaswar TejaÎncă nu există evaluări

- Assgn1 13 v1Document2 paginiAssgn1 13 v1Thejaswar TejaÎncă nu există evaluări

- Oops PGM Assign3Document2 paginiOops PGM Assign3Thejaswar TejaÎncă nu există evaluări

- Data Types in CDocument9 paginiData Types in CrangarajantrÎncă nu există evaluări

- SSN College of Engineering: GE2112-Fundamentals of Computing and Programming Unit Test IDocument2 paginiSSN College of Engineering: GE2112-Fundamentals of Computing and Programming Unit Test IThejaswar TejaÎncă nu există evaluări

- Amplitude Modulation-Voltage DistributionDocument10 paginiAmplitude Modulation-Voltage DistributionThejaswar Teja0% (1)

- Amplitude Modulation - TutorialDocument5 paginiAmplitude Modulation - TutorialThejaswar TejaÎncă nu există evaluări

- Deluge Valve - SD-DVA PDFDocument15 paginiDeluge Valve - SD-DVA PDFboxyfunÎncă nu există evaluări

- MSS SP-42-2009Document17 paginiMSS SP-42-2009Manual Source100% (1)

- ASTM A234 A234M 23 - UnlockedDocument7 paginiASTM A234 A234M 23 - Unlockedrashid isaar0% (1)

- American Fastener - ASTM, S..Document6 paginiAmerican Fastener - ASTM, S..Lee GPÎncă nu există evaluări

- Chapter-17 Weldability ....Document6 paginiChapter-17 Weldability ....shahid khanÎncă nu există evaluări

- A 459 - 97 R03 - Qtq1oqDocument3 paginiA 459 - 97 R03 - Qtq1oqJOSE DE LA TORREÎncă nu există evaluări

- Fastenal Product Specification Sheet: 304 Stainless Steel Hex Cap ScrewsDocument5 paginiFastenal Product Specification Sheet: 304 Stainless Steel Hex Cap ScrewsChris MedeirosÎncă nu există evaluări

- Re.1 Till AKAM SeriesDocument8 paginiRe.1 Till AKAM SeriesMODS AND EMULATORSÎncă nu există evaluări

- Esab Product Catalogue 2010Document351 paginiEsab Product Catalogue 2010S C Gaur67% (3)

- Inoculation of Ductile Iron Why and WhenDocument4 paginiInoculation of Ductile Iron Why and WhenKarthiKeyan SÎncă nu există evaluări

- Welding Journal 1959 7Document134 paginiWelding Journal 1959 7AlexeyÎncă nu există evaluări

- Flange Ansi b16.5 Vs Iso 7005-2Document45 paginiFlange Ansi b16.5 Vs Iso 7005-2Allan EscobarÎncă nu există evaluări

- Asbestos Cement PartitionDocument11 paginiAsbestos Cement PartitionPriya UdamaleÎncă nu există evaluări

- WSI Brochure OilTools1Document44 paginiWSI Brochure OilTools1binny SamuelÎncă nu există evaluări

- Carbon Steel BarDocument11 paginiCarbon Steel Barprajakt_pieÎncă nu există evaluări

- VM 1 1 - 2 Metalen - Handleiding - en PDFDocument21 paginiVM 1 1 - 2 Metalen - Handleiding - en PDFchmatias3Încă nu există evaluări

- NCCCO Rigger Reference Booklet PDFDocument9 paginiNCCCO Rigger Reference Booklet PDFFOZCANÎncă nu există evaluări

- Flexistrut-8 2Document167 paginiFlexistrut-8 2Lachlan RhodesÎncă nu există evaluări

- Astm A 192 A 192m 2001 PDFDocument2 paginiAstm A 192 A 192m 2001 PDFSofiaJabadanEspulgarÎncă nu există evaluări

- 02 Lifting Sockets LRDocument21 pagini02 Lifting Sockets LRHanuman Builders100% (1)

- Unit 5 - Metals and AlloysDocument6 paginiUnit 5 - Metals and AlloysDanielle AdelanteÎncă nu există evaluări

- AWS N-9 Stud Welding Procedure Specification (WPS) FormDocument1 paginăAWS N-9 Stud Welding Procedure Specification (WPS) FormNatalia StarkÎncă nu există evaluări

- Metallurgy Answer KeyDocument44 paginiMetallurgy Answer Keymalsttar82% (11)

- I.S - 2062-2021Document13 paginiI.S - 2062-2021Gajendrasingh RajputÎncă nu există evaluări

- Minaral and MetalDocument109 paginiMinaral and Metaldeva nesan100% (1)

- Inspection and GagingDocument38 paginiInspection and GagingRamji RaoÎncă nu există evaluări

- Resisting Metal Dusting CorrosionDocument2 paginiResisting Metal Dusting CorrosionRonald MesinaÎncă nu există evaluări

- Specification For Philippine Steel Bars For Concrete Reinforcement Product Standard Agency, Department of Trade and Industry (D.T.I.)Document18 paginiSpecification For Philippine Steel Bars For Concrete Reinforcement Product Standard Agency, Department of Trade and Industry (D.T.I.)Azel GarciaÎncă nu există evaluări

- Analytical MetallographyDocument20 paginiAnalytical MetallographyAnthony AbelÎncă nu există evaluări

- BrecoDocument43 paginiBrecopangregisterlang99Încă nu există evaluări