Documente Academic

Documente Profesional

Documente Cultură

Section VIII Cal

Încărcat de

Pradeep KothapalliDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Section VIII Cal

Încărcat de

Pradeep KothapalliDrepturi de autor:

Formate disponibile

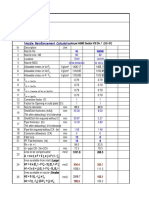

MECHANICAL STRENGTH CALCULATION `

Working Pressure

24 Kg/cm (g) 25 Kg/cm (a)

Design Pressure

Working Temperature Design Temperature Hydro Test Pressure SHELL THICKNESS UNDER INTERNAL PRESSURE---------------MATERIAL UNCORR. INSIDE DIAMETER = D DESIGN PRESSURE CORROSION ALLOWANCE P = =C

28 Kg/cm (a) 218 246 41.25 UG 27 SA 516 GR. 70 1600 0.286 1.5 801.5 E p d = =S E (p-d)/p 780 151 0.806 14.090 KG/MM2 MM MM MM KG/MM2 MM MM

CORRODED INSIDE RADIUS = R LIGAMENT EFFICIENCEY MIN. PITCH IN SHELL DIA OF HOLE LIGAMENT EFFICIENCEY MAX. ALLOW. STRESSES

REQRD. THICKNESS

= tr tr =

(P*R/(S*E-0.6*P))+C 21.98 32 MM MM

ADOPTED WALL THICKNESS OF THE SHELL = HENCE OKAY.

MECHANICAL STRENGTH CALCULATION

Tubesheet thickness under Internal PressureCalculations A) the Minimum thickness of the stay tubes asper UG 47 Sec VIII Div I

P t = p SC Eqn 1

Where

p is the maximum pitch in the tube sheet 27 Kg/cm(G)

119 mm 28 Kg/cm (A) = 0.28 Kg/mm

P is the maximum working pressure

S is the maximum allowable pressure C is the correction factor Mean diameter dm t t = = =

14.07 Kg/mm 2.2 (63.5+53.74)/2 = 58.62 mm

273x SQRT(0.28/(14.07*2.25)) 11.3 mm

Hence provided thickness

32 mm

B) Load to be supported by the Stay tubes as per ASME Sec -VIII The Maximum allowable working pressure for stay tubes as per UG 47 t x S C P = p Allowable stress as per code ASME Sec II part D = S = 14.07 Kg/mm C = 2.2 p = 119 mm dm = 58.62 mm P = 32 x 14.07 x 2.2 119 2.2383233 kg/mm 223.83233 Kg/cm Eqn 2

a) Required area of the stay tube at minimum cross section A = PI() x dm x t = 5893 mm 58.93 cm Eqn 3

MECHANICAL STRENGTH CALCULATION

Load =

P x A

13191 Kg 13.191 tons

Eqn 4

Maximum load on Two stay tubes (as per drawing enclosed) As per UG 50 ASME Sec VIII,

2 x 13.191 26.381 Eqn 5

a)Therefore Required cross sectional area of stay tubes = Max Load / Maximum allowable Stress A A A Taking Margin of 10% = 9.37x 1.1 = = = = 13191/14.07 937.51 mm 9.375067 cm 10.31 cm

whereas we have provided cross sectional area of the stay tube of 58.93 cm and hence it is safe.

B) Check for actual load on Unsupported Tube Sheet area as per UG -50 As per tube sheet drawing attached, two nos of stay tubes carry the load due to unsuppoerted area of tube sheet. Design pressure on the shell side = 27 Kg/cm(g) 28 Kg/cm (a)

Actual Load on the Unsupported area = = = 28 x PI()/4 x (27.3) - 58.93 3055 Kgs 3.055 Tons Eqn 6 26.381 Tons

Where as maximum load on stay tubes (2) holding unsupported tube sheet =

Hence from Eqn 5 & Eqn 6 The stay tube area is adequeatly designed to carry the unsupported area of the tube sheet as per ASME Sec VIII

48.4

53.74 117.24 58.62

41.86

13190.72

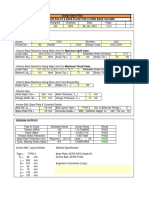

MECHANICAL STRENGTH CALCULATIONS

Dished end thickness calculations As per UG 32, The required thickness of the dished end of semiellipsodial form shall be determine by ( PxD) t = ( 2 S E - 0.2 x P) + C

Maximum working Pressure

28 Kg/cm 0.28 Kg/mm 1.5 1492 mm 1495 mm 14.07 Kg/mm 1

Corrosion allowance

= = = = =

UnCorroded Inside Diameter D Corroded Inside Diameter Allowable Stress Di S E

0.28 x 1492 t = 2 x 14.07 - 0.2 x 0.28 16.41 mm Therefore required thickness t Provided thickness t = = 16.41 mm 32 mm 3

MECHANICAL STRENGTH CALCULATIONS

Nozzle thickness calculations:

Drain Nozzle, Blow down

Nozzle size

40 NB

OD 27 Kg/cm (g)

48.3 mm 28 Kg/cm (a) 1.5 mm for shell 1203 Kg/cm 1407 Kg/cm

4.83 cm 0.28 Kg/mm 1.5 mm for Nozzle 12.03 Kg/mm 14.07 Kg/mm

Max Pressure : Corrosion allowance :

Max allowable stress for Nozzle material: Max allowable stress for Shell material: A) The Minimum required thickness of shell for internal pressure Shell Inner Diameter: ID R E ( PxR) t = ( S E - 0.6 x P) + C = =

1492 mm 746 mm 1 (28 x 74.6)

149.2 cm 74.6 cm

Joint Efficiency

1.5 (1407 x 1 - 0.6 x 28)

1.50

1.5

3.00 mm

Adopted thickness of Nozzle: B) Nozzle size :

7.14 mm

The minimum thickness of Nozzle as per ASME Sec-VIII 40 NB OD ( PxR) t = ( S E - 0.6 x P) = As per ASME Sec VIII of Standard Nozzle thickness = Taking Thinning allowance 12.5% = Thickness t = 0.875 x 3.68 = 3.22+1.5 0.49 + C = (1206 x 1 - 0.6 x 28) 1.5 = #REF! mm #REF! #REF! mm mm 1.99 mm 48.3 mm 4.83 cm (28 x 24.2) + 1.5 R = 24.2 mm

C)

D)

Thickness of nozzle selected as lower of (B) and (C) is The final nozzle thickness is selected as higher of (B) and (D) is Therefore, the nozzle thickness is higher for D is Adopted thickness is = =

1.99 mm 1.99 mm 1.99 mm

7.14 7.14 x 0.875 =

6.25 mm 1.99 mm + 1.5 = 6.25 mm #### mm

Therefore 6.25 > Also from overall design consideration,the nozzle should have thickness of = #REF! Therefore For 40 NB Nozzle we provided 160 Sch So that thickness selected is 7.14 mm > Hence it is safe

MECHANICAL STRENGTH CALCULATIONS

Nozzle thickness calculations: Nozzle size : 150 NB Max Pressure : Corrosion allowance :

Riser & Down comer Stubs OD 168.3 mm 27 Kg/cm (g) 28 Kg/cm (a) 1.5 mm for shell 1203 Kg/cm 1407 Kg/cm

16.83 cm 0.28 Kg/mm 1.5 mm for Nozzle 12.03 Kg/mm 14.07 Kg/mm

Max allowable stress for Nozzle material: Max allowable stress for Shell material: A) The Minimum required thickness of shell for internal pressure Shell Inner Diameter: ID R E ( PxR) t = ( S E - 0.6 x P) + C = =

1492 mm 746 mm 1 (28 x 74.6)

149.2 cm 74.6 cm

Joint Efficiency

1.5 (1407 x 1 - 0.6 x 28)

1.50

1.5

3.00 mm

Adopted thickness of Nozzle: B) Nozzle size :

18.26 mm

The minimum thickness of Nozzle as per ASME Sec-VIII 150 NB OD ( PxR) t = ( S E - 0.6 x P) = As per ASME Sec VIII of Standard Nozzle thickness = Taking Thinning allowance 12.5% = Thickness t = 0.875 x 3.68 = 6.22+1.5 1.69 + C = (1206 x 1 - 0.6 x 28) 1.5 = #REF! mm #REF! #REF! mm mm 3.19 mm 168.3 mm 16.83 cm (28 x 84.2) + 1.5 R = 84.2 mm

C)

D)

Thickness of nozzle selected as lower of (B) and (C) is The final nozzle thickness is selected as higher of (B) and (D) is Therefore, the nozzle thickness is higher for D is Adopted thickness is = =

3.19 mm 3.19 mm 3.19 mm

18.26 18.26 x 0.875 =

15.98 mm 3.19 mm + 1.5 = 8.61 mm #### mm

Therefore 15.98 > Also from overall design consideration,the nozzle should have thickness of = #REF! Therefore For 150 NB Nozzle we provided 160 Sch So that thickness selected is 18.26 mm > Hence it is safe

Mechanical Strength Calculations

OPENING REINFORCEMENTS Design Pressure Allowable stress of shell Allowable stress of nozzle Allowable stress of Pad Joint efficiency Factor of safety Corrosion allowance Uncorroded thk of shell Corroded thk of shell MANHOLE OPENING OD of Nozzle Thk of nozzle Corr. Inside dia. Of nozzle Corr Nozzle Thk Max. Limit of Reinforcement

..UG 36,37,40 P Sv Sn Sp E F C Ts T = = = = = = = = = 2800 140723.00 120376.00 140723.00 1 1 1.5 32 30.5 kg/mm kg/mm kg/mm kg/mm

fr1 = (MIN Sn/Sv,1) fr2 = (MIN Sn/Sv,1) fr3 = (MIN SP/Sv,1) fr4 = (MIN SP/Sv,1)

..UG 36, 37, 40 d t dn tn = = = = 600 32 598.5 31.25 mm mm mm mm

2d or 2(Rn+tn+t) Whicherever is larger 2d Rn=d/2 2(Rn+tn+t) = = = = = = = = 1200 300 726.5 800 25 7.059 15.67 250.00

Pad outside Dia Provided Pad thk. trn = P*0.5*dn/(Sn*E-0.6*P) tr = P*0.5*d/(Sv*E-0.6*P) Height of nozzle

Dp te trn tr h

Mechanical Strength Calculations

Area Required

= =

(dn*tr*F)+2*tn*tr(1-fr) 9518 d*(Ts-tr) 9799.74 2*(tn-trn)*te*fr1 1034.65 2*(t-C)*fr1*h 13045.02 144 (Dp-d-2*tn)*te*fr4 3437.5 A1+A2+A3+A4+A5 27460.91 m (Greater than Required) Hence Okay mm

Area available in shell

A1

= =

Area availble in nozzle outside

A2

= =

Area availble in nozzle inside

A3

= =

Area in fillet weld Area ava. In comp. Pad

A4 A5

= = =

Total available Area

= =

Mechanical Strength Calculations

HAND HOLE OPENING IN SHELL Size

..UG 36,37,40 = ID230 x ID 127 x 32 Thk PR --------------SE-0.6P 2800.00 a/b 230 127 416.54 mm kg/mm

Minimum required thickness

Maximum allowable Pressure Outside Diameter of Nozzle

P D a b D

= = = = = = =

Max. allowable Stress Corrosion allowance

S C

140720.00 kg/mm 1.5

t Provided thickness is Thickness of attached reinforcing pad, mm Thickness of vessel wall Reqd. thk. Of vessel wall Nominal thickness of nozzle Reqd.thk of nozzle wall Dia. in the Plane under consideration of the finished opening

= =

5.69 32 te t tr tn trn d mm = = = = = = 40 32 20.60 32 5.69 127

F Dist. Of nozzle projects inward from the outer surface of the vessel wall h

= =

1 64

Mechanical Strength Calculations

Allowable stress in nozzle Allowable stress in vessel Allowable stress in reinforcement Sn/Sv for nozzle wall inserted through vessel (Lesser of Sn or Sp)/Sv Sp/Sv Area Required (d + 2tn)trF

Sn Sv Sp fr1 fr2 fr3 A A1

= = = = = = = =

140720.00 140720.00 140720.00 1 1 1 3934.60 729.60

Area available in shell (use larger value) (d-2tn)(t-F tr) or 2 t (t - F tr)

Area available in nozzle projecting outward A2 2(tn - trn)(2.5 t fr1) or 2(tn - trn)(2.5 tn+ te) fr1 (use minimum value) Area avail. in nozzle projecting inward (2xtnxfr1xh) Area available in outward nozzle weld (WL1 x fr2) Area available in inward nozzle weld (WL3 x fr2) Area provided through compensation pad Total Area (A1+A2+A3+A4+A5+Ac) A3 A4 A5 Ac

4208.94

= = = = =

4096 144 144 21600 30922.54

0.9 0.9 1.0 1.0

36

mm mm

mm

mm mm mm mm > A Hence OK

CAP OF MAN HOLE STUBS As per ASME Sec VIII UG 32,The required thickness of dished head of semiellipsoidal form shall be determined by P x D t = C ( 2 x S x E - 0.2 x P)

MATERIAL UNCORR. INSIDE DIAMETER DESIGN PRESSURE P D

= = = = = = =

SA 516 GR. 70 406 0.28 1.5 409 1 14.07 KG/MM2 MM KG/MM2 MM MM

CORROSION ALLOWANCE (SHELL) C CORRODED INSIDE DIAMETER JOINT EFFICIENCEY MAX. ALLOW. STRESSES E S D1

REQRD. THICKNESS

tr1

= = =

((P*D1)/(2*S*E-0.2*P))+C ((0.28 x 703)/(2 x 14.07 x 1 -0.6 x 0.28))+1.5 4.094 5.58 4.88 10.46 = 32 MM MM MM MM 1.5

tr1 Taking 12.5% thinning allowance Hence Required thickness ADOPTED WALL THICKNESS OF THE SHELL

= = =

Hence Okay

S-ar putea să vă placă și

- Imperial Piping Weight Load Calculation WorkbookDocument13 paginiImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Bearing Failures and Root CausesDocument19 paginiBearing Failures and Root CausesMiroslav ZecÎncă nu există evaluări

- Spreader Bar CalculationDocument2 paginiSpreader Bar Calculationmahhor82_63564383870% (10)

- Section VIII CalDocument19 paginiSection VIII CalPradeep Kothapalli100% (1)

- CK Tourqe CalculationDocument7 paginiCK Tourqe Calculationamit amity100% (1)

- Sight Glass Flange AnalysisDocument4 paginiSight Glass Flange AnalysisOmil Rastogi0% (2)

- Reinforcement CheckDocument2 paginiReinforcement Checkviv0102Încă nu există evaluări

- Base Plate DesignDocument32 paginiBase Plate DesignGautam Sharma50% (2)

- Design Calculations For Pressure VesselsDocument54 paginiDesign Calculations For Pressure VesselsEdgar A. Arredondo QuirozÎncă nu există evaluări

- Nozzle Reinforcement Calculation Excel SheetDocument3 paginiNozzle Reinforcement Calculation Excel Sheetramesh punjabiÎncă nu există evaluări

- 3-Leg Calculation for Vertical Vessel SupportDocument21 pagini3-Leg Calculation for Vertical Vessel SupportBahtiar Anak LaNangÎncă nu există evaluări

- Design of Pressure Vessel (Int & Ext)Document394 paginiDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- 26 Pressure Vessel.Document21 pagini26 Pressure Vessel.mishtinil93% (14)

- Polangui Community CollegeDocument56 paginiPolangui Community CollegeHoney Avel UrotÎncă nu există evaluări

- Blind flange design calculationDocument4 paginiBlind flange design calculationmukesh100% (2)

- FormulaeDocument33 paginiFormulaeLcm TnlÎncă nu există evaluări

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 paginiDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainÎncă nu există evaluări

- UEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPDocument8 paginiUEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPmkchy12100% (1)

- Design of anchor bolts and base plate for a fixed base columnDocument4 paginiDesign of anchor bolts and base plate for a fixed base columnSuryaSinghÎncă nu există evaluări

- Flange CalculationsDocument3 paginiFlange CalculationssanjaysyÎncă nu există evaluări

- Mathcad - ASME I I VIII I Thickness Cylindrical ShellDocument3 paginiMathcad - ASME I I VIII I Thickness Cylindrical ShellkurcekÎncă nu există evaluări

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 paginiDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunÎncă nu există evaluări

- Design of Pressure Vessel NewDocument200 paginiDesign of Pressure Vessel NewneelÎncă nu există evaluări

- Bracket - 4 DesignDocument1 paginăBracket - 4 Designbjreddy100% (2)

- Blind Flange Thickness Calculation Under 40 CharactersDocument6 paginiBlind Flange Thickness Calculation Under 40 Charactersshazan0% (1)

- Design of Pressure Vessel NewDocument442 paginiDesign of Pressure Vessel NewkhanfaqihÎncă nu există evaluări

- Shell and Tube HE CalculationDocument16 paginiShell and Tube HE CalculationPradip ShindeÎncă nu există evaluări

- SPAN Calc.Document48 paginiSPAN Calc.yoi_123Încă nu există evaluări

- Asme Viii CalcsDocument20 paginiAsme Viii CalcsSriram VjÎncă nu există evaluări

- Aci BeamDocument6 paginiAci BeamkumsbamaÎncă nu există evaluări

- Asme Viii Shell & Se HeadDocument5 paginiAsme Viii Shell & Se HeadSnr George RaczÎncă nu există evaluări

- Thickness Calculation of Pressure Vessel ShellDocument22 paginiThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- Reinforcement Pad DesignDocument3 paginiReinforcement Pad DesignAkshat JainÎncă nu există evaluări

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 paginiSteam Drum, Water Wall & Evaporator - VWHA054Mani SunÎncă nu există evaluări

- ASME B31-11aDocument9 paginiASME B31-11aPradeep KothapalliÎncă nu există evaluări

- SBC303Document126 paginiSBC303KOTAIBA ALJWIMÎncă nu există evaluări

- 31barg CalculationDocument10 pagini31barg Calculationshani5573Încă nu există evaluări

- New - Reinforcement of NozzleDocument31 paginiNew - Reinforcement of NozzleChagar HarshpalÎncă nu există evaluări

- Steam Generator GuidebookDocument117 paginiSteam Generator GuidebookPradeep Kothapalli100% (3)

- Steam Generator GuidebookDocument117 paginiSteam Generator GuidebookPradeep Kothapalli100% (3)

- Boiler CalculationDocument67 paginiBoiler Calculationkeerthi dayarathnaÎncă nu există evaluări

- External Pressure DesignDocument395 paginiExternal Pressure DesignrsubramaniÎncă nu există evaluări

- Elliptical Head Design ToolDocument1 paginăElliptical Head Design ToolSudjono BroÎncă nu există evaluări

- Heat Exchanger DesignDocument7 paginiHeat Exchanger Designsiva sankarÎncă nu există evaluări

- Section VIII CalDocument21 paginiSection VIII CalRuben Samoel Barros RochaÎncă nu există evaluări

- New - Reinforcement of NozzleDocument31 paginiNew - Reinforcement of Nozzlehardik5818Încă nu există evaluări

- Condenser Water and Cooling Tower in Thermal Power PlantDocument131 paginiCondenser Water and Cooling Tower in Thermal Power PlantVivek TiwariÎncă nu există evaluări

- Various Tendering Systems and Their Implication in Project Cost, Time, Quality and PerformanceDocument5 paginiVarious Tendering Systems and Their Implication in Project Cost, Time, Quality and PerformanceZinck Hansen100% (1)

- Checklist For Terrace WaterproofingDocument2 paginiChecklist For Terrace Waterproofingsantoshkumar gurme75% (12)

- Ibr CalcDocument4 paginiIbr CalcUmesh Kondkar100% (7)

- Skirt Support TrialDocument11 paginiSkirt Support TrialAbhishek Nag0% (1)

- Design Calculations For Pressure ShellDocument33 paginiDesign Calculations For Pressure ShellGeorge GeorgianÎncă nu există evaluări

- DESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTDocument12 paginiDESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTfarahanisiliasÎncă nu există evaluări

- Equipment Design As Per Russian Norms - 20090218Document45 paginiEquipment Design As Per Russian Norms - 20090218vikasÎncă nu există evaluări

- Approved Suppliers List: SCM DepartmentDocument2 paginiApproved Suppliers List: SCM DepartmentAbdul MueedÎncă nu există evaluări

- Asme Sec 8 Div 1 - App 1-10Document11 paginiAsme Sec 8 Div 1 - App 1-10BibinBabuÎncă nu există evaluări

- Mogude Rendo Priyudu by BalabhadrapatuniRamaniDocument158 paginiMogude Rendo Priyudu by BalabhadrapatuniRamaniSaiMahima100% (3)

- Hinge Calculation FormulasDocument2 paginiHinge Calculation FormulasamaÎncă nu există evaluări

- Total Middle East New Bitumen Terminal in TlbuDocument25 paginiTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Ibr Calc GSRDocument4 paginiIbr Calc GSRAniket GaikwadÎncă nu există evaluări

- Base Ring Fillet Size CalculationDocument4 paginiBase Ring Fillet Size Calculationmiteshpatel191Încă nu există evaluări

- Saddle CalculationDocument10 paginiSaddle Calculationpharis_chrisÎncă nu există evaluări

- Premium TankDocument26 paginiPremium TankAnonymous p0iwBoÎncă nu există evaluări

- Calculation of left and right saddle supports for offshore tankerDocument12 paginiCalculation of left and right saddle supports for offshore tankerrustamriyadiÎncă nu există evaluări

- SA 516M GR 485: If Actual Thickness of Head After Forming 9 MMDocument2 paginiSA 516M GR 485: If Actual Thickness of Head After Forming 9 MMMehta MehulÎncă nu există evaluări

- ASME Pressure Vessel Design-ADocument190 paginiASME Pressure Vessel Design-AWidyAdityaÎncă nu există evaluări

- Cone Development CalculationsDocument5 paginiCone Development CalculationssaudimanÎncă nu există evaluări

- N74 Engine Technical OverviewDocument51 paginiN74 Engine Technical OverviewChris Ce100% (3)

- Boiler CalcDocument92 paginiBoiler CalcPrasanta Kumar BeheraÎncă nu există evaluări

- Procurement StrategiesDocument11 paginiProcurement StrategiesLarry MarksÎncă nu există evaluări

- L 8 IhjnmklgfDocument27 paginiL 8 IhjnmklgfbrintopvÎncă nu există evaluări

- Reinforcement calculations for multiple nozzlesDocument15 paginiReinforcement calculations for multiple nozzlesMuhammad Hassan MaqsoodÎncă nu există evaluări

- Out of Roundnesscalculations:: Max MinDocument6 paginiOut of Roundnesscalculations:: Max MinAdekimi EmmanuelÎncă nu există evaluări

- 6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3Document8 pagini6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3abdulÎncă nu există evaluări

- 4 3 CogenerationDocument10 pagini4 3 CogenerationJayvin RossÎncă nu există evaluări

- Electric BrakingDocument11 paginiElectric BrakingPradeep KothapalliÎncă nu există evaluări

- 6300 New Installation Single User LicenseDocument17 pagini6300 New Installation Single User LicensePradeep KothapalliÎncă nu există evaluări

- Refractory Thk. Cal.Document1 paginăRefractory Thk. Cal.Pradeep Kothapalli100% (1)

- Dioxins and Furans Fact SheetDocument2 paginiDioxins and Furans Fact SheetNunatsiaqNewsÎncă nu există evaluări

- Area Volume FormulasDocument4 paginiArea Volume FormulasPradeep KothapalliÎncă nu există evaluări

- Triad Series: 3 Piece Ball ValvesDocument8 paginiTriad Series: 3 Piece Ball Valvesevilnemesis133Încă nu există evaluări

- Part DetailsDocument10.059 paginiPart DetailsAmanÎncă nu există evaluări

- U-BOOTS (1) Technical SeminarDocument18 paginiU-BOOTS (1) Technical SeminarBasavaraj M PatilÎncă nu există evaluări

- EC2 Creep and Shrinkage LossesDocument9 paginiEC2 Creep and Shrinkage LossesSorin SavescuÎncă nu există evaluări

- Obnovuvanje Na Crkvata Bogorodica Perivlepta Ohrid. Preservation of The Church of The Holy Mother of God Perivlepta OhridDocument45 paginiObnovuvanje Na Crkvata Bogorodica Perivlepta Ohrid. Preservation of The Church of The Holy Mother of God Perivlepta OhridMartin DodiÎncă nu există evaluări

- Embuild BrochureDocument38 paginiEmbuild BrochureKawish TamourÎncă nu există evaluări

- House of C. Julius Polybius - AD79eruptionDocument6 paginiHouse of C. Julius Polybius - AD79eruptiond cornsÎncă nu există evaluări

- PRESSURE EQUIPMENT SAFETY ACTPart-1Part-8Document1 paginăPRESSURE EQUIPMENT SAFETY ACTPart-1Part-8AlenÎncă nu există evaluări

- Modulus of Resilience: 248 C H A P T E R 6 Mechanical Properties of Metals IDocument1 paginăModulus of Resilience: 248 C H A P T E R 6 Mechanical Properties of Metals IMattia MatrangaÎncă nu există evaluări

- Building Material The Arc MalaysiaDocument19 paginiBuilding Material The Arc MalaysiaJacqueline Tan100% (1)

- Poster Guangzhou CTFDocument3 paginiPoster Guangzhou CTFAlifia Ike PurwantiÎncă nu există evaluări

- S5 Tensile TestDocument7 paginiS5 Tensile Testdanial 95Încă nu există evaluări

- Torque Converter HousingDocument2 paginiTorque Converter HousingOecox Cah DjadoelÎncă nu există evaluări

- Boiler Operating Sequence-Rev1Document11 paginiBoiler Operating Sequence-Rev1Ran NÎncă nu există evaluări

- Type FP - Push-Up Service Door: Stainless Steel - Full Weatherstrip - Face of Wall MountedDocument2 paginiType FP - Push-Up Service Door: Stainless Steel - Full Weatherstrip - Face of Wall MountedSergio Romero GonzalezÎncă nu există evaluări

- Construction Specification 25-Rockfill: 1. ScopeDocument3 paginiConstruction Specification 25-Rockfill: 1. Scopehugo contreras munozÎncă nu există evaluări

- Engine Lubrication System GuideDocument28 paginiEngine Lubrication System GuideDaniel Velásquez 2Încă nu există evaluări

- Tos V Chapter 5 Stairacase Support Systems: Detailing OFDocument21 paginiTos V Chapter 5 Stairacase Support Systems: Detailing OFsmrutiÎncă nu există evaluări

- User ProfilesDocument77 paginiUser ProfilesVictor SeiculescuÎncă nu există evaluări

- Final IHCDocument7 paginiFinal IHCMuskan SinghÎncă nu există evaluări

- LF70PQ - Parts ManualDocument342 paginiLF70PQ - Parts Manualdp solutionsÎncă nu există evaluări