Documente Academic

Documente Profesional

Documente Cultură

MFT 2 and Emm

Încărcat de

sithananthansithuDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MFT 2 and Emm

Încărcat de

sithananthansithuDrepturi de autor:

Formate disponibile

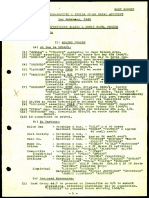

Engineering materials & metallurgy and Manufacturing Technology II

1. Guest theory is used for 1. Brittle materials 4. Plastic materials 2. Babbit metal is a 1. Lead base alloy 2.copper base alloy 3. Tin base alloy 2.ductile materials 3. Elastic materials

8. Malleable cast iron is produced 1. by adding magnesium to molten 2. By quick cooling of molten case iron 3. From white cast iron by annealing process 4. None of these 9. The cupola is used to manufacture 1. Cast iron 2. Mild steel 3. High speed steel 4. Cast tool steel 10. The atomic mass of sulphur is 1).12 2). 14 3). 16 4) 4 .32

4. Cadmium base alloy 3. A molecule consisting of one atom is known as 1. Monatomic 2.diatomic 3. Triatomic 4.polyatomic 12. The flux commonly used in brazing is 4. Extrusion 1. Zinc chloride 2. Ammonium chloride 13. The cold chisels are made by 1. Cast iron 2. Mild steel 3. High speed steel 4. Cast tool steel 14. Discontinues chips are formed during machining of 1. Brittle materials 2. Ductile metals 3. Hard materials 15. Ceramics tools are fixed to tool body by 1. Soldering 2. Brazing 3. Welding 4.clamping 4.soft materials 3. Rosin plus alcohol 4. Borax 11. The surface finish factor for a mirror polished material is 1).0.45 4. The process extensively used for making bolts and nuts is 1. Hot pressing 2.cold heading 3. Cold peening 2). 0.65 3). 0.85 4).1

5. The material which can be best cut with oxygen cutting process is 1. Mild steel 2. Brass 3. Copper 4. Aluminum

6. Shock resisting steels should have 1. Low wear resistance 2. Low hardness 3. Low tensile strength 4. Toughness 7. For the pipe fitting like elbow, tee, union etc., which of the following is preferred? 1. Pig iron 2. Malleable case iron 3. Spheroidal graphite case iron 4. High carbon steel

16. Tool signature consists of ---------- elements 1. Two 2. Six 3. Seven 4.eight

17. A mandrel is used to hold 1. An eccentric work 18. The guide ways are of 1. Flat type 2. Dovetail type 3. V type 19. Drilling is an example of 1. Orthogonal cutting 2. Oblique cutting 3. Simple cutting cutting 20. The operation smoothing and squaring the surface around a hole is known as 1. Spot facing 2.Counter boring 3. Counter sinking 21. Usually the values of helix angle of a drill is 1). 20 2). 30 3). 25 4). 45 4.Trepanning 4.Uniform 4.none of the above 2. A heavy work 3. Thin work 4.none of these

1. Metal removal rates are high 3. High form accuracy is obtained 25. The size of the shaper is given by 1. Stroke length size 26. Surface grinding is done to produce 1. tapered surface 4. All of these 27. The grinding operation is a 2. Flat surface 2. Motor power

2. High surface finish is obtained 4. High dimensional accuracy obtained

3. Mass of machine

4. Rate

3. Internal cylindrical surface

1. Shaping operation 2. Forming operation 4. Dressing operation 28. Buffing wheels are made of 1. Softer metals 2. Cotton fabric

3. Surface finishing operation

22. The cutting speed of a drill depends upon the 1. Material of drill drilled 4. All of these 23. A twist drill is specified by its 1. Shank, material and diameter 2.shank, lip angle and size of flute 3. Material, length of body and helix angle 4. Any one of these 2.Qulity of surface finish desired 3.Tybe of materials to be

3. Carbon

4. Graphite

29. Internal gears can be made by 1. Hobbing Shaping with pinion cutter 30. A process of removing metal by pushing or pulling a cutting tool is called 1. up milling 2. Down milling 3. Forming 4. Broaching 2. Milling 3. Shaping with rack cutter 4.

24. In reaming process

S-ar putea să vă placă și

- 2 MarksDocument12 pagini2 MarksHanurag GokulÎncă nu există evaluări

- Research ArticleDocument16 paginiResearch ArticlesithananthansithuÎncă nu există evaluări

- Research ArticleDocument14 paginiResearch ArticlesithananthansithuÎncă nu există evaluări

- A Deep Learning Approach Replacing The Finite Difference Method For in Situ Stress PredictionDocument12 paginiA Deep Learning Approach Replacing The Finite Difference Method For in Situ Stress PredictionsithananthansithuÎncă nu există evaluări

- 118 Prediction of Mechanical Properties of Fused DeposDocument10 pagini118 Prediction of Mechanical Properties of Fused DepossithananthansithuÎncă nu există evaluări

- Literature ReviewDocument10 paginiLiterature ReviewsithananthansithuÎncă nu există evaluări

- Smart Toilet SystemsDocument11 paginiSmart Toilet SystemssithananthansithuÎncă nu există evaluări

- Habilitation Thesis: Universitatea Transilvania Din BraşovDocument125 paginiHabilitation Thesis: Universitatea Transilvania Din BraşovsithananthansithuÎncă nu există evaluări

- The Fabrication of Long Carbon Fiber Reinforced Polylactic Acid Composites Via Fused Deposition Modelling: Experimental Analysis and Machine LearningDocument1 paginăThe Fabrication of Long Carbon Fiber Reinforced Polylactic Acid Composites Via Fused Deposition Modelling: Experimental Analysis and Machine LearningsithananthansithuÎncă nu există evaluări

- 2 16 Mark MechatranicsDocument118 pagini2 16 Mark MechatranicssithananthansithuÎncă nu există evaluări

- RSC Advances: ReviewDocument14 paginiRSC Advances: ReviewsithananthansithuÎncă nu există evaluări

- 2 Marks in MMDocument10 pagini2 Marks in MMsithananthansithuÎncă nu există evaluări

- Free Ta FEB 13 FreeDocument19 paginiFree Ta FEB 13 Freebhaskarrao01Încă nu există evaluări

- PRELIMINARY INTERVIEW BOARD TERRITORIAL ARMY COMMISSIONDocument4 paginiPRELIMINARY INTERVIEW BOARD TERRITORIAL ARMY COMMISSIONsithananthansithuÎncă nu există evaluări

- Am 13Document3 paginiAm 13Arun ManoÎncă nu există evaluări

- Ibps Cwe Pomt V 2015 EngDocument11 paginiIbps Cwe Pomt V 2015 EngSatyajit SwainÎncă nu există evaluări

- TestDocument4 paginiTestsithananthansithuÎncă nu există evaluări

- Krishnasamy: Lesson Plan - July 2013-October 2013Document2 paginiKrishnasamy: Lesson Plan - July 2013-October 2013sithananthansithuÎncă nu există evaluări

- Mantra PpsDocument21 paginiMantra PpsChanukya Krishna ChamaÎncă nu există evaluări

- Improving a sugarcane juice extractorDocument57 paginiImproving a sugarcane juice extractorsithananthansithu75% (4)

- SM Unit 1 and 2 Important QuestionDocument4 paginiSM Unit 1 and 2 Important QuestionsithananthansithuÎncă nu există evaluări

- Strength of MaterialsDocument21 paginiStrength of MaterialsSabaris KsÎncă nu există evaluări

- Vehicle Centre of GravityDocument10 paginiVehicle Centre of GravitysithananthansithuÎncă nu există evaluări

- Vehicle Centre of GravityDocument10 paginiVehicle Centre of GravitysithananthansithuÎncă nu există evaluări

- Research ArticleDocument15 paginiResearch ArticlesithananthansithuÎncă nu există evaluări

- Gear Calculations Rev3Document5 paginiGear Calculations Rev3ghostghost123Încă nu există evaluări

- Vehicle Centre of GravityDocument10 paginiVehicle Centre of GravitysithananthansithuÎncă nu există evaluări

- Exp-3 Shear TestDocument5 paginiExp-3 Shear TestHanamant HunashikattiÎncă nu există evaluări

- Energy Efficient Secure Ids Based Routing Sceheme in IdsDocument19 paginiEnergy Efficient Secure Ids Based Routing Sceheme in IdssithananthansithuÎncă nu există evaluări

- Review of Ic FabricationDocument45 paginiReview of Ic FabricationsithananthansithuÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Skytrain Avia Services: Emergency Procedures ManualDocument32 paginiSkytrain Avia Services: Emergency Procedures ManualEndro RastadiÎncă nu există evaluări

- Caso - Organizing Fo Innovation at GlenmarkDocument13 paginiCaso - Organizing Fo Innovation at GlenmarkGiancarlo RenzoÎncă nu există evaluări

- Supply Chain Management Practices in Unilever IndonesiaDocument10 paginiSupply Chain Management Practices in Unilever IndonesiaKaushik DuttaÎncă nu există evaluări

- CaseHard BS970-1955EN36ADocument2 paginiCaseHard BS970-1955EN36AtechzonesÎncă nu există evaluări

- Nota Cik Nab - TransportationDocument28 paginiNota Cik Nab - TransportationNoraishah IsaÎncă nu există evaluări

- Syllabus For 2nd Mate OralsDocument2 paginiSyllabus For 2nd Mate Oralsinkugeorge100% (1)

- Network PlanningDocument59 paginiNetwork PlanningVignesh ManickamÎncă nu există evaluări

- Traffic Report RAJUK Flyover DevConDocument161 paginiTraffic Report RAJUK Flyover DevConTahmidSaanidÎncă nu există evaluări

- Marine InsuranceDocument1 paginăMarine InsurancePeanutButter 'n JellyÎncă nu există evaluări

- Provident Kenworth Rajendra Nagar HyderabadDocument3 paginiProvident Kenworth Rajendra Nagar HyderabadProvident KenworthÎncă nu există evaluări

- Condition Inspection Report - RTO 27Document4 paginiCondition Inspection Report - RTO 27Nathan EngeÎncă nu există evaluări

- Rock Bolting Techniques and ApplicationsDocument17 paginiRock Bolting Techniques and ApplicationsMarkusMakuAldoÎncă nu există evaluări

- Dar (Em) 2016Document587 paginiDar (Em) 2016Ramraj Ramachandran75% (12)

- Weldlok Steel Grating-TSB2-PreferredDocument16 paginiWeldlok Steel Grating-TSB2-PreferredferryfÎncă nu există evaluări

- Import CalculationDocument2 paginiImport CalculationFearless SerenityÎncă nu există evaluări

- Eed AssignmentDocument8 paginiEed Assignmentfiola omowaleÎncă nu există evaluări

- Artigo David SmithDocument10 paginiArtigo David SmithandreaseveriÎncă nu există evaluări

- Fluxes For Welding and SurfacingDocument4 paginiFluxes For Welding and SurfacingVăn Trường LêÎncă nu există evaluări

- Self-regulating heating cables for frost protection and temperature maintenanceDocument2 paginiSelf-regulating heating cables for frost protection and temperature maintenanceyannaceckÎncă nu există evaluări

- Documents Governing Welding Inspection and QualificationDocument56 paginiDocuments Governing Welding Inspection and Qualificationtuvu100% (4)

- Top Glove - M. O. S. Unloading & Loading of 1560kWDocument4 paginiTop Glove - M. O. S. Unloading & Loading of 1560kWHaris IsmailÎncă nu există evaluări

- Email Address Roll Number Full Name Contact Number Course at DTUDocument14 paginiEmail Address Roll Number Full Name Contact Number Course at DTUritika singhÎncă nu există evaluări

- 01-28 - Feb - 1943 - Pacific and Indian Ocean Naval Activities PDFDocument237 pagini01-28 - Feb - 1943 - Pacific and Indian Ocean Naval Activities PDFEmmanuelleLizéÎncă nu există evaluări

- Technical Specification: External CladdingDocument36 paginiTechnical Specification: External Claddingalee0007Încă nu există evaluări

- Rock Creek West 2 Livability Study - Appendix DDocument43 paginiRock Creek West 2 Livability Study - Appendix DDistrict Department of TransportationÎncă nu există evaluări

- Term Paper (TALD)Document8 paginiTerm Paper (TALD)Azhar MarzukiÎncă nu există evaluări

- Presentation PAS223 PDFDocument17 paginiPresentation PAS223 PDFAhmedElSayedÎncă nu există evaluări

- ChatralDocument13 paginiChatralbharatÎncă nu există evaluări

- Optimize Operations with the Right LayoutDocument6 paginiOptimize Operations with the Right LayoutwearematalabiÎncă nu există evaluări

- T.Y.B.COM. ResultsDocument913 paginiT.Y.B.COM. ResultsROhan KaDamÎncă nu există evaluări