Documente Academic

Documente Profesional

Documente Cultură

Astm A105

Încărcat de

Betto ArriagaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Astm A105

Încărcat de

Betto ArriagaDrepturi de autor:

Formate disponibile

Quality

According to standards Number

ASTM A 105

ASTM A 105M - 05

Technical card

Lucefin Group

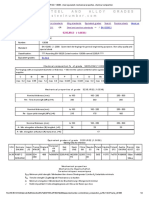

Chemical composition

C% max 0,35 Si% 0,10-0,35 Mn% 0,60-1,05 P% max 0,035 S% max 0,040 Cu% max 0,40 Ni% max 0,40 Cr% max 0,30 Mo% max 0,12 V% max 0,08 Nb% max 0,02

The sum of copper (Cu), chromium (Cr), nickel (Ni) and molybdenum (Mo) should not exceed 1,00% The sum of chromium (Cr) and molybdenum (Mo) should not exceed 0,32% For each reduction of 0,01% under max carbon value (0,35), it is admitted a 0,06% increase of manganese over its max value (1,05%) up to 1,35% On request, this steel grade may be supplied Calcium (Ca) treated Min Al content 0,020% (to be certified) Carbon Equivalent CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/ 15 max 0,47

Temperature C

Hot-forming 1150-850 Soft annealing 700 air cooling Normalizing . 843-927 air cooling Normalizing and Tempering 843-927 air 593 air Quenching 880-930 oil / polymer water Isothermal annealing 860 furnace cooling to 660, then air Tempering 593 air cooling Stress-relieving 50 under the temperature of tempering Pre-heating welding 250 AC1 Stress-relieving after welding (PWHT) 590 furnace cooling MS Mf

AC3

Mechanical properties

Forged values as reference Heat treatments must guarantee the reported values ASTM A 105M - 05 all dimension Testing at room temperature (longitudinal) mm R Rp 0.2% A% L A% T C% L C% T N/mm2 min N/mm2 min. min. min. min. min. T 485 250 22 30 Forged over 4540 Kg may be ordered according to ASTM A 266/A 266M 03a all dimension R Rp 0.2% A% A% T mm N/mm2 min. min. min. N/mm2 T 415-585 205 23 20 T= max heat-treated thickness. Test specimen should correspond to the T Minimum values at high temperatures Rp 0.2 N/mm2 248 228 C 38 93 219 149 212 204 A % 30 32.4 39.2 35.6 28.0 202 260 C-Z % 69.5 63.8 69.0 68.6 63.0 Kv 0 C J 56-64-57 111-136-133 181-222-220 210-203-207 20-18-18

U.K. B.S.

Kv J min.

HB max 187

C% L min. 38

C% T min. 30

Kv J min.

HB 121-170

190 316

184 343

178 371

Mechanical properties ( longitudinal testing) LUCEFIN experience Heat treatment product test at R Rp 0.2 mm C N/mm2 N/mm2 Normalizing 920 C 90 +20 603 485 Normalizing 920 C 90 +400 312 217 Normalizing 900 C 240 +20 578 417 Normalizing 900 C 240 +400 506 248 Normalizing 900 C 400 +20 470 309 Normalizing 900 C 400 +400 424 206 Quenched end tempered 95 +20 579 403 Quenched and tempered 95 +400 520 325 Natural 90 +20 580 400

EUROPE EN ITALY UNI CHINA GB GERMANY DIN C21

Kv -18 C Kv -46 C product J J Hot-rolled Hot-rolled Hot-rolled Hot-rolled Forged Forged Hot-rolled Hot-rolled 14-12-12 10-8-8 Hot-rolled

RUSSIA GOST 20G USA AISI/SAE A 105

FRANCE AFNOR

S-ar putea să vă placă și

- Din 17100Document4 paginiDin 17100Sheby SandyÎncă nu există evaluări

- C45 STD PDFDocument2 paginiC45 STD PDFJeetu GosaiÎncă nu există evaluări

- Hardox 500 PDFDocument2 paginiHardox 500 PDFMustafa Mahmoud ElsayedÎncă nu există evaluări

- C43Document1 paginăC43rudramansingh123Încă nu există evaluări

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 paginiA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrÎncă nu există evaluări

- ASTM A213 T22 ASME SA213 T22 Specification - 3 PDFDocument6 paginiASTM A213 T22 ASME SA213 T22 Specification - 3 PDFbagus asmoroÎncă nu există evaluări

- ASTM A572 Grade 50 Plate: AnalysisDocument2 paginiASTM A572 Grade 50 Plate: Analysisdaniel moreno jassoÎncă nu există evaluări

- ASTM Standards for Steel Pipes, Tubes and FittingsDocument7 paginiASTM Standards for Steel Pipes, Tubes and FittingsHtet Aung ZayÎncă nu există evaluări

- Astm A192 Asme Sa192 PDFDocument4 paginiAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- Nanotech PaintingDocument16 paginiNanotech Paintingkr_abhijeet72356587Încă nu există evaluări

- Nip Material ComparsionDocument1 paginăNip Material ComparsionRob WillestoneÎncă nu există evaluări

- Hastelloy B2 Alloy B2 UNS N10665 DIN 2.4617Document3 paginiHastelloy B2 Alloy B2 UNS N10665 DIN 2.4617SamkitÎncă nu există evaluări

- Prochem Ball ValvesDocument5 paginiProchem Ball Valvesmd_taheriÎncă nu există evaluări

- MaterialsDocument1 paginăMaterialsakv030011Încă nu există evaluări

- Stainless Steel 316Document1 paginăStainless Steel 316Bungsu ZamzamÎncă nu există evaluări

- DIN Flange 2502-2503 PDFDocument2 paginiDIN Flange 2502-2503 PDFHeru Agus SetyawanÎncă nu există evaluări

- European Steel and Alloy Grades: S235JRG2 (1.0038)Document2 paginiEuropean Steel and Alloy Grades: S235JRG2 (1.0038)farshid KarpasandÎncă nu există evaluări

- Item 13. Codo SCH-80 A234 - 783Document1 paginăItem 13. Codo SCH-80 A234 - 783ELMER CHILON MINCHANÎncă nu există evaluări

- Toriconical Head 87 PsiDocument2 paginiToriconical Head 87 PsiFabio Augusto Hincapie HenaoÎncă nu există evaluări

- Material Comparisons For Astm and JisDocument2 paginiMaterial Comparisons For Astm and JisNitesh GargÎncă nu există evaluări

- Catalogue of SteelDocument4 paginiCatalogue of SteelIswar Rauf Aboo 'AqilahÎncă nu există evaluări

- SS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Document3 paginiSS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Harish AmpoluÎncă nu există evaluări

- ASTM A194 A194M 2022 InglesDocument3 paginiASTM A194 A194M 2022 InglesErickÎncă nu există evaluări

- Astm A759Document4 paginiAstm A759Laziz AtmaniÎncă nu există evaluări

- Virgo Trunnion Ball ValveDocument16 paginiVirgo Trunnion Ball ValveKamalÎncă nu există evaluări

- ASTM 재질분류표Document106 paginiASTM 재질분류표오덕환Oh Duckhwan100% (1)

- COMPARISON OF MATERIAL STANDARDS FOR TUBESDocument1 paginăCOMPARISON OF MATERIAL STANDARDS FOR TUBESRaja HoneÎncă nu există evaluări

- 1 7335Document5 pagini1 7335stamatsÎncă nu există evaluări

- Propiedades Grado 50 A572Document2 paginiPropiedades Grado 50 A572daniel moreno jassoÎncă nu există evaluări

- QT 16Cr PDFDocument1 paginăQT 16Cr PDFYaroslav RuizÎncă nu există evaluări

- 6 DIN FlangesDocument12 pagini6 DIN FlangessalimmalmaliÎncă nu există evaluări

- ST 35.8 (Germany / DIN) : Material PropertiesDocument3 paginiST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiÎncă nu există evaluări

- Equivalent Material Cross Valve CastDocument2 paginiEquivalent Material Cross Valve CastsviswaÎncă nu există evaluări

- Steel Data ChartDocument2 paginiSteel Data Chartsmartcad60Încă nu există evaluări

- Astm A105Document1 paginăAstm A105Isaac SamuelÎncă nu există evaluări

- ASTM A536 Ductile Iron Castings Tensile RequirementsDocument1 paginăASTM A536 Ductile Iron Castings Tensile RequirementsTheOne Yasir100% (1)

- ANSI B 16.48 Flange Dimensions for Class 150, 300 and 600Document3 paginiANSI B 16.48 Flange Dimensions for Class 150, 300 and 600l kishoreÎncă nu există evaluări

- ASTM A192, ASME SA192 American StandardDocument1 paginăASTM A192, ASME SA192 American StandardXamir Suarez AlejandroÎncă nu există evaluări

- CD4 PDFDocument1 paginăCD4 PDFMayrym Rey ConÎncă nu există evaluări

- Materials Guide for Over 50 AlloysDocument8 paginiMaterials Guide for Over 50 AlloysMark RomeroÎncă nu există evaluări

- Astm A148Document2 paginiAstm A148raghumnÎncă nu există evaluări

- SS2205 Material SpecificationDocument4 paginiSS2205 Material SpecificationCh FaiÎncă nu există evaluări

- Saramet AlloyDocument2 paginiSaramet AlloyjeffconnorÎncă nu există evaluări

- Engineering Steels 1018 Product GuideDocument2 paginiEngineering Steels 1018 Product GuidejangaswathiÎncă nu există evaluări

- ASTM A633 GR E Data Sheet 2012 04 01Document2 paginiASTM A633 GR E Data Sheet 2012 04 01FrancescoGuglielmo100% (1)

- Astm A106 Ts EnglDocument4 paginiAstm A106 Ts EnglxaviereduardoÎncă nu există evaluări

- Astm 464 Alloy PDFDocument2 paginiAstm 464 Alloy PDFRaul MoyaÎncă nu există evaluări

- Fitting - ASTM A 197Document4 paginiFitting - ASTM A 197yajuÎncă nu există evaluări

- Chemical DetailsDocument3 paginiChemical Detailsemmas18Încă nu există evaluări

- AWS Welding Journal November 2013Document239 paginiAWS Welding Journal November 2013ferrero68Încă nu există evaluări

- Astm A-194-NutsDocument3 paginiAstm A-194-NutsDavid Luna MolinaÎncă nu există evaluări

- SWRCH18A Steel DatasheetDocument2 paginiSWRCH18A Steel DatasheetHari SuthanÎncă nu există evaluări

- Annex H (Summary API 650) : 1. MaterialDocument6 paginiAnnex H (Summary API 650) : 1. MaterialnjkasdncjkdÎncă nu există evaluări

- CRANE-Ficha Tecnica-Valvula CompuertaDocument1 paginăCRANE-Ficha Tecnica-Valvula CompuertaWillyam JiménezÎncă nu există evaluări

- Quality: Astm A 105Document1 paginăQuality: Astm A 105lavius_mÎncă nu există evaluări

- 1 4571a316ti69Document2 pagini1 4571a316ti69Admir TalicÎncă nu există evaluări

- 1330 Crni Mo 831Document2 pagini1330 Crni Mo 831sajay_suryaÎncă nu există evaluări

- 1 4305a30365Document2 pagini1 4305a30365skidanjeÎncă nu există evaluări

- Astm A350 LF2Document1 paginăAstm A350 LF2anjangandak2932100% (1)

- 1.4125 440c PDFDocument2 pagini1.4125 440c PDFsuntansueÎncă nu există evaluări

- Mock Tests 20 20 Class 9 Science SampleDocument13 paginiMock Tests 20 20 Class 9 Science SamplesrilathaÎncă nu există evaluări

- Physics SL Paper 3 TZ2Document20 paginiPhysics SL Paper 3 TZ2Dongjean SeoÎncă nu există evaluări

- Lab 3 - Intro To DynamicDocument36 paginiLab 3 - Intro To DynamicRacheal KirbyÎncă nu există evaluări

- Total Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceDocument5 paginiTotal Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceJesus Gonzalez GracidaÎncă nu există evaluări

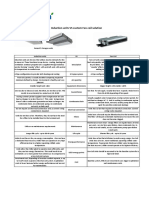

- HotelSolution: Induction Units VS Fan-Coil SolutionDocument1 paginăHotelSolution: Induction Units VS Fan-Coil SolutionMoriyasu NguyenÎncă nu există evaluări

- Weather in Kuttiadi - Google SearchDocument1 paginăWeather in Kuttiadi - Google Searchsorry Its My StyleÎncă nu există evaluări

- Fluidized Bed CombustionDocument600 paginiFluidized Bed Combustionvikasnar100% (7)

- Magnetic Field Intensity (H)Document5 paginiMagnetic Field Intensity (H)M HASIN ISHMAM JEETÎncă nu există evaluări

- Abdel Jawad 2005Document8 paginiAbdel Jawad 2005Alberto Tupa OrtizÎncă nu există evaluări

- Text - Anuario Cader 2018 INGLÉS PDFDocument57 paginiText - Anuario Cader 2018 INGLÉS PDFmicaelaÎncă nu există evaluări

- The Second Term Exam of EnglishDocument2 paginiThe Second Term Exam of Englishsof chimiste100% (1)

- Kinematics of Machinery: Motion and AnalysisDocument29 paginiKinematics of Machinery: Motion and AnalysisShashank SinghÎncă nu există evaluări

- HP Officejet Pro X476 X576 TroubleshootingDocument152 paginiHP Officejet Pro X476 X576 Troubleshootingjason7493Încă nu există evaluări

- About The Company: Machined and Forged ComponentsDocument18 paginiAbout The Company: Machined and Forged ComponentsankitÎncă nu există evaluări

- Transmision de Potencia NewDocument12 paginiTransmision de Potencia NewGustavo ArmellaÎncă nu există evaluări

- Overview Aerodynamics 2017Document10 paginiOverview Aerodynamics 2017marcoÎncă nu există evaluări

- Introducing JiFi ST Petersburg 2014Document4 paginiIntroducing JiFi ST Petersburg 2014danjohhnÎncă nu există evaluări

- Rebound Hammer Test Procedure For Concrete HardnessDocument4 paginiRebound Hammer Test Procedure For Concrete HardnessSite Engineer.2p2Încă nu există evaluări

- Docking With ArgusLabDocument24 paginiDocking With ArgusLabDesmond MacLeod Carey100% (1)

- 2019 Hydropower Status Report 0Document56 pagini2019 Hydropower Status Report 0Titos Nicosio ComéÎncă nu există evaluări

- Complex Numbers: BY Shreya Kuchhal Darshika Kothari Riya Gupta Simran SardaDocument18 paginiComplex Numbers: BY Shreya Kuchhal Darshika Kothari Riya Gupta Simran Sardasimran sardaÎncă nu există evaluări

- 02 Jaulas de Agujas PDFDocument52 pagini02 Jaulas de Agujas PDFRodrigo Schaider Dos SantosÎncă nu există evaluări

- Flux 10 4 New Features Presentation ValideDocument22 paginiFlux 10 4 New Features Presentation ValideleelÎncă nu există evaluări

- Light SourcesDocument5 paginiLight Sources123vidyaÎncă nu există evaluări

- The Theory of Engineering DrawingDocument370 paginiThe Theory of Engineering Drawingcocotess100% (1)

- Basic ShapesDocument11 paginiBasic Shapeschristopher templar100% (1)

- Shoot For Your Grade Lab Write UpDocument5 paginiShoot For Your Grade Lab Write Upapi-254812059Încă nu există evaluări

- Waste Incineration Insert v2Document2 paginiWaste Incineration Insert v2Namik HadziibrahimovicÎncă nu există evaluări

- Distribution System HandbookDocument346 paginiDistribution System HandbookAyan Mandal100% (2)

- Schrodinger Equation DerivationDocument12 paginiSchrodinger Equation DerivationAndrés López Martínez100% (1)