Documente Academic

Documente Profesional

Documente Cultură

TM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part1

Încărcat de

browar444Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part1

Încărcat de

browar444Drepturi de autor:

Formate disponibile

* TM 9-1005-301-30 Technical Manual No.

9-1005-301-30

HEADQUARTERS, DEPARTMENT OF THE ARMY WASHINGTON, D.C., 20 October 1970

DIRECT SUPPORT MAINTENANCE MANUAL REPAIR OF WOODEN, FIBER GLASS/PLASTIC OR PLASTIC COMPONENTS OF SMALL ARMS WEAPONS

Paragraphs CHAPTER CHAPTER Section 1. 2. I. II. 3. I. II. III. IV. INTRODUCTION ....................................................................................1-1, 1-3 DIRECT SUPPORT MAINTENANCE INSTRUCTIONS Repair materials, tools and equipment ................................................... 2-1,2-2 Inspection procedures ....................................................................................2-3 REPAIR INSTRUCTIONS General maintenance ........................................................................... 3-1, 3-3 Repair of wooden components ............................................. .............. 3-4, 3-10 Repair of fiber glass/plastic or plastic components ........................... 3-11, 3-16 Fitting procedures for wooden, fiber glass/ plastic or plastic components.................................................................. 3-17, 3-18 REFERENCES.......................................................................................A-1, A-4

Page 3

5,6 6, 7

CHAPTER Section

9 9, 16 17,24 25, 26 27, 28

APPENDIX

This copy is a reprint which includes current pages from Changes 1 and 2

* This manual supersedes TM 9-1005-301-30, 21 October 1968, including changes. 1/ (2 blank)

Changes in Force C1, C2 CHANGE No. 2

TM 9-1005-301-30 C2 HEADQUARTERS DEPARTMENT OF THE ARMY WASHINGTON, DC, 18 April 1986

DIRECT SUPPORT MAINTENANCE MANUAL REPAIR OF WOODEN, FIBERGLASS/PLASTIC OR PLASTIC COMPONENTS OF SMALL ARMS WEAPONS

TM 9-1005-301-30, 20 October 1970, is changed as follows: Page 6, paragraph 2-3 is changed to add subparagraphs a. through d. a. Refer to figure 2-3.2. b. Under the following conditions, hairline cracks (no chipped away material allowed) originating from the buttplate end of the buttstock are acceptable without repair. 1. One hairline crack, not to exceed one inch in length, per side of buttstock. 2. Two additional hairline cracks up to .22 inch in length, per side of buttstock. 3. A total of three cracks per side of the buttstock, originating from the buttplate end, are allowable without repair. Page 7. Figure 2-3.2 is added. c. Buttstocks with cracks originating from the buttplate end of the buttstock, but not meeting the above criteria, may be repaired if the cracks are not longer than two and one-half inches in length and if the routed width of the unfilled crack is not greater than .125 inch. No more than two cracks may be filled on each side of the buttstock. In addition to these repaired cracks two hairline cracks up to .22 inch in length are allowed per side of the buttstock. d. Cracks in the critical area at the front end of the buttstock are not acceptable. Buttstocks with cracks in this area must be replaced.

NEW STYLE BUTTSTOCK

Figure 2-3.2 (Added). Critical areas of fiber glass/plastic stocks (M16, M16A1 Rifles).

By Order of the Secretary of the Army:

JOHN A. WICKHAM, JR. General, United States Army Chief of Staff Official:

R. L. DILWORTH Brigadier General, United States Army The Adjutant General DISTRIBUTION: To be distributed in accordance with DA Form 12-40, Direct Support and General Support Maintenance requirements for Launcher, Grenade, 40-WI, M79; Rifle, 5.56-MM, M16, M16A1 and Rifle, 7.62-MM, National Match, M14 and M14A1.

Changes in force C1 CHANGE No. 1

TM 9-1005-311-30 C1 HEADQUARTERS DEPARTMENT OF THE ARMY WASHINGTON, D.C., 25 June 1971

DIRECT SUPPORT MAINTENANCE MANUAL REPAIR OF WOODEN, FIBER GLASS/PLASTIC OR PLASTIC COMPONENTS OF SMALL ARMS WEAPONS TM 9-1005-301-30, 20 October 1970 is changed as follows: Page 7. Delete figure 2-3, WE 64787A and substitute figure 2-3, WE 64787A.

Figure 2-3 (Superseded) Critical areas of fiber glass/ plastic stocks and hand guards (M16, M16A1 Rifles).

1

WE 68863

Figure 2-3.1 (Added) Critical areas of fiber glass plastic stocks (M16. M16A1 Rifles). Page 18. Delete figure 3-10, WE 64788A and substitute figure 3-10, WE 64788A.

Figure 3-10 (Superseded) Non-repairable damage to fiber glass/plastic stock assemblies.

2

Figure 3-10.1 (Added) Non-repairable damage to fiber glass/plastic stock assemblies.

3

Page 21. Delete figure 3-15, WE 64790A and substitute figure 3-15, WE 64790A.

Figure 3-15 (Superseded) Repairable fiber glass/ plastic stock assemblies.

Figure 3-15.1 (Added) Repairable fiber glass/ plastic stock assemblies.

By Order of the Secretary of the Army: W. C. WESTMORELAND, General, United States Army, Chief of Staff.

Official:

VERNE L. BOWERS, Major General, United States Army, The Adjutant General. DISTRIBUTION:

To be distributed in accordance with DA Form 1240, Direct/General Support requirements for Carbine, Cal. .30, M1, M2; Grenade launcher, M79; Rifle, Cal..30, M1; Rifle, 5.56-mm, M16, M16A1 and Rifle, 7.62-mm, M14 and M14A1.

TM 9-1005-301-30 CHAPTER 1 INTRODUCTION 1-1. Scope These instructions are in accordance with various military standards governing the repair and reinforcement of wooden, fiber glass/ plastic or plastic components for small arms weapons and are published for the use of direct support maintenance personnel. 1-2. Maintenance Forms and Records Maintenance forms, records, and reports which are to be used by maintenance personnel at all maintenance levels are listed in and prescribed by TM 38-750, The Army Maintenance Management System (TAMMS). 1-3. Reporting of Errors

Report of errors, omissions, and recommendations for improving this publication by the individual user is encouraged. Reports should be submitted on DA Form 2028 (Recommended Changes to DA Publications) and forwarded direct to: Commanding General, U.S. Army Weapons Command, ATTN: AMSWE-SMM-P, Rock Island, Illinois 61201.

3 / (4 blank)

TM 9-1005-301-30 CHAPTER 2 DIRECT SUPPORT MAINTENANCE INSTRUCTIONS Section I. REPAIR MATERIALS, TOOLS AND EQUIPMENT 2-1. Repair Materials 222-35, TM 9-1005-249-34 and TM 9-1010-20534 for requisitioning purposes.

a. Authorized Materials. Refer to table 2-1 for listing authorized materials and TM 9-1005 Table 2-1. Authorized Materials Required for Repair and/or Reinforcement of Wooden and Plastic / Fiber Glass Components of Small Arms Weapons FSN Item Purpose Reference 1005-523-3523 Screw: (large) Used to repair cracks in wooden stocks or Fig 3-4 hand guards. 1005-719-0954 Screw, Stock Repair, Small: Used to repair cracks in wooden stocks or Fig 3-4 hand guards. 6640-171-5198 Spatula Laboratory: 4 in blade, Used to mix resin and hardener and to apply to wooden and plastic components. 73/8 Ig 6810-244-0290 Dichloromethane, Thenical: 5 gal Used to remove excess adhesive and to clean pail tools and equipment of adhesive. 6850-281-1985 Dry Cleaning Solvent: Cleaning. Para 3-14b(1) (SD) and 3-16 7330-272-7876 Measuring Set, Spoon: 4 spoons Used to measure required quantity of resin and hardener (liquid only) 7350-290-0577 Cup, Paper: rd 5 oz capacity Used for mixing epoxical resin and hardener (liquid only) 8010-527-2884 Lacquer: Black (jet) Used to refinish M16 and M16A1 stocks and hand guards. 8030-145-0042 Coating, Baking: Used to touch up M14 Rifle and M79 Grenade Launcher fiber glass/plastic stocks only. 8030-670-8553 Compound, Molding: Same purpose as listed for metal adhesive kit. 8040-944-7292 Adhesive Kit, Metal: A-4 Metal Used to repair cracks, dents and gouges in set wooden, fiber glass / plastic and / or plastic stocks and hand guards. CAUTION Follow the manufacturers mixing directions as adding too much hardener will cause mixture to harden quickly and material will be wasted.

of

b. Non-Stock Commercial Materials. Refer to table 2-2. Table 2-2. Non-Stock Materials Required for Repair of Wooden, Fiber Glass / Plastic or Plastic Components Item Purpose Commercial grade epoxical resin (liquid) (1 gal can) and Mixed with epoxical hardener in accordance with Commercial grade epoxical hardener (liquid) (1 qt can) manufacturers instructions to form resin mixture which is used to repair fiber glass / plastic or plastic; stocks and plastic hand guards. NOTE CAUTION The above materials are not stocked or Follow the manufacturers mixing stored due to limited shelf life and are to be directions as adding too much hardener procured locally. will cause mixture to harden quickly and material will be wasted. Fiber glass tape, 1 /2 inch wide and 105 inches long (roll) Used with epoxical resin mixture to repair stocks, M14 Rifle only.

5

TM 9-1005-301-30 2-2. Tools and Equipment components are authorized in applicable TO&Es or TAs.

All tools and equipment required to repair or reinforce wooden, fiber glass/plastic or plastic

Section II. INSPECTION PROCEDURES 2-3. General one-half inches or less in length in the receiver will not be cause for rejection. However, rifle stocks will be rejected if hairline cracks cited, cross one another or two or more cracks extend from a central location. Rifle stocks exhibiting five or more hairline cracks on any one side will be rejected.

Refer to TB 9-1000-247-35 and figures 2-1 thru 2-4. NOTE M14 Rifle fiber glass stocks exhibiting vertical, horizontal, or diagonal hairline cracks one and

Figure 2-1. General inspection areas of shoulder stocks (M14 Rifle).

Figure 2-2. Inspection areas of fiber glass / plastic stocks (M79 Grenade Launcher).

6

TM 9-1005-301-30 CRITICAL AREA

Figure 2-3. Critical areas of fiber glass/ plastic stocks and hand guards (M16, M16A1 Rifles).

Figure 2-4. Types of repairable damage to wooden hand guards.

7/ (8 blank)

TM 9-1005-301-30 CHAPTER 3 REPAIR INSTRUCTIONS Section I. GENERAL MAINTENANCE Weapon Publication Rifle, Cal. .30, M1, M1C (Snipers) and TM 9-1005-22235 MID (Snipers) Rifle, 7.62-MM, M14 and M14A1 TM 9-1005-223-35 Rifle, 5.56-MM, M16 and M16A1 TM 9-1005-249-34 Launcher, Grenade, 40-MM, M79 TM 9-1010-205-34 3-3. Selection of Type of Repair or Reinforcement

3-1. General This chapter provides instructions on direct support procedures for repairing or reinforcing wooden, fiber glass / plastic or plastic components. 3-2. Disassembly Procedures Groups or assemblies will be disassembled in accordance with applicable publications listed below: Weapon Carbine, Cal..30, M1 and M2 Rifle, Cal..30, Automatic Browning, M1918A2 Publication TM 9-1005-210-35 TM 9-1005-208-35

Selection of the type of repair or reinforcement to be used for unserviceable components must be made on an item basis, when the weapon is inspected at the direct support maintenance shop.

Section II. REPAIR OF WOODEN COMPONENTS 3-4. General damaged area will require the use of epoxy adhesive, reinforcing screws or both. 3-5. Non-Repairable Areas Refer to figure 3-1.

The repair of wooden components by using brass reinforcing screws and / or epoxy adhesive is authorized at direct support maintenance. The small arms repairman will determine if the

TM 9-1005-301-30

Figure 3-1. Types of non-repairable damage to wooden stocks.

10

TM 9-1005-301-30 3-6. Repairable Areas Refer to figures 3-2 and 3-3.

Figure 3-2. Types of repairable damage to wooden stocks. (1 of 2)

11

TM 9-1005-301-30

Figure 3-3. Types of repairable damage to wooden stocks. (2 of 2)

12

TM 9-1005-301-30 3-7. Procedure for Installing Reinforcing Screws

a. Generally, the large reinforcing screw is satisfactory for repairing thick cracks on wooden stocks. The small reinforcing screw should be used for repairing thin cracks on wooden stocks and hand guards. b. Refer to figures 3-2 and 3-3 to determine if screws can be used to repair component. (When epoxical adhesive and screws are both used, refer to paragraph 3-8c thru f.)

c. Place component on smooth, flat surface. Drill screw holes as required. Use No. 55 drill (0.052 in.) for small screw 7190954 and No. 46 drill (0.081 in.) for large screw 5233523. d. Install applicable screw by gripping in the chuck of a hand drill and insert in component being repaired (fig 3-4).

NOTE If a hand drill is not available, use pliers.

Figure 3-4. Repairing damaged wooden stocks using reinforcing screws.

13

TM 9-1005-301-30 e. Cut off screw and file flush so rough edges do not protrude. 3-8. Repairing Damaged Wooden Components Using Epoxy Adhesive

a. Place component in a vise. Use a wooden block to prevent item from being damaged. b. Clean crack of dirt and grease.

c. Proceed with repair as indicated in figure 3-5. The method of spreading the crack prior to inserting the adhesive is the same on all weapons having wooden stocks. d. Remove excess adhesive. e. Keep separated areas tight in the vise until adhesive hardens.

Figure 3-5. Repairing damaged, wooden stocks with epoxy adhesive (M1, M2 Carbines, M1, M14 Rifles and M79 Grenade Launcher). f. Repair wooden hand guards (fig 3-6). Hand guards can be repaired using epoxy adhesive and / or brass reinforcing screws. Unless the separation is extreme, epoxy adhesive alone will

14 suffice to affect the repair of all hand guards, providing adequate clamping facilities are available.

S-ar putea să vă placă și

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.De la EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Evaluare: 5 din 5 stele5/5 (1)

- GG2 Operator's ManualDocument30 paginiGG2 Operator's ManualWerner Patric WengÎncă nu există evaluări

- 9mm Bolt RampingDocument6 pagini9mm Bolt RampingMatthew Nelson100% (1)

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesDe la EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesÎncă nu există evaluări

- M1 Garand Barrel Replacement  " New BarrelDocument35 paginiM1 Garand Barrel Replacement  " New BarrelToschanoÎncă nu există evaluări

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationDe la EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationÎncă nu există evaluări

- M1-M14 Conversion US3362095Document3 paginiM1-M14 Conversion US3362095apoorva singhÎncă nu există evaluări

- Practical Guide to the Operational Use of the PPS-43 Submachine GunDe la EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunÎncă nu există evaluări

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsDe la EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsÎncă nu există evaluări

- Churchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneDe la EverandChurchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneÎncă nu există evaluări

- AR-7 Henry Repeating Arms Semi Auto 22LR Brochure PDFDocument1 paginăAR-7 Henry Repeating Arms Semi Auto 22LR Brochure PDFLeonel Montilla100% (1)

- Tap & Drill Chart W - Decimal Inch & MetricDocument10 paginiTap & Drill Chart W - Decimal Inch & MetricGanesh NatarajanÎncă nu există evaluări

- ChicopeerfDocument15 paginiChicopeerfRomG78Încă nu există evaluări

- A MAC History LessonDocument11 paginiA MAC History Lessonlopezm93Încă nu există evaluări

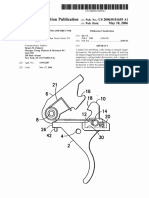

- Us 20060101695Document11 paginiUs 20060101695galak12001100% (1)

- Installing An External Bolt Stop/Release On A Remington 700Document10 paginiInstalling An External Bolt Stop/Release On A Remington 700M Poveda0% (1)

- UZI PRO Pistol Operator Manual 08 011 05 09 30 - 1Document60 paginiUZI PRO Pistol Operator Manual 08 011 05 09 30 - 1Ricardo C TorresÎncă nu există evaluări

- Sten Plans The Sten MkiiDocument28 paginiSten Plans The Sten MkiiJohn FindleyÎncă nu există evaluări

- DeLisle Commando Carbine PDFDocument46 paginiDeLisle Commando Carbine PDFSILVERPALADINÎncă nu există evaluări

- 180 Misc .DXFDocument392 pagini180 Misc .DXFNester Tovar0% (1)

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsDe la EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsÎncă nu există evaluări

- AKT020 Rivet Jaws InstructionsDocument12 paginiAKT020 Rivet Jaws InstructionsDale WadeÎncă nu există evaluări

- Ti25 Advanced Composite Steel Lip Magazine For Ruger 10 - 22 byDocument3 paginiTi25 Advanced Composite Steel Lip Magazine For Ruger 10 - 22 byarizona212Încă nu există evaluări

- Tube Selection ChartDocument6 paginiTube Selection Chartjkruise100% (1)

- AMT LightningDocument9 paginiAMT LightningJustinÎncă nu există evaluări

- 1917 1911m Walther p22 Pistol BibleDocument99 pagini1917 1911m Walther p22 Pistol Biblewilliam6arsenaultÎncă nu există evaluări

- GatlingDocument25 paginiGatlingcoldluckÎncă nu există evaluări

- Product Instructions - Flat Bending Jig InstructionsDocument34 paginiProduct Instructions - Flat Bending Jig InstructionsDale WadeÎncă nu există evaluări

- Novo (A) Documento Do Microsoft Office WordDocument7 paginiNovo (A) Documento Do Microsoft Office Wordyukarisuzumiha100% (1)

- Pressure Air GunDocument7 paginiPressure Air GunyuehanÎncă nu există evaluări

- Thompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866Document28 paginiThompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866johndone100% (1)

- Savage MKII Bolt Action RimfireDocument38 paginiSavage MKII Bolt Action RimfireCarl J. Wilkey100% (1)

- Making Your Own Rivets - The AK Files ForumsDocument7 paginiMaking Your Own Rivets - The AK Files Forumsscout50Încă nu există evaluări

- AK Builder Rivet Tool InstructionsDocument4 paginiAK Builder Rivet Tool InstructionsDale WadeÎncă nu există evaluări

- STEN / 76: 9mm Sub Machine Gun SuppressorDocument6 paginiSTEN / 76: 9mm Sub Machine Gun SuppressorIngo Quander100% (1)

- Hugo Schmeisser (Germany)Document4 paginiHugo Schmeisser (Germany)blowmeasshole1911Încă nu există evaluări

- Easy Jig Information - 80% ArmsDocument2 paginiEasy Jig Information - 80% Arms9fakeemailÎncă nu există evaluări

- Winchester Model 1885Document0 paginiWinchester Model 1885carlosfanjul1Încă nu există evaluări

- Remington 700 Adjustment Guide: Safety PlungerDocument2 paginiRemington 700 Adjustment Guide: Safety PlungerRod PhillipsÎncă nu există evaluări

- FE Analysis of Firearm Locking Systems: Lorenzo CastiglioniDocument15 paginiFE Analysis of Firearm Locking Systems: Lorenzo CastiglionijkruiseÎncă nu există evaluări

- A1 To A2Document45 paginiA1 To A2leeyangseopÎncă nu există evaluări

- GG3 Operators Manual Quickstart PDFDocument5 paginiGG3 Operators Manual Quickstart PDFRebecca MathewsÎncă nu există evaluări

- High Standard-MagazinesDocument3 paginiHigh Standard-MagazinesBob WilliamsÎncă nu există evaluări

- Page 18Document1 paginăPage 18frank1615100% (2)

- 870 Detent Staking PunchDocument1 pagină870 Detent Staking PunchZardoz10900% (1)

- Ruger's Old Army: Guns Magazine Feb, 2004 John TaffinDocument5 paginiRuger's Old Army: Guns Magazine Feb, 2004 John Taffinfalcon62Încă nu există evaluări

- The M14 Conversion To The M1 Garand: Version OneDocument13 paginiThe M14 Conversion To The M1 Garand: Version Oneleleva13Încă nu există evaluări

- How To Fix FAL Rifle Brass StrikesDocument3 paginiHow To Fix FAL Rifle Brass StrikesRalph_Shoop_2662100% (2)

- VZ 58 Military Manual PDFDocument42 paginiVZ 58 Military Manual PDFcasaka100% (1)

- Semiautomatic Rifle SharacDocument3 paginiSemiautomatic Rifle SharacOlegValÎncă nu există evaluări

- Hunting with Muzzleloading Shotguns and Smoothbore Muskets: Smoothbores Let You Hunt Small Game, Big Game and Fowl with the Same GunDe la EverandHunting with Muzzleloading Shotguns and Smoothbore Muskets: Smoothbores Let You Hunt Small Game, Big Game and Fowl with the Same GunÎncă nu există evaluări

- Tell Me Aboot - Building FALs From Parts Kits - AR15Document12 paginiTell Me Aboot - Building FALs From Parts Kits - AR15Pedro VianaÎncă nu există evaluări

- Brownells-2 5LB1911TriggerPullDocument4 paginiBrownells-2 5LB1911TriggerPullRyan ShanksÎncă nu există evaluări

- A 518298Document19 paginiA 518298browar444Încă nu există evaluări

- Beretta 38A 38-44 SMG Receiver BlueprintDocument1 paginăBeretta 38A 38-44 SMG Receiver Blueprinth762x39100% (4)

- MAC 10 CookbookDocument90 paginiMAC 10 Cookbookbrowar44472% (32)

- Stinger Rifles FamilyDocument7 paginiStinger Rifles Familybrowar44467% (9)

- M 1911 A 1Document62 paginiM 1911 A 1Michael C. Burgess88% (16)

- Home Workshop - Vol 5 - AR-15, M-16 - Bill Holmes - Paladin Press PDFDocument110 paginiHome Workshop - Vol 5 - AR-15, M-16 - Bill Holmes - Paladin Press PDFCarlaAndrade100% (2)

- Post-14-01138-M 14 Receiver Ordnance PrintsDocument5 paginiPost-14-01138-M 14 Receiver Ordnance PrintsJustus Pradana AdityawanÎncă nu există evaluări

- Ruger 10-22 Rifle Receiver 1 - BlueprintDocument1 paginăRuger 10-22 Rifle Receiver 1 - BlueprintAride4ever100% (3)

- Firearms - Blueprint - Owen MK II, H&R Reising Submachine Guns and Springfield M60 RifleDocument12 paginiFirearms - Blueprint - Owen MK II, H&R Reising Submachine Guns and Springfield M60 Riflebrowar44484% (19)

- PPSH41 Assault Rifle BlueprintDocument12 paginiPPSH41 Assault Rifle Blueprinth762x3992% (12)

- Ruger Mk1 Grip Frame Left Hole DetailDocument1 paginăRuger Mk1 Grip Frame Left Hole Detailbrowar444100% (1)

- Shotgun Based Pistol BlueprintDocument6 paginiShotgun Based Pistol BlueprintGonzoGranello0% (1)

- 223 Silencer DesignDocument1 pagină223 Silencer DesignFlavio MarçalÎncă nu există evaluări

- UZI SMG ReceiverDocument7 paginiUZI SMG Receiverbrowar444100% (7)

- Spring RatingDocument6 paginiSpring Ratingbrowar444Încă nu există evaluări

- TM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part2Document18 paginiTM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part2browar444Încă nu există evaluări

- SVT40 ManualDocument23 paginiSVT40 Manualandy2205Încă nu există evaluări

- UZI ReceiverDocument7 paginiUZI Receiverbrowar444100% (1)

- Metal Casting Basics Book 2Document67 paginiMetal Casting Basics Book 2browar444100% (2)

- Ruger Mk1 Grip Frame Left SideDocument1 paginăRuger Mk1 Grip Frame Left Sidebrowar444100% (1)

- Ruger Mk1 Right Side Grip FrameDocument1 paginăRuger Mk1 Right Side Grip Framebrowar444Încă nu există evaluări

- Metal Casting Basics Book 1Document57 paginiMetal Casting Basics Book 1browar444100% (1)

- Mac-10 SMG Lower-Upper Receiver - BlueprintsDocument2 paginiMac-10 SMG Lower-Upper Receiver - Blueprintsbrowar44489% (9)

- Nangant Pistol HistoryDocument67 paginiNangant Pistol Historygorlan100% (1)

- Full Auto Volume Three Semi Auto Mac 10 SMG Modification ManualDocument29 paginiFull Auto Volume Three Semi Auto Mac 10 SMG Modification ManualJerry Becraft85% (13)

- MAC-11 9mm Construction Conversion Iron Wulf PublishingDocument86 paginiMAC-11 9mm Construction Conversion Iron Wulf PublishingJordan Voller100% (6)

- MAC .45 ACP ReceiverDocument3 paginiMAC .45 ACP Receiverbrowar444100% (6)

- Machinist Drawings For SMG Frames - MAC10, MAC11, Cobray M11-9, CobrayM12Document13 paginiMachinist Drawings For SMG Frames - MAC10, MAC11, Cobray M11-9, CobrayM12Aride4ever89% (74)

- 361 Mac 10Document5 pagini361 Mac 10browar444100% (1)

- MAC .45 ACP Receiver & Mag HousingDocument3 paginiMAC .45 ACP Receiver & Mag Housingbrowar444Încă nu există evaluări

- Rubber Loc Cleaner A Methyl Ethyl Ketone M.E.K. Conveyor Belt Repair Kit V1 PDFDocument8 paginiRubber Loc Cleaner A Methyl Ethyl Ketone M.E.K. Conveyor Belt Repair Kit V1 PDFOscar Giovani SosaÎncă nu există evaluări

- Performance Appraisal Form: Part 1 Personal ParticularsDocument3 paginiPerformance Appraisal Form: Part 1 Personal ParticularsYoan LetsoinÎncă nu există evaluări

- Syllabus Income TaxationDocument10 paginiSyllabus Income TaxationValery Joy CerenadoÎncă nu există evaluări

- Wafer Check Valves - O&MDocument4 paginiWafer Check Valves - O&MjayakumarÎncă nu există evaluări

- Experiment-6 (Familiarization ofDocument3 paginiExperiment-6 (Familiarization ofacehabiniÎncă nu există evaluări

- 09 Quotation For CC Kerb PDFDocument2 pagini09 Quotation For CC Kerb PDFD V BHASKARÎncă nu există evaluări

- Tata Motors Anual Report 2016Document288 paginiTata Motors Anual Report 2016DwarikaÎncă nu există evaluări

- Ultrapad: Graphics Tablets For Cad and DTP ProfessionalsDocument4 paginiUltrapad: Graphics Tablets For Cad and DTP ProfessionalsOluwatomi AdewaleÎncă nu există evaluări

- Chapter 4 - Car MDocument239 paginiChapter 4 - Car MAshwani Kumar GuptaÎncă nu există evaluări

- Azeez Gupta BainCover LetterDocument1 paginăAzeez Gupta BainCover LetterShubhamGuptaÎncă nu există evaluări

- Omni Flow Computer 3000-6000Document2 paginiOmni Flow Computer 3000-6000syed jeelani ahmedÎncă nu există evaluări

- Hofstede's Cultural DimensionsDocument19 paginiHofstede's Cultural DimensionsbublusÎncă nu există evaluări

- Pumper March 2011 IssueDocument108 paginiPumper March 2011 IssuePumper MagazineÎncă nu există evaluări

- Te 2013 PDFDocument298 paginiTe 2013 PDFadu joshiÎncă nu există evaluări

- Bond Pricing and Bond Yield New - 1Document66 paginiBond Pricing and Bond Yield New - 1Sarang Gupta100% (1)

- Toshiba Air Conditioning Better Air Solutions: Dx-Coil Interface TrainingDocument57 paginiToshiba Air Conditioning Better Air Solutions: Dx-Coil Interface TrainingTín Nguyễn ThànhÎncă nu există evaluări

- Centrifugal Compressors: Renewal PartsDocument76 paginiCentrifugal Compressors: Renewal PartsHectorFalconLlenderrozos100% (1)

- IX Chem Mole Concept Kailash Khatwani FinalDocument8 paginiIX Chem Mole Concept Kailash Khatwani FinalAditya ParuiÎncă nu există evaluări

- Itron Meter Data Management With MicrosoftDocument4 paginiItron Meter Data Management With MicrosoftBernardo Mendez-aristaÎncă nu există evaluări

- 01 Six Sigma Methodology - Wisnu & SadonoDocument3 pagini01 Six Sigma Methodology - Wisnu & SadonojefrymedanÎncă nu există evaluări

- 14 - Press Release - DuravitFranke - enDocument2 pagini14 - Press Release - DuravitFranke - enSaran BaskarÎncă nu există evaluări

- M123SP Service ManualDocument57 paginiM123SP Service ManualJhonatan Diaz100% (1)

- Report HRTP Sanofi PakistanDocument13 paginiReport HRTP Sanofi PakistanANUS AHMED KHANÎncă nu există evaluări

- Multistage Flowsheets - SABC-2Document191 paginiMultistage Flowsheets - SABC-2lewis poma rojasÎncă nu există evaluări

- Income Tax Department: Computerized Payment Receipt (CPR - It)Document2 paginiIncome Tax Department: Computerized Payment Receipt (CPR - It)desaya3859Încă nu există evaluări

- Market Survey ResultsDocument5 paginiMarket Survey ResultsVaibhav BahetiÎncă nu există evaluări

- Ayala de Roxas v. MaglonsoDocument5 paginiAyala de Roxas v. MaglonsoJohn Rey FerarenÎncă nu există evaluări

- MACFOS Investors-PresentationDocument29 paginiMACFOS Investors-PresentationIDEasÎncă nu există evaluări

- Natural Ways To Avoid Bone Loss Around Teeth - HealthspanDocument1 paginăNatural Ways To Avoid Bone Loss Around Teeth - HealthspanRotariu AlexÎncă nu există evaluări

- Appointment Receipt FaizanDocument3 paginiAppointment Receipt Faizanmohammed faizanÎncă nu există evaluări