Documente Academic

Documente Profesional

Documente Cultură

Flow Hood - Steril Biohit Helios 72

Încărcat de

fjghfjghDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Flow Hood - Steril Biohit Helios 72

Încărcat de

fjghfjghDrepturi de autor:

Formate disponibile

Angelantoni Industrie S.p.A.

- Steril Division

Export Office Via Achille Grandi 16, 20017 Mazzo di Rho (MI) ITALY +39 02 939 701 43 / +39 02 939 701 21 Head Quarter Localit Cimacolle 464 06056 Massa Martana (PG) - ITALY +39 075 489551 +39 075 8955200

HELIOS C HORIZONTAL LAMINAR AIRFLOW CABINET

ARTICLE DESCRIPTION HELIOS 48 C HELIOS 72 C Introduction Helios are horizontal laminar airflow cabinets produced by Steril and designed for the situation where is requested the product protection from dangerous effects due to uncontrolled diffusion of air-transported contaminants from the environmental to the product during its handling. Applications Normally used in laboratory of microbiology and cell culture. Furthermore, used in innovative fields of scientific research and above all in the manipulation of: Quality Control in food industries Micro mechanical assembly Preparation of nutritional parentheral bags IVF CODE 00275400000 00277100000

Performances Product Protection Sterility in the working area higher than ISO 5 class according to ISO EN 14644-1 @ 0,3 and 0,5 m particles size (Class 100/M3.5 according to Federal Standard 209E) with a laminar air flow velocity of 0,40 m/s +/-20%. Since HELIOS is not a biosafety cabinet, it is not suitable for handling pathogens components. Norms and directives As far as electrical safety is concerned, the cabinet is manufactured according to EN 61010 norm and in particular: EN 292-1 EN 50082-2 EN 292-2 IEC 801-2 EN 61010-1 IEC 801-4 EN 50081-1 ENV 50140 EN 50082-1 ENV 50141 EN 50081-2

Furthermore it has been designed to fulfil the European Directives like: Machinery Directive 89/392/EEC, 91/368/EEC, 93/44/EEC, 93/68 EEC. Electromagnetic Compatibility Directive 89/336/EEC, 92/31/EEC, 93/68/EEC. The Masini Institute of Milan tested it and copy of the certification is available on request. Low voltage Directive 72/23/EEC, 93/68/EEC. IMPORTANT !! The cabinets we produce, according to the above statements, are manufactured in compliance with the laws on safety into force.

TD_HeliosC_08.doc Rev. Janyary 08

Particularly, they are manufactured in compliance with Art. 6 Dlgs 626/94 and its modification (Italian law in compliance with European Directive EEC/89/391) on the DUTY OF DESIGNERS, OF MANUFACTURERS, OF SUPPLIERS AND INSTALLATORS. The cabinets are NOT submitted to the directive EEC 93/42 on Medical Devices, as indicated in the definition of Medical Devices reported in art. 1 point 2a of the Directive mentioned. STERIL IS NOT responsible for damages to people and objects due to a non proper use of the cabinet, and due to a fail to comply with the user instructions and maintenance that are always supplied with the cabinets. Technical Specification Working surface in stainless steel AISI 304L 2B finishing with 15 mm lift (see picture). Side walls in toughened safety glass with 3 holes 19 mm diameter for the easy passage of external connection of fluids and/or cables without necessity of factory assembly. Lighting on working surface by means of 2 fluorescent lamps of 36W fitted in noncontaminated area for HELIOS 48 and 58W for HELIOS 72. Construction structure in steel epoxy-polyester powder coated, resistant to the most common industrial disinfectants. Ventilation system by means of n motor blower for HELIOS 48 dedicated to the 1 one-way airflow in the working chamber. HELIOS 72 is supplied with n 2 motor blowers in parallel way system The motor blower is centrifugal type, direct driven motor with double aspiration and protection factor IP55. Air filtration by means of disposable high retention capacity pre-filters and H14 HEPA filters with efficiency 99,995% MPPS according to EN 1822 (99,999% tested with DOP @ 0,3 m). Protection grid, for HEPA filter made by anodized aluminium. Command and Controls Air ventilation control by means of automatic regulation of the revolution velocity of the motor blower. High-resolution flow rate volumetric device, directly interfaced to microprocessor, achieve the automatic regulation. The microprocessor guarantees the activity of the motor blower and controls the optimal function even in presence of effects caused by progressive clogging of the HEPA filters. Alarm device optical (red light signal visible from working position and display message) and acoustic (buzzer) type, activated, at real time, by the microprocessor, with indication of type of alarm activate showing on a wide alpha numeric display. Monitoring with alarms of laminar air flow velocity out of the pre-set range; Alpha numeric display showing: Laminar air flow speed in m/s; Date and time Hours counters for cabinet life UV Lamp run hours HEPA filters run hours Date of last HEPA filters change Date of last service Change language Change password Setting UV timer program Date of last power failure Tests control In our Quality Control Dept., according to our procedure WI-MFG-006 included in the Quality manual of Steril Equipment Division. The Quality System of Steril Equipment Division is certified in compliance to EN ISO 9001 2000 with a Certificate n CERT-00669-95-AQ-MIL-SINCERT/B released by DNV Det Norske Veritas. On request, validation tests at site with IQ/OQ protocols are available.

TD_HeliosC_08.doc Rev. January 08

Standard features Automatic air velocity regulation Fluorescent lights Power socket 4 A UNEL IP 55 DOP/DOS 100% test inlet hose-barb port

Optional features Steel support stand epoxy polyester coated Chest of 3 drawers on pivoting wheels in steel epoxy coated 30W germicidal lamp with front screen, wavelength 253.7 nm (UV-C) Gas manual tap manufactured in compliance with UNI/CIG regulations. Tap is provided with the automatic safety valve for interruption in case of electric blackout and/or air velocity out of pre-set range. Terminal connection for 6 mm diameter gas line. Bunsen burner with automatic switch ignition Bunsen burner with automatic foot switch ignition Compressed air line with manual tap Nitrogen line with manual tap Vacuum line with manual tap

Maintenance The replacement of filters can be done from the front of the cabinet. Any other maintenance activity (control of the electric board, replacement of UV lamp) can be done from the top.

TD_HeliosC_08.doc Rev. January 08

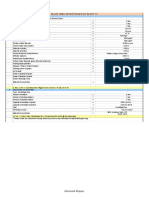

Technical characteristics

Model Overall dimension (WxDxH) Working area dimension (WxDxH) Package dimension (WxDxH) Front opening height Net weight System ventilation data Flow rate (1) Heat emission at 25 C Noise level Lighting Service fluids Max pressure air / Nitrogen / CO2 Max pressure bunsen burner Electrical data Voltage Frequency Power (2) Absorption Electrical classification (with feeding cable) Protection category Power socket (protected by a single fuse 4A) Fluorescent lamps

(1) (2)

Unit mm mm mm mm Kg m /h Kcal/h dB (A) Lux bar mbar V Hz W A

3

Helios 48 C 1310x875x1284 1270x537x814 1430x980x1700 814 160 1316 345 <60 1035 4 20 230V AC F+N+P.E. 50 750 8

Helios 72 C 1920x875x1284 1880x537x814 2010x980x1700 814 240 1975 525 <60 1285 4 20 230V AC F+N+P.E. 50 800 10

1 1 IP 20 IP 20 2P+t 250V 10/16A IP55 for both models 2x36 2x58

Only for cabinets that recirculate air in environmental This value includes max absorption of power socket equal to 4A

TD_HeliosC_08.doc Rev. January 08

M2754-02.DGN

N ETZSPAN U G NN 6

BR N AS EN G

MOD S O U 0 7

LI N K

MOD S I U 1

R H EC TS

MOD S II U 2 8

AU F

A LA R M

Esc

3 4

BELEU H N C TU G 9

AB

U LAM PE V

EN TER

9

5

N EBEN STEC KER

Es c

ESC M U TE

829 (useful)

1284

25

537 (useful) 870

785

LE GI RA F

1700 A

reggia

A HELIOS 48 HELIOS 72

TD_HeliosC_08.doc Rev. January 08

B

B

1310 1430 1920 2010

980

S-ar putea să vă placă și

- Wa0010Document108 paginiWa0010Filimone ThumboÎncă nu există evaluări

- Dfa500 Brochure 04-13 Us HRDocument2 paginiDfa500 Brochure 04-13 Us HREngr Irfan AkhtarÎncă nu există evaluări

- Nuclear, Safety and Protection Catalogue - English 2012 PDFDocument96 paginiNuclear, Safety and Protection Catalogue - English 2012 PDFHatim ApÎncă nu există evaluări

- NTC 2042 CX UMN 3 0Document105 paginiNTC 2042 CX UMN 3 0Sebastian Joehnk100% (1)

- Explosion Proof Axial Fan CertificateDocument7 paginiExplosion Proof Axial Fan CertificateShahlan AnuarÎncă nu există evaluări

- HongFeng Plastic Metalizin MachineDocument12 paginiHongFeng Plastic Metalizin MachineSungam CorbenÎncă nu există evaluări

- Design of Ammonia StripperDocument1 paginăDesign of Ammonia StripperthirumuruganÎncă nu există evaluări

- Kata LogDocument62 paginiKata LogGoh DodyÎncă nu există evaluări

- Biological Safety Cabinet SC2 - ADocument4 paginiBiological Safety Cabinet SC2 - AlucasÎncă nu există evaluări

- Gas Detection Combi Mate PDFDocument2 paginiGas Detection Combi Mate PDFamirouche15Încă nu există evaluări

- XR 0408 RectifierDocument2 paginiXR 0408 RectifierСлободан ИлићÎncă nu există evaluări

- OHRU EcoAir CompactDocument4 paginiOHRU EcoAir Compactlabelel100% (1)

- Catalog Perry 2010 EngDocument120 paginiCatalog Perry 2010 Engl_dumitruÎncă nu există evaluări

- Instruction Manual FTDocument28 paginiInstruction Manual FTJUANITOPYTÎncă nu există evaluări

- Preventa Xps Xpsac5121Document2 paginiPreventa Xps Xpsac5121pedro torresÎncă nu există evaluări

- Piezo HumidifierDocument2 paginiPiezo HumidifierRoberto M. SousaÎncă nu există evaluări

- Harman Kardon Avr45 Service ManualDocument81 paginiHarman Kardon Avr45 Service ManualneonestÎncă nu există evaluări

- Cabero CH Evaporator CatalogueDocument12 paginiCabero CH Evaporator Cataloguehungnn0503100% (2)

- Cdte Thin Film Solar Module: Original SizeDocument2 paginiCdte Thin Film Solar Module: Original SizeKirsten HernandezÎncă nu există evaluări

- Instruction Manual KED150Document36 paginiInstruction Manual KED150Muhammad Asyraf100% (1)

- Inet Scu1284 1280 1200 A4Document4 paginiInet Scu1284 1280 1200 A4Mihai ConstantinescuÎncă nu există evaluări

- 1002 SpecDocument2 pagini1002 Specconejo100% (1)

- LFXGH Basic SetupDocument2 paginiLFXGH Basic SetupAlvin Garcia PalancaÎncă nu există evaluări

- Klean Esp - Ecology Units SpecDocument3 paginiKlean Esp - Ecology Units SpecAdnan KhanÎncă nu există evaluări

- Manual Equipo AUG 25-30 ELBWDocument26 paginiManual Equipo AUG 25-30 ELBWShadow50_4Încă nu există evaluări

- Catalogue 2013Document34 paginiCatalogue 2013arun1957Încă nu există evaluări

- Ba Sarexc1!07!16 Acexc1 Nonin Dp1 FM enDocument48 paginiBa Sarexc1!07!16 Acexc1 Nonin Dp1 FM enkpr_02161371Încă nu există evaluări

- Ecofel Boiler Service ManualDocument38 paginiEcofel Boiler Service ManualCristian PodaruÎncă nu există evaluări

- 2010 Catalogo Americano CompletoDocument1.474 pagini2010 Catalogo Americano CompletoisidriskyÎncă nu există evaluări

- Vortice Domestic VentilationDocument14 paginiVortice Domestic VentilationmmaleniÎncă nu există evaluări

- DP3L1-805A808A Open Loop Stepping Driver ManualDocument17 paginiDP3L1-805A808A Open Loop Stepping Driver ManualNguyen QuanÎncă nu există evaluări

- Photovoltaic CablesDocument8 paginiPhotovoltaic CablesShahid KhanÎncă nu există evaluări

- 1VCF379652S0101 Plug and Socket With 58 Female and Male Pins Amph Plug and Socket Without WirinDocument1 pagină1VCF379652S0101 Plug and Socket With 58 Female and Male Pins Amph Plug and Socket Without WirinMahyar MashayekhiÎncă nu există evaluări

- Obstivision XGP338Document1 paginăObstivision XGP338Pham SangÎncă nu există evaluări

- Manual ZTU EngDocument15 paginiManual ZTU EngIulian TitaÎncă nu există evaluări

- Solar LaminatorDocument6 paginiSolar LaminatorAnonymous XoM50xp84yÎncă nu există evaluări

- 744 and 745 Load Cells - 2586Document1 pagină744 and 745 Load Cells - 2586Luis IglesiasÎncă nu există evaluări

- DNR Duct Detector Installation DetailsDocument6 paginiDNR Duct Detector Installation DetailsBinu SulochananÎncă nu există evaluări

- Schneider - EasyPact TVS ContactorsDocument26 paginiSchneider - EasyPact TVS Contactorsrhap_0925060Încă nu există evaluări

- DVR Dahua 3108 8chDocument2 paginiDVR Dahua 3108 8chJavi KatzÎncă nu există evaluări

- Refrig LBDocument8 paginiRefrig LBMuhammad HafeezÎncă nu există evaluări

- TGS8100 Product InfomationDocument10 paginiTGS8100 Product Infomationbemxgm-1Încă nu există evaluări

- FFB MannualDocument44 paginiFFB MannualRasheed AhamedÎncă nu există evaluări

- Fire Alarm Panel ChemetronDocument2 paginiFire Alarm Panel ChemetronCesar Mos100% (1)

- Feam Junction Box EnclosureDocument36 paginiFeam Junction Box EnclosureMiky MooseÎncă nu există evaluări

- INIMDocument4 paginiINIMstanchan82Încă nu există evaluări

- Potterton Kingfisher MF RS 50 Installation Manual GCNo 41 393 95Document39 paginiPotterton Kingfisher MF RS 50 Installation Manual GCNo 41 393 95lenin6737Încă nu există evaluări

- 1746sc-NI8u Manual 0300172 03DDocument130 pagini1746sc-NI8u Manual 0300172 03Drfg21100% (1)

- Online Coal Analyzer: 6A/B Belt at TP6Document11 paginiOnline Coal Analyzer: 6A/B Belt at TP6Ashish Fating100% (1)

- E-Type Tabletop Ultrasonic Cleaning SystemsDocument4 paginiE-Type Tabletop Ultrasonic Cleaning SystemsSonix IV CorporationÎncă nu există evaluări

- Newtec Mod 2080Document120 paginiNewtec Mod 2080jean27000100% (2)

- VCD-D ManualDocument13 paginiVCD-D ManualnimmuhkÎncă nu există evaluări

- 21FL94 TV Sharp PDFDocument48 pagini21FL94 TV Sharp PDFJose Luis100% (3)

- G2 DSPLAY ManuelDocument38 paginiG2 DSPLAY Manuelalper canturkÎncă nu există evaluări

- Tecnair Close Control Serie PDocument5 paginiTecnair Close Control Serie Psciurescu0% (1)

- O-Ring Kits: Product DescriptionDocument7 paginiO-Ring Kits: Product DescriptionRonildo DuarteÎncă nu există evaluări

- 601P (En)Document2 pagini601P (En)Radu BucuresteanuÎncă nu există evaluări

- Siprotec 7ut82 ProfileDocument2 paginiSiprotec 7ut82 ProfileOliver Atahuichi TorrezÎncă nu există evaluări

- Industrial Air CleanersDocument4 paginiIndustrial Air CleanerssalgoraÎncă nu există evaluări

- Datasheet Safemate CytoDocument4 paginiDatasheet Safemate CytoBiopathÎncă nu există evaluări

- Sterivap En1Document7 paginiSterivap En1DanielRomeo CretuÎncă nu există evaluări

- Motor and VFD ListDocument18 paginiMotor and VFD Listمهند محمدÎncă nu există evaluări

- Catalogo Equipos Loren COOkDocument37 paginiCatalogo Equipos Loren COOkLuis Carlos PardoÎncă nu există evaluări

- Craftsman Blower 24cc ManualDocument13 paginiCraftsman Blower 24cc ManualChristian HumeÎncă nu există evaluări

- Wallmount - JCIDocument12 paginiWallmount - JCIALEXÎncă nu există evaluări

- Air - Knife - Component - Brochure RepublicDocument8 paginiAir - Knife - Component - Brochure RepublicGiovanny MosqueraÎncă nu există evaluări

- TVR PRC001 E4 - 0511Document246 paginiTVR PRC001 E4 - 0511Jashy Gtz100% (1)

- Upcoming Code Changes ASME CSD-1, NFPA 85, and NFPA 87: Prepared ForDocument39 paginiUpcoming Code Changes ASME CSD-1, NFPA 85, and NFPA 87: Prepared ForHimanshu PatelÎncă nu există evaluări

- TEK Airfoil Impellers - Backward Curved: Features & BenefitsDocument4 paginiTEK Airfoil Impellers - Backward Curved: Features & BenefitsUniwes ServiceÎncă nu există evaluări

- M 385 ContentDocument47 paginiM 385 ContentSalmanul FareziÎncă nu există evaluări

- Experiment No. 6-Study of The Constructional Features and Working of Pelton TurbineDocument7 paginiExperiment No. 6-Study of The Constructional Features and Working of Pelton TurbineMilon MirdhaÎncă nu există evaluări

- C65P1 Spec Sheet - E - A4Document3 paginiC65P1 Spec Sheet - E - A4Chandru ChristurajÎncă nu există evaluări

- Fan SpecificationsDocument2 paginiFan SpecificationspavitrakedarÎncă nu există evaluări

- Fan BlowerDocument20 paginiFan BlowerShariq AliÎncă nu există evaluări

- Rosenberg CatalogueDocument24 paginiRosenberg CatalogueFu AunÎncă nu există evaluări

- Section 5 Troubleshooting: Common Problems 5-1Document46 paginiSection 5 Troubleshooting: Common Problems 5-1Adnan AhmadÎncă nu există evaluări

- 03 PAES Master Catalog 39th Edition Aeration PDFDocument66 pagini03 PAES Master Catalog 39th Edition Aeration PDFjcbobedaÎncă nu există evaluări

- Windjammer and Nautialir Blowers Catalog PDFDocument136 paginiWindjammer and Nautialir Blowers Catalog PDFrtgeorgeÎncă nu există evaluări

- Design of Various Components of An Open Circuit Blower Tunnel Without Exit DiffuserDocument6 paginiDesign of Various Components of An Open Circuit Blower Tunnel Without Exit DiffuserprashasscribdÎncă nu există evaluări

- AC - Air ConditioningDocument185 paginiAC - Air ConditioningHari Prasad Ambaripeta100% (1)

- Process Equipment Cost Estimation GuidelinesDocument80 paginiProcess Equipment Cost Estimation Guidelineswriteandrewpaul7707100% (1)

- Blue StarDocument8 paginiBlue StarPrabhakar JhaÎncă nu există evaluări

- Duct Leakage TestingDocument26 paginiDuct Leakage TestingVijay100% (1)

- Robuschi BlowersDocument23 paginiRobuschi Blowers1977jul100% (1)

- Pill AeratorDocument20 paginiPill AeratorAhmed NahrawyÎncă nu există evaluări

- Icarus Reference GuideDocument737 paginiIcarus Reference GuideVictor Diz RicardoÎncă nu există evaluări

- M08.HRE Series - AMCA - ThailandDocument34 paginiM08.HRE Series - AMCA - ThailandMalcom FredrickÎncă nu există evaluări

- Pressure Drop Calculations MA59Document4 paginiPressure Drop Calculations MA59Thakur Nagendra0% (1)

- Vacuum Unit ManualDocument54 paginiVacuum Unit ManualNurlan ValiyevÎncă nu există evaluări

- Industrial Fans Airflow PDFDocument28 paginiIndustrial Fans Airflow PDFSunil Kumar SinghÎncă nu există evaluări