Documente Academic

Documente Profesional

Documente Cultură

JSA M36 Hydro Testing Spool Pieces & Pipework

Încărcat de

MianTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

JSA M36 Hydro Testing Spool Pieces & Pipework

Încărcat de

MianDrepturi de autor:

Formate disponibile

POWER

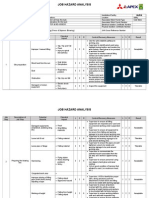

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

ACTIVITY OR TASK:HYDRO TESTING SPOOL PIECES AND PIPE WORK

JSA Preparation & task work team:

Competence = Relevant Training/Qualifications + Experience

Location / Project: Job Number: JSA Number: M36 Codes of Practice & Legislation that are applicable: JSA Revision:

Competence/ Qualificn reqd to complete work safely JSA approved by person responsible i.e.

Team Leader / Tradesman

Name:

Position / Competence/ License:

Date:

2. HAZARD IDENTIFICATION

compulsory

Identify hazards that may be present by ticking items on the list below.

3. PRECAUTIONS: hard hat, safety glasses, safety boots

ADDITIONAL PRECAUTIONS

Gloves: type . Goggles Full Face Shield High Visibility Vest Harness Fire Extinguishers Barricades Ventilation Lighting Erect Scaffolding to access Respirator or Dust mask Erect Warning signs Personal Locks or Tag system Group isolation Welding screen Fall Arrest systems Welding Face Shield

WORK LOCATION

Difficult Entry/Exit Oxygen Deficiency Oxygen Excess Engulfment (trench collapse) Poisonous Gas Present Temperature Extremes Defined Confined Space Explosive Gas Present

HAZARDOUS AREA

Hazardous Substances - attach MSDS to JSA Working at Heights Remote Area Motor Room Hazards Toxic Substances Potential for Difficult Rescue

HIGH RISK

Falling Objects Poor Lighting Slippery Surfaces Multiple Electrical Feeds Trip Hazards Electrical Hazards - LV Electrical Hazards - HV Manual Handling Sharp Materials Ladders used in the task Working at Heights Working near Crane & Crane Runways Rail Movement Pressurised Fluids Flamm. Materials Present

HIGH RISK

Suspended loads Poor Visibility Inhalable Dusts/Fibres High Noise Levels Use of Chemicals Elevated Work Platform Difficulty to Communicate amongst workers Moving Machinery Tools & Equipment Heat/ Sunlight/ Radiation Traffic Movement Working near Operation Processing Lines Live Rails Pneumatics

PERMITS

Hot Work Excavation Confined Space Hazardous Work Clearance Access to Area High Voltage Access Scaffolding Other?

HAZARDOUS SUBSTANCES in work area / to be used

-attach MSDS

PERMIT NUMBER:

4. ENVIRONMENTAL HAZARDS (IMPACTS) tick those identified

Air Pollution (dust, fumes) Noise (plant & equipment) Spills to drains/waterways Spills to ground Soil Erosion Hazard to Flora /Fauna

Other:

RISK RATING TABLE

This table is used to calculate whether the hazard you have identified is Extreme: 9-10 High: 7-8, Medium: 5-6 or Low: 3-4

The objective of rating the risk is to lower the risk by initiating risk control measures. The score is

Likelihood: How likely is it to be that bad? Almost Certain Expected to Occur

Consequences: how severe an injury? Death

Serious Injuries Medical Treatment Reqd 1st Aid reqd

10 9 8 7 6

9 8 7 6

8 7 6 5

7 6 5 4 3

5. EQUIPMENT REQUIRED: Static Plant & Equipment

Mobile Plant & Equipment

Likely could

happen sometime

Moderate could

happen but not likely

Unlikely could

happen but very rare

Revision Date: March 2005

. of ..

Rare - could happen

but probably never will

OHS-03-F01 5 4

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Safety / Emergency Equipt

noted in the JSA risk score column on the next page both before & after risk control measures have been nominated.

NAME OF TASK: HYDRO TESTING SPOOL PIECES AND PIPE WORK

JSA Number: Risk Rating

M36

Rev: Risk Rating

Of the risk following corrective action

Step No.

Logical sequence

Sequence of Basic Job Steps

Break down Job into steps. Each step should accomplish a major task and be logical. Environmental Aspects

Potential Safety & Environmental Hazards/Impacts

Recommended Corrective Action or Procedure

Determine what actions are necessary to eliminate or minimise all hazards that could lead to an accident, injury, illness or environmental incident. The risk must be reduced or controlled to a level that is acceptable before work commences. Indicate who is to perform the action where applicable against each action

Identify the hazards (health and safety or Use table on environmental) associated with each step, the previous examine each to find all possible risk factors page to score

risk

2 3 4

6 7 8

Discuss scope of work and work method Personal Injury resulting from with workforce working with hand tools and lines under pressure Obtain PTW Injury / damage as a result of incorrect information Identify work area Risk of injury due to low awareness of work environment Fit blanks and fittings into spool pieces Personal Injury resulting from incorrect work methods and incorrect tools Hydro Testing Personal Injury resulting from incorrect work methods, incomplete fittings Personal Injury resulting from High Pressure Hose Bursting, Faulty Equipment, Incorrect work methods. Equipment Damage, Personal Injury resulting from Blow out of equipment under test. Removing Blanks and Fittings Personal Injury resulting from trapped pressure escaping Clean up work area Personal Injury resulting from uneven, slippery work area Remove bunting and signage Personal Injury resulting from uneven, slippery work area

Toolbox Meeting, Barriers, Signage, Appropriate tools, PPE, Correct Work Methods Obtain correct PTW. Training in PTW system. Take 5, be aware of hazards Correct Lifting Techniques, Correct tools, PPE, Supervision

Inspect fittings for compatability & condition, correct torque-ing techniques, PPE, Supervision Inspect hoses and fittings prior to use, inspect pressure unit and safety device prior to use, PPE Barriers, Signs, Sentry to control entry to work area, Inspect PSV for condition and correct setting Ensure equipment drained and depressurized prior to removing fittings, PPE, Supervision. Correct lifting techniques, PPE, supervision. Correct lifting techniques, PPE, supervision.

Revision Date: March 2005

. of ..

OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Revision Date: March 2005

. of ..

OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) CONSULTATION & SIGN-OFF RECORD

I confirm by my signature below, that I have attended a briefing on the requirements of the attached Job Safety & Environment Analysis and agree to perform the work in the manner detailed on it. I confirm that copies of the relevant Permits, MSDS's, Isolation Plans etc. have been reviewed.

JSA NAME JSA No:

Rev: DATE

NAME

(Please print)

SIGNATURE

THIS SAFE WORK BRIEFING / TRAINING WAS CARRIED OUT BY (responsible person at that location) : Name: Signature: Date: Client sign off (where applicable) Site / Project Manager sign off (document reviewed)

Revision Date: March 2005

OHS-03-F01

S-ar putea să vă placă și

- Plumber - Drainer SWMSDocument12 paginiPlumber - Drainer SWMSallen2912100% (1)

- JSA G17 Lift Container With CraneDocument4 paginiJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- Akk Jha Installation of Diesel TankDocument3 paginiAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Suroj Buildcon Pvt. LTD.: Job Safety AnalysisDocument6 paginiSuroj Buildcon Pvt. LTD.: Job Safety AnalysisKiran ChenchalaÎncă nu există evaluări

- JSA For Coating and Raping Activity in TankDocument7 paginiJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatÎncă nu există evaluări

- Hse JsaDocument22 paginiHse JsaAnonymous y1pIqcÎncă nu există evaluări

- Form-58 Confined Space Entry LogDocument1 paginăForm-58 Confined Space Entry LogRajesh Kumar SinghÎncă nu există evaluări

- JSA-Construction Right of WayDocument3 paginiJSA-Construction Right of Wayfrancis_e_tan100% (6)

- HIRA No. 08 Rev 04 - Adverse WeatherDocument5 paginiHIRA No. 08 Rev 04 - Adverse WeatherVenkadesh PeriathambiÎncă nu există evaluări

- SAFETY PLAN For Pilling Work at Making AreaDocument8 paginiSAFETY PLAN For Pilling Work at Making AreaBalogun Isaac100% (1)

- Site Safety Procedure-RV1Document21 paginiSite Safety Procedure-RV1raeiszÎncă nu există evaluări

- Jsa-Jha For Using of Hand ToolsDocument2 paginiJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Weekly HSE Report - 13-05-2023Document24 paginiWeekly HSE Report - 13-05-2023abhinav djÎncă nu există evaluări

- Pre-Job Safety Assessment: Site InformationDocument2 paginiPre-Job Safety Assessment: Site Informationgueettaf faresÎncă nu există evaluări

- TEIPL-JSA-044 Maintenance Vehicle, Machine or Const EqmntsDocument4 paginiTEIPL-JSA-044 Maintenance Vehicle, Machine or Const Eqmntsba ratnaparkheÎncă nu există evaluări

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 paginiJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- Ra02 - Container OffloadingDocument3 paginiRa02 - Container OffloadingSamÎncă nu există evaluări

- Manual Handling RubbishDocument1 paginăManual Handling RubbishScribder0% (1)

- RA Excavation For ExcavationDocument13 paginiRA Excavation For ExcavationSasi KumarÎncă nu există evaluări

- HSE Professionals - Working at HeightDocument13 paginiHSE Professionals - Working at Heightchinne046Încă nu există evaluări

- JSA For Pressure Test 2ND REVISIONDocument10 paginiJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- RA Excavation For Trial TrenchDocument9 paginiRA Excavation For Trial TrenchSasi KumarÎncă nu există evaluări

- Flagman/ Banksman TrainingDocument25 paginiFlagman/ Banksman TrainingAatif Patil100% (1)

- Heat Stress ProcedureDocument13 paginiHeat Stress ProcedureKneekEy CastleÎncă nu există evaluări

- Activity Hazard AnalysisDocument4 paginiActivity Hazard AnalysisGerrard Singh100% (1)

- Confined Space Entry ProcedureDocument4 paginiConfined Space Entry Procedurerpsh90100% (1)

- 2015 HSE Campaign PDFDocument4 pagini2015 HSE Campaign PDFAnkit Dudeja100% (1)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 paginiJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- SWMS Scaffold FixedDocument11 paginiSWMS Scaffold FixedEdha AliÎncă nu există evaluări

- JSA For MobilizationDocument3 paginiJSA For MobilizationHossain amjad Hossain100% (1)

- Rescue Plan SRS 1Document4 paginiRescue Plan SRS 1Salah Abd EldayemÎncă nu există evaluări

- Stop Work AuthortyDocument8 paginiStop Work AuthortyRonald Sarillana100% (1)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 paginăJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaÎncă nu există evaluări

- Installation of Underground 2"stainless Steel (1sdou) .Document8 paginiInstallation of Underground 2"stainless Steel (1sdou) .AldrinÎncă nu există evaluări

- Suspended Load SafetyDocument3 paginiSuspended Load Safetymy_agautamÎncă nu există evaluări

- Jsa SKDocument10 paginiJsa SKEngr Tahir UL Haq100% (2)

- Jsa For Steel Structure For Off PlotDocument13 paginiJsa For Steel Structure For Off PlotKhuda BukshÎncă nu există evaluări

- Adverse Weather PolicyDocument10 paginiAdverse Weather Policyvlad100% (1)

- Construction Site Inspection Check List ALMCDocument2 paginiConstruction Site Inspection Check List ALMCAmeerHamzaWarraichÎncă nu există evaluări

- Risk Assessment For Partition MarkingDocument5 paginiRisk Assessment For Partition Markingkhalid14Încă nu există evaluări

- Cold Cutting PDFDocument9 paginiCold Cutting PDFAshraf BottaniÎncă nu există evaluări

- 11-2.3.02 Coshh (Control of Substances Hazardous To Health)Document17 pagini11-2.3.02 Coshh (Control of Substances Hazardous To Health)Francisco M. RamosÎncă nu există evaluări

- RA MEWP 0003 Dec 2011Document3 paginiRA MEWP 0003 Dec 2011Anup George Thomas100% (1)

- JHA Blowing PressDocument5 paginiJHA Blowing PressLuqman OsmanÎncă nu există evaluări

- Jsa For Choke Valve InstallationDocument9 paginiJsa For Choke Valve InstallationjavithÎncă nu există evaluări

- AhaDocument6 paginiAhaCarlits MacallaÎncă nu există evaluări

- HSE PolicyDocument1 paginăHSE PolicyHassan Ali Hassan100% (1)

- HSE PLAN Generic RA PDFDocument5 paginiHSE PLAN Generic RA PDFテレブリコ ジェファーソン100% (1)

- Electrical Work at Wellsite HARCDocument2 paginiElectrical Work at Wellsite HARCErni Tri LestariÎncă nu există evaluări

- Job Safety Analysis - Clinker StorageDocument4 paginiJob Safety Analysis - Clinker StorageMohammed MinhajÎncă nu există evaluări

- 003 SWMS - ExcavationDocument11 pagini003 SWMS - Excavationsasi kumar50% (2)

- JSA IndexDocument2 paginiJSA IndexDie HArdÎncă nu există evaluări

- Confined SpaceRescue Plan - Asad HSEDocument16 paginiConfined SpaceRescue Plan - Asad HSEAsad RazaÎncă nu există evaluări

- Jsa & Hip PlanDocument7 paginiJsa & Hip Plansaquib_jamadar100% (1)

- Health & Safety Professioanl CVDocument5 paginiHealth & Safety Professioanl CVnaveedÎncă nu există evaluări

- Man Machine InterfaceDocument22 paginiMan Machine Interfaceamdarrif3723100% (1)

- P-985-SH-AHA-008, AHA For Demolision WorksDocument4 paginiP-985-SH-AHA-008, AHA For Demolision WorksPatrick Bibila NdansiÎncă nu există evaluări

- 1-Demolation Risk Assessment ReportDocument8 pagini1-Demolation Risk Assessment ReportSyed Ali HassanÎncă nu există evaluări

- JGS SHES JHRA 002 13 Scaffolding Erection and DismantlingDocument2 paginiJGS SHES JHRA 002 13 Scaffolding Erection and Dismantlingarnel sungkip100% (1)

- Cover LetterDocument1 paginăCover LetterMianÎncă nu există evaluări

- New To OSHADocument15 paginiNew To OSHAMianÎncă nu există evaluări

- Sales InvoiceDocument1 paginăSales InvoiceMianÎncă nu există evaluări

- (Company Name) : (Street Address) (City, ST ZIP Code) (Phone) (Fax) (Website)Document1 pagină(Company Name) : (Street Address) (City, ST ZIP Code) (Phone) (Fax) (Website)MrbudakbaekÎncă nu există evaluări

- Contoh Format Apa StyleDocument8 paginiContoh Format Apa StyleFutri F. FauziahÎncă nu există evaluări

- Lumia Windows Phone 8-1 Update UG en GBDocument130 paginiLumia Windows Phone 8-1 Update UG en GBAbishkar SarkarÎncă nu există evaluări

- Certificate of Accreditation: Jamesford UniversityDocument1 paginăCertificate of Accreditation: Jamesford UniversityMianÎncă nu există evaluări

- Contoh Format Apa StyleDocument8 paginiContoh Format Apa StyleFutri F. FauziahÎncă nu există evaluări

- Resume FileDocument1 paginăResume FileMianÎncă nu există evaluări

- Summer HolidaysDocument1 paginăSummer HolidaysMianÎncă nu există evaluări

- Birthday Party CardDocument2 paginiBirthday Party CardMianÎncă nu există evaluări

- The Significance of ShabDocument3 paginiThe Significance of ShabMianÎncă nu există evaluări

- Config: (Street Address, City, ST ZIP Code) (Telephone) (Email)Document1 paginăConfig: (Street Address, City, ST ZIP Code) (Telephone) (Email)MianÎncă nu există evaluări

- Sample ReportDocument1 paginăSample ReportMianÎncă nu există evaluări

- Fire Protection SystemDocument29 paginiFire Protection SystemMianÎncă nu există evaluări

- CVDocument4 paginiCVMianÎncă nu există evaluări

- CVDocument4 paginiCVMianÎncă nu există evaluări

- Environmental Management Plan GuidelinesDocument23 paginiEnvironmental Management Plan GuidelinesMianÎncă nu există evaluări

- Emp GuidelinesDocument12 paginiEmp GuidelinesMianÎncă nu există evaluări

- Chapter5 Environment PlanDocument135 paginiChapter5 Environment PlanMianÎncă nu există evaluări

- Fire SafetyDocument23 paginiFire SafetyYuan ShengÎncă nu există evaluări

- 1800629Document71 pagini1800629kave4923Încă nu există evaluări

- Survey 27-10-15Document1 paginăSurvey 27-10-15MianÎncă nu există evaluări

- Rohail SajidDocument3 paginiRohail SajidMianÎncă nu există evaluări

- Chea Usde AllaccredDocument4 paginiChea Usde AllaccredMianÎncă nu există evaluări

- Business Emergency Plan TemplateDocument7 paginiBusiness Emergency Plan TemplateRoy TannerÎncă nu există evaluări

- Emergency Plan UscsdDocument34 paginiEmergency Plan UscsdMianÎncă nu există evaluări

- Nebosh International General CertificateDocument2 paginiNebosh International General Certificatexeeshan281Încă nu există evaluări

- Sample Emergency PlanDocument11 paginiSample Emergency PlanYusuf Milan PrabowoÎncă nu există evaluări

- Emergency - Plans - Sample Emergency Preparedness WorksheetDocument3 paginiEmergency - Plans - Sample Emergency Preparedness WorksheetMianÎncă nu există evaluări

- Adjectives With Cork English TeacherDocument19 paginiAdjectives With Cork English TeacherAlisa PichkoÎncă nu există evaluări

- Brand Guidelines Oracle PDFDocument39 paginiBrand Guidelines Oracle PDFMarco CanoÎncă nu există evaluări

- Common OPCRF Contents For 2021 2022 FINALE 2Document21 paginiCommon OPCRF Contents For 2021 2022 FINALE 2JENNIFER FONTANILLA100% (30)

- Invoice Acs # 18 TDH Dan Rof - Maret - 2021Document101 paginiInvoice Acs # 18 TDH Dan Rof - Maret - 2021Rafi RaziqÎncă nu există evaluări

- Teralight ProfileDocument12 paginiTeralight ProfileMohammed TariqÎncă nu există evaluări

- U2 - Week1 PDFDocument7 paginiU2 - Week1 PDFJUANITO MARINOÎncă nu există evaluări

- QP 4Document4 paginiQP 4Yusra RaoufÎncă nu există evaluări

- Coca-Cola Summer Intern ReportDocument70 paginiCoca-Cola Summer Intern ReportSourabh NagpalÎncă nu există evaluări

- Hoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFDocument2 paginiHoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFMarco Antonio Gutierrez PulchaÎncă nu există evaluări

- Eclipsecon MQTT Dashboard SessionDocument82 paginiEclipsecon MQTT Dashboard Sessionoscar.diciomma8446Încă nu există evaluări

- Chapter 1.4Document11 paginiChapter 1.4Gie AndalÎncă nu există evaluări

- Charlemagne Command ListDocument69 paginiCharlemagne Command ListBoardkingZeroÎncă nu există evaluări

- EMI-EMC - SHORT Q and ADocument5 paginiEMI-EMC - SHORT Q and AVENKAT PATILÎncă nu există evaluări

- Computerized AccountingDocument14 paginiComputerized Accountinglayyah2013Încă nu există evaluări

- MMMDocument6 paginiMMMReet KanjilalÎncă nu există evaluări

- Civil NatureDocument3 paginiCivil NatureZ_Jahangeer100% (4)

- Consultancy Services For The Feasibility Study of A Second Runway at SSR International AirportDocument6 paginiConsultancy Services For The Feasibility Study of A Second Runway at SSR International AirportNitish RamdaworÎncă nu există evaluări

- Marketing Management - Pgpmi - Class 12Document44 paginiMarketing Management - Pgpmi - Class 12Sivapriya KrishnanÎncă nu există evaluări

- Chap 06 Ans Part 2Document18 paginiChap 06 Ans Part 2Janelle Joyce MuhiÎncă nu există evaluări

- LISTA Nascar 2014Document42 paginiLISTA Nascar 2014osmarxsÎncă nu există evaluări

- Chapter 11 Walter Nicholson Microcenomic TheoryDocument15 paginiChapter 11 Walter Nicholson Microcenomic TheoryUmair QaziÎncă nu există evaluări

- SDM Case AssignmentDocument15 paginiSDM Case Assignmentcharith sai t 122013601002Încă nu există evaluări

- Flyer Manuale - CON WATERMARK PAGINE SINGOLEDocument6 paginiFlyer Manuale - CON WATERMARK PAGINE SINGOLEjscmtÎncă nu există evaluări

- Planas V Comelec - FinalDocument2 paginiPlanas V Comelec - FinalEdwino Nudo Barbosa Jr.100% (1)

- Faida WTP - Control PhilosophyDocument19 paginiFaida WTP - Control PhilosophyDelshad DuhokiÎncă nu există evaluări

- Applications of MathematicsDocument35 paginiApplications of MathematicsRamdas Sonawane100% (1)

- scx4521f SeriesDocument173 paginiscx4521f SeriesVuleticJovanÎncă nu există evaluări

- Vocabulary Practice Unit 8Document4 paginiVocabulary Practice Unit 8José PizarroÎncă nu există evaluări

- Spine Beam - SCHEME 4Document28 paginiSpine Beam - SCHEME 4Edi ObrayanÎncă nu există evaluări

- Fast Binary Counters and Compressors Generated by Sorting NetworkDocument11 paginiFast Binary Counters and Compressors Generated by Sorting Networkpsathishkumar1232544Încă nu există evaluări