Documente Academic

Documente Profesional

Documente Cultură

Industrial Instrumentation Industrial Instrumentation Industrial Instrumentation Industrial Instrumentation

Încărcat de

Dharmesh DevaniDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Industrial Instrumentation Industrial Instrumentation Industrial Instrumentation Industrial Instrumentation

Încărcat de

Dharmesh DevaniDrepturi de autor:

Formate disponibile

Industrial Instrumentation

Mr. DHARMESH DEVANI

Course Outline

Instruments are our eyes

Fundamentals of Electrical Technology and digital logic employed in the measurement Review of Scientific principles employed in instruments Parts of Instrument Performance Characteristics of Instruments Selection and Calibration of Instruments Instruments Identification and Line Symbols Principle measurements desired in industry

(a) Temperature (b) Pressure, Load (c) Level (d) Flow (e) Others ( Weight, Composition, pH etc.) (f) Transducers Installation and Installation Costs Case Studies

Sensors

Human natural observation capabilities are generally not designed for process conditions. Instruments must have desired capabilities to match process conditions. Process Control has the role of a decision makers (Like brain) Sensors feel the condition and originate the signal followed by modification and amplification for effective display /transmission or control objectives.

Importance of effective measurement in process industry

Failure to measure effectively the level of liquid in bottom of the tower lead to --- Fire --- Explosion

Instrument

Typical components of instrument

A Sensor: (measures a physical quantity and converts it into a signal) A Modifier (Change the type of signal) A Display unit (transmitting arrangement )

Functional Elements of an Instrument

Process/ Measured medium

Primary Sensing Element

Variable Conversion Element

Variable Manipulation Element

Data Transmission Element

Data Presentation Element Observer

UMECH RKU RAJKOT

DHARMESH DEVANI

6. Februar 2012 /

DHARMESH DEVANI

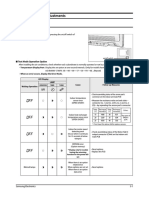

Functional Elements of an Instrument (Contd)

Typical Example:

Functional Elements of an Instrument (Contd)

Fluid Temperature Measured Quantity Temperature Tube Tubing

Process/ Measured medium

Primary Sensing Element

Variable Conversion Element

Pressure

Data Transmission Element

Pressure

Variable Conversion Element

Motion

Variable Manipulation Element

Motion

Data Presentation Element Observer

Spiral Bourdon Tube

Linkage Gear

Scale & Pointer

Performance Characteristics of Instruments

Static characteristics Dynamic characteristics

Performance Characteristics of Instruments (Contd)

Static characteristics

Static characteristics of an instrument includes; Accuracy Precision Repeatability Range Resolution Others ( Sensitivity , Dead zone etc.)

Static Characteristics Static characteristics of an instrument includes;

1. Accuracy

Accuracy is the degree of conformity of the measured value with the accepted standard or ideal value, which we can take as the true physical variable.

Accuracy is usually expressed in engineering units or as a percentage of the sensor range, for example: Thermocouple temperature sensor with accuracy of 1.5 K. Orifice flow meters with accuracy of 3% of maximum flow range

Static Characteristics Static characteristics of an instrument includes;

2. Precision

Precision is the degree of exactness for which an instrument is designed or intended to perform. It is composed of two characteristics; 1. Conformity 2. Number of significant figures

Static Characteristics Static characteristics of an instrument includes; 3. Repeatability

The closeness of agreement among a number of consecutive measurements of the same variable (value) under the same operating conditions, approaching in the same direction.

The term approaching in the same direction means that the variable is increasing (decreasing) to the value for all replications of the experiment.

UMECH RKU RAJKOT

DHARMESH DEVANI

6. Februar 2012 /

DHARMESH DEVANI

14

Static Characteristics Static characteristics of an instrument includes; 4. Reproducibility

The closeness of agreement among a number of consecutive measurements of the same variable (value) under the same operating conditions over a period of time, approaching from both directions.

The period of time is long, so that changes occurring over longer times of plant operation are included. Reproducibility includes hysteresis, dead band, drift and repeatability.

Drift

Gradual change in instruments measurements. OR Measure of difference in repeatability. Under laboratory conditions drift of an element can be determined by one of two ways; 1. Point drift 2. Calibration drift

Point Drift

By maintaining exact operating and load conditions , monitoring of output variations for a fixed input signals as a function of time is called point drift. Used for stable process conditions

Calibration Drift

By maintaining input signals, operating conditions, a load approximately constant comparison of calibration curves at the beginning and at specified intervals of time is called Calibration drift. Used for varying process conditions

Dead Zone

Dead zone is the largest range of values of a measured variable to which the instrument does not respond. This is sometimes called dead spot and hysteresis.

Backlash

Backlash or mechanical hysteresis is defined as that lost motion or free play which is inherent in mechanical elements such as gears, linkages or other mechanical transmission devices that are not rigidly connected.

Static Characteristics Static characteristics of an instrument includes; 5. Range/Span

Range represents the minimum and maximum values which can be determined by an instrument or equipment. Difference between upper and lower range is known as Span. Span can be the same for two different range instruments.

If a chemical reactor typically operates at 300 C, the engineer might select a range of 250-350 C. Since the reactor will be started up from ambient temperature occasionally, an additional sensor should be provided with a range of -50 to 400 C.

Static Characteristics Static characteristics of an instrument includes; 5. Linearity

This is the closeness to a straight line of the relationship between the true process variable and the measurement. Lack of linearity does not necessarily degrade sensor performance. If the nonlinearity can be modeled and an appropriate correction applied to the measurement before it is used for monitoring and control, the effect of the non-linearity can be eliminated.

Linearity is usually reported as non-linearity, which is the maximum of the deviation between the calibration curve and a straight line positioned so that the maximum deviation is minimized

Static Characteristics Static characteristics of an instrument includes; 6. Reliability

Reliability is the probability that a device will adequately perform (as specified) for a period of time under specified operating conditions. Some sensors are required for safety or product quality, and therefore, they should be very reliable.

If sensor reliability is very important, the engineer can provide duplicate sensors, so that a single failure does not require a process shutdown

Calibration

Assigning standard values to an equipment is calibration.

UMECH RKU RAJKOT

DHARMESH DEVANI

6. Februar 2012 /

DHARMESH DEVANI

23

Static Error

Numerical differences between true value of a quantity and its value as obtained by measurement. Static errors are generally of three types; 1. 2. 3. Mistake or gross error (human mistakes) Systematic errors (instrumental or environmental errors) Random or accidental errors (unknown)

Performance Characteristics

Dynamic characteristics Dynamic Characteristics of an instrument includes;

1. 2. 3. 4.

Speed of response Fidelity Lag Drift

Other Issues

1. 2. 3. 4.

Maintenance Consistency with process environment Safety Cost

Other Issues

Consistency with process environment Direct contact

Sensors such as orifice plates and level floats have direct contact with process fluids.

Sheath protection

Sensors such as thermocouples and pressure diaphragms have a sheath between the process fluid and the sensor element

Sample extraction

When the process environment is very hostile or the sensor is delicate and performs a complex physiochemical transformation on the process material, a sample can be extracted.

Other Issues

Location of Measurement Displays

Local display

Local panel display

Centralized control room

Remote monitoring

The Smart Sensor Revolution

Digital conversion and transmission

Diagnostics

Signal conditioning

Configuration

Principle measurements desired in Industry

Principle measurements desired in industry (a) Temperature (b) Pressure (c) Level (d) Flow (e) Others ( Composition, pH etc.)

UMECH RKU RAJKOT

DHARMESH DEVANI

6. Februar 2012 /

DHARMESH DEVANI

30

UMECH RKU RAJKOT

DHARMESH DEVANI

6. Februar 2012 /

DHARMESH DEVANI

31

Discussion & Questions?

6. Februar 2012 /

K M V V PRASAD

32

S-ar putea să vă placă și

- 02 Static and Dynamim CharactersticsDocument29 pagini02 Static and Dynamim CharactersticsNikhil Kumar - 35Încă nu există evaluări

- Industrial Instrumentation: Dr. - Ing. Naveed RamzanDocument32 paginiIndustrial Instrumentation: Dr. - Ing. Naveed Ramzangopir28Încă nu există evaluări

- Unit 1 Mechatronics - S1Document134 paginiUnit 1 Mechatronics - S1SACHIN PATILÎncă nu există evaluări

- I&m 1Document22 paginiI&m 1Aleeza AshfaqueÎncă nu există evaluări

- Industrial Instrumentation Ch.E-401: Kashif IqbalDocument25 paginiIndustrial Instrumentation Ch.E-401: Kashif IqbalBilal AkbarÎncă nu există evaluări

- Industrial Instrumentation Ch.E-401: Kashif IqbalDocument29 paginiIndustrial Instrumentation Ch.E-401: Kashif Iqbaljesustavares100% (1)

- Working and Parts of Domestic Gas MeterDocument7 paginiWorking and Parts of Domestic Gas Meteradnan mukhtarÎncă nu există evaluări

- Intrumentastion and Control For HND IDocument43 paginiIntrumentastion and Control For HND Iolamilekan00100Încă nu există evaluări

- MENG 304: Mechanical Measurements Lect - 02: Presented By: Hussein Fouad Mohamed AliDocument26 paginiMENG 304: Mechanical Measurements Lect - 02: Presented By: Hussein Fouad Mohamed AliWalid KhaledÎncă nu există evaluări

- InstrumentationDocument27 paginiInstrumentationHusnain ArshadÎncă nu există evaluări

- Third LectSATACTIC CHARACTORSTICS OF INSTRUMENT SYSTEMDocument32 paginiThird LectSATACTIC CHARACTORSTICS OF INSTRUMENT SYSTEMDhinakaran VeemanÎncă nu există evaluări

- Chapter One: Review of Basic Instrumentation SystemsDocument14 paginiChapter One: Review of Basic Instrumentation SystemsNatnael BereketÎncă nu există evaluări

- Process Instrumentation Terminology Performance CharaDocument12 paginiProcess Instrumentation Terminology Performance CharaPriÎncă nu există evaluări

- BMMI Unit 2 - Session 1Document31 paginiBMMI Unit 2 - Session 1Yashi SinghÎncă nu există evaluări

- CLB 21303 Process Instrumentation and ControlDocument48 paginiCLB 21303 Process Instrumentation and ControlSyafiqIsmiÎncă nu există evaluări

- Chapter 1Document85 paginiChapter 1babychandu899Încă nu există evaluări

- CLB 21303 Process Instrumentatio N and ControlDocument48 paginiCLB 21303 Process Instrumentatio N and ControlanisÎncă nu există evaluări

- Measurement SystemsDocument103 paginiMeasurement SystemsRikki Macolor50% (2)

- Lecture-5: Static Characteristics of Instruments & CaliberationDocument20 paginiLecture-5: Static Characteristics of Instruments & CaliberationRishabh KÎncă nu există evaluări

- Module 1 Part 1 MergedDocument146 paginiModule 1 Part 1 MergedSankaranarayanan AÎncă nu există evaluări

- Measurement Task (4) (D2)Document7 paginiMeasurement Task (4) (D2)Medo ElzaeemÎncă nu există evaluări

- Sample For Solution Manual Measurement and Instrumentation 3rd Edition by Morris & LangariDocument24 paginiSample For Solution Manual Measurement and Instrumentation 3rd Edition by Morris & Langarigmd technicalÎncă nu există evaluări

- Basics of InstrumentDocument66 paginiBasics of InstrumentnizamuddinÎncă nu există evaluări

- Presntation (Installing Instrumentation and Control Devices)Document35 paginiPresntation (Installing Instrumentation and Control Devices)habtemariam mollaÎncă nu există evaluări

- Mechanical Measurements and Metrology: Unit 1: Introduction To MeasurementsDocument24 paginiMechanical Measurements and Metrology: Unit 1: Introduction To MeasurementsYASH RAYUDU 16131A03N4Încă nu există evaluări

- Metrology and MeasurementsDocument45 paginiMetrology and MeasurementsgurunathramÎncă nu există evaluări

- Static and Dynamic CharacteristicsDocument10 paginiStatic and Dynamic CharacteristicsAshley_RulzzzzzzzÎncă nu există evaluări

- CH 1 - Intro J5800Document54 paginiCH 1 - Intro J5800mohd_mizanÎncă nu există evaluări

- Instrumentation (Lecture, 1)Document65 paginiInstrumentation (Lecture, 1)Abdull SamiÎncă nu există evaluări

- Emi Unit 11Document23 paginiEmi Unit 11ADEPOJU AyobamiÎncă nu există evaluări

- Chap 1 PPT Instr. & Meas PCE 4203 From GUDocument43 paginiChap 1 PPT Instr. & Meas PCE 4203 From GUTemesgen workiye100% (1)

- EE2201 Measurement and Instrumentation Lecture NotesDocument73 paginiEE2201 Measurement and Instrumentation Lecture NotesDeepa Dhilip100% (1)

- Instrumentation and Measurements BE-56 A&B Fall 2020: Instructor: LT Dr. Col Humayun Zubair KhanDocument35 paginiInstrumentation and Measurements BE-56 A&B Fall 2020: Instructor: LT Dr. Col Humayun Zubair Khanahmad khanÎncă nu există evaluări

- Process Instrumentation TerminologyDocument6 paginiProcess Instrumentation TerminologyAnonymous 8pCXXsÎncă nu există evaluări

- SMR1302Document286 paginiSMR1302Mr. RAVI KUMAR IÎncă nu există evaluări

- MEASUREMENT TechniqueDocument13 paginiMEASUREMENT Techniqueseherr719Încă nu există evaluări

- Measurement and Instrumentation Lecture NotesDocument73 paginiMeasurement and Instrumentation Lecture NotesRakesh Thapliyal83% (6)

- Unit 2 SensorsDocument69 paginiUnit 2 SensorsSrinivasan V PÎncă nu există evaluări

- Introduction To Instrumentation PDFDocument34 paginiIntroduction To Instrumentation PDFJuan Carlos Flores PoblanoÎncă nu există evaluări

- Solomon Bekele Department of Electrical and Computer Engineering (Instrumentation and Control Engineering)Document21 paginiSolomon Bekele Department of Electrical and Computer Engineering (Instrumentation and Control Engineering)Samuel AdamuÎncă nu există evaluări

- Lecture 2 - Characteristics of MSDocument33 paginiLecture 2 - Characteristics of MSSceva AquilaÎncă nu există evaluări

- Electrical Measurements and Instrumentation: by Dereje D. Dereder@dtu - Edu.etDocument23 paginiElectrical Measurements and Instrumentation: by Dereje D. Dereder@dtu - Edu.etDereje DeribÎncă nu există evaluări

- Meas Ins1Document148 paginiMeas Ins1HilalAldemir0% (1)

- MT8591 S&I IA1 Q&A IIIyearDocument60 paginiMT8591 S&I IA1 Q&A IIIyearILYASÎncă nu există evaluări

- LECTURE NOTE ON MEC 314 UpdatedDocument72 paginiLECTURE NOTE ON MEC 314 UpdatedYoung ProfÎncă nu există evaluări

- Cat One Ecen 427.Document3 paginiCat One Ecen 427.AMOS SIFUNA100% (1)

- UNIT 1 - Introduction To Measurement SystemDocument55 paginiUNIT 1 - Introduction To Measurement SystemPoornima AÎncă nu există evaluări

- SENSOR and Signal Processing UnitDocument57 paginiSENSOR and Signal Processing UnitRohit Ghulanavar100% (1)

- Process InstrumentationDocument71 paginiProcess InstrumentationPrasanna kumar subudhiÎncă nu există evaluări

- ECE 311 Measurement & Instrumentation-1Document25 paginiECE 311 Measurement & Instrumentation-1SamuelÎncă nu există evaluări

- P.Shanmuga Raja: Professor, E&I Dept.Document34 paginiP.Shanmuga Raja: Professor, E&I Dept.EI020 JAYARAM SÎncă nu există evaluări

- Lec (1) - Measurement System Calibration and Errors - 2Document16 paginiLec (1) - Measurement System Calibration and Errors - 2Nawaf Al-TamimiÎncă nu există evaluări

- Industrial InstrumentationDocument74 paginiIndustrial InstrumentationAjish AJÎncă nu există evaluări

- HTTPWWW - Pc-Education - Mcmaster.cainstrumentationgo Inst - HTMDocument85 paginiHTTPWWW - Pc-Education - Mcmaster.cainstrumentationgo Inst - HTMTaha HasanÎncă nu există evaluări

- MECE4103: Mechanical Processes Instrumentation and Control: Chapter One: General Concepts of Measurement SystemDocument30 paginiMECE4103: Mechanical Processes Instrumentation and Control: Chapter One: General Concepts of Measurement SystemPuwa CalvinÎncă nu există evaluări

- Chapter1 Piceng215Document56 paginiChapter1 Piceng215Hawraa JaafarÎncă nu există evaluări

- Instrumentation Overview: Pelatihan Instrumentation and Control FundamentalDocument58 paginiInstrumentation Overview: Pelatihan Instrumentation and Control FundamentalfaridaÎncă nu există evaluări

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDe la EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionEvaluare: 4.5 din 5 stele4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentDe la EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentEvaluare: 4.5 din 5 stele4.5/5 (3)

- Microcontroller Based Automatic Railway Gate ControlDocument21 paginiMicrocontroller Based Automatic Railway Gate ControlAtchyuth Sonti100% (3)

- 08 ADT 672 Digital Pressure CalibratorDocument3 pagini08 ADT 672 Digital Pressure CalibratorphongÎncă nu există evaluări

- Motion Detection Using Passive Infrared Sensor - 24 Pages PDFDocument24 paginiMotion Detection Using Passive Infrared Sensor - 24 Pages PDFStephanie May DancesÎncă nu există evaluări

- CRT 06 PDFDocument8 paginiCRT 06 PDFdovdorÎncă nu există evaluări

- Solar Based E-Uniform For SoldiersDocument8 paginiSolar Based E-Uniform For SoldiersIJRASETPublicationsÎncă nu există evaluări

- Flow Switch With 4-20 Ma OutputDocument20 paginiFlow Switch With 4-20 Ma OutputHariprasad ManavalanÎncă nu există evaluări

- ASTM D4984 CO2 en Gas NaturalDocument3 paginiASTM D4984 CO2 en Gas Naturalfamturbo0% (1)

- Is A Battery Temperature Sensor NecessaryDocument13 paginiIs A Battery Temperature Sensor NecessaryjackÎncă nu există evaluări

- HAVPro ManualDocument168 paginiHAVPro ManualaverammsteinÎncă nu există evaluări

- Measurement-Technology-Catalogue ENG WebDocument44 paginiMeasurement-Technology-Catalogue ENG WebbzivkovicÎncă nu există evaluări

- Fan Regulator Using 8051 MicrocontrollerDocument2 paginiFan Regulator Using 8051 MicrocontrollerSatyam LalaÎncă nu există evaluări

- Module 3 ELNDocument21 paginiModule 3 ELNbalakrishnak eceÎncă nu există evaluări

- Electric SkinDocument17 paginiElectric Skinabhisekh mohantyÎncă nu există evaluări

- Instrumentation Course 1Document130 paginiInstrumentation Course 1FACE BOOK100% (1)

- (Ultrasonic Radar-Naman Kataria-CSB) PresentationDocument15 pagini(Ultrasonic Radar-Naman Kataria-CSB) PresentationHimanshu VermaÎncă nu există evaluări

- Mazda 3 OBD Codes: EngineDocument13 paginiMazda 3 OBD Codes: EnginecpureaperÎncă nu există evaluări

- fm1202 User Manual v1.02 PDFDocument82 paginifm1202 User Manual v1.02 PDFSergio Manuel BarrantesÎncă nu există evaluări

- PR 00062 enDocument20 paginiPR 00062 enWilliam EdwardsÎncă nu există evaluări

- PVED-CL Controller For Electro-Hydraulic SteeringDocument128 paginiPVED-CL Controller For Electro-Hydraulic SteeringcjalanisÎncă nu există evaluări

- Fault Code List: Información de ServicioDocument6 paginiFault Code List: Información de ServicioMiguel Angel Garrido CardenasÎncă nu există evaluări

- Slide Present Ee Full Heart BeatDocument21 paginiSlide Present Ee Full Heart BeatRedzuan Kamarudin100% (1)

- AQ18FCN Service Manual - Shematic DiagramDocument9 paginiAQ18FCN Service Manual - Shematic DiagramDrinski67Încă nu există evaluări

- Univario Tech Data CombinedDocument10 paginiUnivario Tech Data CombineddbrodarÎncă nu există evaluări

- In Line Turbidity Meter Opthaze I Haffmans Leaflet v2052 enDocument2 paginiIn Line Turbidity Meter Opthaze I Haffmans Leaflet v2052 enheprÎncă nu există evaluări

- Rele de Proteccion DGPT2 2Document8 paginiRele de Proteccion DGPT2 2WALTERÎncă nu există evaluări

- ICT ApplicationsDocument61 paginiICT ApplicationsemilyÎncă nu există evaluări

- Tracker DocumentationDocument16 paginiTracker DocumentationIMARÎncă nu există evaluări

- LPG Gas Sensor Interfacing With 8051Document8 paginiLPG Gas Sensor Interfacing With 8051gprodan2002a2948Încă nu există evaluări

- Fotoceldas Laser LG10Document12 paginiFotoceldas Laser LG10Armando SotoÎncă nu există evaluări

- Sensor Selector Guide Industrial 551814 enDocument19 paginiSensor Selector Guide Industrial 551814 enALEXSANDROÎncă nu există evaluări