Documente Academic

Documente Profesional

Documente Cultură

Control Philosophies

Încărcat de

devcharuDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Control Philosophies

Încărcat de

devcharuDrepturi de autor:

Formate disponibile

CONTROL PHILOSOPHIES

Introduction : This Philosophy has developed based on the practical experiences on peculiar phenomenon. Without giving the start command the drive starts on some other occasions even after giving a stop command the drive does not stop. In some cases DCS input contact is observed to Burn frequently on control signal input System study and analysis proven that the physical parameters such as ,control voltage level , Type of cable and length of cable etc are responsible for the behaviour.

Causes : 1. Larger the distance between the field control and MCC : Capacitance of cable increases in proportion to the control cable length, Due to this even if stop command is given, voltage is still appears across the contactor coil, if this voltage is more than the drop off voltage ,contactor does not drop off , Similarly due to cable capacitance start command is experienced if the accumulated charged voltage is higher than the pickup value. 2. Higher control voltage like 240V : The capacitance between the pair of cable shunts the remote signal contact , This provided an alternate path to the coil current and if the capacitance is high enough will prevent the contactor dropping off Even if the switch is opened. 3. Unused conductors in the Multicore cable : In a Multicore cable unused conductor will increase the capacitance effect to overcome this effect unused conductor in multicore cable is earthed to reduce the capacitance effect.

Recommendation for Plant Control Supply system :

1. Use of Lower control voltage : Using 110V AC instead of 240V AC in the control circuit allows the Higher cable length.

2. Earthing of Unused cores : In Multi core cable the unused cable conductors to be earthed to over come the capacitance effect. 3. Use of Resistance in parallel with the contactor coil : The voltage drop across the contactor coil reduces which helps in deenergizing the contactor. 4. Cables with Low dielectric Constant : The cable with low dielectric constant can significantly reduce the capacitance to a very lower value. 5. Seperate Route for Power and Control Cables : Normally power and control cables are routed together ,the surges in power cable induce voltage in the control cable , to reduce the effect power and control cables shall be routed in a separate cable tray. 6. Use of Shielded Twisted wire : Some times magnetic interference induce voltage in the control wire ,the effect can be nullified by use of Shielded twisted wire as compared to Normal PVC Wire. 7. Layout to restrict the control cable length to 250 -300 Mtrs.

Standard Control Voltage Levels : Slno 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Description of Equipment HT Board LT Switchboard IMCC APFC GRR/LRS Load Break Switch MLDB Trafo Cooler control panel Trafo RTCC Panel Energy Saver Sub control Panel Local Control Panel Solenoid/other Switches DCS Interrogation Supply Monitoring and Signalling Control Voltage Level 110V DC as well as 110VAC 110V DC as well as 110VAC 110V AC 110V AC 110VAC 110VDC 110VAC 110VAC 110VAC 220VAC 110V AC 110V AC 110V AC 110VAC 110VAC

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- SafeStartingOfMotors 0514Document4 paginiSafeStartingOfMotors 0514Enrique Javier González HenríquezÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- RCFA TablesOfContents PDFDocument26 paginiRCFA TablesOfContents PDFasrinivasareddyÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Resumo Diogo Silva 73583Document11 paginiResumo Diogo Silva 73583devcharuÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Distribution Transformer Main Handbook PDFDocument84 paginiDistribution Transformer Main Handbook PDFdevcharuÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Marland 2014Document154 paginiMarland 2014devcharuÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Power TransformerMaintenance ScheduleDocument3 paginiPower TransformerMaintenance Scheduledh24992499Încă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- DC ComponentDocument5 paginiDC ComponentjoseÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- 5 Carbon Brush Technical Guide Mersen - 07Document40 pagini5 Carbon Brush Technical Guide Mersen - 07Dhanraj PatilÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Indian DIN &BS Fuse Link & Base - Technical Catalog - 23-04-15 PDFDocument26 paginiIndian DIN &BS Fuse Link & Base - Technical Catalog - 23-04-15 PDFdevcharuÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- ABB - Technical Guide No.7 - REVCDocument40 paginiABB - Technical Guide No.7 - REVCgafscottÎncă nu există evaluări

- 32083-Guidance Notes For Generators - Submission of Grid Code DataDocument39 pagini32083-Guidance Notes For Generators - Submission of Grid Code DataJuan AntonioÎncă nu există evaluări

- Predicting Transformer Temperature Rise and Loss oDocument10 paginiPredicting Transformer Temperature Rise and Loss odevcharuÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Condition Monitoring of Transformers SAILDocument17 paginiCondition Monitoring of Transformers SAILavadiraja100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- TransformerDocument204 paginiTransformerdevcharu75% (4)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- 12 Maintenance Best PracticesDocument22 pagini12 Maintenance Best Practicespepenapao1217Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- V35s1a11 PDFDocument9 paginiV35s1a11 PDFdevcharuÎncă nu există evaluări

- Signal Conditioning Circuits1Document16 paginiSignal Conditioning Circuits1Karthik SriramakavachamÎncă nu există evaluări

- ML12334A508Document22 paginiML12334A508devcharuÎncă nu există evaluări

- White Paper The Value of A Maintenance AuditDocument5 paginiWhite Paper The Value of A Maintenance AuditdevcharuÎncă nu există evaluări

- TealBookDocument2 paginiTealBookdevcharuÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Recip or Screw - The Customers Choice PDFDocument2 paginiRecip or Screw - The Customers Choice PDFdevcharuÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- 11 Chap3Document28 pagini11 Chap3tutywaodeÎncă nu există evaluări

- Transformer Insulation Life ExtensionDocument31 paginiTransformer Insulation Life ExtensiondevcharuÎncă nu există evaluări

- Cement Plant Emission ManualDocument71 paginiCement Plant Emission Manualtsrinivasan5083Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- 6668 LossEffective DD 20150318 WebDocument9 pagini6668 LossEffective DD 20150318 WebChristos ApostolopoulosÎncă nu există evaluări

- Distribution System Redesign EPRIDocument210 paginiDistribution System Redesign EPRIhafezasadÎncă nu există evaluări

- Cooling Tower Handbook - FINAL PDFDocument33 paginiCooling Tower Handbook - FINAL PDFOscarJimenez19870% (1)

- Workshop Transformer Residual Life EnhancementDocument4 paginiWorkshop Transformer Residual Life EnhancementdevcharuÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Transformer Age AssessmentDocument7 paginiTransformer Age AssessmentEngr Irfan AkhtarÎncă nu există evaluări

- Distribution System Redesign EPRIDocument210 paginiDistribution System Redesign EPRIhafezasadÎncă nu există evaluări

- Sheath CurrentDocument7 paginiSheath CurrentJackson Suresh100% (1)

- Level Past Paper Questions - Physics O: TOPIC-14 DC Circuits PAPER-1 Multiple ChoiceDocument17 paginiLevel Past Paper Questions - Physics O: TOPIC-14 DC Circuits PAPER-1 Multiple Choiceelty Tan50% (2)

- SSC Je SyllabusDocument5 paginiSSC Je SyllabusteyllerÎncă nu există evaluări

- Physics of The Ignition System PDFDocument10 paginiPhysics of The Ignition System PDFmeetbalakumar100% (1)

- MIdterm Exam Answer KeyDocument3 paginiMIdterm Exam Answer KeySteve B. BondocÎncă nu există evaluări

- Questions About Electric CircuitsDocument49 paginiQuestions About Electric Circuitsashok50% (2)

- BGM User ManualDocument48 paginiBGM User ManualAlgebra92Încă nu există evaluări

- Fluke-190 Service ManualDocument140 paginiFluke-190 Service Manual15101980100% (1)

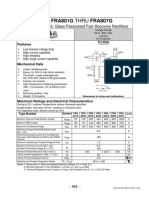

- Fra801G Thru Fra807G: 8.0 AMPS. Glass Passivated Fast Recovery RectifiersDocument2 paginiFra801G Thru Fra807G: 8.0 AMPS. Glass Passivated Fast Recovery RectifiersJose Luis LopezÎncă nu există evaluări

- KCET Mock Test Paper 6Document55 paginiKCET Mock Test Paper 6indigohghÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 15Ee103L Electric Circuits Lab: Register No: Name of The Student: Semester: DepartmentDocument66 pagini15Ee103L Electric Circuits Lab: Register No: Name of The Student: Semester: DepartmentArvind N LakshmananÎncă nu există evaluări

- Electric field in a plate capacitorDocument5 paginiElectric field in a plate capacitorRayane RayanoÎncă nu există evaluări

- (Megabras) DataSheet - Megôhmetro MD-1000RDocument2 pagini(Megabras) DataSheet - Megôhmetro MD-1000RGregory AssisÎncă nu există evaluări

- Rp130X Series: Low Noise 150ma Ldo RegulatorDocument33 paginiRp130X Series: Low Noise 150ma Ldo RegulatorСергей БрегедаÎncă nu există evaluări

- Alternating CurrentDocument68 paginiAlternating CurrentGovind Mani BhattÎncă nu există evaluări

- Harmony Enhanced, XPIC Installation Method of Procedure - TN-000050-01-EN-02-00Document51 paginiHarmony Enhanced, XPIC Installation Method of Procedure - TN-000050-01-EN-02-00Muhammad ShahidÎncă nu există evaluări

- TLEd 201 - Module 3 Lesson 1Document5 paginiTLEd 201 - Module 3 Lesson 1charmen rogandoÎncă nu există evaluări

- SolvedTechnical Papers by IftikharDocument26 paginiSolvedTechnical Papers by IftikharNoman Ahmed100% (5)

- Series and Parellel Circuit: Madam Anati Syahirah Binti HedzirDocument58 paginiSeries and Parellel Circuit: Madam Anati Syahirah Binti HedzirAnati Syahirah Binti HedzirÎncă nu există evaluări

- Daewoo Chassis CP-195LDocument71 paginiDaewoo Chassis CP-195LadiÎncă nu există evaluări

- Digital Panel Meters Modular Indicator and Controller Type UDM35Document14 paginiDigital Panel Meters Modular Indicator and Controller Type UDM35Reca DewantoroÎncă nu există evaluări

- 12th CRP Mains PDFDocument28 pagini12th CRP Mains PDFdipanshu gayakwadÎncă nu există evaluări

- Durant 47000-920Document2 paginiDurant 47000-920Zanes Teh 鋐杰Încă nu există evaluări

- Current ElectricityDocument20 paginiCurrent ElectricityParth GuptaÎncă nu există evaluări

- Codigos SP y SC Ricoh 2238cDocument114 paginiCodigos SP y SC Ricoh 2238cXelcop RojasÎncă nu există evaluări

- Mag 704Document144 paginiMag 704jeffd1787Încă nu există evaluări

- Physical Sciences Paper 1 (Physics) Grade 12 Terms & Definitions, Questions & Answers Per Topic 2019Document124 paginiPhysical Sciences Paper 1 (Physics) Grade 12 Terms & Definitions, Questions & Answers Per Topic 2019BONGUMENZI MTSHALI88% (8)

- Physics Project File 2222333333Document12 paginiPhysics Project File 2222333333Harsh Arora100% (1)

- Dhule-Vadodra Charging Study Voltage Difference AnalysisDocument22 paginiDhule-Vadodra Charging Study Voltage Difference AnalysisGopesh Kumar JhajhariaÎncă nu există evaluări

- PhysivvcsdfyDocument10 paginiPhysivvcsdfyOM CHAVANÎncă nu există evaluări

- Confinement (Book #1 in the Love and Madness series)De la EverandConfinement (Book #1 in the Love and Madness series)Încă nu există evaluări

- Cadet Willie McBride - Operation CrocodileDe la EverandCadet Willie McBride - Operation CrocodileÎncă nu există evaluări

- The Voice of God: Experience A Life Changing Relationship with the LordDe la EverandThe Voice of God: Experience A Life Changing Relationship with the LordÎncă nu există evaluări