Documente Academic

Documente Profesional

Documente Cultură

Welding Workbook

Încărcat de

Chris NenovDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Welding Workbook

Încărcat de

Chris NenovDrepturi de autor:

Formate disponibile

WELDING WORKBOOK

Datasheet 303

Fusion Welding for Aerospace Applications

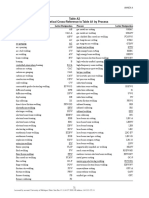

Due to the criticality of many aerospace weldments, the identification, storage, and use of all welding consumables (including wires, rods, inserts, fluxes, gases, etc.) require proper controls. It is important to store fluxes and covered electrodes in a clean, dry environment or in sealed containers. To prevent moisture accumulation, employ heating as necessary. Low-hydrogen shielded metal arc welding (SMAW) and flux cored arc welding (FCAW) electrodes should be handled and stored according to the manufacturers recommendations or according to AWS A5.1, A5.5, A5.20, or A5.29, as appropriate. Proper identification and storage of consumables will have a positive contribution to the quality of the product. Filler materials, when used in the welding process, must be specified by the Engineering Authority. Tables 13 list the filler materials normally used in welding aerospace base metals. Unless the Engineering Authority allows the use of the table in the selection of fill material, it is only to be used as a guide by the fabricator. The fabricator is responsible for verifying the correct application of any filler material through the Welding Procedure Specification/Procedure Qualification Record cycle. Welding fluxes are to be labeled and segregated by type and/or by their particular application. To prevent moisture pickup, store fluxes in sealed containers or keep them in a suitably clean and dry environment. Clean, unfused flux may be reused after reconditioning according to the manufacturers recommendations. Consumables used in welding are to be identified using an established standard or specification or by a standard specified in the procurement specification. If the identification marking is destroyed or missing, dont use the consumable. When specified on the engineering drawing or a contract document, traceability of the consumables must be maintained throughout the welding process.

Table 1 Filler Metal for Welding Aluminum Alloys Using GMAW, GTAW, and PAW Processes(a) Base Metal 1100 3003 2219 A5.10 5052 6013 6061 Filler Material Specification ER1100 or ER4043 ER1100 or ER4043 ER2319 ER5356 or ER4043 ER4043 ER4043 or ER5356 Filler Material AWS A5.10 AWS A5.10 AMS 4191 or AWS AWS A5.10 AWS A5.10 AWS A5.10

Table 3 Filler Metal for Welding Corrosion-Resistant Steels and Heat-Resistant Alloys Using GMAW, GTAW, and PAW Processes(a) Base Metal 304L and 316L 321 and 347 A286 21-6-9 PH 13-8Mo PH 15-7Mo PH 15-5 Filler Material ER308L ER321 or ER347 A286 ER219 WPH 13-8Mo ELC WPH 15-7Mo-VM 15-5PH or ER630 WPH 17-4 or ER630 PH17-7 WPH 15-7Mo-VM ERNiCrFe-5 Inconel 625 Hastelloy W or ERNiMo-3 Inconel 718 ERNiCrFe-7 Filler Material Specification AWS A5.9 AWS A5.9 AMS 5804 or AMS 5805 AWS A5.9 AMS 5840 AMS 5812 AMS 5826 or AWS A5.9 AMS 5825 or AWS A5.9 AMS 5824 AMS 5812 AWS 5.14 AMS 5837 AMS 5786 or AWS A5.14 AMS 5832 AWS A5.14

(a) Refer to C5.12 in the Commentary and 5.12 in the main body of the AWS D17.1 specification.

Table 2 Filler Metal for Welding Titanium Alloys Using GMAW, GTAW, and PAW Processes(a) Base Metal Commercially Pure Titanium 3Al-2.5V Ti 5Al-2.5Sn-Ti 6Al-4V or 6Al-4VELI Filler Material CP ERTi-4 ERTi-3Al-2.5V 5Al-2.5Sn ERTi-5Al-2.5Sn 6-4 ERTi-6Al-4V Filler Material Specification AMS 4951 AWS A5.16 AWS A5.16 AMS 4953 AWS A5.16 AMS 4956 AWS A5.16

PH 17-4 PH 17-7 Inconel 600 Inconel 625

Inconel 718 Inconel X750

(a) Refer to C5.12 in the Commentary and 5.12 in the main body of the AWS D17.1 specification.

(a) Refer to C5.12 in the Commentary and 5.12 in the main body of the AWS D17.1 specification.

Excerpted from AWS D17.1: 2001, Specification for Fusion Welding for Aerospace Applications. 54 FEBRUARY 2009

S-ar putea să vă placă și

- Taining Materials 2021, HobartDocument28 paginiTaining Materials 2021, HobartVijo JoseÎncă nu există evaluări

- The Evolution of Modern Band Saw Mills for Sawing LogsDe la EverandThe Evolution of Modern Band Saw Mills for Sawing LogsÎncă nu există evaluări

- Etchant Selection Guide (SS Superalloy) 11-2015Document3 paginiEtchant Selection Guide (SS Superalloy) 11-2015Malik Ansar HayatÎncă nu există evaluări

- Aw StandartsDocument12 paginiAw StandartsKiukStaksÎncă nu există evaluări

- TStud Concertina Leaflet Single Pages PDFDocument12 paginiTStud Concertina Leaflet Single Pages PDFVinicius Geraldini PiantolaÎncă nu există evaluări

- Welding Inspection TechnologyDocument13 paginiWelding Inspection TechnologyParthasarathy VadapalliÎncă nu există evaluări

- Arc Welding ElectrodesDocument6 paginiArc Welding ElectrodeswaleedyossefÎncă nu există evaluări

- Nickel Titanium Heat EngineDocument9 paginiNickel Titanium Heat EngineHans De Keulenaer100% (1)

- WeldingDocument45 paginiWeldingParveen KumarÎncă nu există evaluări

- Filler Metals Chemical Industry enDocument16 paginiFiller Metals Chemical Industry enrakeshbablooÎncă nu există evaluări

- The Highs, Lows of A New Metal Fabricating BusinessDocument60 paginiThe Highs, Lows of A New Metal Fabricating BusinesshernanalvaÎncă nu există evaluări

- Metal Joining Processes: Prof. Mayur S Modi Assistant Professor Mechanical Engineering Department Ssasit, SuratDocument79 paginiMetal Joining Processes: Prof. Mayur S Modi Assistant Professor Mechanical Engineering Department Ssasit, SuratPrateekÎncă nu există evaluări

- Pipe Welding and How To Pass A SMAW 6G (Open Root) Pipe Welding CertificationDocument13 paginiPipe Welding and How To Pass A SMAW 6G (Open Root) Pipe Welding CertificationMichael TayactacÎncă nu există evaluări

- Zinc Nickel Electroplating Guide ZyliteDocument9 paginiZinc Nickel Electroplating Guide ZyliteBryan DixÎncă nu există evaluări

- Welding Procedure: Dura-Tuff Grouser ProductsDocument4 paginiWelding Procedure: Dura-Tuff Grouser ProductsEhab Attia SelimÎncă nu există evaluări

- HLAWDocument26 paginiHLAWFebu LuthfianiÎncă nu există evaluări

- AWS Cdes Listing PDFDocument14 paginiAWS Cdes Listing PDFSha Mas Sha100% (1)

- Aluminum - Filler - Alloy - Selection - Chart Alcotec PDFDocument2 paginiAluminum - Filler - Alloy - Selection - Chart Alcotec PDFAnonymous nw5AXJqjdÎncă nu există evaluări

- Welding: Subpart QDocument65 paginiWelding: Subpart QRathnakrajaÎncă nu există evaluări

- TB Welding-English PDFDocument20 paginiTB Welding-English PDFdanghpÎncă nu există evaluări

- Pipe Fitting - WikipediaDocument5 paginiPipe Fitting - Wikipediaramthecharm_46098467Încă nu există evaluări

- 1.lesson Plan Welding Basic Metals - 0 - 0Document6 pagini1.lesson Plan Welding Basic Metals - 0 - 0Romel A. De GuiaÎncă nu există evaluări

- Nelson Stud Welding 2009Document110 paginiNelson Stud Welding 2009LhenzMorrizÎncă nu există evaluări

- Optimization of MIG Welding ParametersDocument6 paginiOptimization of MIG Welding ParametersMario Antonio Araya MorosoÎncă nu există evaluări

- Classification of Hardfacing AlloysDocument5 paginiClassification of Hardfacing AlloyssainivijayÎncă nu există evaluări

- Cat 06 2 PDFDocument44 paginiCat 06 2 PDFAnonymous O0T8aZZÎncă nu există evaluări

- This Home-Made 3-1/2in. Lathe Has Novel Features: George B. RoundDocument3 paginiThis Home-Made 3-1/2in. Lathe Has Novel Features: George B. Roundwienslaw5804Încă nu există evaluări

- Weld Cost Calc XL1.3.2mmDocument3 paginiWeld Cost Calc XL1.3.2mmDhimas Surya NegaraÎncă nu există evaluări

- Arc Welding ProjectDocument11 paginiArc Welding ProjectLeahÎncă nu există evaluări

- Factors in Selection of Filler Metals in WeldingDocument2 paginiFactors in Selection of Filler Metals in WeldingBalakumarÎncă nu există evaluări

- Tungsten Electrodes and Color Codes: Green RedDocument17 paginiTungsten Electrodes and Color Codes: Green RedclanonÎncă nu există evaluări

- Care & Cleaning - Stainless Steel PDFDocument7 paginiCare & Cleaning - Stainless Steel PDFpsp710Încă nu există evaluări

- Thermal Barrier Coatings Material Selection, Method of Preparation and Applications - ReviewDocument8 paginiThermal Barrier Coatings Material Selection, Method of Preparation and Applications - ReviewAbdelkader TayebiÎncă nu există evaluări

- Braze Training ManualDocument26 paginiBraze Training Manualritch99Încă nu există evaluări

- Welders Hand BookDocument23 paginiWelders Hand Booksamyqatar100% (2)

- Welding ProcessDocument6 paginiWelding ProcessRENGANATHAN PÎncă nu există evaluări

- US Navy Engineering Aid BasicsDocument41 paginiUS Navy Engineering Aid BasicsteddyÎncă nu există evaluări

- Fundamentals of Welding InspectionDocument53 paginiFundamentals of Welding InspectionIlyes kÎncă nu există evaluări

- Choosing The Best Pocket Knife: Knife Steel Composition ChartDocument12 paginiChoosing The Best Pocket Knife: Knife Steel Composition ChartNguyễn Thống NhấtÎncă nu există evaluări

- BOC 216295 GeneralGasesBrochure AUS v12Document28 paginiBOC 216295 GeneralGasesBrochure AUS v12idontlikeebooksÎncă nu există evaluări

- FCAW or Flux Cored Arc W..Document5 paginiFCAW or Flux Cored Arc W..smartcad60Încă nu există evaluări

- Stainless Steel Five TypesDocument40 paginiStainless Steel Five Typessids82Încă nu există evaluări

- Welding Al CastingsDocument13 paginiWelding Al CastingsSmartÎncă nu există evaluări

- Metallographic EtchantsDocument2 paginiMetallographic EtchantsturoramaÎncă nu există evaluări

- Power Mig 210 PDFDocument104 paginiPower Mig 210 PDFDannielOrellanaÎncă nu există evaluări

- Soldadura de Hierro ColadoDocument10 paginiSoldadura de Hierro ColadoclnÎncă nu există evaluări

- 9-Haz, Welding Defecs, Causes and RemdiesDocument24 pagini9-Haz, Welding Defecs, Causes and RemdiesRamu Amara100% (1)

- Weld Duplex Ss SteelDocument12 paginiWeld Duplex Ss SteelSan JaÎncă nu există evaluări

- Exotic Metal Base Metal & Filler GuideDocument1 paginăExotic Metal Base Metal & Filler GuideJuan RodriguezÎncă nu există evaluări

- Guidance On The Welding of Weathering SteelsDocument0 paginiGuidance On The Welding of Weathering Steelsinfinity_178Încă nu există evaluări

- Astm A351-14Document5 paginiAstm A351-14Marcel Dandaro100% (3)

- Astm A351 A351m 18Document4 paginiAstm A351 A351m 18Milady OyuelaÎncă nu există evaluări

- C 12 FastenersDocument5 paginiC 12 FastenersMithun Unni NairÎncă nu există evaluări

- Astm A234 A234m - 20252Document9 paginiAstm A234 A234m - 20252OscarBoneÎncă nu există evaluări

- Approval - Procedure For Control of Welding ConsumablesDocument16 paginiApproval - Procedure For Control of Welding Consumablesimran100% (1)

- Astm A193 A193m 23Document7 paginiAstm A193 A193m 23huicholeÎncă nu există evaluări

- Astm A351Document5 paginiAstm A351Srinivasan KrishnamoorthyÎncă nu există evaluări

- M-121 Aluminium Structural Material Rev1Document17 paginiM-121 Aluminium Structural Material Rev1vlong3003100% (1)

- MIL-W-8604 - A (Welding, Fusion Aluminum Alloys Process and Performance Of)Document20 paginiMIL-W-8604 - A (Welding, Fusion Aluminum Alloys Process and Performance Of)ccorp0089Încă nu există evaluări

- Astm A351Document5 paginiAstm A351Iksan MustofaÎncă nu există evaluări

- Astm A36 1977Document6 paginiAstm A36 1977Ben Yie Min100% (1)

- Control Valves - Basic HydraulicsDocument44 paginiControl Valves - Basic HydraulicsChris NenovÎncă nu există evaluări

- Owners Manual Suppl 1999 Bayliner Capri 1950clDocument23 paginiOwners Manual Suppl 1999 Bayliner Capri 1950clChris NenovÎncă nu există evaluări

- Mil-B-007883 Brazing - Cancelled - See Cancellation NoteDocument26 paginiMil-B-007883 Brazing - Cancelled - See Cancellation NoteChris NenovÎncă nu există evaluări

- 7.NASA-Selection of Metallic Materials For Stress Corrosion Cracking Resistance in Sodium Chloride EnvironmentsDocument52 pagini7.NASA-Selection of Metallic Materials For Stress Corrosion Cracking Resistance in Sodium Chloride EnvironmentsHyunjung LeeÎncă nu există evaluări

- Aluminum Chromate ConversionDocument2 paginiAluminum Chromate ConversionChris NenovÎncă nu există evaluări

- Carbide Design HandbookDocument53 paginiCarbide Design HandbookDidier MarneffeÎncă nu există evaluări

- Hardness Conversion TableDocument14 paginiHardness Conversion TableArun KumarÎncă nu există evaluări

- Engine Fuel PumpDocument2 paginiEngine Fuel PumpChris NenovÎncă nu există evaluări

- Super Austenitic StainlessDocument9 paginiSuper Austenitic StainlessChris NenovÎncă nu există evaluări

- Melting PracticeDocument17 paginiMelting PracticeAshish Kumar Jha100% (1)

- Summer Traning DLW ReportDocument55 paginiSummer Traning DLW ReportRavi Sagar83% (6)

- Soldering and WeldingDocument111 paginiSoldering and WeldingLohith DÎncă nu există evaluări

- Soft and Hard Soldering +brazingDocument28 paginiSoft and Hard Soldering +brazingJoseph Magbanua Dato-on67% (3)

- Reflow ManualDocument47 paginiReflow Manuallcnblzr3877100% (1)

- Dhanalakshmi College of Engineering Department of Mechanical Engineering Me 6302 Manufacturing Technology - 1 (Question Bank)Document10 paginiDhanalakshmi College of Engineering Department of Mechanical Engineering Me 6302 Manufacturing Technology - 1 (Question Bank)arulÎncă nu există evaluări

- C710-Electrodos Lincoln PDFDocument56 paginiC710-Electrodos Lincoln PDFCésar García TeruelÎncă nu există evaluări

- Esab Shelf LifeDocument3 paginiEsab Shelf LifeMahmud MaherÎncă nu există evaluări

- Use of Waste Copper Slag, A Sustainable MaterialDocument15 paginiUse of Waste Copper Slag, A Sustainable MaterialDaniel VegaÎncă nu există evaluări

- Oerlikon - Pipe - Mills - Market - Segment - enDocument26 paginiOerlikon - Pipe - Mills - Market - Segment - entanveer ahmedÎncă nu există evaluări

- Philips 32MF231D ChasisTPE1.0U LADocument102 paginiPhilips 32MF231D ChasisTPE1.0U LASaul Muñoz100% (1)

- Project DescriptionDocument32 paginiProject Descriptionxiangjintao50% (2)

- Ts 1Document25 paginiTs 1NaveenÎncă nu există evaluări

- First Year Metalwork.: Class Notes and Homework WorkbookDocument117 paginiFirst Year Metalwork.: Class Notes and Homework Workbookbrian DeckerÎncă nu există evaluări

- BZ Manual St500ckcDocument4 paginiBZ Manual St500ckcLouR2011Încă nu există evaluări

- Reading2020A FireASSAY USGS PDFDocument7 paginiReading2020A FireASSAY USGS PDFSantiago Molina HuertasÎncă nu există evaluări

- Super GlossDocument1.519 paginiSuper GlossIvan Pinto33% (3)

- Abbrivation For Welding Terms - 2Document1 paginăAbbrivation For Welding Terms - 2kapsarcÎncă nu există evaluări

- Weld Procedures For Cryogenic Service - SNC - LAVALINDocument8 paginiWeld Procedures For Cryogenic Service - SNC - LAVALINdwimukh360Încă nu există evaluări

- Pyrotek PromagDocument2 paginiPyrotek PromaggpucellaÎncă nu există evaluări

- 08252016122551manual of ProcedureDocument305 pagini08252016122551manual of ProcedureSuyog patilÎncă nu există evaluări

- How To Properly Cut Probe CablesDocument7 paginiHow To Properly Cut Probe CablesDon HagenÎncă nu există evaluări

- IOGP S-616 - 2022 - Supp. Specification To API SPEC 5L & ISO 3183 Line PipeDocument187 paginiIOGP S-616 - 2022 - Supp. Specification To API SPEC 5L & ISO 3183 Line PipeFerryÎncă nu există evaluări

- Material Properties Requirements For Metallic MaterialsDocument70 paginiMaterial Properties Requirements For Metallic Materialsعزت عبد المنعمÎncă nu există evaluări

- MMA Welding LastDocument76 paginiMMA Welding LastMahmoud Elemam100% (1)

- AGW TrainingDocument23 paginiAGW TraininglimasmildredÎncă nu există evaluări

- Weld Repair - PR - 0XXDocument10 paginiWeld Repair - PR - 0XXRAMAKRISHNAÎncă nu există evaluări

- Fundamentals of Solder Paste TechnologyDocument5 paginiFundamentals of Solder Paste TechnologyVimal Kumar VarmaÎncă nu există evaluări

- Patent For Slip Production For Sanitaryware ManufacturingDocument8 paginiPatent For Slip Production For Sanitaryware ManufacturingDhaval PadaliaÎncă nu există evaluări

- Pre-Roman Silver Miners at Riotinto: J. M. LuzonDocument11 paginiPre-Roman Silver Miners at Riotinto: J. M. LuzonΣέρχιο ΙσπανίαÎncă nu există evaluări