Documente Academic

Documente Profesional

Documente Cultură

Super Green Burner

Încărcat de

Shima RahmanianDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Super Green Burner

Încărcat de

Shima RahmanianDrepturi de autor:

Formate disponibile

Well Testing

Super Green Burner

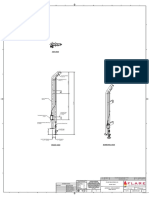

Expros Super Green Burner is designed for maximum clean burn capability with minimal fall-out.

The oil path through the burner is via a 2" mixing chamber which also allows the passage of solids without causing blockages and subsequent performance problems. The propellant (air) enters the mixing chamber through a series of ports drilled tangentially across the inner mandrel, thus creating both linear and rotational shearing effects which help improve atomisation immediately upon exit of the chamber. This produces a more effective flame pattern, which aids the combustion of the crude oil and reduces background radiated heat. The design of the Super Green Burner also reduces operating pressures, which results in significant safety advantages by lowering the overall well test system operating pressure. The Super Green Burner system can be supplied in various head configurations, sized to suit flow conditions. Higher performance units have modified nozzle arrangements, which in turn require higher volumes of compressed air. The Super Green Burner design concept, although extremely effective is very simple thus guaranteeing continuous trouble free operation.

OIL

EXIT ORIFICE

The Super Green Burner allows hydrocarbons to be burnt with no visible smoke or fall-out pollution.

AIR

Feature & Benefits: Unique burner head design No moving parts Low operating pressures Complete crude oil disposal through combustion Dynamic, elongated flame pattern Minimises smoke and fallout pollution Reduced maintenance during operations Maximises the operating parameters of a well test / clean-up package Eliminates the requirement for storage tanks Assists in directing radiated heat away from the installation

exprogroup.com

Well Testing

Super Green Burner

Technical Specifications: Typical hook-up Ignition System Oil Line Connection Air Line Connection Water Line Connection Propane lance from 110 / 240 volt supply 3" fig 602 female (multiple atomising heads) 2" fig 602 female (single atomising head) 4" fig 206 or 602 female (multiple atomising heads 3" fig 602 female (if utilised)

Codes & Ratings Design Code (piping) Service Max. Working Pressure Max. Working Temperature ASME B31.3 in accordance with SI 289 NACE MR-01-75 (H_S) 1440 psi (99 Bar) 248F (120C)

Estimated Weights & Dimensions Single Head Burner Three Head Burner Five Head Burner 2020 lbs (6.14 x 4.92 x 6.07) 915 kgs (1.87m x 1.5m x 1.85m) 2205 lbs (7.5 x 5.4 x 6.56) 1000 kgs (2.29m x 1.65m x 2m) 2656 lbs (8 x 5.8 x 7.2) 1200 kgs (2.4m x 1.8m x 2.2m) * Weights and dimensions are for indicative purposes only, varying burner head configurations can be supplied.

Typical Oil Capacities Single Head Burner Three Head Burner Five Head Burner 3000 bpd (475 m3/d) 9000 bpd (1430 m3/d) 15000 bpd (2385 m3/d)

*The above quoted rates require variable air capacities together with deliverable air pressures up to 125 psi.

Expro International Group PLC SuperGeenBurner100907_v1

exprogroup.com

S-ar putea să vă placă și

- H07127 Three Phase Horz Test Separator HLBDocument2 paginiH07127 Three Phase Horz Test Separator HLBsyazwanÎncă nu există evaluări

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDe la EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsÎncă nu există evaluări

- Piping: Wing Union ConnectionsDocument8 paginiPiping: Wing Union ConnectionsMahmoud Ahmed Ali AbdelrazikÎncă nu există evaluări

- UBM 85 FT BoomDocument2 paginiUBM 85 FT Boomwahid_100Încă nu există evaluări

- Burn BodyDocument32 paginiBurn BodyMahmoud Ahmed Ali AbdelrazikÎncă nu există evaluări

- Pillard - Packlight Buk 117 CDocument2 paginiPillard - Packlight Buk 117 CAlfonso Blanco100% (1)

- General Arrangement For Mod 245 Pilot, SS316 PDFDocument1 paginăGeneral Arrangement For Mod 245 Pilot, SS316 PDFJabel Oil Services Technical DPTÎncă nu există evaluări

- Surface Well Testing Reporting Format and Standard GD-GL-HAL-SWT-601Document10 paginiSurface Well Testing Reporting Format and Standard GD-GL-HAL-SWT-601Said100% (1)

- Cleancut CCB PDFDocument2 paginiCleancut CCB PDFbruce lian100% (1)

- Model 245 Fuel Efficient PilotDocument2 paginiModel 245 Fuel Efficient PilotRommy RomanzaÎncă nu există evaluări

- QMT Energy Surface Well Testing (SWT) - Fourth Generation Green Emission Oil Burner Head PDFDocument2 paginiQMT Energy Surface Well Testing (SWT) - Fourth Generation Green Emission Oil Burner Head PDFTg TarroÎncă nu există evaluări

- Surge Tank: Pressurized Vessel H S Gas Leaving The Surge Tank Is Burned OffDocument13 paginiSurge Tank: Pressurized Vessel H S Gas Leaving The Surge Tank Is Burned OffMahmoud Ahmed Ali AbdelrazikÎncă nu există evaluări

- Well Stimulation VesselsDocument2 paginiWell Stimulation VesselsOscar RamirezÎncă nu există evaluări

- Den Con CatalogDocument36 paginiDen Con Catalogbaskaran vÎncă nu există evaluări

- Burner Manual - 60 FTDocument18 paginiBurner Manual - 60 FTsambhajiÎncă nu există evaluări

- 143 756 Flowatch 2013 1Document8 pagini143 756 Flowatch 2013 1YLW-BEKASIÎncă nu există evaluări

- LPR-N Tester Valve Funcionamiento 1Document33 paginiLPR-N Tester Valve Funcionamiento 1Александр КинтероÎncă nu există evaluări

- Wellsite Pressure TestDocument5 paginiWellsite Pressure TestBambang PermanaÎncă nu există evaluări

- Mud Gas Separator Sizing and EvaluationDocument3 paginiMud Gas Separator Sizing and EvaluationIvan Cerda0% (1)

- MGS Capacity CalculatorDocument13 paginiMGS Capacity CalculatorRodolfo MendezÎncă nu există evaluări

- Champ Ion PackerDocument2 paginiChamp Ion PackerCHO ACHIRI HUMPHREYÎncă nu există evaluări

- Super Safety ValveDocument1 paginăSuper Safety ValvePaul Ticona SÎncă nu există evaluări

- Ees ExampleDocument12 paginiEes ExamplesbjÎncă nu există evaluări

- Testing OverviewDocument30 paginiTesting Overviewashish7541Încă nu există evaluări

- 26 Mill-EZ Composite Bridge PlugDocument2 pagini26 Mill-EZ Composite Bridge PlugzbhdzpÎncă nu există evaluări

- Mud/Gas Separator Sizing and Evaluation: Aipu Solids ControlDocument24 paginiMud/Gas Separator Sizing and Evaluation: Aipu Solids ControlNicoFocheÎncă nu există evaluări

- Texas Oil Tools: Packer Inserts & EnergizersDocument12 paginiTexas Oil Tools: Packer Inserts & Energizersshahrol effendy rodziÎncă nu există evaluări

- Mud Gas Separator Poor Boy DegasserDocument3 paginiMud Gas Separator Poor Boy DegasserZain Ul AbdeenÎncă nu există evaluări

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Document8 paginiTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmÎncă nu există evaluări

- H07127 ThreePhaseHorzSepDocument2 paginiH07127 ThreePhaseHorzSepGuillermo Manuel SchödlÎncă nu există evaluări

- Well Test Standards WTS 3.8 Coflexip Hoses: Global ManualDocument9 paginiWell Test Standards WTS 3.8 Coflexip Hoses: Global ManualEmmanuel100% (1)

- Foss & Gaul PDFDocument17 paginiFoss & Gaul PDFnicolasbelliniÎncă nu există evaluări

- Heavy Oil: Presented By: Ali SaminDocument25 paginiHeavy Oil: Presented By: Ali SaminAli SaminÎncă nu există evaluări

- Vane Separator (Brochure PEERLESSMFG)Document6 paginiVane Separator (Brochure PEERLESSMFG)Julio OrtegaÎncă nu există evaluări

- Drain Valve - Bussines CatalogDocument2 paginiDrain Valve - Bussines CatalogAnne SophiaÎncă nu există evaluări

- Surface Safety Valve PsDocument2 paginiSurface Safety Valve PsDani JuandaÎncă nu există evaluări

- Separator GeneralDocument12 paginiSeparator GeneralMeshariAlEnezi100% (1)

- Gas Seperator PDFDocument11 paginiGas Seperator PDFshy_boyÎncă nu există evaluări

- Section 34 - Sight GlassDocument27 paginiSection 34 - Sight GlasshammamiÎncă nu există evaluări

- Chapter 3 (B)Document26 paginiChapter 3 (B)dinesh_hsenidÎncă nu există evaluări

- H010920 MPFM PDFDocument2 paginiH010920 MPFM PDFFriday IjokgwungÎncă nu există evaluări

- 11 - Data Obtained During WTDocument18 pagini11 - Data Obtained During WTAmin Amin100% (1)

- MPD Dhs 1400 RCDDocument2 paginiMPD Dhs 1400 RCDali_yy2003Încă nu există evaluări

- Choke Manifold EXPRODocument2 paginiChoke Manifold EXPROfurnaÎncă nu există evaluări

- Presentation CVM Zwick PDFDocument19 paginiPresentation CVM Zwick PDFteacgÎncă nu există evaluări

- 3 Phase Separators ( Separators') - Ascom SeparationDocument5 pagini3 Phase Separators ( Separators') - Ascom Separationnaveenbaskaran1989Încă nu există evaluări

- Mahad3 - WaterLess Fracturing TechnologyDocument48 paginiMahad3 - WaterLess Fracturing Technologycj100% (1)

- Mud Cooler ReportDocument14 paginiMud Cooler ReportAlok Singh100% (1)

- Rasci ChartDocument6 paginiRasci Charteng7mohamed7hashimÎncă nu există evaluări

- Wellhead Desander Brochure SpanishDocument2 paginiWellhead Desander Brochure SpanishRichard MangutaÎncă nu există evaluări

- Phase Tester VXDocument2 paginiPhase Tester VXlaaliauto100% (1)

- Camco Subsurface Chemical Injection SystemsDocument24 paginiCamco Subsurface Chemical Injection SystemsBruceÎncă nu există evaluări

- Methods To Improve The Efficiency of Rod-Drawn Subsurface PumpsDocument16 paginiMethods To Improve The Efficiency of Rod-Drawn Subsurface PumpsRichard More LeonÎncă nu există evaluări

- Agar408series MPFM SpecDocument2 paginiAgar408series MPFM SpecJADÎncă nu există evaluări

- BakerSPD Choke Tech Handbook 5-9-06 PDFDocument14 paginiBakerSPD Choke Tech Handbook 5-9-06 PDFCassielAlexzylalas LiambaÎncă nu există evaluări

- Well Testing: Super Green BurnerDocument2 paginiWell Testing: Super Green BurnerSadegh AhmadiÎncă nu există evaluări

- Kinemax Gas or Oil Burners: Bulletin 4200Document26 paginiKinemax Gas or Oil Burners: Bulletin 4200agua1829Încă nu există evaluări

- Series 1: Forced Draft Dual Fuel BurnersDocument4 paginiSeries 1: Forced Draft Dual Fuel Burnersdiogenes torresÎncă nu există evaluări

- 2 Catalog Solid FlameDocument4 pagini2 Catalog Solid FlamenitantharaniÎncă nu există evaluări

- Multistage Transistor AmplifiersDocument8 paginiMultistage Transistor Amplifiersbree789Încă nu există evaluări

- Nandpur: Gas Field, OgdclDocument5 paginiNandpur: Gas Field, OgdclAsad Ul HaqÎncă nu există evaluări

- Gradually Varied Flow and Rapidly Varied FlowDocument3 paginiGradually Varied Flow and Rapidly Varied FlowCourtneyÎncă nu există evaluări

- XFEM Analysis of A Plate With An Edge Crack PDFDocument14 paginiXFEM Analysis of A Plate With An Edge Crack PDFNagaraj RamachandrappaÎncă nu există evaluări

- ObservationsDocument6 paginiObservationsjeffreyÎncă nu există evaluări

- Quick Reference GuideDocument2 paginiQuick Reference GuideRalf MaurerÎncă nu există evaluări

- ABS HistoryDocument172 paginiABS Historyap1948Încă nu există evaluări

- Energy Meter Smart Meter and Prepaid MetersDocument35 paginiEnergy Meter Smart Meter and Prepaid MetersJEERATSE AMÎncă nu există evaluări

- The Aura-Soma Colour Essences PDFDocument2 paginiThe Aura-Soma Colour Essences PDFhelen100% (1)

- Tesla Motors Shelby LeeDocument13 paginiTesla Motors Shelby Leeflh21gmail100% (1)

- Get Back To Balance: Unbalanced Rotors Can Damage More Than Just BearingsDocument2 paginiGet Back To Balance: Unbalanced Rotors Can Damage More Than Just BearingsAnonymous PVXBGg9TÎncă nu există evaluări

- OBE Syllabus - PHYS TECH PDFDocument8 paginiOBE Syllabus - PHYS TECH PDFNicko CortoÎncă nu există evaluări

- E Instruction sk7615 7625Document7 paginiE Instruction sk7615 7625Abdalhakeem AlturkyÎncă nu există evaluări

- Inox Grade CF WikipediaDocument4 paginiInox Grade CF WikipediatrfihomeÎncă nu există evaluări

- Department of Water ResourcesDocument57 paginiDepartment of Water ResourcesGlenn Sabanal GarciaÎncă nu există evaluări

- ExtrusionDocument12 paginiExtrusionNitesh YadavÎncă nu există evaluări

- LSS Range Brochure 2019Document15 paginiLSS Range Brochure 2019Minh NguyenÎncă nu există evaluări

- PDS7114 Iss5 ESB OFFSHORE BATTERYDocument7 paginiPDS7114 Iss5 ESB OFFSHORE BATTERYSonthi MooljindaÎncă nu există evaluări

- Oscilloscope and Rc-Circuits Physics 230, Lab 5 Objective: Name PartnerDocument5 paginiOscilloscope and Rc-Circuits Physics 230, Lab 5 Objective: Name PartnerSanira LasanthaÎncă nu există evaluări

- Valaris 122: Primary Rig Characteristics CapacitiesDocument1 paginăValaris 122: Primary Rig Characteristics Capacitiesmelody04223Încă nu există evaluări

- Design Optimization of A High-Power Transformer For Three-Phase Dual Active Bridge DC-DC Converter For MVDC GridsDocument6 paginiDesign Optimization of A High-Power Transformer For Three-Phase Dual Active Bridge DC-DC Converter For MVDC GridsBhalchandra InamdarÎncă nu există evaluări

- Enhanced 1Document8 paginiEnhanced 1Lakshman JangamÎncă nu există evaluări

- EC ActDocument24 paginiEC ActKartik KulhariÎncă nu există evaluări

- Nema CatalogDocument56 paginiNema CatalogMarimuthu Ayyamperumal100% (1)

- Power Hump Project DetailsDocument67 paginiPower Hump Project DetailsSantosh Kumar Alpete33% (3)

- Sony Kdl-40nx710 - kdl40nx711 & Kdl-46nx710 - kdl46nx711 Ch. Az1-H LCD TV SMDocument40 paginiSony Kdl-40nx710 - kdl40nx711 & Kdl-46nx710 - kdl46nx711 Ch. Az1-H LCD TV SMedsel72Încă nu există evaluări

- TI LT PanelsDocument12 paginiTI LT PanelsHemant ChauhanÎncă nu există evaluări

- Making Mars The New EarthDocument4 paginiMaking Mars The New EarthPavel50% (2)

- The 12 Principles of Green ChemistryDocument1 paginăThe 12 Principles of Green ChemistryGonzalo BenavidesÎncă nu există evaluări