Documente Academic

Documente Profesional

Documente Cultură

Imote Case Study PDF

Încărcat de

sapiencecorpTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Imote Case Study PDF

Încărcat de

sapiencecorpDrepturi de autor:

Formate disponibile

Objets 3D printing method enabled us to quickly create the remote control prototype our customer needed and make

this product a reality. Without 3D printing, there was no way we could have succeeded.

Hilik Nottman,

Owner, Digmey Hagalil, Ltd.

3D final part of child-friendly TV remote unit courtesy of Comfy Inc.

Case Study

At a glance

Company: Digmey Hagalil Ltd. URL: www.digmeyhagalil.co.il Location: Israel Industry: Consumer electronics (service bureau)

High-accuracy Objet 3D printing creates sellable model of child-friendly TV remote

Ensuring young children watch only age-appropriate TV programs is often a challenge. With that in mind, entrepreneurial inventor Gil Lavi designed a unique, child-friendly television remote control unit that would enable parents to precisely define which channels their children would be allowed to watch. Lavi worked with an industrial designer, who brought the CAD designs to Digmey Hagalil, a rapid prototyping and 3D printing service bureau. In order to turn his concept into reality, Lavi required a working, high-level 3D prototype that would allow him to successfully present his product. To meet such high standards for quality, accuracy and precision, model builder Digmey Hagalil relied on 3D printing technology from Objet Geometries. Digmey Hagalil, a service bureau established in 1990 and located in the north of Israel, specializes in building models of all kinds for an international clientele. It also offers 3D printing and prototyping services for yachts, medical, industrial design, mechanical engineering and electronics applications. For Lavis remote control model, Digmey Hagalil produced the parts on its Objet Eden500V 3D Printing System which is based on Objets core PolyJet Technology. The Objet technology provided high levels of precision and speed, enabling Lavi to quickly produce the high-quality working model he needed in order to sell his idea to a consumer electronics company. The model was ready in just a few weeks, from the time the CAD design was completed, through to a working remote control. With a flexible grip area and working electronics, the 3D printed prototype was so close to the real thing that it passed the ultimate focus group test: young children were given the prototype to use, enabling Lavi to check functionality with the real-life target market. If it wasnt for the 3D printing, theres a good chance that I wouldnt have succeeded in making this product a reality, says Lavi. All I would have had would have been a slide presentation or something similar and I probably wouldnt have been able to sell the idea, he added.

Challenges

Create a highly accurate, life-size, 3D

prototype of an innovative television remote control unit Meet tough customer demands for aesthetic perfection in color and fit

Solution Results

Objet Eden500V 3D Printer Fast, exact process from CAD to More accurate parts than is possible with

alternative technologies Smooth surfaces and fine details that are easily painted for realistic-looking models Ability to insert electronics to create a working model for marketing purposes finished model

Value

Objets unique silicone molding

duplication capabilities enabled small, transparent and accurate parts Objet was the only technology able to print flexible materials to simulate touch and feel of the end product, enabling ergonometric testing Due to smooth surfaces, there was no need for post processing or polishing

Accuracy and speed make Objet the only choice

In addition to the Objet Eden500V, Digmey Hagalil also has a Connex500 multi-material 3D printer. According to company owner Hilik Gottman, choosing Objet 3D printing systems was the right move for this project and in general for his company. Objet systems offer high-quality printing, Gottman says. And, the time we save due to the fast printing speed of the Objet machines is an important advantage. Without Objet, I would not be in this business. The competition is very tough and other technologies, which are slower and less accurate, are not worth considering. Ease of use was another primary decision criteria for Digmey Hagalil. Gottman says: the Objet printing systems are very easy to use, and changing the cartridges is simple as well. The Objet systems enable Gottman and his team to troubleshoot for design problems early on in the process, as models are delivered with the files to clients for error review. If there are issues with the files, the client takes care of the problems and sends them back to us so that we can recreate the model correctly, notes Gottman. Lavis remote control model was printed at full size using Objet FullCure VeroGray model material and then painted with automobile paints. The electronic components were then inserted, creating a fully working model. Using the Objet printing system was the best solution, says Gottman. It was the simplest way to do it. The turnaround time is excellent. The machine works fast, which means that we can too.

Postscript

When Lavi worked with Digmey HaGalil, he was a private entrepreneur. Since then, he has joined the Objet team as Regional Sales Manager, Israel and Eastern Europe, enabling him to relate to his job, and to Objet technology, with a particularly personal passion.

Without Objet, I would not be in this business Other technologies, which are slower and less accurate, are not worth considering.

AbOUT ObJET GEOMETRIES

Objet Geometries Ltd., the innovation leader in 3D printing for rapid prototyping and additive manufacturing, provides 3D printing systems that enable manufacturers and industrial designers to reduce cost of product development and dramatically shorten time-to-market of new products. Objets ultra-thin-layer, high-resolution 3D printing systems and materials utilize PolyJet polymer jetting technology, to print ultra-thin16-micron layers. The market-proven Eden line of 3D Printing Systems and the Alaris30 3D desktop printer are based on Objets patented office-friendly PolyJet Technology. The Connex family is based on Objets PolyJet Matrix Technology, which jets multiple model materials simultaneously and creates composite Digital Materials on the fly. All Objet systems use Objets FullCure materials to create accurate, clean, smooth, and highly detailed 3D parts. Objet systems are in use by world leaders in many industries, such as Education, Medical / Medical Devices & Dental, Consumer Electronics, Automotive, toys, consumer goods, and footwear industries in North America, Europe, Asia, Australia, and Japan. Founded in 1998, Objet serves its growing worldwide customer base through offices in USA, Mexico, Europe, Japan, China and Hong Kong, and a global network of distribution partners. Objet owns more than 50 patents and patent pending inventions. For more information, visit us at www.objet.com.

Objet Geometries Ltd. Headquarters 2 Holtzman st., Science Park, P.O Box 2496, Rehovot 76124, Israel T: +972-8-931-4314 F: +972-8-931-4315

Objet Geometries Inc. North America 5 Fortune Drive Billerica, MA 01821 USA T: +1-877-489-9449 F: +1-866-676-1533

Objet Geometries GmbH Europe Airport Boulevard B 210 77836 Rheinmnster Germany T: +49-7229-7772-0 F: +49-7229-7772-990

Objet Geometries AP Asia Pacific Unit28, 10/f, HITEC 1 Trademart Drive Kowloon Bay, Kowloon Hong Kong T: +852-217-40111 F: +852-217-40555

Objet Geometries AP Limited China Rep Office Rm1701, CIMIC Tower, 1090 Century Blvd, Pudong Shanghai 200120 China T: +86-21-5836-2468 F: +86-21-5836-2469

2010 Objet, Quadra, QuadraTempo, PolyJet, FullCure, SHR, Eden, Eden250, Eden260, Eden260V, Eden330, Eden350, Eden350V, Eden500V, Job Manager, Objet Studio, CADMatrix, Connex, Connex350, Connex500, Alaris, Alaris30, PolyLog, TangoBlack, TangoBlackPlus TangoGray, TangoPlus, VeroBlue, VeroWhite, VeroBlack, VeroGray, Durus, Digital Materials, Polyjet Matrix and ObjetGreen are trademarks of Objet Geometries Ltd. and may be registered in certain jurisdictions. All other trademarks belong to their respective owners.

Q4/10

info@objet.com www.objet.com

S-ar putea să vă placă și

- Objet Eden250™ PDFDocument2 paginiObjet Eden250™ PDFsapiencecorpÎncă nu există evaluări

- Objet30 PDFDocument2 paginiObjet30 PDFsapiencecorpÎncă nu există evaluări

- Education Brochure SapienceDocument4 paginiEducation Brochure SapiencesapiencecorpÎncă nu există evaluări

- Eden500V PDFDocument2 paginiEden500V PDFsapiencecorpÎncă nu există evaluări

- FullCure950-TangoGray - US MSDS Rev4 PDFDocument5 paginiFullCure950-TangoGray - US MSDS Rev4 PDFsapiencecorpÎncă nu există evaluări

- Optimax Press Release PDFDocument2 paginiOptimax Press Release PDFsapiencecorpÎncă nu există evaluări

- PolyJet Matrix 3D Printing Technology Letter PDFDocument4 paginiPolyJet Matrix 3D Printing Technology Letter PDFsapiencecorpÎncă nu există evaluări

- Nanyang Tech University Case Study PDFDocument2 paginiNanyang Tech University Case Study PDFsapiencecorpÎncă nu există evaluări

- University of Camerino Architectural Case Study PDFDocument2 paginiUniversity of Camerino Architectural Case Study PDFsapiencecorpÎncă nu există evaluări

- Objet Eden350350V™ PDFDocument2 paginiObjet Eden350350V™ PDFsapiencecorpÎncă nu există evaluări

- Mahidol University Case Study PDFDocument2 paginiMahidol University Case Study PDFsapiencecorpÎncă nu există evaluări

- Objet260 Connex™ PDFDocument2 paginiObjet260 Connex™ PDFsapiencecorpÎncă nu există evaluări

- Objet Eden260V™ PDFDocument2 paginiObjet Eden260V™ PDFsapiencecorpÎncă nu există evaluări

- Zurich University Case Study PDFDocument4 paginiZurich University Case Study PDFsapiencecorpÎncă nu există evaluări

- Metro Health Case Study PDFDocument2 paginiMetro Health Case Study PDFsapiencecorpÎncă nu există evaluări

- Nimrod Racing Case Study PDFDocument2 paginiNimrod Racing Case Study PDFsapiencecorpÎncă nu există evaluări

- Arch Day Design Case Study PDFDocument4 paginiArch Day Design Case Study PDFsapiencecorpÎncă nu există evaluări

- Concept Molding Peltor AB PDFDocument2 paginiConcept Molding Peltor AB PDFsapiencecorpÎncă nu există evaluări

- University of Maryland Case Study PDFDocument2 paginiUniversity of Maryland Case Study PDFsapiencecorpÎncă nu există evaluări

- Biorep Technologies, Inc Case Study PDFDocument4 paginiBiorep Technologies, Inc Case Study PDFsapiencecorpÎncă nu există evaluări

- Geberit Case Study PDFDocument2 paginiGeberit Case Study PDFsapiencecorpÎncă nu există evaluări

- Ivivi Technologies Case Study PDFDocument2 paginiIvivi Technologies Case Study PDFsapiencecorpÎncă nu există evaluări

- NordicNeuroLab (NNL) Case Study PDFDocument2 paginiNordicNeuroLab (NNL) Case Study PDFsapiencecorpÎncă nu există evaluări

- APEX Dental Center Case Study PDFDocument2 paginiAPEX Dental Center Case Study PDFsapiencecorpÎncă nu există evaluări

- Zebco Case Study PDFDocument2 paginiZebco Case Study PDFsapiencecorpÎncă nu există evaluări

- Balda Solutions Case Study PDFDocument2 paginiBalda Solutions Case Study PDFsapiencecorpÎncă nu există evaluări

- Orchid Design Case Study PDFDocument2 paginiOrchid Design Case Study PDFsapiencecorpÎncă nu există evaluări

- NordicNeuroLab (NNL) Case Study PDFDocument2 paginiNordicNeuroLab (NNL) Case Study PDFsapiencecorpÎncă nu există evaluări

- Helvex Case Study PDFDocument2 paginiHelvex Case Study PDFsapiencecorpÎncă nu există evaluări

- Bremen University Case Study PDFDocument2 paginiBremen University Case Study PDFsapiencecorpÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- CASTINGQDocument15 paginiCASTINGQAshok PradhanÎncă nu există evaluări

- CVDocument2 paginiCVAjay KumarÎncă nu există evaluări

- Jurutera Pembinaan Dan Penyelenggaraan MesinDocument4 paginiJurutera Pembinaan Dan Penyelenggaraan MesinSyazwan ZulhilmiÎncă nu există evaluări

- Ffs Su 5218Document33 paginiFfs Su 5218BolarinwaÎncă nu există evaluări

- Direct: CNC Machining CentreDocument2 paginiDirect: CNC Machining CentreRivas IsaacÎncă nu există evaluări

- Nanolite CLC Blocks PDFDocument2 paginiNanolite CLC Blocks PDFKrishna YarlagaddaÎncă nu există evaluări

- Revised CH 5 Material Handling PDFDocument19 paginiRevised CH 5 Material Handling PDFTaha Bzizi100% (1)

- Ca 1035Document4 paginiCa 1035petethefrenchÎncă nu există evaluări

- Joining Stainless Steel by Soldering, Brazing and Resistance WeldingDocument4 paginiJoining Stainless Steel by Soldering, Brazing and Resistance WeldingA K SinghÎncă nu există evaluări

- Notes - Injection MoldingDocument10 paginiNotes - Injection MoldingNaveen VasanthÎncă nu există evaluări

- Die Steel OHNS - Saaj SteelDocument4 paginiDie Steel OHNS - Saaj SteelHarsha PrasadÎncă nu există evaluări

- Development of Recycled PET Fiber and Its Application As Concrete-Reinforcing FiberDocument8 paginiDevelopment of Recycled PET Fiber and Its Application As Concrete-Reinforcing FiberJunaid Ahmad100% (1)

- SWECs External 15 June 2020Document230 paginiSWECs External 15 June 2020Hamzah ZakiÎncă nu există evaluări

- Dry Wall Grid Material DataDocument2 paginiDry Wall Grid Material Datakhalid14Încă nu există evaluări

- Automation of System of BoilerDocument52 paginiAutomation of System of BoilerHarshil SanghaviÎncă nu există evaluări

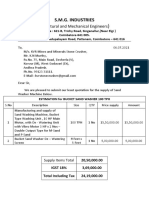

- S.M.G. Industries: (Structural and Mechanical EngineersDocument2 paginiS.M.G. Industries: (Structural and Mechanical EngineersRamÎncă nu există evaluări

- Casting ChecklistDocument4 paginiCasting Checklistmihai90Încă nu există evaluări

- Supply Chain Design and Analysis PDFDocument14 paginiSupply Chain Design and Analysis PDFTropic Thunder100% (1)

- Polca PDFDocument2 paginiPolca PDFJose Carlos OcoroÎncă nu există evaluări

- Unit-10 Time and Cost AnalysisDocument29 paginiUnit-10 Time and Cost AnalysisFaizanÎncă nu există evaluări

- WPS, PQR & WQT According To ASME Section IX - 2019Document50 paginiWPS, PQR & WQT According To ASME Section IX - 2019Anon YmousÎncă nu există evaluări

- Global Construction Summit: Construction Project Management Best Practice 2010Document11 paginiGlobal Construction Summit: Construction Project Management Best Practice 2010initiative1972Încă nu există evaluări

- Kanpur Confectionaries Private Limited: Case Study AnalysisDocument18 paginiKanpur Confectionaries Private Limited: Case Study Analysispraku_jhaÎncă nu există evaluări

- SCH GroupDocument29 paginiSCH GroupCalvin WongÎncă nu există evaluări

- Faisal Zeineddine ResumeDocument3 paginiFaisal Zeineddine ResumeFaisal ZeineddineÎncă nu există evaluări

- 1-Compliance Statement-Cable TrunkDocument3 pagini1-Compliance Statement-Cable Trunkvtalex100% (1)

- PEL PharmaDocument3 paginiPEL PharmaLilly TheresaÎncă nu există evaluări

- Chapter 10 - ROLE of HUB PORT-note 4 CreditDocument26 paginiChapter 10 - ROLE of HUB PORT-note 4 CreditNishaliney NadarajanÎncă nu există evaluări

- Material Requirements PlanningDocument1 paginăMaterial Requirements Planningflor gamboaÎncă nu există evaluări

- Layout TypesDocument6 paginiLayout TypeswearematalabiÎncă nu există evaluări