Documente Academic

Documente Profesional

Documente Cultură

41st AIAA Paper

Încărcat de

Srini KalmulaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

41st AIAA Paper

Încărcat de

Srini KalmulaDrepturi de autor:

Formate disponibile

2000-1376

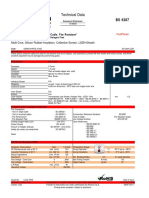

AN INTEGRATED DESIGN AND ANALYSIS TOOL FOR 3D WOVEN STRUCTURES Jon Goering Technical Specialist Composites Albany International Techniweave, Inc. Rochester, NH 03868

ABSTRACT A PC based software package for the design of 3D woven preforms is presented. This software integrates many of the design, analysis, and manufacturing tasks associated with these preforms. It incorporates a graphical textile CAD system, algorithms for calculating effective composite properties, and algorithms for generating weaving instructions. An overview of the software and examples of its use are included. INTRODUCTION

properties of components that are processed from the woven preforms they design. Albany International Techniweave, Inc. (AITI) has invested significant resources in the development of technology for producing complex 3D woven preforms. An important aspect of this work has been the development of an integrated preform design and analysis tool. This tool, named Techniweaver, is a graphical, PC based software package that incorporates a sophisticated textile CAD system, algorithms for calculating effective composite properties, algorithms for generating weaving instructions, and a material database (Figure 1). GRAPHICAL TOW PATH DEFINITION

The engineering community recognizes the benefits that may be realized through the use of fiber reinforced composite materials. The relatively high specific strengths and stiffnesses of these materials have led to reduced weight and improved performance for a variety of applications. These applications have concentrated primarily on the use of laminated composites consisting of a stack of unidirectional tape and/or 2D fabric plies. Although composites in this family are adequate for many structural applications, they typically suffer from relatively low through-thickness tensile strengths and stiffnesses, low interlaminar shear strengths and stiffnesses, and relatively poor impact damage tolerance. These properties can be improved through the use of 3D woven preforms that are processed into composites using techniques such as resin transfer molding or resin film infusion. Improvements in the through-thickness properties of 3D reinforced composites come at the expense of in-plane properties. Because of this tradeoff, a primary objective in the design of a woven preform is to strike an acceptable balance between the in-plane and through-thickness behavior. It is therefore essential that designers have reliable tools for evaluating the effective Copyright 2000 by Albany International Techniweave, Inc. Published by the American Institute of Aeronautics and Astronautics, Inc. with permission.

A fundamental objective of Techniweaver is the definition of accurate tow paths throughout a preform. These tow paths are defined by specifying the positions of picks (tows in the fill direction), and then graphically specifying the paths that warp tows take as they weave over and under these picks. An array of editing tools is available to simplify this process, including options to cut, copy, move, or modify existing paths. A graphical representation of the tow paths is continuously updated and displayed to help the designer ensure that the intended path has been specified. The amount of flattening that occurs as tows are woven and the fiber packing efficiency within the tows are also specified so that the graphical representation of the fiber architecture will be an accurate reflection of the actual preform. The fiber architecture for a typical 3D weave, as defined by Techniweaver, is compared to a photomicrograph of the actual fiber architecture in Figure 2. An algorithm that compresses the thickness of the preform to provide an estimate of the dimensions of the as-molded component is included in Techniweaver. This capability is essential for minimizing the cost and time required to develop near net shape preforms. Virtual prototyping exercises can be conducted within Techniweaver prior to the fabrication of the preform. Design deficiencies can then be corrected without

1 American Institute of Aeronautics and Astronautics

having to conduct a costly and time consuming trial and error development program. An accurate estimate of the dimensions of the finished component is also essential for calculating the total fiber content, and the distribution of fiber in the warp, fill, and through-thickness directions. Algorithms are also included to automatically calculate these quantities. EFFECTIVE PROPERTY CALCULATIONS Accurate definition of the tow paths and component dimensions also lead to more accurate predictions of effective composite properties. Techniweaver calculates the effective properties using a three step process. First, effective properties of unidirectional tows are calculated using the composite cylinder model. These unidirectional properties are then integrated along the path of the tow to get effective global properties of each tow. Finally, the effective tow properties are combined, using the uniform field model, to estimate the effective composite properties. This approach to material modeling is really an extension of the conventional approach used for 2D laminated composites (Figure 3). The process used in the 2D case assumes that the composite can be treated as a collection of unidirectional plies and that each unidirectional ply is a collection of fibers in a matrix. The effective properties of a unidirectional ply are typically estimated using a well known model, such as the composite cylinder assemblage or rule of mixtures, and the effective properties of the composite are calculated using classical laminated plate theory. In the three dimensionally reinforced composite analogy, fibers and matrix are combined into a unidirectional tow, rather than a ply, but the same unidirectional material models still apply. A collection of these unidirectional tows are then assembled at specific orientations in three dimensions, rather than two, to model the composite. Effective properties for the resulting material are then typically calculated using a volume averaging scheme. A common scheme is to transform the stiffness matrix of each oriented tow into global coordinates and volume average the results. In effect, this approach assumes that each tow is subject to the same global strain. Again, this is analogous to the 2D approach, which is based on making assumptions regarding the distribution of in-plane strain through the thickness of the laminate. The effective properties calculated by Techniweaver include the elastic properties ( i.e. moduli of elasticity, shear moduli, and Poissons ratios), coefficients of

thermal expansion, thermal conductivities, and density. Since the effective properties of a composite fabricated from a woven preform may not be orthotropic, Techniweaver also calculates the effective stiffness matrix, thermal expansion vector, and thermal conductivity matrix. By integrating this analytical capability into the design software, the designer can quickly evaluate the impact that design changes will have on the performance of a preform. Typical examples of the correlation between effective properties, as predicted by Techniweaver, and actual test data for two fiber architectures are shown in Figure 4. Bulk properties, such as those shown in Figure 4, are adequate for flat panels with uniform fiber architectures, but many preforms have architectures that vary in the warp and/or fill directions. A tapered preform is a common example of a preform with variable fiber architecture. Since the fiber architecture is changing along the length or width, the effective properties can be expected to change as well. Techniweave addresses this by including the ability to calculate effective properties on a pick column by pick column basis for architectures that vary in the warp direction, and on a dent by dent basis for those that vary in the fill direction. An example of the property distributions predicted by Techniweaver for a preform that tapers in the warp direction is shown in Figure 5. AUTOMATED WEAVING INSTRUCTIONS Once a design has been finalized, weaving instructions that control the loom used to fabricate the preform must be generated. AITI has developed sophisticated electronic Jacquard looms that are capable of independently controlling thousands of warp ends (Figure 6). The action of each of these ends must be specified for every pick insertion. Since there can be thousands of pick insertions in a typical design, it is impractical to program the loom manually. Techniweaver eliminates this problem by automating the generation of weaving instructions. This is analogous to having the program for a numerically controlled machine automatically generated from a CAD drawing, a practice that is common for machined metal or composite parts. In their most basic form, these instructions can be a simple description, in english, of when and where to raise heddles, when to insert picks, when to perform a beat up, and how much take-up is required. For electronic jacquards, these instructions can be translated into the looms native machine language and stored directly on a diskette for transfer to the loom. Lift plans,

2 American Institute of Aeronautics and Astronautics

for conventional harness type looms or mechanical jacquards that must be programmed manually, can also be generated automatically and displayed graphically. The ability to automatically generate weaving instructions minimizes the potential for errors in the weaving program, and greatly simplifies the implementation of design changes. A typcial design change is shown in Figure 7. In this example, the original design, shown on the left, did not weave well on an electronic jacquard. The design on the right was developed in a matter of hours, using Techniweaver, and its effective property distribution was calculated. These properties were found to be practically the same as the original design. New weaving instructions were then generated in a matter of minutes, transferred to electronic jacquard, and weaving was resumed with minimum downtime. MATERIAL DATABASE The use of an integrated material database throughout this process ensures that all designers are using a consistent set of material properties. This database includes thermo-mechanical properties for common fiber and matrix materials, as well as descriptions of commercially available material forms ( i.e. 6K AS4, 12K IM7, etc.). The material database is easily expanded and can be customized for specific applications. A library of historical data for the aspect ratios and fiber packing efficiency in tows of common fibers is also being established to simplify the specification of these parameters. This use of empirical data helps ensure that the design accurately reflects the geometry of the woven preform. CONCLUSION By coupling the preform design and analysis tasks, AITI has developed a tool that allows successful designs to be developed very quickly. It also allows a much broader range of design alternatives to be evaluated in a given period of time. Integrating the analytical evaluation of a preform directly into the design process also enables the concept of virtual prototyping for 3D woven composite structures, which reduces both the time and cost required to develope a new component. Further time and cost reductions are achieved by automating the generation of weaving instructions, which also improves first part quality.

3 American Institute of Aeronautics and Astronautics

4 American Institute of Aeronautics and Astronautics

5 American Institute of Aeronautics and Astronautics

6 American Institute of Aeronautics and Astronautics

7 American Institute of Aeronautics and Astronautics

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- DNV OS D101 Machi Sys PDFDocument61 paginiDNV OS D101 Machi Sys PDFSaid Elhamydy100% (1)

- Substation Equipment Failure Report October 14 To August 15Document95 paginiSubstation Equipment Failure Report October 14 To August 15Yogendra SwarnkarÎncă nu există evaluări

- Bondek User GuideDocument0 paginiBondek User GuidemarioxguzmanÎncă nu există evaluări

- LNG Technology SelectionDocument9 paginiLNG Technology SelectionWayne MonneryÎncă nu există evaluări

- Ansi C84.1Document24 paginiAnsi C84.1jojagucaÎncă nu există evaluări

- Carregadeira LiebherrDocument17 paginiCarregadeira Liebherrsanches pita100% (5)

- ISO 8217 2010 Fuel Standard For Marine Distillate FuelsDocument2 paginiISO 8217 2010 Fuel Standard For Marine Distillate FuelsiceburnerÎncă nu există evaluări

- Building Material - Timber & WoodDocument47 paginiBuilding Material - Timber & WoodSaurav ShresthaÎncă nu există evaluări

- Differences Between GATT and WTODocument6 paginiDifferences Between GATT and WTOSrini KalmulaÎncă nu există evaluări

- Atm Course PlanDocument5 paginiAtm Course PlanSrini KalmulaÎncă nu există evaluări

- Agro Textiles - General Property Requirement of Agrotextiles - Fibers Used For Agro-Textiles - Application of Agro Textiles - Textile Learner PDFDocument4 paginiAgro Textiles - General Property Requirement of Agrotextiles - Fibers Used For Agro-Textiles - Application of Agro Textiles - Textile Learner PDFSrini KalmulaÎncă nu există evaluări

- Introduction To Manufacturing ProcessDocument12 paginiIntroduction To Manufacturing ProcessSrini Kalmula100% (2)

- CAD Systems in Fashion and Textile Industry: Jimmy Lam The Hong Kong Polytechnic UniversityDocument34 paginiCAD Systems in Fashion and Textile Industry: Jimmy Lam The Hong Kong Polytechnic UniversitySrini KalmulaÎncă nu există evaluări

- General Textile Technology: Unit - IDocument1 paginăGeneral Textile Technology: Unit - ISrini KalmulaÎncă nu există evaluări

- Practical Manual: Garment Construction Paper Iii - I Year (Voc)Document13 paginiPractical Manual: Garment Construction Paper Iii - I Year (Voc)Srini KalmulaÎncă nu există evaluări

- DPF CeramicDocument11 paginiDPF Ceramicelliott_wolfÎncă nu există evaluări

- Steel Angles D 1322Document2 paginiSteel Angles D 1322Shanmuga SundaramÎncă nu există evaluări

- 14 Disperse Systems With AnswersDocument5 pagini14 Disperse Systems With AnswersPatricia Camryne Ambida100% (2)

- 2016good and ImportantDocument4 pagini2016good and ImportantMahdi koolivandÎncă nu există evaluări

- Wiring Diagram SectionDocument76 paginiWiring Diagram Sectiondavydenkoanton5Încă nu există evaluări

- Cabin Pressure:: ExampleDocument47 paginiCabin Pressure:: ExamplePrasanth ViratÎncă nu există evaluări

- Bonded App Gear GrindingDocument7 paginiBonded App Gear GrindingvengadeshÎncă nu există evaluări

- Pentapharm Brochure (En) 3.17.14Document12 paginiPentapharm Brochure (En) 3.17.14imakantisÎncă nu există evaluări

- Experiment 1Document4 paginiExperiment 1Kathrine E. BautistaÎncă nu există evaluări

- Mepoxe ANewDocument4 paginiMepoxe ANewHasbi Ashidiqi PÎncă nu există evaluări

- Anugrah Raya: Shear ConnectorDocument6 paginiAnugrah Raya: Shear ConnectordedeÎncă nu există evaluări

- Z&J Technologies GMBH: Conversion Table of EN - Materials vs. US Materials (Assorted by ASTM No.)Document1 paginăZ&J Technologies GMBH: Conversion Table of EN - Materials vs. US Materials (Assorted by ASTM No.)Nattapong PongbootÎncă nu există evaluări

- COF Neutral Solventless Adhesive Solution For Flexible PackagingDocument2 paginiCOF Neutral Solventless Adhesive Solution For Flexible PackagingalfredoÎncă nu există evaluări

- Design of Solar Panel Deployment Mechanism For A 1U CubeSatDocument7 paginiDesign of Solar Panel Deployment Mechanism For A 1U CubeSatAliMurtazaKothawalaÎncă nu există evaluări

- Hardtop XP Alu: Technical Data SheetDocument5 paginiHardtop XP Alu: Technical Data SheetAfrizal Albar RamadhanÎncă nu există evaluări

- Manufacturing Assignment 3: Steel Rolling ProcessDocument5 paginiManufacturing Assignment 3: Steel Rolling ProcessSrinivasan SridharanÎncă nu există evaluări

- Brittle Vs Sloughing ShaleDocument9 paginiBrittle Vs Sloughing ShaleJoseph BimoÎncă nu există evaluări

- Pararrayo CooperpowerDocument16 paginiPararrayo CooperpowerCristian AndresÎncă nu există evaluări

- Super End ChipperDocument14 paginiSuper End ChipperalphatoolsÎncă nu există evaluări

- The Threaded Style BackDocument6 paginiThe Threaded Style Backsharif339Încă nu există evaluări

- ANODIZING The Finish of ChoiceDocument4 paginiANODIZING The Finish of ChoiceAhmed HelalÎncă nu există evaluări

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 paginăSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaÎncă nu există evaluări