Documente Academic

Documente Profesional

Documente Cultură

Role of Quick Response To Supply Chain

Încărcat de

Sanuwar RashidDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Role of Quick Response To Supply Chain

Încărcat de

Sanuwar RashidDrepturi de autor:

Formate disponibile

Contents

The Role of Quick Response for Demand Driven Globalized Apparel Supply Chain Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Md. Sanuwar Rashid

Author Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

J. Xu et al. (eds.), International Conference on Management Science and Engineering Management 2012, v Lecture Notes in Electrical Engineering XXX, DOI: XXXXXXXXXX c Springer-Verlag London Limited 2012

Chapter 1

The Role of Quick Response for Demand Driven Globalized Apparel Supply Chain Management

Md. Sanuwar Rashid

Abstract The purpose of this paper is to explore the impact of quick response (QR) issue on demand driven supply chain management (SCM) and to establish an objective measure for the implementation of QR in apparel supply chain to remain competitive in global fashion market. This research work is based on critical review and synthesis from prior conceptual paper to get a measure of QR. This paper fabricates the suitability of QR business strategy in SCM to cope with the changing behavior of consumer preference and to incline the business as per consumer requirement. To minimize the uncertainties and demand variation, this paper determines elements and dimension of QR by identifying the essential virtues of supply chain. This paper is also devoted to recommend the driver and tools to merge QR with demand driven apparel SCM. This work extends previous research on the importance of QR strategy in SCM and lls a gap in traditional framework of demand driven supply chain. It illustrates how this strategy empowers by its components and split up into different dimensions, virtues and elements that allow more customer-oriented SCM. Keywords Quick Response (QR) Apparel supply chain Supply chain management (SCM) Globalization QR drivers Tools

1.1 Introduction

Developed countries belong to devolving countries for manufacturing product. Therefore, the various brands of developed countries emerge as branded marketer or brander retailer rather than branded manufacturer. So they needs to consider higher lead time to upload their product per season in retail shops. As the forecasting of demand trend is virtually impossible, there is a high risk of stock out of any parM. Rashid (B) Textile Engineering Department, Southeast University, Dhaka 1213, Bangladesh e-mail: sanuwar.rashid@gmail.com J. Xu et al. (eds.), International Conference on Management Science and Engineering Management 2012, 1 Lecture Notes in Electrical Engineering XXX, DOI: XXXXXXXXXX c Springer-Verlag London Limited 2012

M. Rashid

ticular product rapidly for consumer preference. And if the replenishment requires long lead time, customer demand may not exist up to then. In this paradigm, Quick Response methodology shows us the way to overcome the barrier like lower service levels and ensure the fewer lost sales and better end of season markdown performance [3, 9]. The supply chain of fashion enterprise faces many challenges for shorter product life cycle, change of fashion trend overnight, higher SKU range. These characteristics make the fashion market volatile than ever. Therefore, QR, in whole or in part, has been accepted and implemented by many retailers to get in time delivery of stock out product from their vendor [9, 19]. To cope with the demand of fundamentally changing global competition, QR and supply chain partnering issues gaining attention [18]. Analysis by Robert O Knorr, on QR and supply chain excellence, emphasized on new kind of trust based relationship between the manufacturer and the retailer and on redesigned business processes throughout the entire supply chain. And the supply chain inspired by QR including Just in time (JIT) delivery concepts and exible manufacturing of small lot of bulk production, will synchronized the ow of goods to retail consumer demand. Various studies have been conducted to indicate the components of quick response [8]. And insist on implementation of the key elements of QR methodologies by various organizations in supply chain [9]. A number of studies have investigated implementation of quick response (QR) concepts in the apparel industry [1, 917, 19, 20, 26]. However, there is a lack of research focusing on supplier perception of QR implementation (QRI). In this perspective, this paper work is devoted to represent the basis of an evolving and effective QR model for globalized apparel supply chain. The QR model in here is comprehended by its component and aimed to relate all prescribed dimension and key elements for a successful implementation. This model is interpretive and developed theoretically and oriented by its dimension, virtues and elements according to their driving power and dependence. The implementation process of QR is a prioritize matter of this paper which is fabricated by the value enhancement of globalized apparel supply chain.

1.2 The Literature Review 1.2.1 Todays Fashion Market

As we are now in twenty rst century, all retail segments are facing new challenges: perhaps the fashion industries are going to face the most critical situation. Hot trends are created overnight; consumer preferences change frequently, moreover assortment and SKU maintain is the tough job but these are essential for remaining competitive in market. The traditional method of marketing which was largely forecast based is no longer viable to us. Traditionally, what a apparel company sought to do is sort of

1 The Role of Quick Response for Demand Driven

plan ahead, pile up inventory and then just seat back and waiting for customer demand. But in this new environment the regular basis supply of product in market is emphasize enough to retain its sales opportunity every time. Non availability means that in the event of non supply the particular sales opportunity is lost forever [6]. Therefore over the time, evolvement of business process and its activities has gradually been inclining towards customer demand [19].

Scale Based

Mass Marketing

Flexible Scope Based Flexible Scope Based Quick Response

Mass marketing Low Labor content High Productivity Importance of experience curve

Mass marketing Low variety High volume

Mass marketing Flexible product, mix volume, delivery Economics of scope

Mass customization Flexibility plus rapid response Importance of variety in products & markets Product and process diversity

Low cost

Fig. 1.1 Changes of marketing strategy in response to consumers demand with the pace of time

Nowadays, in order to being able to realize the real value system of apparel Supply chain, we have to shift from the supply chain management to demand driven supply chain management [7]. Traditionally the value system was only designed with a chain of arrows horizontally from raw material to end consumer and feeding back an opposite arrows from end consumer to source for information ow (Fig. 1.2).

Unit Level

Purchasing

Marketing

Costomer/ Supplier

Planning

Costomer/ Supplier

Manufacturing

Inspection

Products Sheep Spinning Weaving Dyeing Cut & Garment trim manufacturing Fashion retail Customers

Information

Fig. 1.2 Traditional Supply Chain as well as value system

M. Rashid

Unlike the traditional business concept, nowadays branded marketer as well as branded retailer comes to developing country to manufacture their product. Therefore, every fashion company needs to count lead time to bring out the new product into market. To offer the right product at the right place to the right customer it is very necessary to shorten down the lead time. Therefore, the concept of vertical integration transform into virtual integration to manage the business process. In this paradigm, what we have to do is rearrange the supply chain. For example, the value system should slightly modify to prioritize the consumer preference where the demand side is represented by the retailers. Based on their experience and the assessment of consumer needs and desire, retailers performed the assortment planning, inventory management and the activities related with purchasing [19, 21]. Subsequently, the retailer would conduct his production in another country from sourcing to distribution and to integrate -the distribution of product and purchasing activitiesvirtually while quick response comes in to action (Fig. 1.3).

Sourcing

Manufacturing

Packaging Distribution

QR

Inventory Assortment Purchasmanagement planning ing

Fig. 1.3 Supply Chain tends to be demand driven to react quickly to consumer demand

1.2.2 Quick Response (QR) Strategy

In a demand driven supply chain perspective, quick response is suited for apparel sector to make the supply chain member and customer beneted while the same kind of benet is taken from efcient consumer response (ECR) system for grocery sector [3]. Automatic replenishment (AR) is more commonly used strategy accepted by many rms in recent years. Based on point of sales data, AR triggers the restocking of inventory to avoid the lost sales and ensure the availability of demandable SKUs throughout the selling season. It made long range forecast and safety stock less viable [22]. QR is one type of AR system that has been widely adopted by fashion retailers and their suppliers in response to the fast fashion trend. It is a strategy which guide retailer to link up with their supplier to get a replenishment of stock out product. Therefore, the replenishment is free from prognosis error. Lowson et al [19] dened QR as: A state of responsiveness and exibility in which an organization seeks to provide a highly diverse range of products and services to a customer/consumer in the exact quantity, variety and quality, and at the right time, place and price as dictated by real-time customer/ consumer demand . Quick response is the combination of Just in time system and IT systems such as electronic point of sale (EPOS), Electronic data interchange (EDI), Computer aided design (CAD) and computer aided manufacturing (CAM) for enabling the supply

1 The Role of Quick Response for Demand Driven

chain to become more efcient [9]. Where production is demand driven rather than forecast based, there QR plays its ultimate role of information data sharing of retail store. Based on SKUs and specications about order schedules and deliveries, QR strategy creates the eld of buyer and supplier relationship. According to the model induced by Fiorito et al [9], retailer collects information by evaluating his sales data which is mainly based on consumer needs and demand. Merchandise information, such as size, style, color and brand are collected through scanning barcodes. EDI is then subjected to transfer the information to vendor and based on this sales data of retail store, production is ordered for specic items to prevent the stock out of these products. It is important as I mentioned earlier that non availability means that in the event of non supply the particular sales opportunity is lost forever. From the above gure it is clear to us that implementation of QR in reality is only possible through the development of IT. The rms which has wish to integrated itself virtually with upstream and downstream, needs to install information technology (IT) in their supply chain management procedure. According to [19], implementation of quick response is not something that deals with IT, but a strategy for information system (IS).

1.3 Discussion & Analysis 1.3.1 Generalization of QR System

The processes, components and systems of QR cannot and will not be applicable in a same manner to each SCM business process. It is, like its outcomes, exible and contingent upon considerations of various perspectives. Therefore, it is not easy to implement QR in a business process while the retail shops are in Europe or USA and the manufacturer stay behind; may be somewhere in Asian country. So, QR should be supported by IS and by its component to create an uninterruptable network to respond to customer demand. Gunston and Harding [23] emphasize on the contribution of its component for a smooth ow of products: A mode of operation in which a manufacturing or service industry strives to provide products and services to its customers in the precise quantities, varieties and within the time-frames that those customers require. Some of the components of QR system are listed below. (1) Electronic data interchange (EDI) EDI is the procedure of transferring the business data from a rms computer system to the supplier computer system. Business data covers the purchase orders & conrmation, invoices, remittance advice, shipment releases, advance shipment notice and planning schedule which are effectively belongs to implementing QR. (2) Bar-coded merchandise Bar-coding is essential to get the information on SKUs volume and mixes. Here information means the accountability of transaction and remaining inventories. Bar-

M. Rashid

code basically an electrical safety mark and it demonstrates to everyone in supply chain. The record keeping system of inbound and outbound material can help them to calculate the waiting time and total time duration to receive the raw material as well as to deliver the product to the retail shop. So the partners of supply pipeline can go one step ahead in implementation of QR if they are adopted with the bar code facilities. (3) PoS data sharing with customer It is one kind of software covering the data of inventory values, remaining SKUs information rather than just recording of cash transaction. PoS have the signicance of estimating reorder quantities for a particular time. By evaluating the point of sales data, we can easily identify the slow moving and fast moving goods of a retail shop. On the basis of this evaluation, we can take initiatives to minimize the lost sales as well as maximize the sell through percentage. (4) Shared planning Business partner should take part in a SCM process with shared degree of strategy and collaborative planning. Each partner should be updated about others activity rather than being autonomous. (5) Universal product codes (UPC) UPC should be entitled to each and individual SKUs. And it should remain same throughout the SCM network. UPC plays an important role in identifying and tracking of bar code. (6) Store ready deliveries Direct store delivery with having price ticketing and nal packaging as per retailers specication will reduce the pressure of packing and repacking at DC and warehouse. Therefore, each delivery cycle will cause less time as the goods are ready to be placed on shelf once delivered. There are some other components for a smooth generation of QR in supply chain like electronic reorder, continual and automatic replenishment, sales captured at item level, container shipping codes, electronic purchase order and invoicing, shared inventory management system, small batch orders, sharing product information with trading partners, modular or cellular manufacturing, joint product planning, consumer demographic information system and demand relationship [19].

1.3.2 Dimension

To cover the wider spread area of supply and demand chain, quick response enlarges its dimension or attribute in every possible way and Christopher expressed this matter as 4Rs. According to Christopher as we move rapidly into the era of supply chain competition, a number of principles emerge to guide . These can be conveniently summarized as the 4Rs of responsiveness, reliability, resilience and relationships. (1) Responsiveness

1 The Role of Quick Response for Demand Driven

The highly unpredictable demand creates volatility and causes high obsolete inventory, lost sales, and markdowns [21]. To ensure the material ow as per demand of upstream, quick response emphasized on responsiveness and exibility [19]. Responsiveness ensures the effectiveness and efciency of need for speed-to-market, exibility and market orientation. Therefore, it is the ability to react purposefully and within an appropriate time-scale to consumer demand or change in fragmented marketplace while competitive advantage will be ensured and eventually this tactic will minimize the lost sales and markdowns [24]. In several ways, exibility inclines toward the achievement of responsiveness within the dened supply chain parameters. The unpredictable change and volatility affect the supply chain ow and the concept of agility is come in action to minimize this problem [2]. Thus exibility and agility reinforce the proposition of responsiveness being the one dimension of QR. (2) Reliability Reliability is something which is truly related with the quality or authenticity of supply chain management procedure and more importantly it ensures the continuous optimization of QR. The consumer driven approach of supply chain brings out the new perspective of quality - total quality management (TQM). It encompasses the core concepts which are known as the heart of quick response [19]: customer focus, error prevention, cost of quality, right rst time or zero defects, acceptable quality level, competitive benchmarking, involvement to everyone, synergetic partnerships and team work etc. Youssef et al [25] argued that TQM is not only a quality related issue but it also measure the ability of rm to be a time based competitor. Therefore, TQM stimulates quick response culture through recognition, awareness, problem, ownership, and involvements which are known as core of developing reliability. (3) Resilience Risk management becomes the most prioritize area of every supply chain management business process. Supply chain; in general, use to experience continual turbulence, creating a potential for unpredictable disruption. The reason of experience the turbulence may vary from different perspective but causes complexity in supply chain. Therefore, the concept of resilience comes forward which measure the capacity of an enterprise to survive, adapt, and grow in the face of turbulent change. According to [5], resilience is the ability of a system to return to its original state or move to a new, more desirable state after being disturbed. For an effective and efcient quick response strategy in business process, value chain should be supported by adequate and sufcient resilience in terms of exibility, redundancy, robustness and risk management. It is urgency to have sufcient resilient to resist disruptions, respond quickly and fulll customer day to day demand changes to make quick response truly successful. In this sense, for managing and mitigating the vulnerability of supply chain, the concept of resiliency promoted as another dimension of quick response. (4) Relationship To be efcient and more structure oriented, the development of supply chain relationship is more emphasized by quick response perspective. And the relationship is mainly based on collaboration, partnerships, integrations and information sharing.

M. Rashid

The performance of a supply chain depends much on alliances and relationships and mutual understanding or compromising ability of different role player. Competition is now between mutual networks rather than individual rms [4]. The co-ordination and relationships between these various entities is a matter for strategic consideration. From a QR perspective, the web of relationships and mutual networks upon which the organization depends, requires a professional management approach, and increasingly rms are devoting staff and other resources to this task [19]. Apparel manufacturers operate within a distribution channel with suppliers, retailers and consumers. Relationship in an apparel value chain could be inter-organizational at same or different levels (integration -horizontal or vertical respectively or collaboration), intra-organizational (collaboration based on organizational culture) or with customer (customer focus).

Fig. 1.4 QR strategy empowered by its components and headed towards customer response throughout its dimension, virtues and key elements

1.4 Quick Response Implementation

The volatility of todays fragmented and intensely competitive marketplace is the obstacle to understand the customer demand and offer them the right product at the right place. Even consumers have never been more sophisticated. They wish to be fully satised by purchasing an item. In this perspective, QR offers a wealth of opportunity to the partners of SCM but the matter is to be adopted with this systematic

1 The Role of Quick Response for Demand Driven

approach. Analysis of number of studies [9, 11, 13, 14, 19, 26] on implementation of QR in apparel supply chain shows that there are some drivers; (1) viable supply chain partnership (2) advanced manufacturing techniques (3) QR related information sharing (4) QR organization (5) Bar code technologies and electronic communication; which are successfully subjected for QR implementation (QRI). And each driver is constructed by their elements or tools to manage the customer-demand driven SCM. In the following gure it has been seen that the excellence of supply chain is inspired by ve categories of QR where the ultimate outcome is customer satisfaction as well as nancial benets.

Viable Supply Chain Partnership

Advanced Manufacturing Techniques CAD CAM CIM Automation FMS (Modular or UPS) JIT, Lean Production Statistical Process control

QR related Information sharing

QR Organization

Bar code technologies and electronic communication EDI UPC Bar coding for product & shipping container RFID CPFR VALUE Added Network

Trust Shared risk Group goal setting Regular planning Review meeting

Product design Specification Production planning Capacity cost Cross functional Info

Top level commitment Joint planning TQM Program Time-based benchmark Adequate sourcing

End customers

Sourcing

Manufacturing

Packaging Distribution

QR empowered by its elements

Inventory Assortment Purchasmanagement planning ing

Timely delivery or Arrival of correct product

Improved Supply Chain Relationship

Financial Benefits

Fig. 1.5 Five basic drivers of QRI for apparel supply chain empowered by its tools

1.5 Conclusion & Further Work

This research work makes a sense of QR denition, its background and the area it covers under the paradigm of apparel supply chain. The ndings can be summed up in some words: a effective business strategy that works on wider spread area of marketing management and better suited on changing nature of competitive market place and generates responsiveness to customer demand, encourages business relationship and reliability with adequate resiliency of risk avoidance and ensures effective use of resources and shortening the cycle of SCM business process. Therefore, this methodology consists of its components and split up into different dimensions, virtues and elements, allows more customer oriented SCM. This research work struggled to comprehend theoretical frame work of QR and intended to show how an organization and its supply pipeline could adopted with

10

M. Rashid

its components and become beneted by practicing through different dimensions of QR. Anyway, this research work needs further validation by empirical case studies conducted through various questionnaires and surveys. It is also essential to take a measure of time and expanses for the implementation procedure throughout the entire value chain.

References

1. Bertolini M, Bevilacqua M, Bottani E et al (2004) Requirements of an ERP enterprise modeller for optimally managing the fashion industry supply chain. Journal of Enterprise Information Management 17:180189 2. Bernardes ES, Hanna MD (2009) A theoretical review of exibility, agility and responsiveness in the operations management literature: Toward a conceptual denition of customer responsiveness. International Journal of Operations & Production Management 29:3053 3. Birtwistle G, Fiorito S, Christopher M (2006) Supplier perceptions of quick response systems. Journal of Enterprise Information Management 19:334345 4. Christopher M (2005) Logistics and supply chain management: Creating value-added networks. 3rdn, Pearson education 5. Christopher M, Lee H (2004) Mitigating supply chain risk through improved condence. International Journal of Physical Distribution & Logistics Managemen 34:388396 6. Debasis D (2003) Supply chain management: An integrated solution to apparel industry. Journal of Apparel Association, July-August 7. Ericsson D (2003) Supply/demand chain management: The next frontier for competitiveness. Waters D: Global Logistics and Distribution Planning 8. Fernie J, Azuma N (2004) The changing nature of Japanese fashion: Can quick response improve supply chain efciency? European Journal of Marketing 38:790808 9. Fiorito SS, May E, Straughn K (1995) Quick Response in retailing: Components and implementation. International Journal of Retail & Distribution Management 23:1221 10. Fiorito SS, Giunipero LC, He Y (1998) Retail buyers perceptions of quick response systems. International Journal of Retail & Distribution Management 26:237246 11. Giunipero LC, Fiorito SS, Pearcy DH et al (2001) The impact of vendor incentives on quick response. The International Review of Retail, Distribution and Consumer Research 11:359 376 12. Ko E, Kincade DH (1997) The impact of quick response technologies on retail store attributes. International Journal of Retail & Distribution Management 25:9098 13. Ko E, Kincade D, Brown JR (2000) Impact of business type upon the adoption of quick response technologies: The apparel industry experience. International Journal of Operations & Production Management 20:10931111 14. KSA (1998) Response Implementation: Action Steps for Retailers, Manufacturers and Suppliers. Kurt Salmon Associates, Atlanta, GA 15. KSA (1996) Floor-ready merchandise is a win-win. RIS News, March. 16. KSA (1997) Quick response mandate today. Apparel Industry Magazine, March 17. KSA (1997) Quick response: Meeting customer needs. Kurt Salmon Associates, Atlanta, GA 18. Knorr R, Neuman J (1992) Quick response technology: The key to outstanding growth. Journal of Business Strategy 13:6164 19. Lowson B, King R, Hunter A (1999) Quick response: Managing the supply chain to meet consumer demand. Wiley, Chichester 20. Perry M, Sohal AS (2000) Quick response practices and technologies in developing supply chains. International Journal of Physical Distribution & Logistics Management 30:627639

1 The Role of Quick Response for Demand Driven

11

21. Wong CY, Hvolby H (2007) Coordinated responsiveness for volatile toy supply chains. International Journal of Production Planning & Control 18:407419 22. Stank TP, Daugherty PJ, Autry CW (1999) Collaborative planning: Supporting automatic replenishment programs. Supply Chain Management 4:7585 23. Gunston R, Harding P (1987) QR: US and UK experiences. Textile Outlook International 10:4351 24. Kritchanchai D, MacCarthy BL (1999) Responsiveness of the order fullment process. International Journal of Production & Operations Management 19:812833 25. Youseff MA, Boyd J, Williams E (1996) The impact of total quality management on rms responsiveness: An empirical analysis. Total Quality Management 7:127144 26. Perry M, Sohal A, Laney R (2002) An Australian quick response supply chain model. Department of Management, Faculty of Business and Economics, Monash University, Working paper

Author Index

Md. Sanuwar Rashid, 1

J. Xu et al. (eds.), International Conference on Management Science and Engineering Management 2012, 13 Lecture Notes in Electrical Engineering XXX, DOI: XXXXXXXXXX c Springer-Verlag London Limited 2012

S-ar putea să vă placă și

- CRM MCQ SecondDocument11 paginiCRM MCQ Secondvarun k sureshÎncă nu există evaluări

- CPFR ModelDocument10 paginiCPFR ModelUcheÎncă nu există evaluări

- Category Management GTDocument2 paginiCategory Management GTArun MaithaniÎncă nu există evaluări

- Product Line Management A Complete Guide - 2019 EditionDe la EverandProduct Line Management A Complete Guide - 2019 EditionÎncă nu există evaluări

- L.E.K. 4 Steps To Optimizing Trade Promotion EffectivenessDocument5 paginiL.E.K. 4 Steps To Optimizing Trade Promotion EffectivenessAditi JaitlyÎncă nu există evaluări

- Value Chain Management Capability A Complete Guide - 2020 EditionDe la EverandValue Chain Management Capability A Complete Guide - 2020 EditionÎncă nu există evaluări

- AOL.com (Review and Analysis of Swisher's Book)De la EverandAOL.com (Review and Analysis of Swisher's Book)Încă nu există evaluări

- IT Operating Model Complete Self-Assessment GuideDe la EverandIT Operating Model Complete Self-Assessment GuideÎncă nu există evaluări

- Digital Marketing Trends and Prospects: Develop an effective Digital Marketing strategy with SEO, SEM, PPC, Digital Display Ads & Email Marketing techniques. (English Edition)De la EverandDigital Marketing Trends and Prospects: Develop an effective Digital Marketing strategy with SEO, SEM, PPC, Digital Display Ads & Email Marketing techniques. (English Edition)Încă nu există evaluări

- An Introduction To CRMDocument48 paginiAn Introduction To CRMDora Nasike100% (2)

- Consumer Goods Key Account Management: Best Practices: A Perspective On The IssuesDocument21 paginiConsumer Goods Key Account Management: Best Practices: A Perspective On The IssuesEdrialÎncă nu există evaluări

- supplier segmentation A Complete Guide - 2019 EditionDe la Everandsupplier segmentation A Complete Guide - 2019 EditionÎncă nu există evaluări

- Effective Category ManagementDocument20 paginiEffective Category Managementharjyot cheemaÎncă nu există evaluări

- Boost Sales With Promo Compliance TrackingDocument18 paginiBoost Sales With Promo Compliance TrackingFabrice K RascoÎncă nu există evaluări

- CPFR Whitepaper Spring 2008-VICSDocument25 paginiCPFR Whitepaper Spring 2008-VICSakashkrsnaÎncă nu există evaluări

- Nielsen SipDocument45 paginiNielsen Sipmonali gangulyÎncă nu există evaluări

- Assignment-Demand ManagementDocument26 paginiAssignment-Demand Managementharendra choudhary100% (1)

- Customer Relationship Management ROIDocument19 paginiCustomer Relationship Management ROIHồng PhúcÎncă nu există evaluări

- Optimize Customer Portfolio Management with Data-Driven InsightsDocument20 paginiOptimize Customer Portfolio Management with Data-Driven InsightsRedwanul IslamÎncă nu există evaluări

- KHFL supply chain analysis and recommendationsDocument18 paginiKHFL supply chain analysis and recommendationsHarsheshChopra100% (1)

- Integrated Business Planning A Complete Guide - 2020 EditionDe la EverandIntegrated Business Planning A Complete Guide - 2020 EditionÎncă nu există evaluări

- Customer Relationship Management: Strategic Application of ItDocument52 paginiCustomer Relationship Management: Strategic Application of ItShipra SrivastavaÎncă nu există evaluări

- "Think Fresh, Deliver More": A PresentationDocument63 pagini"Think Fresh, Deliver More": A PresentationKapil Kumar JhaÎncă nu există evaluări

- BUS416Week5PricingTaxonomy 11466Document12 paginiBUS416Week5PricingTaxonomy 11466diana.yantiÎncă nu există evaluări

- Marketing Information System A Complete Guide - 2020 EditionDe la EverandMarketing Information System A Complete Guide - 2020 EditionÎncă nu există evaluări

- Organizational Behavior and Management - Final Project - Spring 2014Document24 paginiOrganizational Behavior and Management - Final Project - Spring 2014api-270981092Încă nu există evaluări

- Customer Portfolio Management StrategiesDocument49 paginiCustomer Portfolio Management StrategiesSahil MathurÎncă nu există evaluări

- Sales and Ditribution CHP 12Document36 paginiSales and Ditribution CHP 12rohan_jangid8Încă nu există evaluări

- Private Sector DevelopmentDocument29 paginiPrivate Sector Developmenthimelhimel34Încă nu există evaluări

- Customer Relationship Management and Customer ExperienceDocument43 paginiCustomer Relationship Management and Customer ExperienceYusrah JberÎncă nu există evaluări

- Lecture 6 - Of&CS (Meeting Customers' Real Needs)Document28 paginiLecture 6 - Of&CS (Meeting Customers' Real Needs)Amjad AliÎncă nu există evaluări

- Levy - Chapter 1Document8 paginiLevy - Chapter 1Sachin Umbaraje100% (1)

- Machine Learning For Revenue Management A Complete Guide - 2020 EditionDe la EverandMachine Learning For Revenue Management A Complete Guide - 2020 EditionÎncă nu există evaluări

- Customer Survey Evaluation The Ultimate Step-By-Step GuideDe la EverandCustomer Survey Evaluation The Ultimate Step-By-Step GuideÎncă nu există evaluări

- Ch02 CRM Industry LandscapeDocument21 paginiCh02 CRM Industry LandscapeVignesh VikkyÎncă nu există evaluări

- Future Series Category Management White PaperDocument11 paginiFuture Series Category Management White PaperDeepak KumarÎncă nu există evaluări

- Chapter 03Document33 paginiChapter 03Laiba KhanÎncă nu există evaluări

- Marketing When Customer Equity MattersDocument2 paginiMarketing When Customer Equity MattersDevante DixonÎncă nu există evaluări

- 21i - 2305 - 21i - 2322 Role of Big Data in Target MarketingDocument13 pagini21i - 2305 - 21i - 2322 Role of Big Data in Target MarketingAtif SaeedÎncă nu există evaluări

- Category Management and Private LabelsDocument4 paginiCategory Management and Private LabelsAditi ChauhanÎncă nu există evaluări

- Chap 3Document16 paginiChap 3Timothy BlakeÎncă nu există evaluări

- A. Company OverviewDocument12 paginiA. Company Overviewsauvik ghoshÎncă nu există evaluări

- The Robert Donato Approach to Enhancing Customer Service and Cultivating RelationshipsDe la EverandThe Robert Donato Approach to Enhancing Customer Service and Cultivating RelationshipsÎncă nu există evaluări

- BPR-ProcessReengineeringDocument9 paginiBPR-ProcessReengineeringGunjan NarulkarÎncă nu există evaluări

- Channel Institutions - Retailing: SDM-CH 10Document39 paginiChannel Institutions - Retailing: SDM-CH 10satyamehtaÎncă nu există evaluări

- CRM and SCM Integration for Improved Customer CommunicationDocument33 paginiCRM and SCM Integration for Improved Customer CommunicationPoornima Kesavan100% (1)

- Retail Book Chap10Document23 paginiRetail Book Chap10Harman Gill100% (2)

- Future Key Account ManagementDocument11 paginiFuture Key Account Managementaditya bagus yunanda100% (1)

- High-Tech Marketing Research ToolsDocument82 paginiHigh-Tech Marketing Research ToolsHarshit MarwahÎncă nu există evaluări

- Brand Management AssignmentDocument23 paginiBrand Management Assignmental mamunÎncă nu există evaluări

- The Case Study P& GDocument64 paginiThe Case Study P& GzeeÎncă nu există evaluări

- Operational Readiness Review A Complete Guide - 2020 EditionDe la EverandOperational Readiness Review A Complete Guide - 2020 EditionÎncă nu există evaluări

- Information Technology Project Report - IT in Retail Merchandising SystemDocument24 paginiInformation Technology Project Report - IT in Retail Merchandising SystemSuman MondalÎncă nu există evaluări

- Two PageDocument2 paginiTwo PageSanuwar RashidÎncă nu există evaluări

- CCSEDocument8 paginiCCSESanuwar RashidÎncă nu există evaluări

- Article ForThe Textile JournalDocument12 paginiArticle ForThe Textile JournalSanuwar RashidÎncă nu există evaluări

- Fashion Marketing 12Document99 paginiFashion Marketing 12Sanuwar RashidÎncă nu există evaluări

- Md. Sanuwar Rashid's Research on Product Specific Sourcing StrategiesDocument12 paginiMd. Sanuwar Rashid's Research on Product Specific Sourcing StrategiesSanuwar RashidÎncă nu există evaluări

- Fashion Marketing 12Document99 paginiFashion Marketing 12Sanuwar RashidÎncă nu există evaluări

- B.Sc. Textile Engineering 1st Year Course OverviewDocument46 paginiB.Sc. Textile Engineering 1st Year Course OverviewSanuwar RashidÎncă nu există evaluări

- Category Management. The Effective Way of Managing Retail BusinessDocument59 paginiCategory Management. The Effective Way of Managing Retail BusinessRafał Wacławski100% (1)

- The Ultimate Advanced Family PDFDocument39 paginiThe Ultimate Advanced Family PDFWandersonÎncă nu există evaluări

- To Introduce BgjgjgmyselfDocument2 paginiTo Introduce Bgjgjgmyselflikith333Încă nu există evaluări

- BIBLIO Eric SwyngedowDocument34 paginiBIBLIO Eric Swyngedowadriank1975291Încă nu există evaluări

- Analytical Approach To Estimate Feeder AccommodatiDocument16 paginiAnalytical Approach To Estimate Feeder AccommodatiCleberton ReizÎncă nu există evaluări

- 3 - Performance Measurement of Mining Equipments by Utilizing OEEDocument8 pagini3 - Performance Measurement of Mining Equipments by Utilizing OEEGonzalo GarciaÎncă nu există evaluări

- Exercises 6 Workshops 9001 - WBP1Document1 paginăExercises 6 Workshops 9001 - WBP1rameshqcÎncă nu există evaluări

- Rubber Chemical Resistance Chart V001MAR17Document27 paginiRubber Chemical Resistance Chart V001MAR17Deepak patilÎncă nu există evaluări

- Manual Analizador Fluoruro HachDocument92 paginiManual Analizador Fluoruro HachAitor de IsusiÎncă nu există evaluări

- Marketing Plan for Monuro Clothing Store Expansion into CroatiaDocument35 paginiMarketing Plan for Monuro Clothing Store Expansion into CroatiaMuamer ĆimićÎncă nu există evaluări

- Lecture02 NoteDocument23 paginiLecture02 NoteJibril JundiÎncă nu există evaluări

- Olympics Notes by Yousuf Jalal - PDF Version 1Document13 paginiOlympics Notes by Yousuf Jalal - PDF Version 1saad jahangirÎncă nu există evaluări

- 2010 - Impact of Open Spaces On Health & WellbeingDocument24 pagini2010 - Impact of Open Spaces On Health & WellbeingmonsÎncă nu există evaluări

- Photographing Shadow and Light by Joey L. - ExcerptDocument9 paginiPhotographing Shadow and Light by Joey L. - ExcerptCrown Publishing Group75% (4)

- Portfolio by Harshit Dhameliya-1Document85 paginiPortfolio by Harshit Dhameliya-1Aniket DhameliyaÎncă nu există evaluări

- Liebert PSP: Quick-Start Guide - 500VA/650VA, 230VDocument2 paginiLiebert PSP: Quick-Start Guide - 500VA/650VA, 230VsinoÎncă nu există evaluări

- Experiences from OJT ImmersionDocument3 paginiExperiences from OJT ImmersionTrisha Camille OrtegaÎncă nu există evaluări

- Book Networks An Introduction by Mark NewmanDocument394 paginiBook Networks An Introduction by Mark NewmanKhondokar Al MominÎncă nu există evaluări

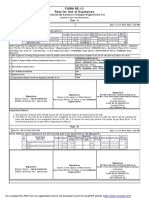

- Reg FeeDocument1 paginăReg FeeSikder MizanÎncă nu există evaluări

- Ensayo Bim - Jaime Alejandro Martinez Uribe PDFDocument3 paginiEnsayo Bim - Jaime Alejandro Martinez Uribe PDFAlejandro MartinezÎncă nu există evaluări

- Philippine Coastal Management Guidebook Series No. 8Document182 paginiPhilippine Coastal Management Guidebook Series No. 8Carl100% (1)

- Water Jet CuttingDocument15 paginiWater Jet CuttingDevendar YadavÎncă nu există evaluări

- Ancient Greek Divination by Birthmarks and MolesDocument8 paginiAncient Greek Divination by Birthmarks and MolessheaniÎncă nu există evaluări

- FS2004 - The Aircraft - CFG FileDocument5 paginiFS2004 - The Aircraft - CFG FiletumbÎncă nu există evaluări

- Table of Specification for Pig Farming SkillsDocument7 paginiTable of Specification for Pig Farming SkillsYeng YengÎncă nu există evaluări

- Striedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsDocument22 paginiStriedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsOsny SillasÎncă nu există evaluări

- 2023 Test Series-1Document2 pagini2023 Test Series-1Touheed AhmadÎncă nu există evaluări

- Archlinux 之 之 之 之 Lmap 攻 略 ( 攻 略 ( 攻 略 ( 攻 略 ( 1 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 )Document16 paginiArchlinux 之 之 之 之 Lmap 攻 略 ( 攻 略 ( 攻 略 ( 攻 略 ( 1 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 )Goh Ka WeeÎncă nu există evaluări

- PESO Online Explosives-Returns SystemDocument1 paginăPESO Online Explosives-Returns Systemgirinandini0% (1)

- Surgery Lecture - 01 Asepsis, Antisepsis & OperationDocument60 paginiSurgery Lecture - 01 Asepsis, Antisepsis & OperationChris QueiklinÎncă nu există evaluări

- Sarvali On DigbalaDocument14 paginiSarvali On DigbalapiyushÎncă nu există evaluări