Documente Academic

Documente Profesional

Documente Cultură

Decision Support System For Periodic Review Inventory Model With Backorder Price Discounts Under Controllable Lead Time

Încărcat de

Joko PrasetyoDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Decision Support System For Periodic Review Inventory Model With Backorder Price Discounts Under Controllable Lead Time

Încărcat de

Joko PrasetyoDrepturi de autor:

Formate disponibile

DECISION SUPPORT SYSTEM FOR PERIODIC REVIEW

INVENTORY MODEL WITH BACKORDER PRICE DISCOUNTS

UNDER CONTROLLABLE LEAD TIME

Ming-Feng Yang

1

, Ming-Cheng Lo

2*

, Chun-Ying Huang

3

1

Department of Transportation Science,

National Taiwan Ocean University, Keelung 202,Taiwan (R.O.C.)

1

yang60429@mail.ntou.edu.tw

2,3

Department of Business Administration,

Ching Yun University,

229, Chien-Hsin Rd., Jung-Li 320, Taiwan(R.O.C).

2

lmc@cyu.edu.tw

*

3

cyhuang@cyu.edu.tw

*corresponding author: Ming-Cheng Lo

ABSTRACT

Lead time reduction has been one of the major factors in the successful

implementation of the popular just-in-time (JIT) inventory system. In many practical

situations, this controllable lead time can be decomposed into several components;

each having a crashing cost for the reduced lead time and the associated crashing

expenses contains a fixed cost and a variable cost per unit product. If an item is out of

stock in an inventory system in which shortage is allowed, the supplier may offer a

negotiable price discount to the loyal, patient and captive customers to compensate for

the inconvenience of backordering. This project studies the integrated inventory

systems with the objective to simultaneously optimizing the order period, lead time,

backorder discount and service level. Because the reduction of inventory cost plays an

important role in production management, this research builds a decision support

system to deal with the optimal reorder point inventory model. In the decision support

system concerning about the inventory model, we take many parameters into account

and help the decision maker to take choice.

Keywords: Lead Time, Crashing Cost, Backorder Price Discount, Service Level,

Decision Support System

INTRODUCTION

Competition features of 90s have evolved into time-based manufacturing (TBM)

(Blackburn 1991). The two time elements considered in TBM are the replenishment

lead time to supply a product to the customer for a specific order and the time to

develop a product from concept to final market delivery. Therefore, reducing lead

time on product supply is the strategic objective of a TBM company (Bockerstette &

Shell, 1993). Although the time compression will inevitably raise the cost, a customer

will pay a premium to the supplier who can furnish its product faster and more

reliably than the competition and the premium may be respectable. Silver, Pyke &

Peterson (1998) defined the replenishment lead time as the time elapsed from the

moment at which it is decided to place an order, until it is physically on the shelf to

Business and Information 2012

(Sapporo, July 3-5)

F 344

satisfy customer demands. Although lead time can be a constant or a random variable,

it is often treated as a prescribed parameter [3, 4]; thus not controllable. However,

lead time can be reduced at extra cost and shorter lead time is the primary driver to

achieving customer satisfaction in successful TBM operations Bockerstette & Shell,

1993). The benefits resulting from reduced lead time include lower cost, less waste

and less obsolescence, greater flexibility to response to change, closely linked

organization priorities to customers needs, improved service, quality and reliability,

and substantially accelerated supply system improvements (Blackburn 1991). Tersine

(1994) and Vollmann, Berry & Whybark (1992) attributed the replenishment lead time

mostly to manufacturing considerations and addressed some guidelines for its

reduction. Liao & Shyu (1991) suggested that lead time could be decomposed into n

components each having a different crashing cost for reduction. Ben-Daya & Raouf

(1994) generalized the Liao & Shyu (1991) model by considering both lead time and

the order quantity as decision variables.

Ouyang, Yen & Wu (1996) extended the Ben-Daya & Raoufs(1994) model to

include a mixture of backorder and lost sales in the model by assuming a

predetermined service level with both reorder point and backorder rate being fixed.

Moon & Choi (1998) suggested that it was not appropriate to include the service

constraint if the shortage cost was explicitly specified and claimed that a better

solution could be obtained by allowing the reorder point to be variable. Hariga and

Ben-Daya (1999) also revised Ouyang et al. (1996) model by including the reorder

point as a decision variable. Ouyang & Wu (1998) relaxed the assumption on the form

of cumulative distribution function of the lead time demand and applied the minimax

distribution free procedure to solve the problem. Pan and Hsiao (2001) presented two

inventory models where shortage was allowed with controllable back ordering.

This research considers a periodic review inventory system in which the lead

time is controllable and can be decomposed into several components each having a

crashing cost function. In addition, shortage is permitted and the total amount of

stockout is a combination of backorder and lost sale. It is further assumed that the

patient customers with outstanding orders during the shortage period are offered a

backorder price discount and consequently the backorder ratio is proportional to the

magnitude of this discount (Pan & Hsiao, 2001). Ouyang, Chuang, & Lin (2003)

extended Pan & Hsiao (2001) model by including the consideration of backorder

discounts under periodic review model. Since the shortage cost is explicitly included,

the reorder point is also treated as a decision variable in this paper (Moon &

Choi ,1998). Sprague & Carson (1982) thought a complete framework of decision

support system should include Data Base, Model Base and Software System. Next we

construct a decision support system to analysis the inventory model, then find out the

Business and Information 2012

(Sapporo, July 3-5)

F 345

best choice with period review time, backorder discount and lead time. Once we build

the decision support system, we can use the result to apply into other inventory model

and adjust the parameter to fit the other different inventory situations.

NOTATIONS AND ASSUMPTIONS

The following notations and assumptions are made in this research:

Notations

L = the length of lead time (decision variable);

T = length of a review period (decision variable);

t

x

= backorder price discount offered by the supplier per unit (decision variable);

k = safety factor (decision variable);

r = the reorder point;

t

0

= the gross marginal profit per unit;

D = average demand per year;

A = fixed ordering cost per order;

h = inventory holding cost per unit per year;

= the average demand rate in units/day;

| = the backorder ratio;

|

0

= the upper bound of the backorder ratio;

| = The standard normal distribution

= The standard normal cumulative distribution function

X = The lead time demand which has a distribution function (d. f.) F(x) with finite

mean DL and standard deviation L

1/2

, where denotes the standard deviation

of the demand per unit time

E() Mathematical expectation

x

+

= Maximum value of x and 0, that is x

+

= max{x,0}

Assumptions

1. The inventory level is reviewed every T units of time. A sufficient quantity is

ordered up to the target level r. The target level r = expected demand during lead

time + safety stock, that is, r = D(T+L) + ko L T + , where k is a nonnegative

safety factor.

2. The lead time L has n mutually independent components, where the ith

component has a normal duration T

i

and a minimum duration t

i

, i = 1, 2, , n and

a crashing cost per unit time a

i

. These a

i

's are arranged such that a

1

s a

2

s s a

n

.

The lead times are crashed one component at a time starting with the one of least

c

i

, and so on.

3. Let L

i

denote the length of lead time with component 1, 2, , i crashed to their

minimum values, then L

i

can be expressed as L

i

=

1

n

j

j

U

=

1

( ).

i

j j

j

U u

=

Thus,

the lead time crashing cost R(L) per replenishment cycle is given by

R(L) = a

i

(L

i1

L) +

1

1

( )

i

j j j

j

a U u

, for L e [L

i

, L

i1

].

4. The backorder ratio | is variable and is in proportion to the backorder price

discount offered by the supplier per unit t

x

; thus, | = |

0

t

x

/t

0

, for 0 < |

0

s 1, 0 s

t

x

s t

0

(Pan & Hsiao, 2001).

DECISION SUPPORT SYSTEM

Business and Information 2012

(Sapporo, July 3-5)

F 346

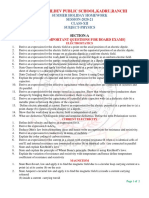

Sprague & Carson (1982) thought a complete framework of decision support

system should include the following events shown as figure 1:

Data BaseStore up the data that the decision support system requires.

Model BaseStore up the data analysis model and decision analysis model or

view these models as sub-patterns which are independent with each other.

Software SystemThe software system includes the following three subsystems.

Data Base Management Subsystem, DBMSs.

Model Base Management Subsystem, MBMSs.

Dialog Generation and Management Subsystem, DGMSs.

System Analysis

Data base Model base

MBMSs

DGMSs

DBMSs

Figure 1 DSS System Framework

Business and Information 2012

(Sapporo, July 3-5)

F 347

System Framework

Setup Cost Data

Ordering Cost

Data

Backorder Data

Crashing Cost

Data

Holding Cost

Data

Normal Demand

Cost Model

Distrbution Free

Demand Cost

Model

Uncertainty factors

Database system

Model management

system

User platform

Cost data

Model data

Figure 2 System framework

NORMAL DEMAND MODEL

The problem under study is to minimize the following total expected annual cost:

EAC(T, t

x

, k, L) = OC + HC + SC + CC

where OC stands for ordering cost, HC for holding cost, SC for shortage cost,

and CC for crashing cost. Consequently, the total expected annual cost EAC(T, t

x

, k,

L) is

EAC(T, t

x

, k, L) )] ( T ) 1 ( T

2

DT

[

T

A

k L L k h + + + + + + = o | o

) ( ] ) 1 ( [

1

0

k L T

T

x

+ + + + o t | |t

Business and Information 2012

(Sapporo, July 3-5)

F 348

(

+ +

1

1

1

) ( ) (

1

i

j

j j j i i

t T a L L a

T

for L

i

s L s L

i1

(1)

Taking the first partial derivatives of EAC(T, t

x

, k, L) with respect to T t

x

, k and

L, respectively, it follows that

2 0

0 0

2

0

EAC( , , , )

2

( )

2

x

x x

T

T L

T k L hk

T L

k

T T T L

t | o

t t | t o

t

+

( c

+

= + +

(

c +

1

1 2 2

1

1

( ) ( )

T 2 T

i

i i i j j

j

A hD

a L L a T t

=

(

+ +

(

(2)

0 0

x 0

0 0

EAC( , , , ) 2 1

= ( ) ( )

x

x

T k L

h T L k T L k

T

t | |

t | o

t t t

( c

+ + + + +

(

c

(3)

0

0

2 0

0 0

0

1

EAC( , , , )

(1- ( ))

x

x

x x

h

T k L

h T L T L k

k

T

|

t

t

t

o o

|

t t | t

t

(

| |

( |

c \ .

(

= + + u

(

c

| |

(

+ +

|

(

\ .

(4)

( ) ( ) ( )

0

1 1

0

2 2

2 0

0

0

1

EAC( , , , ) 1 1 1

4 2

1

x

x

x x

h

T k L

L T k hk L T

L T

T

|

t

t

t

o o

|

t |t

t

(

| |

( |

c \ .

(

= + + + +

(

c

| |

(

+

|

(

\ .

(5)

Setting equation (4) to zero and solving for t

x

, it follows that

0

2

x

hT t

t

+

= (6)

Setting equation (3) to zero and substituting (6) into (3) to solve for T, thus

( ) ( ) ( ) 0

4

1 2

2

1

0

0

0

0 2

=

(

+ + + |

.

|

\

|

+

|

|

.

|

\

|

+ + L R k L T A k L T

D

h

Dh T o

|

t o

t

|

(7)

Setting equation (4) to zero and substituting (6) into (4) to solve for k, then

( )

(

|

|

.

|

\

|

|

.

|

\

|

+ +

= u

4

1

4

1

)

2 2

1 (

1 ) (

0

0

2

0

0 0

0

0

|

t

t

| |

t

|

hT

T

hT

h

h

k

(8)

It can be shown from (8) that hT s t

0

, so u(k) > 0.5 holds for nonnegative safety

Business and Information 2012

(Sapporo, July 3-5)

F 349

factor k. Consequently, the value of t

x

derived in (6) will automatically be positioned

between 0 and t

0

as specified in assumption 4.

DISTRIBUTION FREE MODEL

In a distribution free model, the lead time demand assumption is relaxed to any

distribution function by only assuming that the distribution function F belongs to the

class with finite mean DL and variance o

2

L. Again, the expected total annual cost

of the model can be expressed as EAC(T, t

x

, k, L) = OC + HC + SC + CC. While the

expected ordering and expected crashing costs are of the same forms as those of the

normal demand model, the expected shortage at the end of a cycle can be expressed

by B(r) = E[X r]

+

the expected total annual cost can be presented by

0

1

1

1

DT

EAC( , , , ) T (1 ) [ ]

T 2

1

[ (1 ) ] [ ]

T

1

( ) ( )

T

x

x

i

i i j j j

j

A

T k L h k L E X r

E X r

a L L a T t

t o |

|t | t

+

+

=

(

= + + + +

(

+ +

(

+ +

(

for L

i

s L s L

i-1

(9)

Since the form of the lead time demand distribution is not known, the minimax

criterion is applied to find the least favorite distribution function inOfor each (T, t

x

, k,

L) and then find the optimal values of T

*

, t

x

*

, k

*

and L

*

that minimize the expected total

annual cost. In mathematical symbolization, the problem under investigation can be

expressed as

O e > > F L Q

max min

0 , 0

EAC(T, t

x

, k, L)

Gallego & Moon (1993) proved that the following inequality holds for any F e

O,

| | ) ) (T ( ) ) (T ( ) (T

2

1

) ( E

2 2

L D r L D r L r X + + + + s

+

o (10)

Substituting r = DL + ko L into the model, the problem can be reduced to

minimize

1

1

1

0

0

2

2 0

0 0

0

A DT 1

EAC( , , , ) T ( ) ( )

T 2 T

1

1

T ( 1 )

2

1

T

i

x i i j j j

j

x

x x

T k L h k L a L L a T t

h

L k k

t o

|

t

t

o

|

t t | t

t

=

(

(

= + + + + +

(

(

(

(

+ + +

`

(

+ +

(

)

for L

i

s L s L

i1

(11)

Business and Information 2012

(Sapporo, July 3-5)

F 350

Taking the partial derivatives of EAC(T, t

x

, k, L) with respect to T, t

x

, k and L in

each time interval [L

i

, L

i1

] in (11), we obtain

( )

2

2 2 0

0 0

2

0

1

1

2

1

EAC( , , , )

T 2 2

2

1

2

1

( ) ( )

T

x

x x

i

i i i j j

j

T k L A hD hk

T T L

T

T L

T L

k k

T

a L L a T t

t o

|

t t | t o

t

=

c

= + +

c +

+

(

+

+ +

(

(

+

(

(12)

) , , , EAC(

x

x

L k T

t

t

c

c

= ( ) k k L T

T

k L T h + +

(

+ + +

2

0 x

0

0

0

0

1

2

2

1

) ( o | t

t

|

t

|

(13)

0

0

2 2 0

0 0

0

1

EAC( , , , ) 1

(1- )

2

1

x

x

x x

h

T k L k

h T L T L

k

k

T

|

t

t

t

o o

|

t t | t

t

(

| |

( |

\ .

(

c

(

= + +

| |

c

(

+ +

|

(

\ .

+

(

(14)

( )

( )

( )

0

0

1

0

2

2

2

0

0

1

2

1

EAC( , , , ) 1

1

8

1

1 1

2

x

x

x x

h

T k L

L T k k

L

T

hk L T

T

|

t

t

t

o

|

t | t

t

o

(

| |

( |

c \ .

(

= + +

(

c

| |

(

+

|

(

\ .

+ +

(15)

Setting equation (13) to zero and solving for t

x

, it follows that

0

2

x

hT t

t

+

= (16)

Setting equation (12) to zero and substituting (16) into (12) to solve for T, it

follows that

( )

( )

( )

2 2 0

0

2 0 0

1 1

4

2 1 1 0

2 4

h

T Dh T L k k

D

A T L k k R L

|

o

t

t |

o

| |

+ +

|

\ .

(

| |

+ + + + =

| (

\ .

(17)

Business and Information 2012

(Sapporo, July 3-5)

F 351

Solving for k by setting equation (14) to zero and substituting (16) into (14), we have

( )

(

(

|

|

.

|

\

|

|

|

.

|

\

|

+ +

=

+

4

1

4

1

)

2 2

1 (

2

1

1

0

0

2

0

0 0

0

0

2

|

t

t

| |

t

|

hT

T

hT

h

h

k

k

(18)

The following algorithm can be used to find the optimal values of the order

quantity, backorder discount, reorder point and lead time.

Step 1. For i = 0, 1, 2, , n

(i) Set k

io

= 0

(ii) Substitute k

io

into (17) to evaluate T

io

.

(iii) Use T

io

to determine k

in

from (18), then find k

in

. Let k

io

= k

in

.

(iv) Repeat (ii) and (iii) until no change occurs in the values of T

i

and k

i

.

Denote these resulting solutions by T

i

and k

i

.

(v) Use T

i

and equation (16) to compute the backorder price discount t

xi

.

(vi) Use equation (1) to compute the expected total annual cost EAC(T

i

, t

xi

,

k

i

, L

i

).

Step 2. Set EAC(T

*

, t

x

*

, k

*

, L

*

) = Min{EAC(T

i

, t

xi

, k

i

, L

i

), i = 0, 1, 2, , n}

Step 3.(T

*

, t

x

*

, k

*

, L

*

) is a set of optimal solutions.

Numerical Example

Consider an inventory system with the following data: D = 600 units/year, A =

$200 per order, h = $20 per unit per year, t

0

= $150 per unit, o = 7 unit/week, and the

lead time has three components with data shown in Table 1 (Pan & Hsiao, 2001).

Apply the proposed algorithm to solve the problem for the upper bound of the

backorder ratio |

0

= 0.95, 0.80, 0.65, 0.50, 0.35 and 0.20, respectively. The resulting

optimal solutions are summarized in Table 2 and Table 3.

Table 1. Lead time data of the examples

Lead time component i 1 2 3

Normal duration U

i

(days) 20 20 16

Minimum duration u

i

(days) 6 6 9

Unit fixed crashing cost a

i

($/day)

0.4 1.2 5.0

Business and Information 2012

(Sapporo, July 3-5)

F 352

Table 2. Summary of the results for Example in Normal Demand (

i

L in weeks)

L

0

|

i 0 1 2 3

L

i

8 6 4 3

0.2

T

24.75 23.41 21.85 21.14

t

x

79.76 79.50 79.20 79.07

k

1.53 1.53 1.53 1.53

EAC(T, t

x

, k, L)

4916.69 4753.27 4596.42 4582.02

0.35

T

24.32 23.02 21.50 20.83

t

x

79.68 79.43 79.13 79.01

k

1.52 1.52 1.52 1.52

EAC(T, t

x

, k, L)

4884.67 4726.44 4576.32 4566.46

0.50

T

23.89 22.62 21.15 20.50

t

x

79.59 79.35 79.07 78.94

k

1.50 1.50 1.50 1.50

EAC(T, t

x

, k, L)

4852.73 4699.84 4556.59 4551.34

0.65

T

23.45 22.22 20.79 20.18

t

x

79.51 79.27 79.00 78.88

k

1.49 1.49 1.49 1.49

EAC(T, t

x

, k, L)

4820.93 4673.50 4537.29 4536.70

0.80

T

23.01 21.81 20.42 19.85

t

x

79.42 79.19 78.93 78.82

k

1.47 1.47 1.47 1.47

EAC(T, t

x

, k, L)

4789.29 4647.49 4518.47 4522.60

0.95

T

22.55 21.39 20.05 19.51

t

x

79.34 79.11 78.86 78.75

k

1.45 1.45 1.45 1.45

EAC(T, t

x

, k, L)

4757.88 4621.86 4500.20 4509.10

Business and Information 2012

(Sapporo, July 3-5)

F 353

Table 3 Summary of the results for Example in Distribution Free Demand (

i

L in

weeks)

L

0

|

i 0 1 2 3

L

i

8 6 4 3

0.2

T

27.32 25.80 23.98 23.09

t

x

80.25 79.96 79.61 79.44

k

2.55 2.62 2.72 2.77

EAC(T, t

x

, k, L)

5895.09 5634.61 5351.24 5250.03

0.35

T

26.84 25.35 23.58 22.72

t

x

80.16 79.88 79.53 79.37

k

2.55 2.62 2.71 2.76

EAC(T, t

x

, k, L)

5844.37 5589.60 5313.98 5218.28

0.50

T

24.82 23.48 21.91 21.20

t

x

79.77 79.52 79.21 79.08

k

2.52 2.58 2.65 2.69

EAC(T, t

x

, k, L)

5635.76 5405.93 5163.83 5091.59

0.65

T

25.85 24.43 22.76 21.97

t

x

79.97 79.70 79.38 79.23

k

2.54 2.60 2.69 2.73

EAC(T, t

x

, k, L)

5741.23 5498.49 5239.08 5154.82

0.80

T

25.34 23.96 22.34 21.59

t

x

79.87 79.61 79.30 79.15

k

2.53 2.59 2.67 2.71

EAC(T, t

x

, k, L)

5688.79 5452.39 5201.49 5123.16

0.95

T

24.82 23.48 21.91 21.20

t

x

79.77 79.52 79.21 79.08

k

2.52 2.58 2.65 2.69

EAC(T, t

x

, k, L)

5635.76 5405.93 5163.83 5091.59

Business and Information 2012

(Sapporo, July 3-5)

F 354

CONCLUSIONS

This paper extends the Pan and Hsiao model (Pan & Hsiao, 2001) to study the

impact of safety factor on the periodic review inventory model involving controllable

lead time and backorder price discount with mixture of backorder and partial lost

sales. The objective is to minimize the expected total annual cost by simultaneously

optimizing order period, backorder price discount, safety factor and lead time. There

are two models considered in the plan, one with normal demand distribution and

another with general demand distribution having both mean and variance known and

finite. Algorithms are developed to find the optimal solutions for the two models and

examples are provided to illustrate the procedures of the algorithms. We construct a

decision support system to analysis the inventory model, then find out the best choice

with period review time, backorder discount and lead time. Once we build the

decision support system, we can use the result to apply into other inventory model and

adjust the parameter to fit the other different inventory situations. The calculation of

the expected value of additional information for the distribution free problem are

demonstrated in the examples as well.

Business and Information 2012

(Sapporo, July 3-5)

F 355

REFERENCES

Ben-Daya, M. & Raouf, A. 1994. Inventory models involving lead time as a decision

variable. Journal of the Operation Research Society. 45, 579-582.

Blackburn, J. D. 1991. Time-Based Competition: The Next Battleground in American

Manufacturing. Homewood, Illinois: Business One Irwin.

Bockerstette, J. A. & Shell, R. L. 1993. Time Based Manufacturing, New York:

McGraw-Hill.

Gallego, G. & Moon, I. 1993. The distribution free newsboy problem: Review and

extensions, Journal of the Operational Research Society, 44, 825-834.

Hariga, M. A. & Ben-Daya, M. 1999. Some stochastic inventory models with

deterministic variable lead time. European Journal of Operational Research. 113,

42-51.

Liao, C. J. & Shyu, C. H. 1991. Analytical determination of lead time with normal

demand. International Journal of the Operational Research and Production

Management, 11, 7278

Moon, I. & Choi, S. 1998. A Note on lead time and distribution assumptions in

continuous review inventory models. Computers and Operations Research. 25,

1007-1012.

Naddor ,N. 1996. Inventory System. New York: John Wiley.

Ouyang, L. Y. Yen, N. C. & Wu, K. S. 1996. Mixture inventory model with

backorders and lost sales for variable lead time. Journal of the Operation

Research Society, 47, 829-832.

Ouyang, L. Y. & Wu, K. S. 1998. A minimax distribution free procedure for mixed

inventory model with variable lead time. International Journal of Production

Economics. 56, 511516.

Ouyang, L. Y. Chuang, B.R. & Lin, Y. J. 2003. Impact of backorder discounts on

periodic review inventory model. International Journal of Information and

Management Sciences. 14(3), 1-13.

Pan, J. C. & Hsiao, Y. C. 2001. Inventory models with backorder discounts and

variable lead time. International Journal of Systems Science. 32, 925929.

Silver, E. A. Pyke, D. F. & Peterson, R. 1998. Inventory Management and Production

Planning and Scheduling, 3/e. New York: John Wiley.

Sprague, R H. & Carson, E. D. 1982. Building Effective Decision Support System.

Prentice-Hall.

Tersine, R. J. 1994. Principles of Inventory and Material Management. New York:

North Holland.

Vollmann, T.E., Berry, W.L. & Whybark, D.C. 1992. Manufacturing Planning and

Control System 3/e. Chicago: Irwin.

Business and Information 2012

(Sapporo, July 3-5)

F 356

S-ar putea să vă placă și

- Two Echleon by JHa JKDocument9 paginiTwo Echleon by JHa JKaggarwalankit911Încă nu există evaluări

- Writing SampleDocument13 paginiWriting SampleMonika Aditia PutriÎncă nu există evaluări

- Louly Dolgui 2002 IglsDocument6 paginiLouly Dolgui 2002 IglsKate Marulanda JimenezÎncă nu există evaluări

- Modelo de Inventario Periodico Con Costo Por Pedido Reducido Bajo Restriccion de Nivel de ServicioDocument13 paginiModelo de Inventario Periodico Con Costo Por Pedido Reducido Bajo Restriccion de Nivel de ServicioLuisa SehuanezÎncă nu există evaluări

- Integrated Vendor-Buyer Cooperative Inventory Models With Controllable Lead Time and Ordering Cost ReductionDocument15 paginiIntegrated Vendor-Buyer Cooperative Inventory Models With Controllable Lead Time and Ordering Cost ReductionmohanpusÎncă nu există evaluări

- Mathematical and Computer Modelling: Minjae Park, Hoang PhamDocument16 paginiMathematical and Computer Modelling: Minjae Park, Hoang PhamMubashir UnnissaÎncă nu există evaluări

- What Is InventoryDocument7 paginiWhat Is Inventorydeepmangal222Încă nu există evaluări

- Customer Lead Time Management When Both Demand and Price Are Lead Time SensitiveDocument13 paginiCustomer Lead Time Management When Both Demand and Price Are Lead Time Sensitive007mbsÎncă nu există evaluări

- Q1. Safety Stock Determination Based On Parametric Lead TimeDocument18 paginiQ1. Safety Stock Determination Based On Parametric Lead TimeFaridz Mohammad EdrieÎncă nu există evaluări

- End-of-Period vs. Continuous Accounting of Inventory-Related CostsDocument11 paginiEnd-of-Period vs. Continuous Accounting of Inventory-Related CostsJuan David Arias SuárezÎncă nu există evaluări

- Cycle Cost Considerations in A Continuous Review Inventory Control ModelDocument23 paginiCycle Cost Considerations in A Continuous Review Inventory Control ModelSaga CÎncă nu există evaluări

- DOC-20230517-WA0028Document6 paginiDOC-20230517-WA0028layansafsouf1Încă nu există evaluări

- Song Zhao MSOM 09Document16 paginiSong Zhao MSOM 09Crystal StoneÎncă nu există evaluări

- Cost System Design FinalDocument6 paginiCost System Design Finallayansafsouf1Încă nu există evaluări

- Om Lecture Inventory Management JC A 12 The DDocument7 paginiOm Lecture Inventory Management JC A 12 The DkunjanÎncă nu există evaluări

- Manufacturing Lead Times, Order Release and Capacity LoadingDocument43 paginiManufacturing Lead Times, Order Release and Capacity Loading孫ウィーユÎncă nu există evaluări

- Economic Order QuantityDocument7 paginiEconomic Order QuantityShuvro RahmanÎncă nu există evaluări

- 9.+247114 Proof DoneDocument10 pagini9.+247114 Proof Donerim zamzamiÎncă nu există evaluări

- Cost Management: A Case for Business Process Re-engineeringDe la EverandCost Management: A Case for Business Process Re-engineeringÎncă nu există evaluări

- 56 FBBCFDD 01Document12 pagini56 FBBCFDD 01Sri Susilawati IslamÎncă nu există evaluări

- Periodic Review Inventory Model WithDocument18 paginiPeriodic Review Inventory Model WithDr-Mohammed FaridÎncă nu există evaluări

- Partcipacion 3..Document11 paginiPartcipacion 3..Ivonne CMÎncă nu există evaluări

- Note A Separation Principle For A Class of AssemblDocument13 paginiNote A Separation Principle For A Class of Assemblvaddi santosh kumarÎncă nu există evaluări

- Integrated Inventory and Transportation Mode Selection: A Service Parts Logistics SystemDocument19 paginiIntegrated Inventory and Transportation Mode Selection: A Service Parts Logistics Systemmasalac543Încă nu există evaluări

- European Journal of Operational Research: Anderson J. Brito, Adiel T. de AlmeidaDocument11 paginiEuropean Journal of Operational Research: Anderson J. Brito, Adiel T. de AlmeidaMustafa FarragÎncă nu există evaluări

- Chapter VI. Independent Demand Inventory SystemsDocument12 paginiChapter VI. Independent Demand Inventory Systemssimi1690Încă nu există evaluări

- Inventory Control in Closed Loop Supply Chain Using System DynamicsDocument33 paginiInventory Control in Closed Loop Supply Chain Using System DynamicsAritra SenÎncă nu există evaluări

- Metrics Paper 19july96 PDFDocument20 paginiMetrics Paper 19july96 PDFfronendÎncă nu există evaluări

- Optimal Lot SizingDocument17 paginiOptimal Lot SizingHansenÎncă nu există evaluări

- Optimal Replenishment Policies With Allowable Shortages For A Product Life CycleDocument13 paginiOptimal Replenishment Policies With Allowable Shortages For A Product Life Cycle翁慈君Încă nu există evaluări

- Dynamic Inventory Lot SizeDocument13 paginiDynamic Inventory Lot SizeOtieno MosesÎncă nu există evaluări

- Dynamic Optimization Model For Mining Equipment ReDocument11 paginiDynamic Optimization Model For Mining Equipment ReMantenimiento MineroÎncă nu există evaluări

- Inventory Theory (Quantitative Techniques)Document41 paginiInventory Theory (Quantitative Techniques)Lexter Smith Albay100% (2)

- Calculation of The Reorder Point For Items With Exponential and Poisson Distribution of Lead Time DemandDocument10 paginiCalculation of The Reorder Point For Items With Exponential and Poisson Distribution of Lead Time DemandRaj ChauhanÎncă nu există evaluări

- Manufacturing Lead-Time Rules: Customer Retention Versus Tardiness CostsDocument32 paginiManufacturing Lead-Time Rules: Customer Retention Versus Tardiness CostsДанило КулиничÎncă nu există evaluări

- Inventory Model With Time Dependent Demand Rate Under Inflation When Supplier Credit Linked To Order QuantityDocument14 paginiInventory Model With Time Dependent Demand Rate Under Inflation When Supplier Credit Linked To Order QuantityAkshay BhattÎncă nu există evaluări

- Inventory Management: Some Terms and DefinitionsDocument6 paginiInventory Management: Some Terms and DefinitionsRaj ChauhanÎncă nu există evaluări

- Suministro de Repuestos Basado en CondicionDocument9 paginiSuministro de Repuestos Basado en CondicionDaniel Carvajal TinocoÎncă nu există evaluări

- A Multi-Criterion Decision-Making On Preventive MaintenanceDocument9 paginiA Multi-Criterion Decision-Making On Preventive Maintenanceieom2012Încă nu există evaluări

- Multicriteria Inventory Model For Spare Parts PDFDocument6 paginiMulticriteria Inventory Model For Spare Parts PDFsaeedalemveÎncă nu există evaluări

- Msom InventInventory Pooling To Deliver Differentiated Serviceory Pooling InformalDocument30 paginiMsom InventInventory Pooling To Deliver Differentiated Serviceory Pooling InformalmarcelojscostaÎncă nu există evaluări

- E-Business and Circular Supply ChainsDocument24 paginiE-Business and Circular Supply ChainsNipun BansalÎncă nu există evaluări

- Vol3 Iss4 390 - 395 Decision-Making For A Single Item EDocument6 paginiVol3 Iss4 390 - 395 Decision-Making For A Single Item ESaketh ReddyÎncă nu există evaluări

- Full Name: Pham Thi Khanh Linh POM Chapter 3 Process StrategyDocument10 paginiFull Name: Pham Thi Khanh Linh POM Chapter 3 Process StrategyThi Khanh Linh PhamÎncă nu există evaluări

- AMM SarkerDocument12 paginiAMM SarkerlesanÎncă nu există evaluări

- Production Planning and Order AcceptanceDocument21 paginiProduction Planning and Order AcceptancebnadjibÎncă nu există evaluări

- Working Papers: Ntegrated OST Anagement Hroughout The Roduct IFE Ycle by R. C and R. S 2001/110/ACDocument42 paginiWorking Papers: Ntegrated OST Anagement Hroughout The Roduct IFE Ycle by R. C and R. S 2001/110/ACAbdulrahmanAhmedÎncă nu există evaluări

- ENGG ZC242 Regular Solution MidsemDocument4 paginiENGG ZC242 Regular Solution MidsemymsyaseenÎncă nu există evaluări

- Maintenance Spare Parts Planning and Control: A Framework For Control and Agenda For Future ResearchDocument35 paginiMaintenance Spare Parts Planning and Control: A Framework For Control and Agenda For Future ResearchIKÎncă nu există evaluări

- Channel CoordinationDocument7 paginiChannel CoordinationMohammed JashidÎncă nu există evaluări

- Modelling of Repairable Items For Production Inventory With Random DeteriorationDocument14 paginiModelling of Repairable Items For Production Inventory With Random DeteriorationInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Reliability Based Spare Parts Forecasting and Procurement StrategiesDocument30 paginiReliability Based Spare Parts Forecasting and Procurement Strategiesm7shahidÎncă nu există evaluări

- Process Improvement For A Container-"Lling Process With Random ShiftsDocument9 paginiProcess Improvement For A Container-"Lling Process With Random ShiftsLivia MarsaÎncă nu există evaluări

- Production ManagementDocument39 paginiProduction ManagementRisath AhamedÎncă nu există evaluări

- Choudhary and ShankarDocument6 paginiChoudhary and ShankarzawadzahinÎncă nu există evaluări

- Demand Forecasting and Inventory Control A Simulation Study On Automotive Spare Parts PDFDocument16 paginiDemand Forecasting and Inventory Control A Simulation Study On Automotive Spare Parts PDFRais HaqÎncă nu există evaluări

- Using Life Cycle Costing For Product ManagementDocument14 paginiUsing Life Cycle Costing For Product ManagementJooxmusicÎncă nu există evaluări

- Quality - Reliability - Maintenance - Issues - I C. DialloDocument6 paginiQuality - Reliability - Maintenance - Issues - I C. Diallotanmay0107Încă nu există evaluări

- Inventory Management: Pivotal in Effective and Efficient Organizations. A Case StudyDocument6 paginiInventory Management: Pivotal in Effective and Efficient Organizations. A Case StudyOnnoSaikatÎncă nu există evaluări

- The Value of Manufacturing Flexibility: Real Options in PracticeDocument16 paginiThe Value of Manufacturing Flexibility: Real Options in PracticeswapnilnemadeÎncă nu există evaluări

- Using Scoria As Fine Aggregate in Lightweight Mortar and ConcreteDocument14 paginiUsing Scoria As Fine Aggregate in Lightweight Mortar and ConcreteFoolad GharbÎncă nu există evaluări

- Supply - Chain - Master - Data - SAP IBPDocument12 paginiSupply - Chain - Master - Data - SAP IBPharry4sapÎncă nu există evaluări

- Analog - RF VLSI Design (ECE 503) (Makeup) PDFDocument2 paginiAnalog - RF VLSI Design (ECE 503) (Makeup) PDFRahul PinnamaneniÎncă nu există evaluări

- Paper 1: Year 9 Mathematics TestDocument32 paginiPaper 1: Year 9 Mathematics TestMa XóÎncă nu există evaluări

- 3 Paramater Untuk Men-Synchron-Kan Komunikasi: Set 2 For Modbus CommunicationDocument5 pagini3 Paramater Untuk Men-Synchron-Kan Komunikasi: Set 2 For Modbus CommunicationAhmad FathurachmanÎncă nu există evaluări

- Tugas Paper Mekanika PatahanDocument1 paginăTugas Paper Mekanika PatahanRahmandhika Firdauzha Hary HernandhaÎncă nu există evaluări

- Prospect ATR901.RevB Eng PDFDocument25 paginiProspect ATR901.RevB Eng PDFUntea LiviuÎncă nu există evaluări

- Waste Polymer Chemistry (PHD Thesis of Tina) PDFDocument387 paginiWaste Polymer Chemistry (PHD Thesis of Tina) PDFrubikaÎncă nu există evaluări

- Must-On Board Diagnostics II PCED PDFDocument19 paginiMust-On Board Diagnostics II PCED PDFRopama BraÎncă nu există evaluări

- Dav Kapildev Public School, Kadru, Ranchi: ( Most Important Questions For Board Exams)Document2 paginiDav Kapildev Public School, Kadru, Ranchi: ( Most Important Questions For Board Exams)MD JahangirÎncă nu există evaluări

- Solutions - JEE Main 2024 January Question Bank - MathonGoDocument7 paginiSolutions - JEE Main 2024 January Question Bank - MathonGoLeo UzumakiÎncă nu există evaluări

- 22-01 Simple Linear Motion 1Document1 pagină22-01 Simple Linear Motion 1David BumbaloughÎncă nu există evaluări

- Elx FW FC 8g-F1.11a7-B5.11x2 Linux-Bc 32-64Document52 paginiElx FW FC 8g-F1.11a7-B5.11x2 Linux-Bc 32-64mail2rajajiÎncă nu există evaluări

- Abdi CCA2018Document16 paginiAbdi CCA2018jozsefÎncă nu există evaluări

- H12 211Document24 paginiH12 211fraesser100% (16)

- Headphone Technology Hear-Through, Bone Conduction, Noise CancelingDocument6 paginiHeadphone Technology Hear-Through, Bone Conduction, Noise CancelingRichard HallumÎncă nu există evaluări

- Data and SignalsDocument3 paginiData and Signalsnr syhdhÎncă nu există evaluări

- Granlund Software Help: RiuskaDocument14 paginiGranlund Software Help: RiuskaObi-Wan KenobiÎncă nu există evaluări

- Dart Language SpecificationDocument111 paginiDart Language SpecificationLiaboÎncă nu există evaluări

- P30 Drivetrain Repair - Sports CarDocument104 paginiP30 Drivetrain Repair - Sports CarAllan Cancino100% (1)

- Laser Jet AlignmentDocument190 paginiLaser Jet AlignmentsatfasÎncă nu există evaluări

- Acr 1 Final 2021Document5 paginiAcr 1 Final 2021CAROLYN RhoeÎncă nu există evaluări

- Genome Annotation and ToolsDocument20 paginiGenome Annotation and ToolsKumar KunalÎncă nu există evaluări

- BBFH107Document102 paginiBBFH107lord100% (1)

- Internal and External Exposure: The Body Is Equally Exposed To Radiation in Both CasesDocument53 paginiInternal and External Exposure: The Body Is Equally Exposed To Radiation in Both CasesKross OgbeborÎncă nu există evaluări

- Repeaters in CDMA and UMTS CellularDocument86 paginiRepeaters in CDMA and UMTS CellularJoseph ShapiraÎncă nu există evaluări

- Repetition Radiation. Gradation.: Pure Colors TintsDocument4 paginiRepetition Radiation. Gradation.: Pure Colors TintsKathrine MacapagalÎncă nu există evaluări

- STPM Trial 2009 Che Q&A (Johor)Document43 paginiSTPM Trial 2009 Che Q&A (Johor)SimPor100% (1)

- COMPUTER PROGRA-WPS OfficeDocument5 paginiCOMPUTER PROGRA-WPS OfficeGurpreet KumarÎncă nu există evaluări