Documente Academic

Documente Profesional

Documente Cultură

PT SlabOnGround

Încărcat de

anumnedDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PT SlabOnGround

Încărcat de

anumnedDrepturi de autor:

Formate disponibile

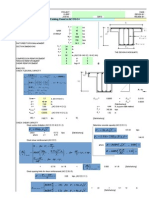

PROJECT : CLIENT : JOB NO.

: DATE :

PAGE : DESIGN BY : REVIEW BY :

Design of PT Slabs on Expansive Soil Ground Based on Standards of PTI 3rd Edition

1. DESIGN METHODS

1.1 1.2 1.3 MAKE SURE THAT THE FOUNDATION PLAN SATISFIES THE SHAPE FACTOR REQUIREMENT: SF = (ENTIRE FOUNDATION PERIMETER) / (ENTIRE FOUNDATION AREA) 24 , (Sec. 4.5.1) DIVIDE AN IRREGULAR FOUNDATION PLAN INTO OVERLAPPING RECTANGLES AND USING THIS SPREADSHEET DESIGN EACH RECTANGULAR SECTION SEPARATELY. ONCE THE RIBBED FOUNDATION HAS BEEN DESIGNED TO SATISFY MOMENT, SHEAR, AND DIFFERENTIAL DEFLECTION REQUIREMENTS, IT MAY BE CONVERTED TO AN EQUIVALENT UNIFORM THICKNESS FOUNDATION.

2. INPUT DATA & DESIGN SUMMARY

2.1 SOILS PROPERTIES (FROM SOIL REPORT / GEOTECHNICAL INVESTIGATION) ALLOWABLE SOIL-BEARING PRESSURE EDGE MOISTURE VARIATION DISTANCE qallow em ym

DIFFERENTIAL SOIL MOVEMENT SLAB-SUBGRADE FRICTION COEFFICIENT

= = = = = =

2000 9 5.2 0.07 0.46 0.75

psf ft, for center lift ft, for edge lift in, for center lift in, for edge lift

2.2 STRUCTURAL DATA AND MATERIALS PROPERTIES SLAB LENGTH SLAB WIDTH SLAB THICKNESS PERIMETER LOADING MAX BEARING LOADING ON THE SLAB ADDED DEAD LOAD LIVE LOAD AVERAGE STIFFENING BEAM SPACING, L DIRECTION AVERAGE STIFFENING BEAM SPACING, B DIRECTION STIFFENING BEAM DEPTH STIFFENING BEAM WIDTH CONCRETE STRENGTH SLAB PRESTRESSING TENDONS, L DIRECTION SLAB PRESTRESSING TENDONS, B DIRECTION TENDON IN THE BOTTOM OF EACH BEAM EFFECTIVE PRESTRESS AFTER ALL LOSSES EXCEPT SG CONVERT UNIFORM THICKNESS (Sec. 6.12) ? No THE DESIGN IS ADEQUATE. SUGGESTED RATIO OF EXPECTED ELONGATION IS 0.00777 5 9 1 fe L B t P Pb DL LL SL SB h b f'c

= = = = = = = = = = = =

tendons w/ tendons w/ tendons w/

42 24 4 695 2700 150 40 40 40 14.5 12 3 0.153 0.153 0.153 174

ft ft in plf plf psf psf ft ft in in ksi in2 at each tendon. in2 at each tendon. in2 (only for edge lift governing required) ksi

3. DETERMINE SECTION PROPERTIES

L DIRECTION n A I CGS = = = = 3 1530 19969 9.03 in2 in4 in yb St Sb e = = = = 10.71 5267 1865 -1.68 in in3 in3 in B DIRECTION n A I CGS = = = = 5 2646 33706 9.20 in2 in4 in yb St Sb e = = = = 10.77 9046 3129 -1.58 in in3 in3 in

4. CALCULATE MAXIMUM APPLIED SERVICE MOMENTS (Sec. 6.8)

4.1 CENTER LIFT MOMENT AT L DIRECTION For em = 9 ft 2.05 ft-kips / ft 0.383 ML = A0 (B em1.238 + C) = Where CENTER LIFT MOMENT AT B DIRECTION For em = 9 ft

MB = (58 + em) ML / 60, for L /B > 1.1 MB = ML, for L /B < 1.1

A0 = (L0.013 SB0.306 h0.688 P0.534 ym0.193) / 727 = B = 1, for em < 5 B = MIN[(ym - 1) / 3, 1], for em > 5 C = 0, for em < 5 C = MAX{[8 - (P - 613) / 255] (4 - ym) / 3], 0}, for em > 5

2.29

ft-kips / ft

-0.31

10.06 For em = 5 ft (Sec. 4.3.2)

For em =

ft (Sec. 4.3.2) 2.81 ft-kips / ft 0.383

ML = A0 (B em1.238 + C) = Where

MB = (58 + em) ML / 60, for L /B > 1.1 MB = ML, for L /B < 1.1

A0 = (L0.013 SB0.306 h0.688 P0.534 ym0.193) / 727 = B C

2.95

ft-kips / ft

= =

ML = 2.81

1.00 0.00 ft-kips / ft USE MB = 2.95 ft-kips / ft

USE

4.2 EDGE LIFT MOMENT AT L DIRECTION ML = SB0.10 (h em)0.78 ym0.66 / (7.2 L0.0065 P0.04) = 2.33 ft-kips / ft

EDGE LIFT MOMENT AT B DIRECTION MB = h0.35 (19 + em) ML / 57.75, for L /B > 1.1 MB = ML, for L /B < 1.1

2.49

ft-kips / ft

5. CHECK FLEXURAL CONCRETE STRESSES (Sec. 6.5)

5.1 ALLOWABLE CONCRETE STRESSES FLEXURAL TENSILE STRESS FLEXURAL COMPRESSIVE STRESS ft,allow = - 6 (fc')0.5 = fc,allow = - 0.45 fc' = -0.329 1.350 ksi ksi

(cont'd) 5.2 TOP STRESS, FOR CENTER LIFT MOMENT, AT L DIRECTION f= Pr / A - ML / St + Pr e / St = Where Pr = Pe - SG = Pe = fe Aps = 212.98 SG = W slab m / 2000 = -0.092 ksi 182.71 kips 30.27 kips kips TOP STRESS, FOR CENTER LIFT MOMENT, AT B DIRECTION f = Pr / A - MB / St + Pr e / St = Where Pr = Pe - SG = Pe = fe Aps = 372.71 SG = W slab m / 2000 = -0.095 ksi 342.44 kips / ft 30.27 kips kips

Then

> <

ft,allow fc,allow

[Satisfactory] [Satisfactory]

Then

> <

ft,allow fc,allow

[Satisfactory] [Satisfactory]

5.3 BOTTOM STRESS, FOR CENTER LIFT MOMENT, AT L DIRECTION f = Pr / A + ML / Sb - Pr e / Sb = 0.718 ft,allow fc,allow ksi

BOTTOM STRESS, FOR CENTER LIFT MOMENT, AT B DIRECTION f = Pr / A + MB / Sb - Pr e / Sb = 0.778 ft,allow fc,allow ksi

Then

> <

[Satisfactory] [Satisfactory]

Then

> <

[Satisfactory] [Satisfactory]

5.4 TOP STRESS, FOR EDGE LIFT MOMENT, AT L DIRECTION f = Pr / A - ML / Sb - Pr e / Sb = -0.077 ft,allow fc,allow ksi

TOP STRESS, FOR EDGE LIFT MOMENT, AT B DIRECTION f = Pr / A - MB / Sb - Pr e / Sb = -0.100 ft,allow fc,allow ksi

Then

> <

[Satisfactory] [Satisfactory]

Then

> <

[Satisfactory] [Satisfactory]

5.5 BOTTOM STRESS, FOR EDGE LIFT MOMENT, AT L DIRECTION f= Pr / A + ML / St + Pr e / St = 0.189 ft,allow fc,allow ksi

BOTTOM STRESS, FOR EDGE LIFT MOMENT, AT B DIRECTION f = Pr / A + MB / St + Pr e / St = 0.209 ft,allow fc,allow ksi

Then

> <

[Satisfactory] [Satisfactory]

Then

> <

[Satisfactory] [Satisfactory]

6. CHECK MINIMUM FOUNDATION STIFFNESS (Sec. 6.10)

6.1 RELATIVE STIFFNESS LENGTH AT L DIRECTION b = (Ecr I / Es)1/4 / 12 = Where Ecr = (0.5) 33 w Es = w =

1.5

RELATIVE STIFFNESS LENGTH AT B DIRECTION ft b = (Ecr I / Es)1/4 / 12 = 1660280 psi pcf CHECK MINIMUM FOUNDATION STIFFNESS AT B DIRECTION FOR CENTER LIFT psi Where 7.208 ft 1660280 psi psi Ecr = (0.5) 33 w1.5 (fc')0.5 = Es = 1000

6.323 (fc')

0.5

1000 150

6.2 CHECK MINIMUM FOUNDATION STIFFNESS AT L DIRECTION FOR CENTER LIFT 12000 ML B CD zL / Ecr = Where CD IL = FOR EDGE LIFT 12000 ML B CD zL / Ecr = Where CD 11060 in4 6660 in

4

<

[Satisfactory]

IL

12000 MB L CD zB / Ecr = Where CD IB = FOR EDGE LIFT

7741 360 24.00 33706 13082 720

in4

<

[Satisfactory]

IB

360 37.94 19969 ft in4

zL = min(L , 6b) =

zB = min(B , 6b) =

ft in4 in4

<

[Satisfactory]

IL

12000 MB L CD zB / Ecr = Where CD

<

[Satisfactory]

IB

720

7. CHECK SHEAR CAPACITY (Sec. 6.11)

7.1 APPLIED SERVICE LOAD SHEAR AT L DIRECTION FOR CENTER LIFT VL = L0.09 SB0.71 h0.45 P0.44 ym0.16 em0.93 / 1940 = FOR EDGE LIFT VL = L0.07 h0.4 P0.03 ym0.67 em0.16 / (3.0 SB0.015) = 7.2 ALLOWABLE CONCRETE SHEAR STRESS, AT L DIRECTION vc = 2.4 (fc')0.5 + 0.2 fp = Where fp = 0.155 0.119 ksi ksi 1.145 kips/ft 1.260 kips/ft APPLIED SERVICE LOAD SHEAR AT B DIRECTION FOR CENTER LIFT VB = B0.19 SL0.45 h0.20 P0.54 ym0.04 em0.97 / 1350 = FOR EDGE LIFT VB = B0.07 h0.4 P0.03 ym0.67 em0.16 / (3.0 SL0.015) = ALLOWABLE CONCRETE SHEAR STRESS, AT B DIRECTION vc = 2.4 (fc')0.5 + 0.2 fp = 0.157 0.129 ksi ksi 1.101 kips/ft 1.836 kips/ft

>

[Satisfactory]

50 psi

Where

fp =

>

[Satisfactory]

50 psi

7.3 SHEAR STRESS OF RIBBED FOUNDATION, AT L DIRECTION FOR CENTER LIFT v = V B / (n h b) = FOR EDGE LIFT v = V B / (n h b) = 0.053 ksi 0.058 ksi

SHEAR STRESS OF RIBBED FOUNDATION, AT B DIRECTION FOR CENTER LIFT

<

[Satisfactory]

vc

v = V L / (n h b) = FOR EDGE LIFT

0.089

ksi

<

[Satisfactory]

vc

<

[Satisfactory]

vc

v = V L / (n h b) =

0.053

ksi

<

[Satisfactory]

vc

8. CHECK SOIL BEARING (Sec. 4.5)

8.1 APPLIED LOADING SLAB WEIGHT ADDED DL LIVE LOAD BEAM WEIGHT PERIMETER LOAD 150 L B t DL L B LL L B 150 (h-t) b (Total Length) P (2L + 2B) = = = = = 50400 15120 40320 30319 91740 lbs lbs lbs lbs lbs RIB BEARING AREA (Sec. 4.5.2.3) SOIL PRESSURE = 811.44 281 q = Total Load / THE AREA = ft2 psf qallow

<

[Satisfactory]

9. CHECK SLAB STRESS DUE TO LOAD-BEARING PARTITIONS (Sec. 6.14)

9.1 RELATIVE STIFFNESS LENGTH AT L DIRECTION Mmax = Pb b / 4 = Where 8.10 ft-kips / ft 12 ft lb / in3 RELATIVE STIFFNESS LENGTH AT B DIRECTION Mmax = Pb b / 4 = Where 8.10 ft-kips / ft 12 ft lb / in3

= MIN[(Ec t3 / 3 ks)0.25, SB] = 4

= MIN[(Ec t3 / 3 ks)0.25, SL] = 4

ks = 9.2 TENSILE STRESS AT L DIRECTION f = Pr / A - Mmax / 2 t2 =

ks = TENSILE STRESS AT B DIRECTION

-0.134

ksi [Satisfactory]

f = Pr / A - Mmax / 2 t2 =

-0.124 ft,allow

ksi [Satisfactory]

>

ft,allow

>

(cont'd)

10. CHECK CRACKED SECTION CAPACITY (Sec. 4.5.7 & 6.12)

10.1 CHECK CRACKED SECTION CAPACITY AT L DIRECTION FOR CENTER LIFT Mcr = F (h - 2" - 0.5a) = Where F= a = F / 0.85 fc' b = 0.9 ML = FOR EDGE LIFT Mcr = F (h - 3" - 0.5a) = Where F= a = F / 0.85 fc' b = 0.9 ML = 76.2 79.87 0.11 50.4 ft-kips kips in ft-kips, total 130.6 133.11 1.45 60.7 ft-kips kips in ft-kips, total

[Satisfactory] CHECK CRACKED SECTION CAPACITY AT B DIRECTION FOR CENTER LIFT

>

[Satisfactory]

0.9 ML

Mcr = F (h - 2" - 0.5a) = Where F= a = F / 0.85 fc' b = 0.9 MB = FOR EDGE LIFT

233.9 239.60 1.57 111.6 127.0 133.11 0.10 94.3

ft-kips kips in ft-kips, total ft-kips kips in ft-kips, total

>

[Satisfactory]

0.9 MB

>

[Satisfactory]

0.9 ML

Mcr = F (h - 3" - 0.5a) = Where F= a = F / 0.85 fc' b = 0.9 MB =

>

[Satisfactory]

0.9 MB

11. CONVERT UNIFORM THICKNESS (Sec. 6.12)

H= MAX[ ( I / L)1/3, ( I / B)1/3 ] = N/A (Does not apply for beam tendons)

12. SUGGEST RATIO OF EXPECTED ELONGATION

r = fe / 0.8 Eps = Where Eps = 7.77E-03 28000 ksi

Technical References: 1. "Design of Post-Tensioned Slab-on-Ground, Third Edition", Post-Tensioning Institute, 2004. 2. "Addendum No.1 to The 3RD Edition of Design of Post-Tensioned Slab-on-Ground", Post-Tensioning Institute, May 2007. 3. "Addendum No.2 to The 3RD Edition of Design of Post-Tensioned Slab-on-Ground", Post-Tensioning Institute, May 2008.

PROJECT : CLIENT : JOB NO. : DATE :

PAGE : DESIGN BY : REVIEW BY :

Design of PT Slabs on Compressible Soil Ground Based on Standards of PTI 2nd Edition

1. INPUT DATA & DESIGN SUMMARY

1.1 SOILS PROPERTIES ALLOWABLE SOIL-BEARING PRESSURE EXPECTED SETTLEMENT BY GEOTECHNICAL ENR SLAB-SUBGRADE FRICTION COEFFICIENT 1.2 STRUCTURAL DATA AND MATERIALS PROPERTIES SLAB LENGTH SLAB WIDTH SLAB THICKNESS PERIMETER LOADING MAX BEARING LOADING ON THE SLAB ADDED DEAD LOAD LIVE LOAD AVERAGE STIFFENING BEAM SPACING, L DIRECTION AVERAGE STIFFENING BEAM SPACING, B DIRECTION STIFFENING BEAM DEPTH STIFFENING BEAM WIDTH CONCRETE STRENGTH SLAB PRESTRESSING TENDONS, L DIRECTION SLAB PRESTRESSING TENDONS, B DIRECTION TENDON IN THE BOTTOM OF EACH BEAM EFFECTIVE PRESTRESS AFTER ALL LOSSES EXCEPT SG 8 8 0 fe L B t P Pb DL LL SL SB h b f'c qallow

d m

= = = = = = = = = = = = = = =

tendons w/ tendons w/ tendons w/

1500 0.75 0.75 50 50 6 840 2700 15 40 10 10 36 24 4 0.153 0.153 0 174

psf in

ft ft in plf plf psf psf ft ft in in ksi in2 at each tendon. in2 at each tendon. in

2

THE DESIGN IS INADEQUATE, SEE BELOW.

ksi

2. DETERMINE SECTION PROPERTIES

L DIRECTION n A I CGS = = = = 6 7920 971018 34.00 in2 in4 in yb St Sb e = = = = 23.18 75753 41887 10.82 in in3 in3 in B DIRECTION n A I CGS = = = = 6 7920 971018 34.00 in2 in4 in yb St Sb e = = = = 23.18 75753 41887 10.82 in in3 in3 in

3. CALCULATE MAXIMUM APPLIED SERVICE MOMENTS

L DIRECTION McsL = (d / DnsL)0.5 MnsL = Where 4.99 ft-kips / ft 1.15 0.04 ft-kips / ft MnsL = h1.35 SB0.36 / 80 L0.12 P0.10 = B DIRECTION McsS = McsL (970-h) / 880 = 5.30 ft-kips / ft

DnsL = L1.28 SB0.80 / 133 h0.28 P0.62 = 4. CHECK FLEXURAL CONCRETE STRESSES

4.1 ALLOWABLE CONCRETE STRESSES FLEXURAL TENSILE STRESS FLEXURAL COMPRESSIVE STRESS ft,allow = - 6 (fc')0.5 = fc,allow = - 0.45 fc' =

DnsL = L1.28 SB0.80 / 133 h0.28 P0.62 =

0.04

-0.379 1.800

ksi ksi TOP STRESS, FOR CENTER LIFT MOMENT, AT B DIRECTION f = Pr / A + MB / St + Pr e / St = 0.040 ksi -5.84 213 kips 218.81 kips kips

4.2 TOP STRESS, FOR CENTER LIFT MOMENT, AT L DIRECTION f = Pr / A + ML / St + Pr e / St = Where Pr = Pe - SG = Pe = fe Aps = 213 kips 218.81 kips SG = W slab m / 2000 = 0.038 ksi -5.84 kips

Where

Pr = Pe - SG = Pe = fe Aps = SG = W slab m / 2000 =

Then

> <

ft,allow fc,allow

[Satisfactory] [Satisfactory]

Then

> <

ft,allow fc,allow

[Satisfactory] [Satisfactory]

4.3 BOTTOM STRESS, FOR CENTER LIFT MOMENT, AT L DIRECTION f = Pr / A - ML / Sb - Pr e / Sb = -0.071 ft,allow fc,allow ksi

BOTTOM STRESS, FOR CENTER LIFT MOMENT, AT B DIRECTION f = Pr / A - MB / Sb - Pr e / Sb = -0.075 ft,allow fc,allow ksi

Then

> <

[Satisfactory] [Satisfactory]

Then

> <

[Satisfactory] [Satisfactory]

5. CHECK DIFFERENTIAL DEFLECTIONS

5.1 RELATIVE STIFFNESS LENGTH AT L DIRECTION b = (Ec I DnsL / Es d )1/4 / 12 = Where 8.318 ft 1917127 psi in4 pcf ALLOWABLE DIFFERENTIAL DEFLECTION AT B DIRECTION Dallow = 12 MIN(B, 6b) / CD = Where CD 0.31 1920 in psi Ecr = (0.5) 33 w1.5 (fc')0.5 = Es = I = w = 1000 971018 150 RELATIVE STIFFNESS LENGTH AT B DIRECTION b = (Ec I DnsB / Es d )1/4 / 12 = Where 8.318 ft 1917127 psi in4 psi Ecr = (0.5) 33 w1.5 (fc')0.5 = Es = I = 1000 971018

5.2 ALLOWABLE DIFFERENTIAL DEFLECTION AT L DIRECTION Dallow = 12 MIN(L, 6b) / CD = Where CD 0.31 1920 in

5.3 DIFFERENTIAL DEFLECTION WITHOUT PRESTRESSING Dcs = d en0{1.78 - 0.103 h -1.65E-03 P + 3.95E-07 P P) = 0.04 in Dallow

DIFFERENTIAL DEFLECTION WITHOUT PRESTRESSING Dcs = d en0{1.78 - 0.103 h -1.65E-03 P + 3.95E-07 P P) = 0.04 in Dallow

<

[Satisfactory]

<

[Satisfactory]

6. CHECK SHEAR CAPACITY

6.1 APPLIED SERVICE LOAD SHEAR AT L DIRECTION VcsL = (d / DnsL)0.30 VnsL = Where 1.121 kips/ft 0.465 kips/ft ALLOWABLE CONCRETE SHEAR STRESS, AT B DIRECTION v c = 2.4 (fc')0.5 + 0.2 fp = 0.152 -0.001 ksi ksi VnsL = h0.90 (PSB)0.30 / 550 L0.10 = APPLIED SERVICE LOAD SHEAR AT B DIRECTION VcsS = VcsL (116-h) / 94 = 0.954 kips/ft

6.2 ALLOWABLE CONCRETE SHEAR STRESS, AT L DIRECTION v c = 2.4 (fc')0.5 + 0.2 fp = Where fp = 0.152 -0.001 ksi ksi

<

50 psi

Where

fp =

<

50 psi

[Unsatisfactory] 6.3 SHEAR STRESS OF RIBBED FOUNDATION, AT L DIRECTION v = V B / (n h b) = 0.011 ksi SHEAR STRESS OF RIBBED FOUNDATION, AT B DIRECTION

[Unsatisfactory]

<

[Satisfactory]

vc

v = V L / (n h b) =

0.009

ksi

<

[Satisfactory]

vc

7. CHECK SOIL BEARING

7.1 APPLIED LOADING SLAB WEIGHT ADDED DL LIVE LOAD BEAM WEIGHT PERIMETER LOAD 150 L B t DL L B LL L B 150 (h-t) b (Total Length) P (2L + 2B) = = = = = 187500 37500 100000 396000 168000 lbs lbs lbs lbs lbs BEAM BEARING AREA SOIL PRESSURE (b)(Total Length) = q = Total Load / THE AREA = 1056 842 ft2 psf qallow

<

[Satisfactory]

8. CHECK SLAB STRESS DUE TO LOAD-BEARING PARTITIONS

8.1 RELATIVE STIFFNESS LENGTH AT L DIRECTION Mmax = Pb b / 4 = Where 6.75 ft-kips / ft 10.000 ft lb / in3 RELATIVE STIFFNESS LENGTH AT B DIRECTION Mmax = Pb b / 4 = Where 6.75 ft-kips / ft 10.000 ft lb / in3

= MIN[(Ec h3 / 3 ks)0.25, SB] = 4

= MIN[(Ec h3 / 3 ks)0.25, SB] = 4

ks = 8.2 TENSILE STRESS AT L DIRECTION f = Pr / A - Mmax / 2 t2 =

ks = TENSILE STRESS AT B DIRECTION

-0.094 ft,allow

ksi [Satisfactory]

f = Pr / A - Mmax / 2 t2 =

-0.094 ft,allow

ksi [Satisfactory]

>

>

9. CONVERT UNIFORM THICKNESS

H= MAX[ ( I / L)1/3, ( I / B)1/3 ] = 26.88 in

10. SUGGEST RATIO OF EXPECTED ELONGATION

r = fe / 0.8 Eps = Where Eps = 7.77E-03 28000 ksi

Technical References: 1. "Design of Post-Tensioned Slab-on-Ground, Second Edition", Post-Tensioning Institute, 1996. 2. "1997 Uniform Building Code, Volume 2, Chapter 18", International Conference of Building Officials, 1997.

S-ar putea să vă placă și

- Southern Marine Engineering Desk Reference: Second Edition Volume IDe la EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IÎncă nu există evaluări

- Prestressed Pile r3Document43 paginiPrestressed Pile r3megget100% (1)

- Double TeeDocument3 paginiDouble Teeyanu13Încă nu există evaluări

- Circular Column Design Based On ACI 318-19: Input Data & Design SummaryDocument5 paginiCircular Column Design Based On ACI 318-19: Input Data & Design SummaryJEEVENDRANÎncă nu există evaluări

- Shear WallDocument2 paginiShear WallLam Tran100% (1)

- Slab On GradeDocument105 paginiSlab On Gradevijaystructural100% (6)

- ACI-350 Concrete Beam Design 1.1Document6 paginiACI-350 Concrete Beam Design 1.1nhulugalla33% (3)

- Design of Masonry WallDocument4 paginiDesign of Masonry WallIrene Valentino PacunayenÎncă nu există evaluări

- Design of Slab On GradeDocument6 paginiDesign of Slab On GradeLa BeamÎncă nu există evaluări

- Raft Foundation BowlesDocument4 paginiRaft Foundation BowlesdsanandaÎncă nu există evaluări

- RCC91 One-Way Solid Slabs (Tables)Document7 paginiRCC91 One-Way Solid Slabs (Tables)Sachin RajaleÎncă nu există evaluări

- Cell K11 1 Cell K11 0.5 For F 0, For F 0Document9 paginiCell K11 1 Cell K11 0.5 For F 0, For F 0HaymanAHMEDÎncă nu există evaluări

- GRDSLABDocument15 paginiGRDSLABmjlazo0% (1)

- Concrete Beam Design, For New or Existing, Based On ACI 318-14Document6 paginiConcrete Beam Design, For New or Existing, Based On ACI 318-14teren_vnzareÎncă nu există evaluări

- Concrete Design Excel SheetDocument16 paginiConcrete Design Excel SheetCleth Hiren Santos25% (4)

- A Spreadsheet of RC Two Way Slab DesigningDocument1 paginăA Spreadsheet of RC Two Way Slab DesigningTRPMEINHARDTÎncă nu există evaluări

- Concrete Industrial Ground Floor Slab (TR34)Document3 paginiConcrete Industrial Ground Floor Slab (TR34)David Thomson100% (5)

- Slab DesignDocument28 paginiSlab DesignUlasi IfeanyiÎncă nu există evaluări

- Deflection Calculation of Concrete Floors TN292 PDFDocument38 paginiDeflection Calculation of Concrete Floors TN292 PDFSheik Mohamed LiakathÎncă nu există evaluări

- Ground Bearing Slab - What Are The Options - Joseph Khoo - Part 5Document79 paginiGround Bearing Slab - What Are The Options - Joseph Khoo - Part 5Fransisca WijayaÎncă nu există evaluări

- RC Beam Onewayslab DesignDocument10 paginiRC Beam Onewayslab Designmegget100% (1)

- Slab On Grade-Calculation ReportDocument17 paginiSlab On Grade-Calculation ReportSudathipTangwongchai100% (1)

- Open Newal Stair Case With Quater Space LandingDocument6 paginiOpen Newal Stair Case With Quater Space LandingBharat VagadiaÎncă nu există evaluări

- ACI-14 Beam Ledge Design v1.0Document6 paginiACI-14 Beam Ledge Design v1.0Raymund Dale P. BallenasÎncă nu există evaluări

- Slab On GradeDocument954 paginiSlab On Graderadem3100% (3)

- Kda - Factory Ii (Gen - Trias, Cavite) Design of MicropilesDocument4 paginiKda - Factory Ii (Gen - Trias, Cavite) Design of MicropilesRoda Cadiz100% (4)

- Minimum Thickness of Solid Slab According To ACIDocument1 paginăMinimum Thickness of Solid Slab According To ACImuhanned100% (1)

- Strap Footing TheoryDocument4 paginiStrap Footing TheorySwopnilOjhaÎncă nu există evaluări

- Sample Steel Framing ElevationDocument1 paginăSample Steel Framing ElevationJoseph Cloyd LamberteÎncă nu există evaluări

- Design of SlabDocument3 paginiDesign of SlabKetan Dhameliya100% (2)

- Slab PunchingDocument14 paginiSlab Punchinghala_azhariÎncă nu există evaluări

- Retaining Wall Design With GEO5Document2 paginiRetaining Wall Design With GEO5danzh250% (1)

- Grade Slab Design For Heavy LoadsDocument2 paginiGrade Slab Design For Heavy LoadsIrshad Farrukh100% (1)

- Analysis of Concrete Slabs On GradeDocument25 paginiAnalysis of Concrete Slabs On GradeTuanQuachÎncă nu există evaluări

- Multiple RC Staircase DesignDocument3 paginiMultiple RC Staircase Designezarul fitri100% (1)

- TCC63 Core Wall DesignDocument12 paginiTCC63 Core Wall DesignMario Sajulga Dela Cuadra100% (1)

- Beam DesignDocument1 paginăBeam Designzeal86Încă nu există evaluări

- Prestressed Girder Design - Roof Deck by FrameDocument93 paginiPrestressed Girder Design - Roof Deck by FrameJonasIrvinGallego100% (1)

- Two Way Slab Design (DRAFT)Document72 paginiTwo Way Slab Design (DRAFT)ابو عمر الأسمريÎncă nu există evaluări

- Retaining Wall DesignDocument6 paginiRetaining Wall DesignpkÎncă nu există evaluări

- Circular Column DesignDocument10 paginiCircular Column DesignVasanthapragash Nadarajha100% (1)

- Design Guide of Slab On GradeDocument20 paginiDesign Guide of Slab On GradePriyanka100% (2)

- Squre Footing Design (WSD)Document3 paginiSqure Footing Design (WSD)api-19753598Încă nu există evaluări

- Lintel DesignDocument3 paginiLintel DesignPrashant HuddarÎncă nu există evaluări

- Circular Water Tank (Flexible Joint)Document59 paginiCircular Water Tank (Flexible Joint)prasadnn2001Încă nu există evaluări

- 7H Prestressed Double TeesDocument10 pagini7H Prestressed Double TeesSughanyaa VeÎncă nu există evaluări

- Super Composite ColumnDocument2 paginiSuper Composite ColumnCheng Por EngÎncă nu există evaluări

- Design of PT Slabs On Expansive Soil Ground Based On Standards of PTI EditionDocument2 paginiDesign of PT Slabs On Expansive Soil Ground Based On Standards of PTI EditionRafaArdiSyahrezaÎncă nu există evaluări

- Conventional Slab On GradeDocument7 paginiConventional Slab On GradeLyhalim SethÎncă nu există evaluări

- Edificios SMRF ACIDocument5 paginiEdificios SMRF ACIJorge AlbertoÎncă nu există evaluări

- Beam With TorsionDocument22 paginiBeam With TorsionFranklyn P. GenoveÎncă nu există evaluări

- Sheet Pile Wall Design Based On 2015 IBC / 2013 CBC / ACI 318-14Document39 paginiSheet Pile Wall Design Based On 2015 IBC / 2013 CBC / ACI 318-14andyhrÎncă nu există evaluări

- Design of PT Slabs On Compressible Soil Ground Based On Standards of PTI EditionDocument2 paginiDesign of PT Slabs On Compressible Soil Ground Based On Standards of PTI EditionRafaArdiSyahrezaÎncă nu există evaluări

- SteelColumn 8Document8 paginiSteelColumn 8Mahbub AlamÎncă nu există evaluări

- Flange Tapered GirderDocument12 paginiFlange Tapered GirderZevanyaRolandTualakaÎncă nu există evaluări

- Plate GirderDocument22 paginiPlate GirdertitlesaengÎncă nu există evaluări

- Concrete Forming Work in ProgressDocument37 paginiConcrete Forming Work in Progresslindavg67Încă nu există evaluări

- Concrete Pool Design Based On ACI 318-05: Input Data & Design SummaryDocument13 paginiConcrete Pool Design Based On ACI 318-05: Input Data & Design SummaryRicardo Vega ZamoraÎncă nu există evaluări

- Mathcad - RC Pier DesignDocument7 paginiMathcad - RC Pier Designlnt4Încă nu există evaluări

- Ebf IbcDocument2 paginiEbf IbcMurat TopbaştekinÎncă nu există evaluări

- Geotech InvestigationDocument10 paginiGeotech InvestigationanumnedÎncă nu există evaluări

- GRC ManufacturingDocument2 paginiGRC ManufacturinganumnedÎncă nu există evaluări

- Nokia 2.2 User GuideDocument44 paginiNokia 2.2 User GuideanumnedÎncă nu există evaluări

- Astm A572-50Document1 paginăAstm A572-50anumnedÎncă nu există evaluări

- Problems in Flow NetDocument8 paginiProblems in Flow NetanumnedÎncă nu există evaluări

- Earth RetentionDocument48 paginiEarth Retentionanumned100% (1)

- Flow NetDocument30 paginiFlow Netanumned100% (8)

- Polyheed 997Document2 paginiPolyheed 997anumnedÎncă nu există evaluări

- 6.5 Proble MS: K K H TDocument8 pagini6.5 Proble MS: K K H TanumnedÎncă nu există evaluări

- CSL PDFDocument6 paginiCSL PDFanumnedÎncă nu există evaluări

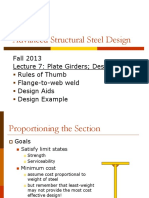

- Rules of Thumb - Flange Area: A FH M ADocument10 paginiRules of Thumb - Flange Area: A FH M AanumnedÎncă nu există evaluări

- CE 591 Advanced Structural Steel DesignDocument10 paginiCE 591 Advanced Structural Steel DesignanumnedÎncă nu există evaluări

- Outer View of Indus Hospital's Existing BuildingDocument6 paginiOuter View of Indus Hospital's Existing BuildinganumnedÎncă nu există evaluări

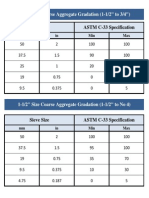

- 1-1/2" Size Coarse Aggregate Gradation (1-1/2" To 3/4") : ASTM C-33 Specification Sieve SizeDocument1 pagină1-1/2" Size Coarse Aggregate Gradation (1-1/2" To 3/4") : ASTM C-33 Specification Sieve SizeanumnedÎncă nu există evaluări

- Progress Update Sheet: S. No. Activity Floor %age Completion Division (In Case)Document4 paginiProgress Update Sheet: S. No. Activity Floor %age Completion Division (In Case)anumnedÎncă nu există evaluări

- Defining Relative Clause Non-Defining Relative Clause: ReminderDocument1 paginăDefining Relative Clause Non-Defining Relative Clause: ReminderFouad BoudraaÎncă nu există evaluări

- All Articles Listed Below by Week Are Available at UCSD Electronic ReservesDocument4 paginiAll Articles Listed Below by Week Are Available at UCSD Electronic ReservesvictorvienÎncă nu există evaluări

- Election and Representation: Chapter ThreeDocument27 paginiElection and Representation: Chapter ThreefarazÎncă nu există evaluări

- TNPSC Group 4 Govt Notes - Indian National Movement - EnglishDocument68 paginiTNPSC Group 4 Govt Notes - Indian National Movement - Englishdeebanmegam2Încă nu există evaluări

- My Nudist, Holocaust-Survivor Grandma Spied On The NazisDocument4 paginiMy Nudist, Holocaust-Survivor Grandma Spied On The NazisperzaklieÎncă nu există evaluări

- PAPER1Document2 paginiPAPER1Rajdeep BorgohainÎncă nu există evaluări

- Socioeconomic Disparities Intensifying - ReportDocument4 paginiSocioeconomic Disparities Intensifying - ReportNinna NannaÎncă nu există evaluări

- King Charles' Coronation TVDocument2 paginiKing Charles' Coronation TV9LO JadziaÎncă nu există evaluări

- Environmental Science: STS: Science, Technology and SocietyDocument3 paginiEnvironmental Science: STS: Science, Technology and SocietyStephen Mark Garcellano DalisayÎncă nu există evaluări

- British Columbia Application For Change of NameDocument8 paginiBritish Columbia Application For Change of NamecalebfriesenÎncă nu există evaluări

- Treasury FOIA Response 6-8-11Document60 paginiTreasury FOIA Response 6-8-11CREWÎncă nu există evaluări

- CBK Power Co LTD Vs CirDocument1 paginăCBK Power Co LTD Vs CirlacbayenÎncă nu există evaluări

- Northcote School EnrolmentDocument2 paginiNorthcote School EnrolmentfynnygÎncă nu există evaluări

- Sources of LawDocument4 paginiSources of LawBaskaran ManogaranÎncă nu există evaluări

- Glossary SociologyDocument10 paginiGlossary SociologydigitalfaniÎncă nu există evaluări

- A-P-, AXXX XXX 411 (BIA Oct. 24, 2017)Document8 paginiA-P-, AXXX XXX 411 (BIA Oct. 24, 2017)Immigrant & Refugee Appellate Center, LLCÎncă nu există evaluări

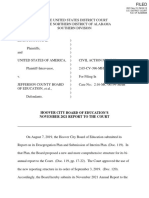

- Hoover City Schools Status Report November 2021Document294 paginiHoover City Schools Status Report November 2021Trisha Powell CrainÎncă nu există evaluări

- The Jats of Northern India: Their Traditional Political SystemDocument4 paginiThe Jats of Northern India: Their Traditional Political SystemSandeep BadoniÎncă nu există evaluări

- Global Governance: Rhea Mae Amit & Pamela PenaredondaDocument28 paginiGlobal Governance: Rhea Mae Amit & Pamela PenaredondaRhea Mae AmitÎncă nu există evaluări

- 2010 Jan11 Subject Jan-DecDocument132 pagini2010 Jan11 Subject Jan-DecSumit BansalÎncă nu există evaluări

- Lisa Lowe - The Intimacies of Four Continents-Duke University Press (2015) PDFDocument329 paginiLisa Lowe - The Intimacies of Four Continents-Duke University Press (2015) PDFAndré Fogliano100% (4)

- Yamaguchi Yoshiko and Fujiwara Sakuya - Fragrant Orchid - The Story of My Early LifeDocument418 paginiYamaguchi Yoshiko and Fujiwara Sakuya - Fragrant Orchid - The Story of My Early LifeJp Vieyra Rdz100% (1)

- Class XII History 2010 DelhiDocument29 paginiClass XII History 2010 DelhiRamita UdayashankarÎncă nu există evaluări

- Final John Doe's Reply To Plaintiffs' Opp To Motion To Quash SubpoenaDocument21 paginiFinal John Doe's Reply To Plaintiffs' Opp To Motion To Quash SubpoenaspiritswanderÎncă nu există evaluări

- International Trade TheoryDocument35 paginiInternational Trade TheorySachin MalhotraÎncă nu există evaluări

- Sample Certification LetterDocument3 paginiSample Certification LetterNgan TuyÎncă nu există evaluări

- PJA Vs PRADO CASE DIGEST ETHICSDocument3 paginiPJA Vs PRADO CASE DIGEST ETHICSAerith AlejandreÎncă nu există evaluări

- SS 5 Aralin 1 PDFDocument26 paginiSS 5 Aralin 1 PDFChris Micah EugenioÎncă nu există evaluări

- Jim Crow PassiveDocument5 paginiJim Crow PassiveAngel Angeleri-priftis.Încă nu există evaluări

- Report To The MayorDocument3 paginiReport To The MayorTommy D. SoledadÎncă nu există evaluări