Documente Academic

Documente Profesional

Documente Cultură

Checklist Maintenance Managment - Industrial Washing Machine

Încărcat de

Aashutosh VatsaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Checklist Maintenance Managment - Industrial Washing Machine

Încărcat de

Aashutosh VatsaDrepturi de autor:

Formate disponibile

Maintenance Checklist of Industrial Washing Machine.

Ashutosh Vatsa Pankaj Pathak 2/20/2012

Maintenance Management

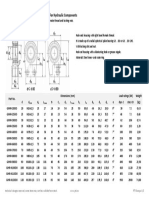

Daily Preventive Maintenance Checklist

Machine: Operato r:

Checks

Disconnect power to the machine before performing the daily maintenance procedure Beginning of the day Inspect water inlet valve hose connections on the back of the washer extractor for leaks Inspect steam hose connections for leaks, where applicable. Verify that insulation is intact on all external wires and that all connections are secure. Inspect door lock and interlock before starting operation: Attempt to start the washer with door open. Close the door without locking it and attempt to start the washer. Close and lock the door, start a cycle, and attempt to open the door while the cycle is in progress Inspect all water circulation pipe connection, if applicable End of the day Clean the AC drive box filter(s). Clean the door gasket of all foreign matter. Clean automatic supply dispenser and lid. Clean the washers top, front and side panels. Leave loading door open at the end of each day to allow moisture to evaporate. Clean water recirculation filter, if applicable.

Days

Unload the machine promptly after each maintenance cycle to prevent moisture buildup, leave loading door open after each completed cycle to allow moisture to evaporate.

Weekly Preventive Maintenance Checklist

Machine: Operator:

Checks

Disconnect power to the machine before performing the daily maintenance procedure Check the washer extractor for Leaks:

Weeks

Start an unloaded cycle to fill the machine Verify that door and door gasket do not leak Verify that the drain value is operating

Monthly Preventive Maintenance Checklist

Machine: Operator:

Checks

Disconnect power to the machine before performing the daily maintenance procedure Each month or every 200 hours of operation, lubricate Bearings Clean the AC drive fins Determine if V-belts require replacement or adjustment: Check V-belts for uneven wear and frayed edges Verify that V-belts are properly tensioned

Months

Verify that V-belts are properly aligned.

Remove back panel and check hoses for leaks. Unlock the hinged lid and check supply dispenser hoses and connections Clean inlet hose filter screens. Replace if worn or damaged Tighten motor mounting bolt locknuts and bearing, if necessary. Use compressed air to clean lint from motor. Clean interior of washer-xtractor, both basket and shell, by wiping with a water-soaked sponge or cloth. Use compressed air to clean moisture and dust from all electrical components.

Quarterly Preventive Maintenance Checklist

Machine: Operator:

Checks

Disconnect power to the machine before performing the daily maintenance procedure Tighten door hinges and fasteners, if necessary Tighten anchor bolts, if necessary. Verify that the drain motor shield is in place and secure. Check all painted surfaces for bare metal. Repair, if necessary. Clean steam filter, if applicable.

Quarter

S-ar putea să vă placă și

- MaintenanceDocument4 paginiMaintenanceNileshSondagarÎncă nu există evaluări

- Grinder Checklist2Document3 paginiGrinder Checklist2jovyÎncă nu există evaluări

- PPM Task Sheet - MPGSDocument4 paginiPPM Task Sheet - MPGSJacobÎncă nu există evaluări

- Engineering Breakdown Maintenance SOPDocument2 paginiEngineering Breakdown Maintenance SOPMdrahaman Mithu100% (1)

- Workshop Inspection ChecklistDocument1 paginăWorkshop Inspection ChecklistMAXIMOS ULTIMOS50% (2)

- SOP Preventive Maintenance 33KVA TransformerDocument5 paginiSOP Preventive Maintenance 33KVA TransformerPandu Birumakovela100% (1)

- A13 - Daily Weighing Scale Checklist-NemDocument1 paginăA13 - Daily Weighing Scale Checklist-NemSuresh Selvaraju100% (3)

- PPM Check List: Floor: Wing: Room No: DateDocument3 paginiPPM Check List: Floor: Wing: Room No: DateMdrahaman MithuÎncă nu există evaluări

- SOP-09 Preventive Maintenance - MachineDocument10 paginiSOP-09 Preventive Maintenance - MachinePandu BirumakovelaÎncă nu există evaluări

- Vacuum Cleaner SOP Operating and CleaningDocument2 paginiVacuum Cleaner SOP Operating and CleaningRainMan75Încă nu există evaluări

- Monthly Preventive Maintenance ChecklistDocument2 paginiMonthly Preventive Maintenance ChecklistAlia Marouf90% (10)

- Cautery Machines and Electrosurgical Units PREVENTIVE MAINTENANCEDocument2 paginiCautery Machines and Electrosurgical Units PREVENTIVE MAINTENANCERaymond Ogi100% (2)

- Equipment History SheetDocument6 paginiEquipment History SheetAnkur SinghÎncă nu există evaluări

- Electrical Tools Inspection ChecklistDocument1 paginăElectrical Tools Inspection Checklistcharles von100% (1)

- SOP's For Facility ServicesDocument4 paginiSOP's For Facility Servicesrahul soodÎncă nu există evaluări

- Operations and Maintenance Preventive Maintenance Checklists PDFDocument35 paginiOperations and Maintenance Preventive Maintenance Checklists PDFAdewale BamgbadeÎncă nu există evaluări

- Truck Inspection ChecklistDocument1 paginăTruck Inspection Checklistdnmule100% (1)

- Boiler Maintenance ChecklistDocument2 paginiBoiler Maintenance ChecklistRidwanAlwi50% (4)

- Generator ChecklistDocument2 paginiGenerator Checklistramakrishna6650% (2)

- Housekeeping Checklist For Contractors: Walking-Working Surfaces General Work EnvironmentDocument4 paginiHousekeeping Checklist For Contractors: Walking-Working Surfaces General Work Environmentcynthia100% (1)

- 02 Equipment Maintenance ScheduleDocument1 pagină02 Equipment Maintenance ScheduleDominic DizonÎncă nu există evaluări

- Checklist For Electrical Safety InspectionDocument1 paginăChecklist For Electrical Safety InspectionSatya Naidu100% (2)

- Angle Grinder Check ListDocument2 paginiAngle Grinder Check ListEdhz Bilog100% (11)

- Preventive Maintenance Checklist UpsDocument1 paginăPreventive Maintenance Checklist Upssree100% (9)

- Fork Lift Checklist (IBSF)Document1 paginăFork Lift Checklist (IBSF)Mohammad Imtiaz Ali100% (1)

- R-16 Safety Management Review MeetingDocument2 paginiR-16 Safety Management Review MeetingSandeep Kumar100% (1)

- IRE ETS: Uc Davis Fire Prevention Self Inspection ChecklistDocument3 paginiIRE ETS: Uc Davis Fire Prevention Self Inspection ChecklistAsif HameedÎncă nu există evaluări

- Top Preventive Maintenance Tips For Your CNC Machine Tools - Hwacheon Asia Pacific Pte. Ltd.Document11 paginiTop Preventive Maintenance Tips For Your CNC Machine Tools - Hwacheon Asia Pacific Pte. Ltd.Saif Uddin AhmedÎncă nu există evaluări

- Daily Machine Check List - Radial DrillDocument6 paginiDaily Machine Check List - Radial Drillshailendra5508110100% (1)

- Weekly Machine Check List - Lathe MachineDocument6 paginiWeekly Machine Check List - Lathe Machineshailendra550811067% (3)

- Centurion Power Cables (P) LTD.: MaintenanceDocument3 paginiCenturion Power Cables (P) LTD.: MaintenancetriveshÎncă nu există evaluări

- Standard Operating System For GeneratorDocument2 paginiStandard Operating System For GeneratorZobayerHossain50% (6)

- Dewatering PumpDocument14 paginiDewatering PumpparthaÎncă nu există evaluări

- Daily Fuel Truck ChecklistDocument1 paginăDaily Fuel Truck ChecklistTFattah0% (1)

- Jumping Compactor Inspection ChecklistDocument1 paginăJumping Compactor Inspection Checklistarunjith rÎncă nu există evaluări

- Preventive Maintenance Electrical FormDocument7 paginiPreventive Maintenance Electrical FormAdriawan AnnesÎncă nu există evaluări

- Pre-Trip Inspection ChecklistDocument2 paginiPre-Trip Inspection ChecklistBeatrix Uy50% (2)

- Electrical Drill Maintenance ChecklistDocument1 paginăElectrical Drill Maintenance ChecklistJaime Ferdinand CiprianoÎncă nu există evaluări

- DG Maintenance Scope MKDocument9 paginiDG Maintenance Scope MKBahati ValerianÎncă nu există evaluări

- 6) Perform Underchassis Preventive MaintenanceDocument52 pagini6) Perform Underchassis Preventive MaintenanceROSAN YUMANGÎncă nu există evaluări

- FORMET Preventive Maintenance Check List of Air CompressorDocument1 paginăFORMET Preventive Maintenance Check List of Air CompressorReza100% (1)

- Boom Truck Inspection Checklist-Daily..Document1 paginăBoom Truck Inspection Checklist-Daily..Chaudhary Wasim Murtaza100% (4)

- Crane InspectionDocument2 paginiCrane InspectionAdhy DarmawanÎncă nu există evaluări

- Civil Work Permit: Contractor: ContractorDocument1 paginăCivil Work Permit: Contractor: ContractorAshwani Dogra100% (1)

- Tractor Backhoe Pre-Operation ChecklistDocument3 paginiTractor Backhoe Pre-Operation Checklistmanny daleonÎncă nu există evaluări

- Maintenance PlanDocument6 paginiMaintenance PlanabdullahqqÎncă nu există evaluări

- 7.electrical LOTO Check List InspectionDocument1 pagină7.electrical LOTO Check List Inspectionfitri widyaÎncă nu există evaluări

- Portable Grinder Operating ProceduresDocument2 paginiPortable Grinder Operating ProceduresSammie Williams100% (1)

- Equipment Maintenance Schedule and ChecklistDocument3 paginiEquipment Maintenance Schedule and ChecklistTimothy John Natal Mandia67% (3)

- Preventive Maintenace RecordDocument47 paginiPreventive Maintenace RecordArunPrakash JÎncă nu există evaluări

- SOP For Action To Be Taken During Spillage - Breakage of Materials - Pharmaceutical GuidelinesDocument1 paginăSOP For Action To Be Taken During Spillage - Breakage of Materials - Pharmaceutical GuidelinesJose Ramon Dalo BautistaÎncă nu există evaluări

- Safety Inspection Checklist Abrasive Wheel Grinders Bench and PedestalDocument1 paginăSafety Inspection Checklist Abrasive Wheel Grinders Bench and PedestalSanthosh Kumar100% (1)

- Daily Plant Inspection ChecklistDocument1 paginăDaily Plant Inspection Checklist8460272421Încă nu există evaluări

- Weekly Preventative Maintenance ChecklistDocument5 paginiWeekly Preventative Maintenance Checklisttoni annÎncă nu există evaluări

- Weekly pump checklist for Jazan-Abha pipeline relocationDocument1 paginăWeekly pump checklist for Jazan-Abha pipeline relocationAli Hassan100% (4)

- SOP of Hydraulic Press PDFDocument2 paginiSOP of Hydraulic Press PDFAdil Fareed100% (1)

- Check List For Cutting MachineDocument1 paginăCheck List For Cutting MachineGita Iyer0% (1)

- The Basics: Equipment Maintenance and SafetyDocument32 paginiThe Basics: Equipment Maintenance and Safetyrussel1435Încă nu există evaluări

- Method Statement of Chiller Preventive MaintenanceDocument5 paginiMethod Statement of Chiller Preventive MaintenanceBalajiÎncă nu există evaluări

- Safey & SOP (Hydraulic)Document3 paginiSafey & SOP (Hydraulic)afiqzeroÎncă nu există evaluări

- Bolts Torque CalculatorDocument3 paginiBolts Torque CalculatorAlexandre LaraÎncă nu există evaluări

- STRENGTH OF MATERIALS REFRESHER SETDocument4 paginiSTRENGTH OF MATERIALS REFRESHER SETGracielle Nebres67% (3)

- Codes Standards For Architectural FinishesDocument4 paginiCodes Standards For Architectural FinishesVipin Kumar ParasharÎncă nu există evaluări

- Hilton Hotels Corporation: A Leader in HospitalityDocument26 paginiHilton Hotels Corporation: A Leader in HospitalityFarzana KhanÎncă nu există evaluări

- 02-04 Chap GereDocument12 pagini02-04 Chap GereSri DÎncă nu există evaluări

- Innvo8 Squash Court Panel System: Specification InformationDocument5 paginiInnvo8 Squash Court Panel System: Specification InformationDaniil TriznoÎncă nu există evaluări

- Process Ball Valve Vent Options: E X Ternal and Internal Ball VentsDocument4 paginiProcess Ball Valve Vent Options: E X Ternal and Internal Ball VentsAlexÎncă nu există evaluări

- Sabic® PP 38MK10RDocument2 paginiSabic® PP 38MK10RGiang CaoÎncă nu există evaluări

- Documentation On Construction of Small Scaled Strap Footing: Cover PageDocument5 paginiDocumentation On Construction of Small Scaled Strap Footing: Cover PageGlaiza MarieÎncă nu există evaluări

- Cubs Lawsuit DetailsDocument4 paginiCubs Lawsuit DetailsTodd FeurerÎncă nu există evaluări

- Instruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsDocument2 paginiInstruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsJonÎncă nu există evaluări

- Staad Training Day 1Document116 paginiStaad Training Day 1Bee AnquilianoÎncă nu există evaluări

- Universal Blowout Preventers: Instruction Manual 8520Document23 paginiUniversal Blowout Preventers: Instruction Manual 8520G100% (2)

- Fabrication EnquiryDocument180 paginiFabrication Enquiryvinod23456100% (1)

- Schedule Q (Quality Requirements)Document86 paginiSchedule Q (Quality Requirements)jeswinÎncă nu există evaluări

- GIHR-K..DO - Rod Ends For Hydraulic ComponentsDocument1 paginăGIHR-K..DO - Rod Ends For Hydraulic ComponentsQuintrae DelfinÎncă nu există evaluări

- Fuzhou Tianyu Electric Co., LTD.: KYN31-24 Armored Metal-Enclosed SwitchgearDocument22 paginiFuzhou Tianyu Electric Co., LTD.: KYN31-24 Armored Metal-Enclosed SwitchgearRusman LumbantoruanÎncă nu există evaluări

- Aramco Hot Tap Welding Procedure Rev 1Document3 paginiAramco Hot Tap Welding Procedure Rev 1BWQÎncă nu există evaluări

- Project Proposal: Rationale / ApproachDocument5 paginiProject Proposal: Rationale / ApproachKrysthalKate Amor Lastimosa Lopez100% (13)

- Polycarbonate Glazing SystemDocument16 paginiPolycarbonate Glazing SystemGirish DhawanÎncă nu există evaluări

- Visco Crete For UHPCDocument3 paginiVisco Crete For UHPCKarnalPreethÎncă nu există evaluări

- Assignment-2 Shear StrengthDocument3 paginiAssignment-2 Shear StrengthRabindraSubediÎncă nu există evaluări

- SD05wi1 Structural Inspection WorkpackDocument22 paginiSD05wi1 Structural Inspection WorkpackidrisÎncă nu există evaluări

- ECO AUDIT STEAM IRONDocument7 paginiECO AUDIT STEAM IRONUlisses Heredia0% (1)

- BR Knauf Ceiling Solutions Metal and Mesh Solutions enDocument64 paginiBR Knauf Ceiling Solutions Metal and Mesh Solutions enAshraf AbdellatefÎncă nu există evaluări

- HLS Sleeve Anchor Technology ManualDocument5 paginiHLS Sleeve Anchor Technology ManualHerli SiswoyoÎncă nu există evaluări

- 19G412-1180-E2 Parts ListDocument31 pagini19G412-1180-E2 Parts ListNeilÎncă nu există evaluări

- PVCPressPipeSteelA 24Document1 paginăPVCPressPipeSteelA 24Mustafa AlluhaibiÎncă nu există evaluări

- Manual Partes 6135JDocument1.012 paginiManual Partes 6135JEsther Roncal MoscolÎncă nu există evaluări

- Emile - Warre.people - Hive.plans - Engl. .11pDocument0 paginiEmile - Warre.people - Hive.plans - Engl. .11ptewngomÎncă nu există evaluări